吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 122-133.doi: 10.13229/j.cnki.jdxbgxb20190948

• 车辆工程·机械工程 • 上一篇

金属切削加工知识图谱构建及应用

- 四川大学 机械工程学院,成都 610065

Building and application of metal cutting knowledge graph

Yang DUAN( ),Li HOU(

),Li HOU( ),Song LENG

),Song LENG

- School of Mechanical Engineering,Sichuan University,Chengdu 610065,China

摘要:

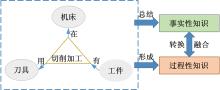

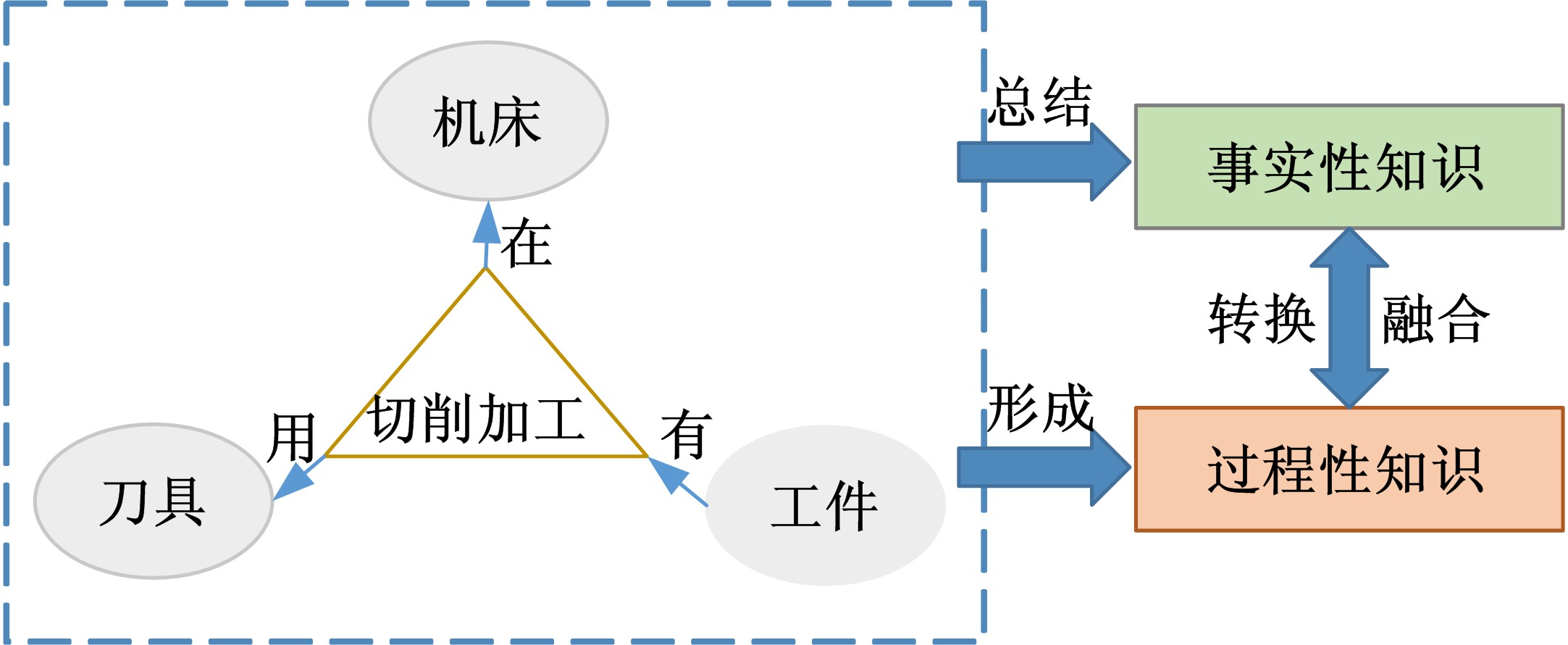

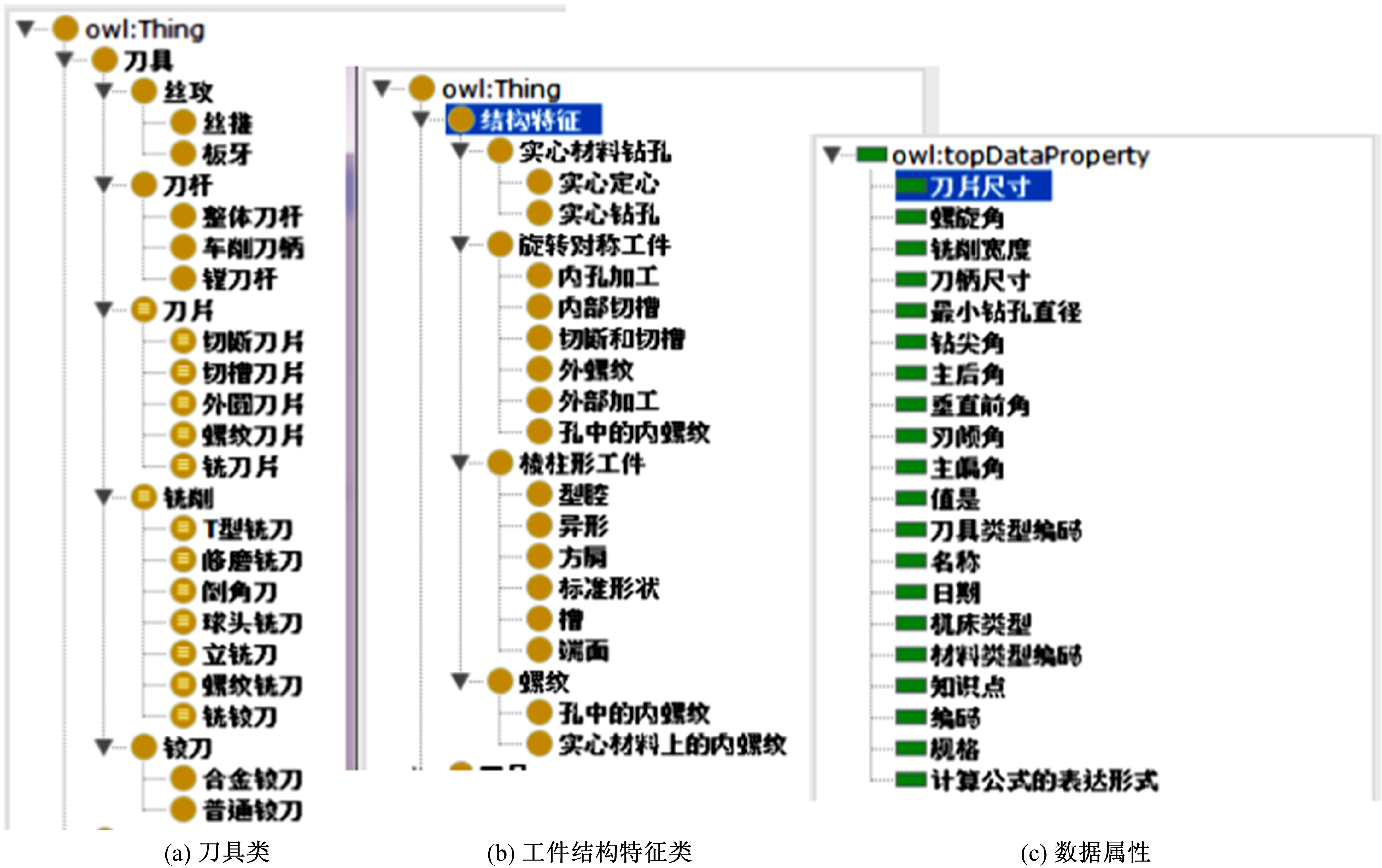

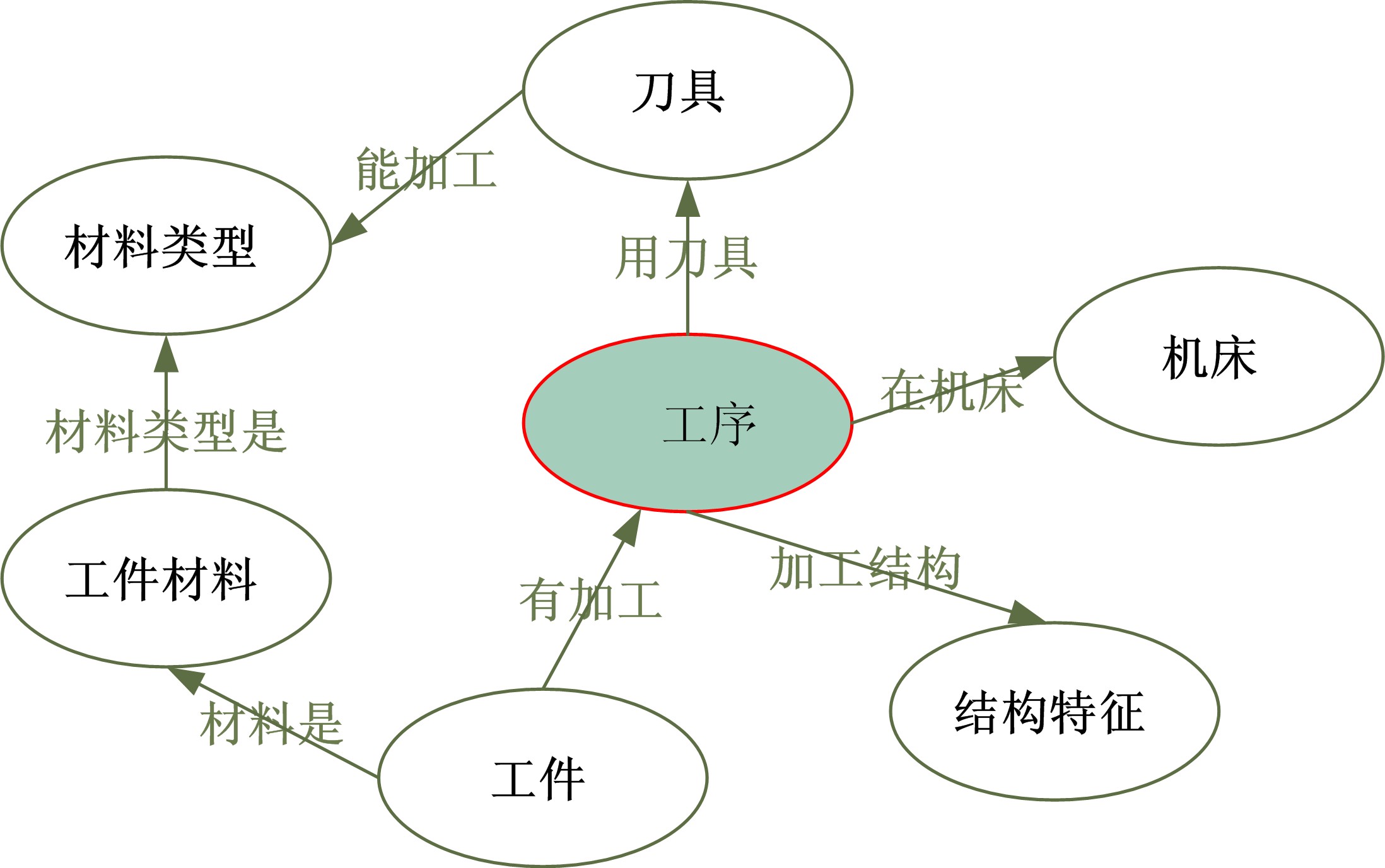

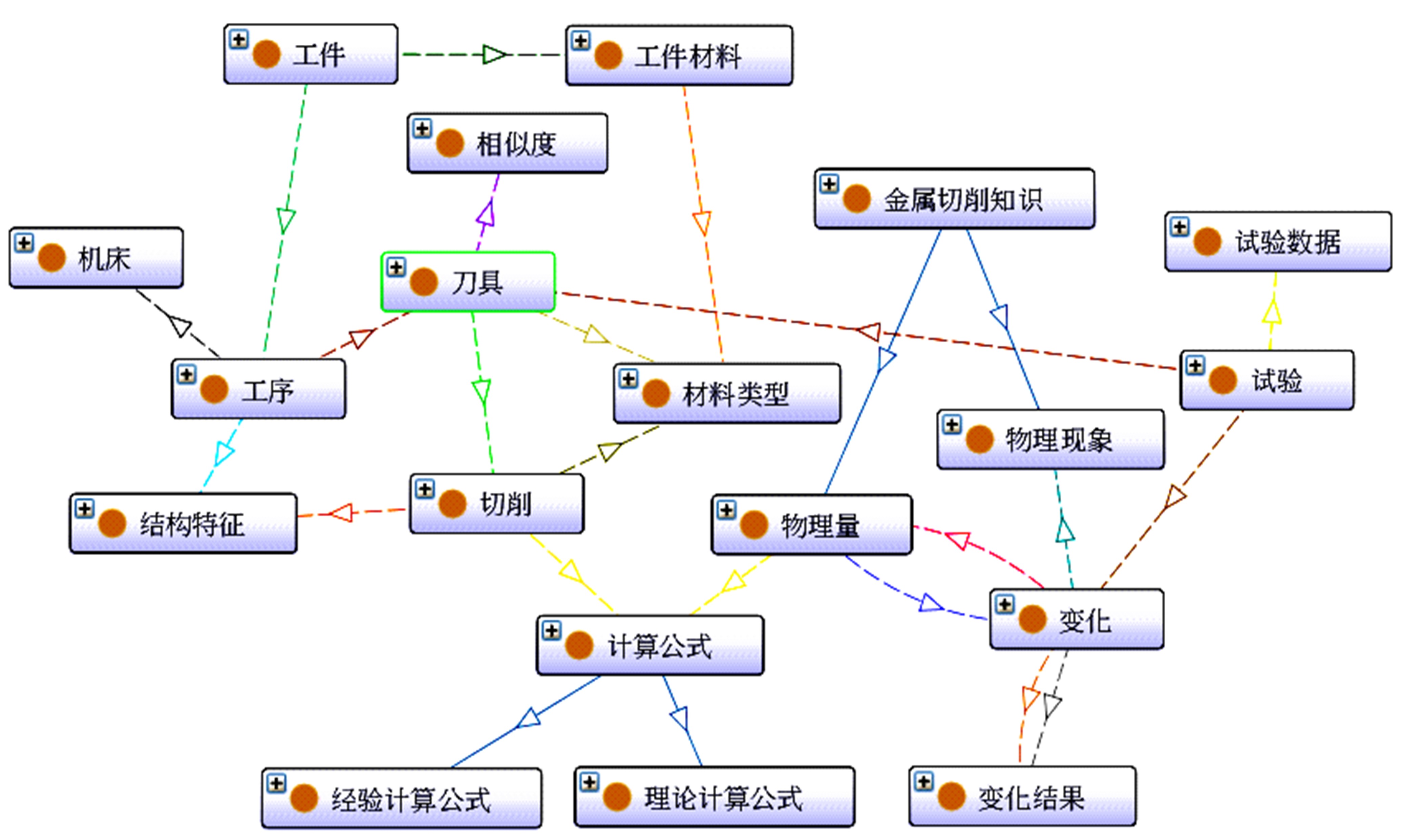

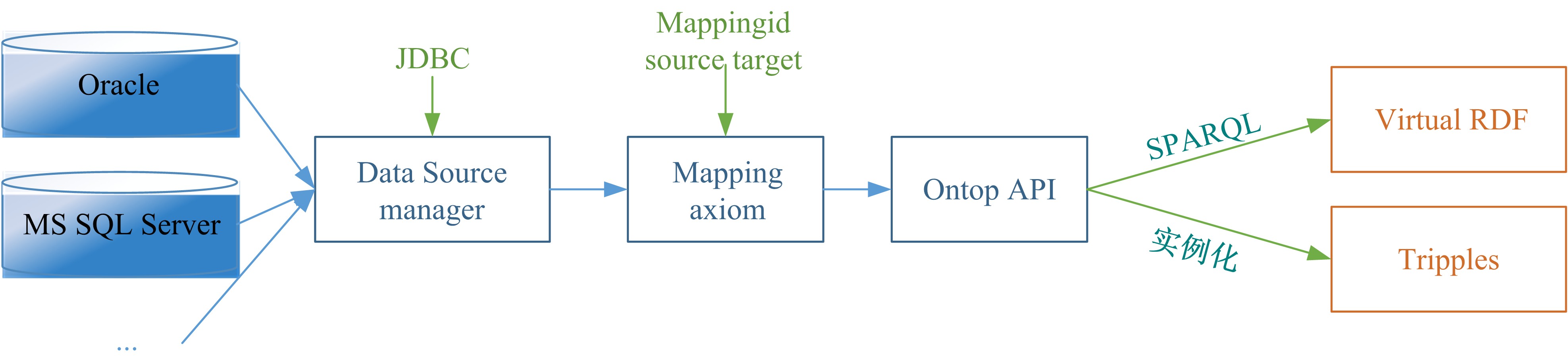

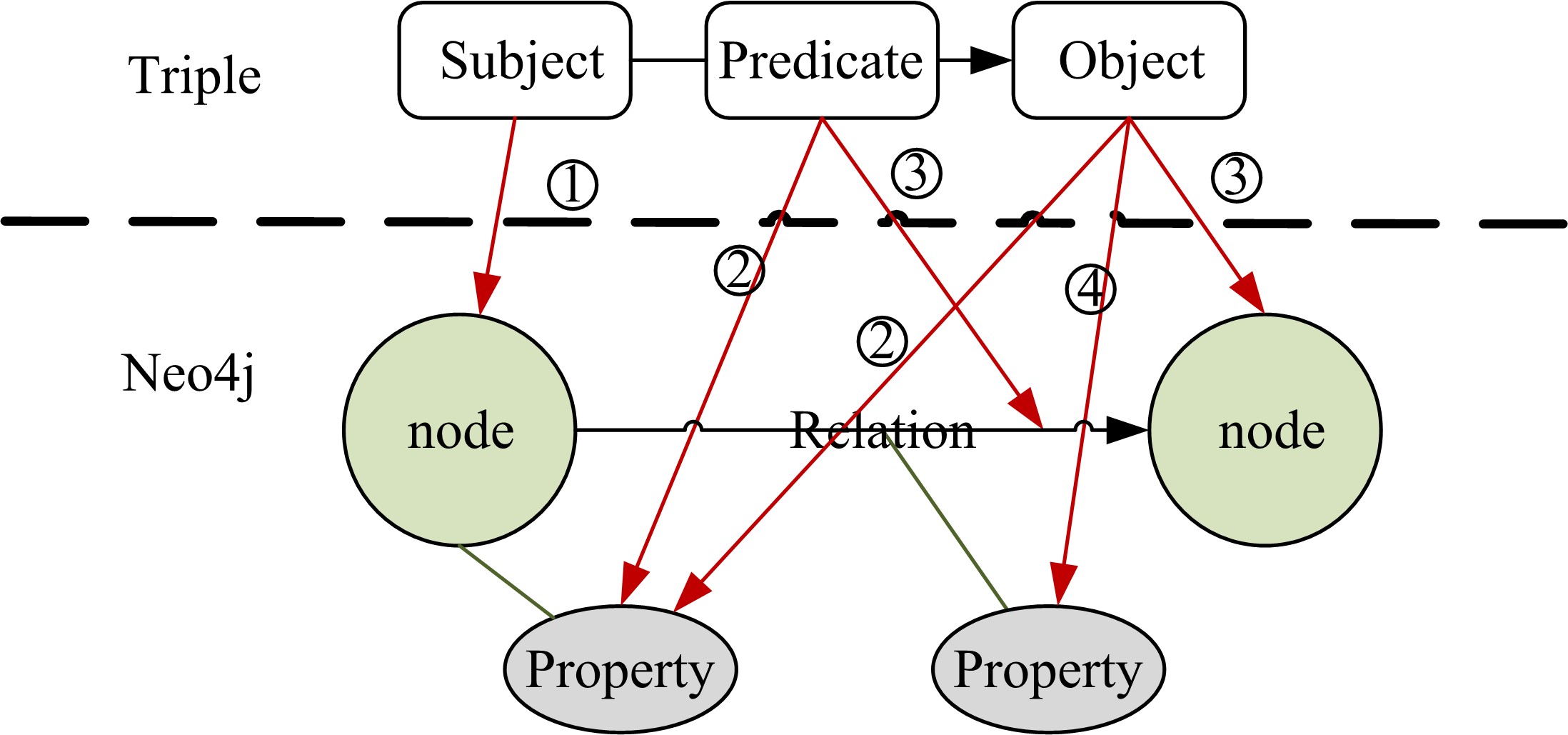

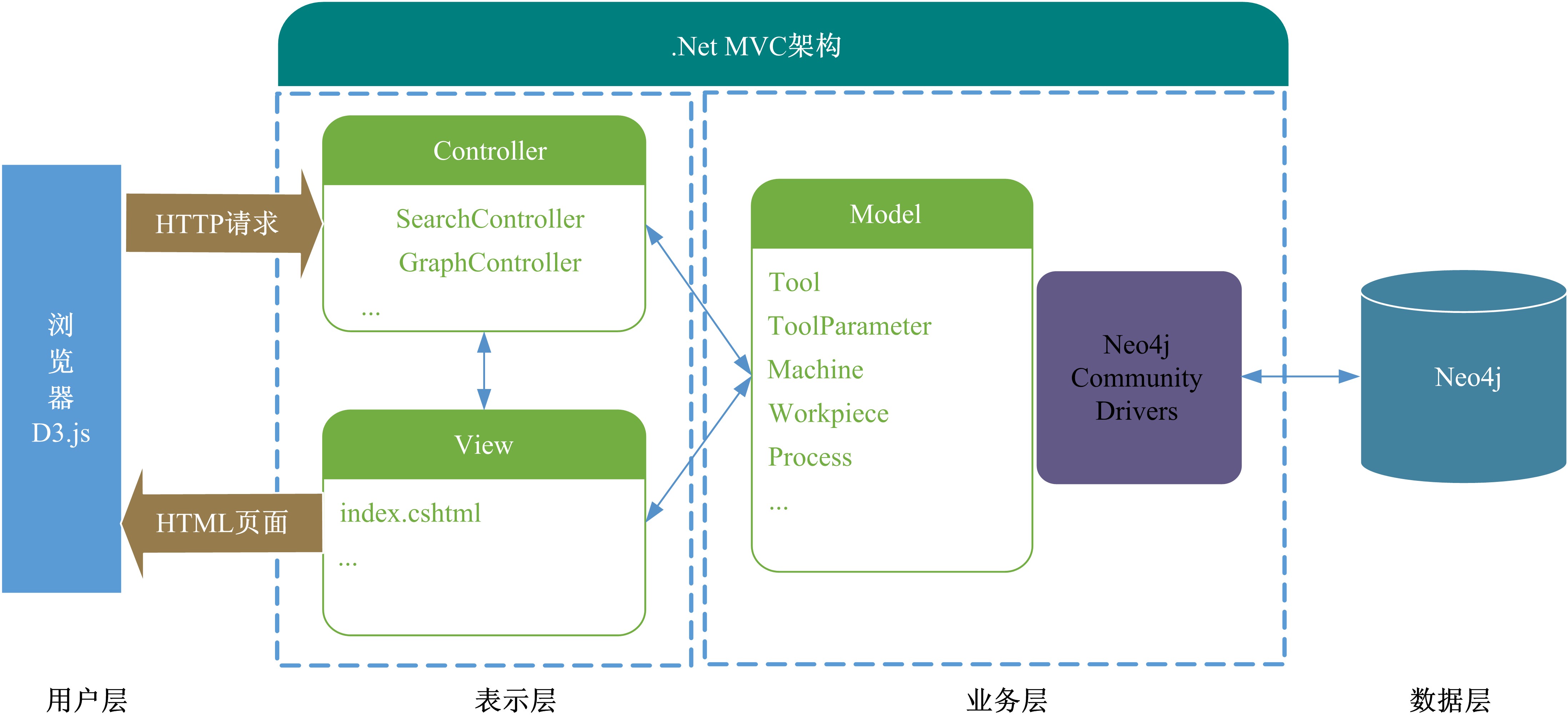

针对制造型企业普遍存在无法深度利用散布在各应用系统中的金属切削加工数据资源问题,提出了通过建立金属切削加工知识图谱的途径,实现切削加工数据全面融合,提升数据的价值密度。首先,将金属切削加工知识归纳为事实性知识和过程性知识两类,采用自顶向下的方法,用OWL语言建立了完整的金属切削加工本体模型。然后,构建了多源数据集成框架,确定了适于切削加工数据等价实体判别的数据融合算法。最后,开发了知识图谱的可视化系统,在国内某航空发动机维修公司获得初步应用。本文研究结果可为构建基于数据驱动的智能化金属切削加工提供参考。

中图分类号:

- TH166

| 1 | 刘战强, 黄传真, 万熠, 等. 切削数据库的研究现状与发展[J]. 计算机集成制造系统, 2003, 9(11): 937-943. |

| Liu Zhan-qiang, Huang Chuan-zhen, Wan Yi, et al. Research state and development directions of cutting database[J]. Computer Integrated Manufacturing Systems, 2003, 9(11): 937-943. | |

| 2 | Walter GPS.[EB/OL]. [2019-10-08].. |

| 3 | ToolLibrary CoroPlus.[EB/OL]. [2019-10-08].. |

| 4 | 谭方浩. 基于特征的智能型车削数据库系统研究与开发[D]. 北京: 北京理工大学机械与车辆学院, 2015. |

| Tan Fang-hao. Research and development of intelligent turning database system based on machining features[D]. Beijing: School of Machinery and Vehicle, Beijing University of Technology, 2015. | |

| 5 | 任莹晖, 纪会敏, 杜勇, 等. 切削刀具综合管理系统的数据采集和存储设计研究[J].计算机应用研究, 2016, 33(10): 3031-3035. |

| Ren Ying-hui,Ji Hui-min,Du Yong,et al. Study on design of data acquisition and storage for comprehensive tool management system[J]. Application Research of Computers, 2016, 33(10): 3031-3035. | |

| 6 | 海源, 张松, 李剑峰, 等. 基于射频识别技术的车间级刀具管理系统[J]. 计算机集成制造系统, 2016, 22(8): 1907-1918. |

| Hai Yuan, Zhang Song, Li Jian-feng, et al. Workshop-level tool management system based on radio frequency identification technology[J]. Computer Integrated Manufacturing Systems, 2016, 22(8): 1907-1918. | |

| 7 | 廖生辉, 王建军, 卓勇, 等. 在线智能刀具管理系统的开发与研究[J]. 锻压技术, 2018, 43(9): 189-195. |

| Liao Sheng-hui,Wang Jian-jun,Zhuo Yong, et al. Development and research on online intelligent tool management system[J]. Forging & Stamping Technology, 2018, 43(9): 189-195. | |

| 8 | 白雪, 鄢萍. 齿轮加工数字化车间刀夹具管理系统的设计[J]. 计算机集成制造系统, 2020, 26(5): 1233-1245. |

| Bai Xue, Yan Ping. Design of cutting tools and fixtures management system for digital workshop of gear machining[J]. Computer Integrated Manufacturing Systems, 2020, 26(5): 1233-1245. | |

| 9 | Peng C, Du H, Warren Liao T. A research on the cutting database system based on machining features and TOPSIS[J]. Robotics and Computer-Integrated Manufacturing, 2017, 43: 96-104. |

| 10 | 张丹丹. 基于特征的航空结构件工艺知识库建立和数据挖掘研究[D]. 山东:山东大学机械工程学院, 2018. |

| Zhang Dan-dan. Feature-based knowledge base building and data mining for aeronautical structural parts[D]. Shandong: School of Mechanical Engineering, Shandong University, 2018. | |

| 11 | Zhang Y Z, Luo X F, Zhang H. A knowledge representation for unit manufacturing processes[J]. International Journal of Advanced Manufacturing Technology, 2014, 73: 1011-1031. |

| 12 | 王晶, 张定华, 吴宝海, 等. 基于临界约束的四轴数控加工刀轴优化方法[J]. 机械工程学报, 2012, 48(17): 114-120. |

| Wang Jing, Zhang Ding-hua, Wu Bao-hai, et al. Tool orientation optimization method in four-axis CNC machining based on critical constraints[J]. Journal of Mechanical Engineering, 2012, 48(17): 114-120. | |

| 13 | 吴宝海, 梁满仓, 张莹, 等. 复杂曲面通道多轴加工的刀具选择方法[J]. 机械工程学报, 2018, 54(3): 117-124. |

| Wu Bao-hai, Liang Man-cang, Zhang Ying, et al. Tool selection of multi-axis machining for channel parts with sculptured surface[J]. Journal of Mechanical Engineering, 2018, 54(3): 117-124. | |

| 14 | 陈行政, 李聪波, 吴磊, 等. 面向能耗的多刀具孔加工刀具直径及工艺参数集成优化模型[J]. 机械工程学报, 2018, 54(15): 221-231. |

| Chen Xing-zheng, Li Cong-bo, Wu Lei, et al. Integrating optimization of cutter diameter and cutting parameters for energy-aware multi-tool hole machining[J]. Journal of Mechanical Engineering, 2018, 54(15): 221-231. | |

| 15 | An Q, Chen J, Tao Z, et al. Experimental investigation on tool wear characteristics of PVD and CVD coatings during face milling of Ti-6242S and Ti-555 titanium alloys[J]. International Journal of Refractory Metals and Hard Materials, 2020, 86: 105091. |

| 16 | Sun J, Huang S, Ding H, et al. Cutting performance and wear mechanism of Sialon ceramic tools in highspeed face milling GH4099[J]. Ceramics International, 2020, 46(2): 1621-1630. |

| 17 | 黄恒琪, 于娟, 廖晓, 等. 知识图谱研究综述[J]. 计算机系统应用, 2019, 28(6): 1-12. |

| Huang Heng-qi, Yu Juan, Liao Xiao, et al. Review on knowledge graphs[J]. Computer Systems & Applications, 2019, 28(6): 1-12. | |

| 18 | YAGO. [EB/OL]. [2019-10-08]. . |

| 19 | GeoNames.[EB/OL]. [2019-10-08]. . |

| 20 | 中国中医科学院中医药信息研究所. 中医药知识图谱[EB/OL]. [2019-10-08]. . |

| 21 | Calvanese D, Cogrel B, Komla-Ebri S, et al. Ontop: answering SPARQL queries over relational databases[J]. Semantic Web, 2016, 8(3): 471-487. |

| 22 | Barrasa Jesús.[EB/OL]. [2019-10-08]. . |

| [1] | 欧阳丹彤,马骢,雷景佩,冯莎莎. 知识图谱嵌入中的自适应筛选[J]. 吉林大学学报(工学版), 2020, 50(2): 685-691. |

| [2] | 陈磊,王江锋,谷远利,闫学东. 基于思维进化优化的多源交通数据融合算法[J]. 吉林大学学报(工学版), 2019, 49(3): 705-713. |

| [3] | 杨兆升, 莫祥伦, 于尧, 张彪. 非常态下路段行程时间估计方法[J]. 吉林大学学报(工学版), 2013, 43(06): 1459-1464. |

| [4] | 周婧, 高印寒, 陈小林, 刘长英, 刘静. 基于单摄像机视觉测量系统的网络化数据融合[J]. 吉林大学学报(工学版), 2013, 43(01): 92-97. |

| [5] | 杨炽夫, 郑淑涛, 姜洪洲, 韩俊伟. 飞行模拟器原型系统导航数据库的构建[J]. 吉林大学学报(工学版), 2010, 40(03): 863-0867. |

| [6] | 焦竹青, 熊伟丽, 徐保国. 基于加权最小二乘法的异质传感器数据融合[J]. 吉林大学学报(工学版), 2010, 40(03): 816-0820. |

| [7] | 赵一兵,王荣本,李琳辉,郭烈 . 基于D-S证据理论的障碍目标身份识别[J]. 吉林大学学报(工学版), 2008, 38(06): 1295-1299. |

| [8] | 冯志刚,王祁 . 基于模糊数据融合的液氢供应系统健康评价方法 [J]. 吉林大学学报(工学版), 2006, 36(05): 751-0756. |

| [9] | 周洁敏, 韩静, 肖纪立. 利用数据融合来解决目标识别问题[J]. 吉林大学学报(工学版), 2001, (4): 69-72. |

|

||