吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 351-360.doi: 10.13229/j.cnki.jdxbgxb20190826

• 农业工程·仿生工程 • 上一篇

清选筛运动参数对玉米芯轴堵筛规律的影响

程超1,2( ),付君1,2(

),付君1,2( ),郝付平3,陈志2,3,周德义2,任露泉1,2

),郝付平3,陈志2,3,周德义2,任露泉1,2

- 1. 吉林大学 工程仿生教育部重点实验室,长春 130022

2. 吉林大学 生物与农业工程学院,长春 130022

3. 中国农业机械化科学研究院,北京 100083

Effect of motion parameters of cleaning screen on corn cob blocking law

Chao CHENG1,2( ),Jun FU1,2(

),Jun FU1,2( ),Fu-ping HAO3,Zhi CHEN2,3,De-yi ZHOU2,Lu-quan REN1,2

),Fu-ping HAO3,Zhi CHEN2,3,De-yi ZHOU2,Lu-quan REN1,2

- 1. Key Laboratory of Bionic Engineering, Ministry of Education, Jilin University, Changchun 130022, China

2. College of Biological and Agricultural Engineering, Jilin University, Changchun 130022, China

3. Chinese Academy of Agricultural Mechanization Sciences, Beijing 100083, China

摘要:

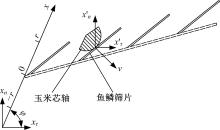

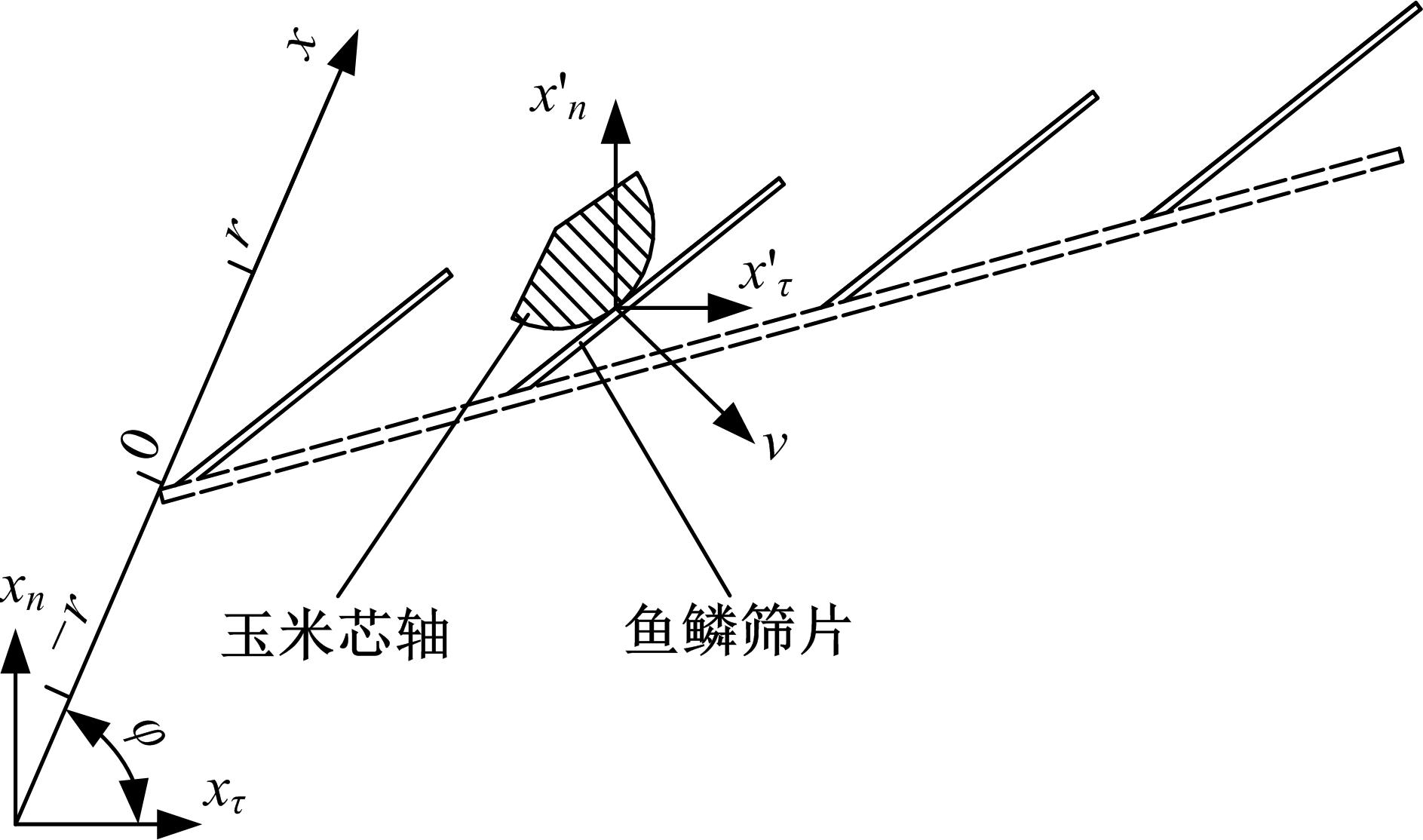

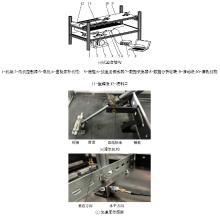

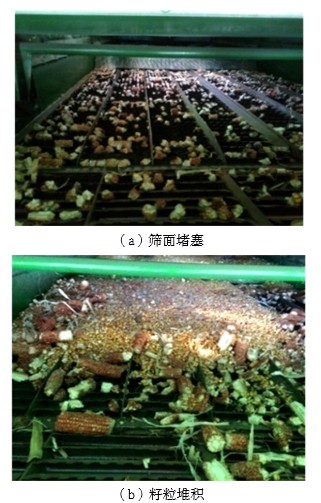

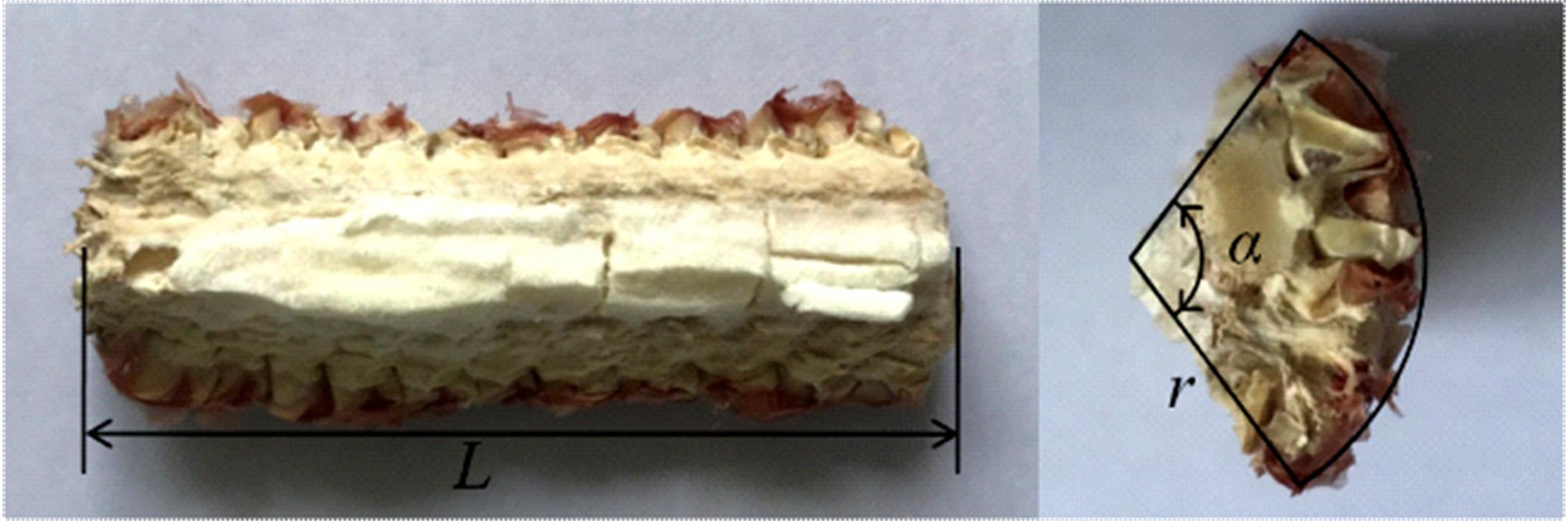

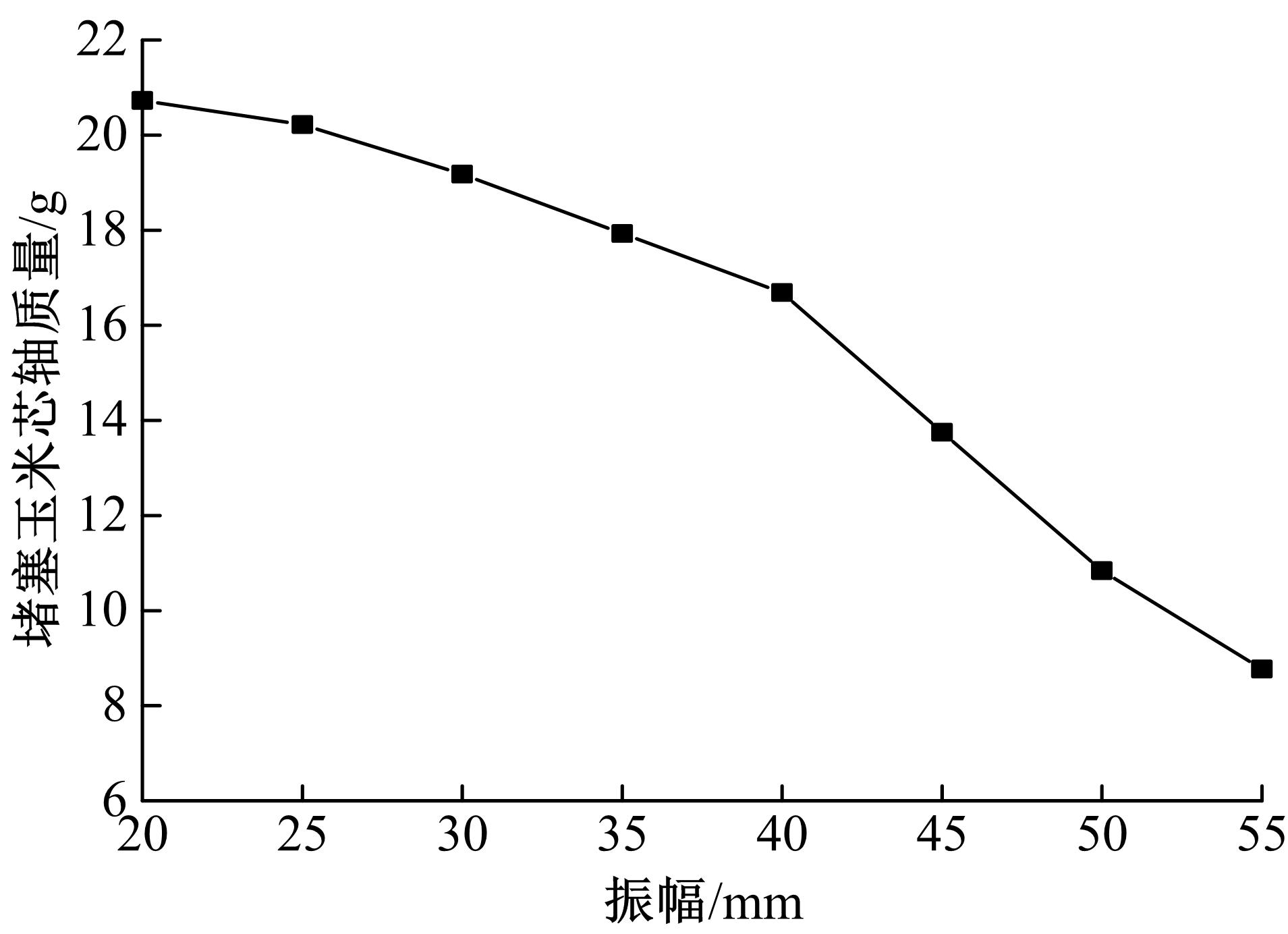

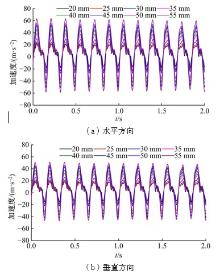

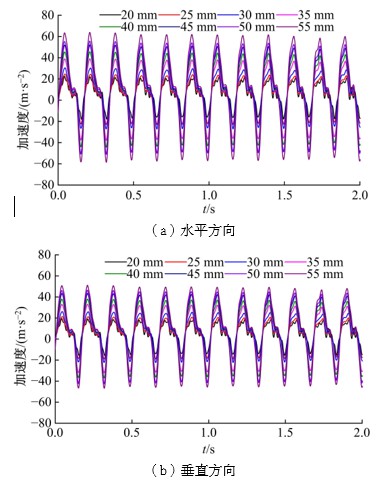

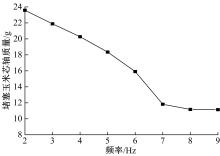

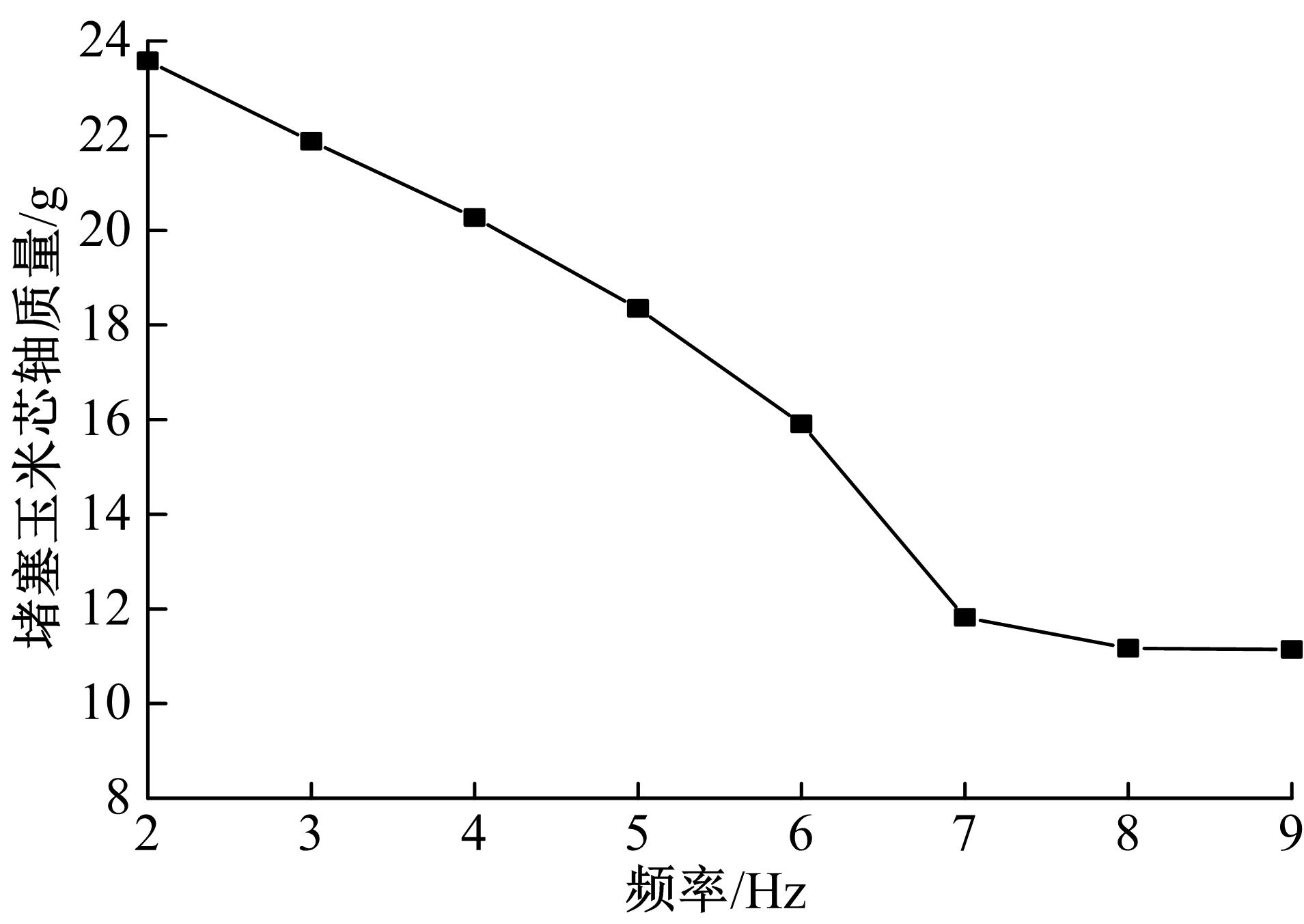

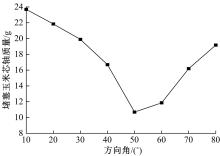

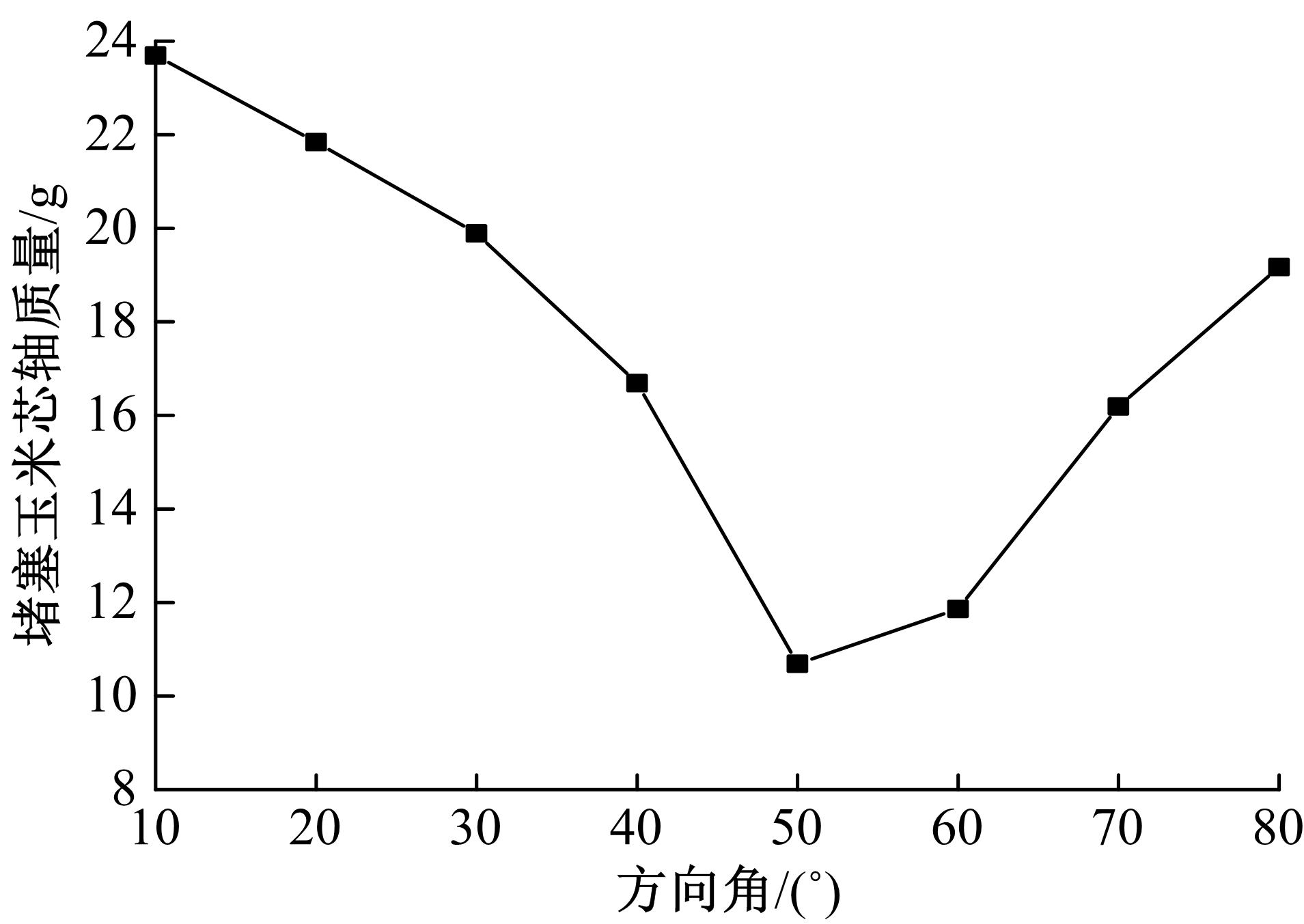

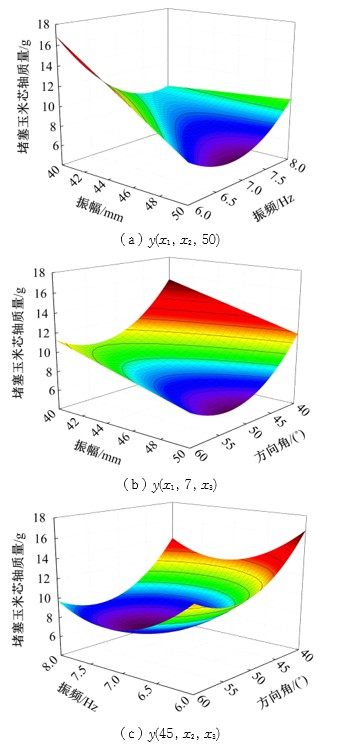

针对玉米联合收获机清选作业过程中芯轴堵塞清选筛的问题,本文利用自制清选筛堵塞性能试验台研究了振幅、振频和方向角3个关键运动参数对玉米芯轴堵筛规律的影响,并利用改装玉米联合收获机进行验证试验。通过单因素试验揭示了清选筛加速度和芯轴堵塞质量随运动参数增大的变化规律。通过正交试验建立了运动参数对玉米芯轴堵筛影响规律回归模型,得到了清选筛运动参数最优组合:振幅50 mm、振频7 Hz、方向角55°。验证试验表明,清选筛运动参数最优组合具有良好的筛分性能,堵塞玉米芯轴质量为10.39 g,籽粒含杂率为0.9%,清选损失率为1.09%,能够满足玉米联合收获机清选作业的要求。

中图分类号:

- S225.5

| 1 | 张丽娜,陈志,杨敏丽,等 . 我国玉米生产效率时空特征分析[J]. 农业机械学报,2018,49(1):183-193. |

| Zhang Li-na , Chen Zhi , Yang Min-li ,et al . Spatio-temporal feature of maize production efficiency in main producing provinces of China[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(1):183-193. | |

| 2 | 陈印军,王琦琪,向雁 . 我国玉米生产地位、优势与自给率分析[J]. 中国农业资源与区划,2019,40(1):7-16. |

| Chen Yin-jun , Wang Qi-qi , Xiang Yan . Analysis on the status, superiority and self-sufficiency ratio of maize in China[J]. Chinese Journal of Agricultural Resources and Regional Planning, 2019, 40(1): 7-16. | |

| 3 | 耿爱军,杨建宁,张兆磊,等 . 国内外玉米收获机械发展现状及展望[J]. 农机化研究,2016,38(4):251-257. |

| Geng Ai-jun , Yang Jian-ning , Zhang Zhao-lei ,et al .Discuss about the current situation and future of corn harvest machinery about domestic and abroad[J]. Journal of Agricultural Mechanization Research,2016,38(4):251-257. | |

| 4 | 陈志,郝付平,王锋德,等 . 中国玉米收获技术与装备发展研究[J]. 农业机械学报,2012,43(12):44-50. |

| Chen Zhi , Hao Fu-ping , Wang Feng-de ,et al . Development of technology and equipment of corn harvester in China[J]. Transactions of the Chinese Society for Agricultural Machinery,2012,43(12):44-50. | |

| 5 | 陈志 . 玉米全价值收获关键技术与装备[M]. 北京:科学出版社,2014. |

| 6 | 程超,付君,陈志,等 . 玉米籽粒收获机清选装置参数优化试验[J]. 农业机械学报,2019,50(7):151-158. |

| Cheng Chao , Fu Jun , Chen Zhi , et al . Optimization experiment on cleaning device parameters of corn kernel harvester[J]. Transactions of the Chinese Society for Agricultural Machinery,2019,50(7):151-158. | |

| 7 | 王立军,李洋,梁昌,等 . 贯流风筛清选装置内玉米脱出物运动规律研究[J]. 农业机械学报,2015,46(9):122-127. |

| Wang Li-ju , Li Yang , Liang Chang ,et al . Motion law of maize mixture in cross air-and-screen cleaning device[J]. Transactions of the Chinese Society for Agricultural Machinery,2015,46(9):122-127. | |

| 8 | 李杰,闫楚良,杨方飞 .联合收割机振动筛的动态仿真与参数优化[J]. 吉林大学学报:工学版,2006,36(5):701-704. |

| Li Jie , Yan Chu-liang , Yang Fang-fei . Dynamic simulation and parameter optimization of the combine harvester vibration sieve[J]. Journal of Jilin University (Engineering and Technology Edition),2006,36(5):701-704. | |

| 9 | 杜小强,肖梦华,胡小钦,等 . 贯流式谷物清选装置气固两相流数值模拟与试验[J]. 农业工程学报,2014,30(3):27-34. |

| Du Xiao-qiang , Xiao Meng-hua , Hu Xiao-qin ,et al . Numerical simulation and experiment of gas-solid two-phase flow in cross-flow grain cleaning device[J]. Transactions of the Chinese Society of Agricultural Engineering,2014,30(3):27-34. | |

| 10 | Fu Jun , Chen Zhi , Han Lu-jia , et al . Review of grain threshing theory and technology[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(3): 12-20. |

| 11 | 樊晨龙,崔涛,张东兴,等 . 纵轴流联合收获机双层异向清选装置设计与试验[J]. 农业机械学报,2018,49(增刊):239-248. |

| Fan Chen-long , Cui Tao , Zhang Dong-xing ,et al . Design and experiment of double-layered reverse cleaning device for axial flow combine Harvester[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(Sup.):239-248. | |

| 12 | 王立军,张传根,丁振军 . 玉米收获机清选筛体结构优化[J]. 农业机械学报,2016,47(9):108-114. |

| Wang Li-jun , Zhang Chuan-gen , Ding Zhen-jun . Structure optimization of cleaning screen for maize harvester[J]. Transactions of the Chinese Society for Agricultural Machinery,2016,47(9):108-114. | |

| 13 | 王立军,冯鑫,武振超,等 . 玉米联合收获机贯流风阶梯式振动筛设计与试验[J]. 农业机械学报,2018,49(10):115-123. |

| Wang Li-jun , Feng Xin , Wu Zhen-chao ,et al . Design and test of stepped vibrating screen with cross air for maize harvester[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(10):115-123. | |

| 14 | 王立军,段良坤,郑招辉,等 . 三移动两转动振动筛驱动机构优化与试验[J]. 农业机械学报,2018,49(6):138-145. |

| Wang Li-jun , Duan Liang-kun , Zheng Zhao-hui ,et al . Optimization and experiment on driving mechanism of vibrating screen with three translations and two rotations[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(6):138-145. | |

| 15 | Wang L J , Ding Z J , Meng S ,et al . Kinematics and dynamics of a particle on a non-simple harmonic vibrating screen[J]. Particuology,2017,32:167-177. |

| 16 | 王立军,彭博,宋慧强 . 玉米收获机聚氨酯橡胶筛筛分性能仿真与试验[J]. 农业机械学报,2018,49(7):138-145. |

| Wang Li-jun , Peng Bo , Song Hui-qiang ,et al . Cleaning of maize mixture based on polyurethane rubber sieve[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(7):138-145. | |

| 17 | 王卓,车东,白晓平,等 . 玉米联合收获机清选损失监测装置设计与试验[J]. 农业机械学报,2018,49(12):100-108. |

| Wang Zhuo , Che Dong , Bai Xiao-ping ,et al . Improvement and experiment of cleaning loss rate monitoring device for corn combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(12):100-108. | |

| 18 | 张真,迟瑞娟,杜岳峰,等 . 基于CAN总线的玉米收获智能控制系统研究[J]. 农业机械学报,2018,49(增刊):275-281. |

| Zhang Zhen , Chi Rui-juan , Du Yue-feng ,et al . Investigation on CAN-bus-based corn harvester intelligent control system[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(Supp.):275-281. | |

| 19 | 李耀明,马征,徐立章 . 油菜联合收获机筛面粘附物摩擦特性[J]. 农业机械学报,2010,41(12):54-57. |

| Li Yao-ming , Ma Zheng , Xu Li-zhang . Tribological characteristics of adhesive materials on cleaning sieve of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 54-57. | |

| 20 | 李耀明,马征,徐立章 . 油菜混合物与仿生筛面基体间的粘附特性[J]. 农业机械学报,2012,43(2):75-78. |

| Li Yao-ming , Ma Zheng , Xu Li-zhang . Adhesion property between rape mixture and bionic screen matrix[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(2): 75-78. | |

| 21 | 李耀明 . 谷物联合收割机的设计与分析[M]. 北京:机械工业出版社,2014. |

| 22 | 李宝筏 . 农业机械学[M]. 北京:中国农业出版社,2003. |

| 23 | 任露泉 . 试验设计及其优化[M]. 北京:科学出版社,2009. |

| [1] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [2] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

|

||