吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 831-839.doi: 10.13229/j.cnki.jdxbgxb20200040

基于计算流体仿真的双作用叶片泵气蚀机理分析

- 浙江大学 流体动力与机电系统国家重点实验室,杭州 310027

Cavitation mechanism of double⁃acting vane pump based on computational fluid dynamics simulation method

Bin ZHANG( ),Guo-zan CHENG,Hao-cen HONG(

),Guo-zan CHENG,Hao-cen HONG( ),Chun-Xiao ZHAO,Hua-yong YANG

),Chun-Xiao ZHAO,Hua-yong YANG

- State Key Laboratory of Fluid Power & Mechatronic Systems,Zhejiang University,Hangzhou 310027,China

摘要:

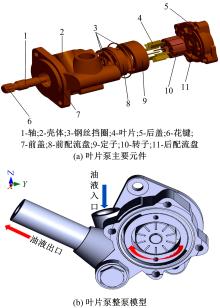

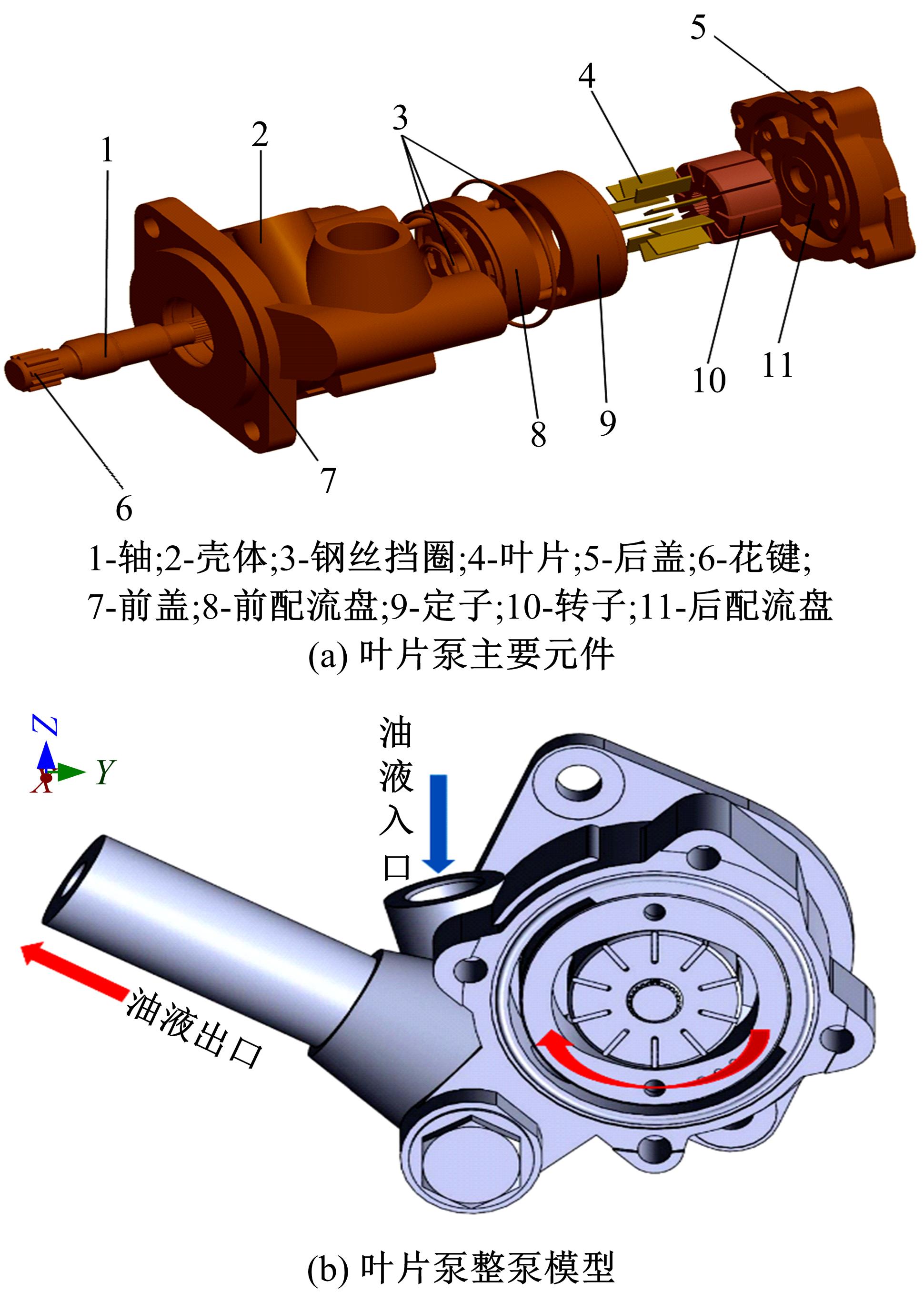

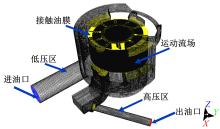

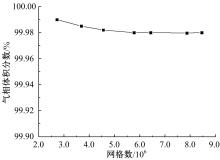

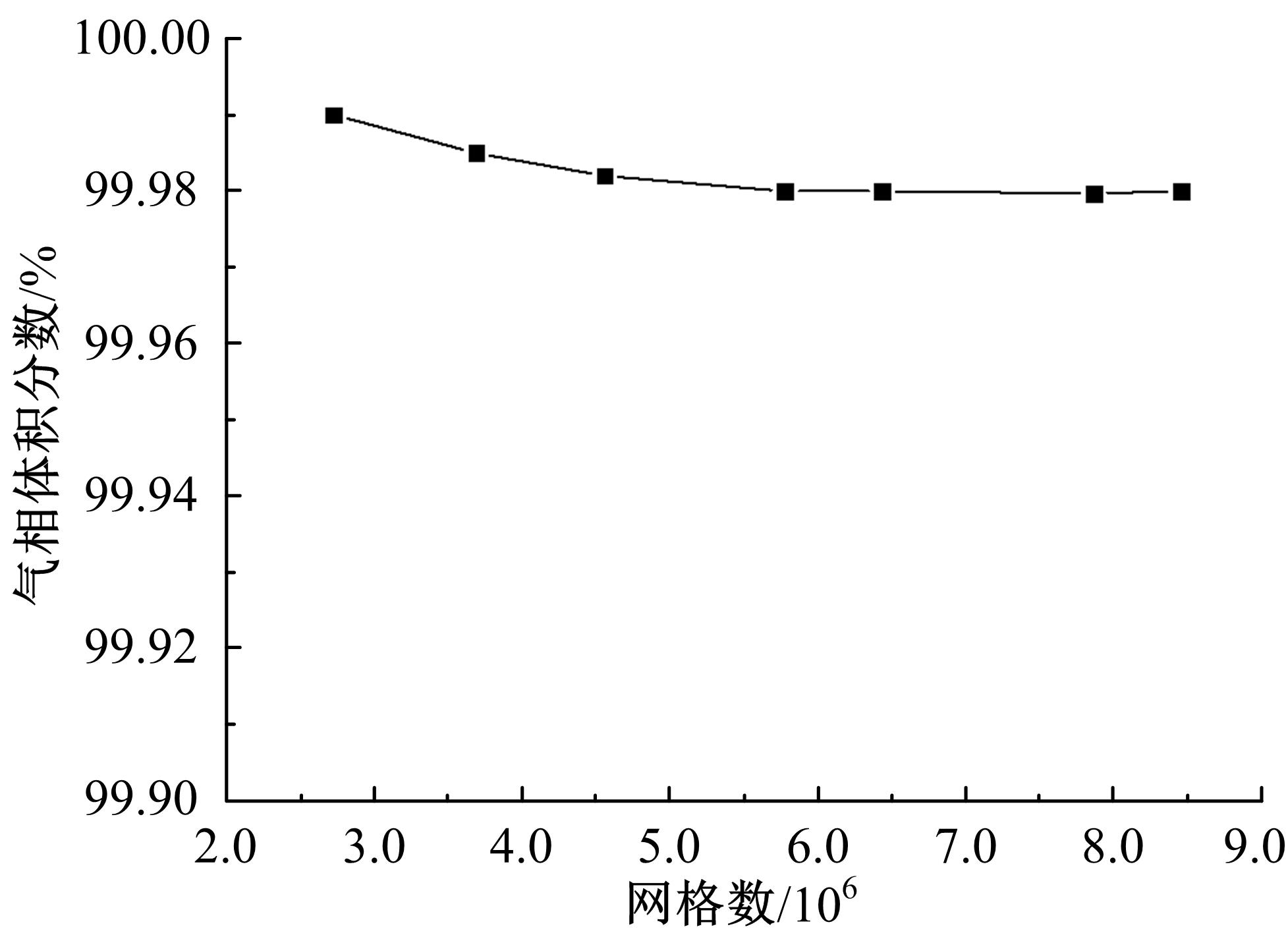

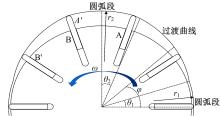

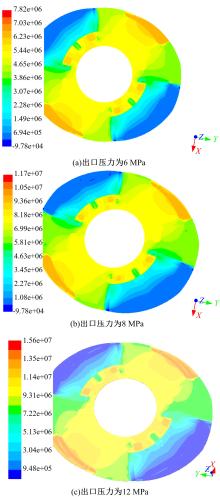

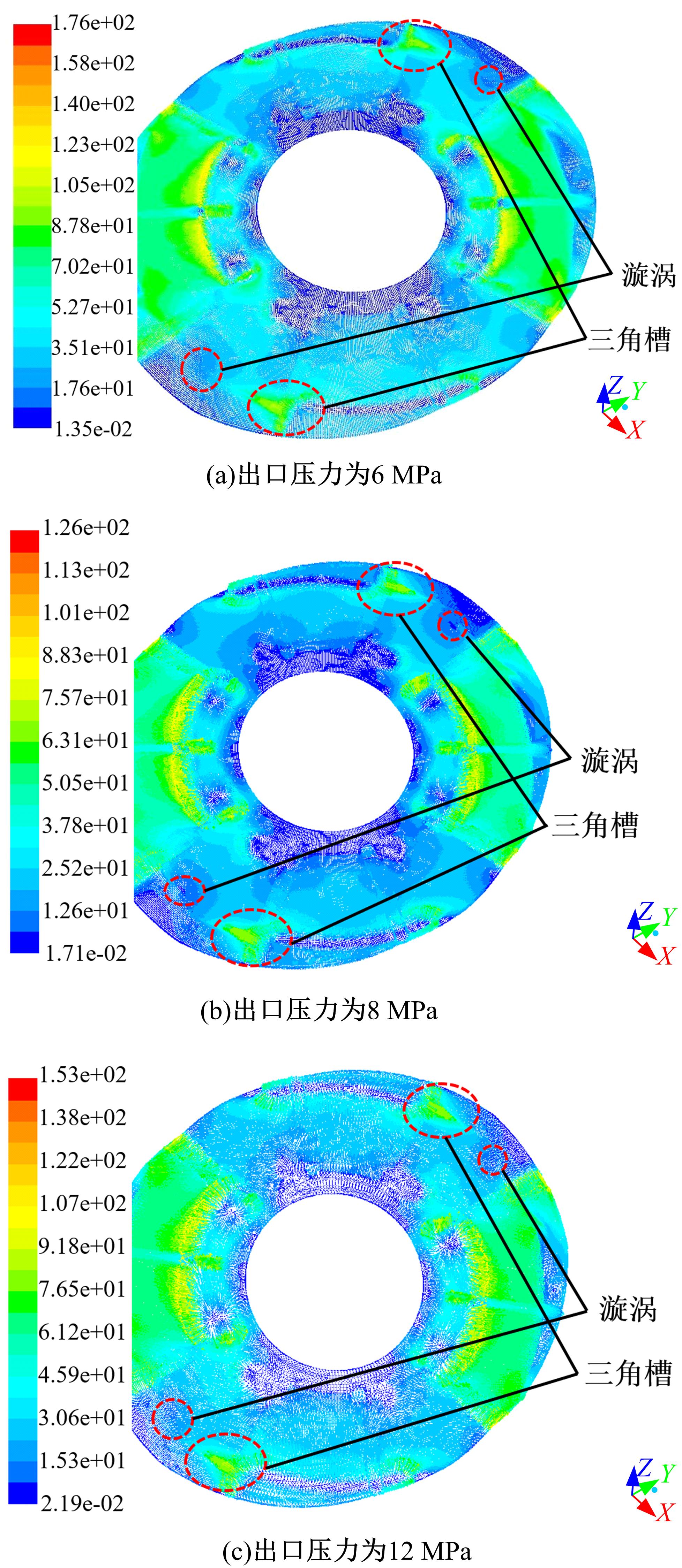

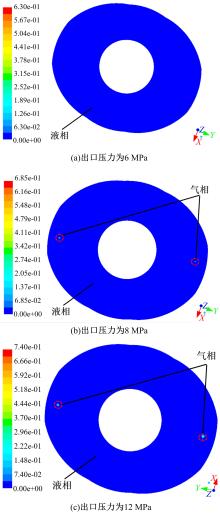

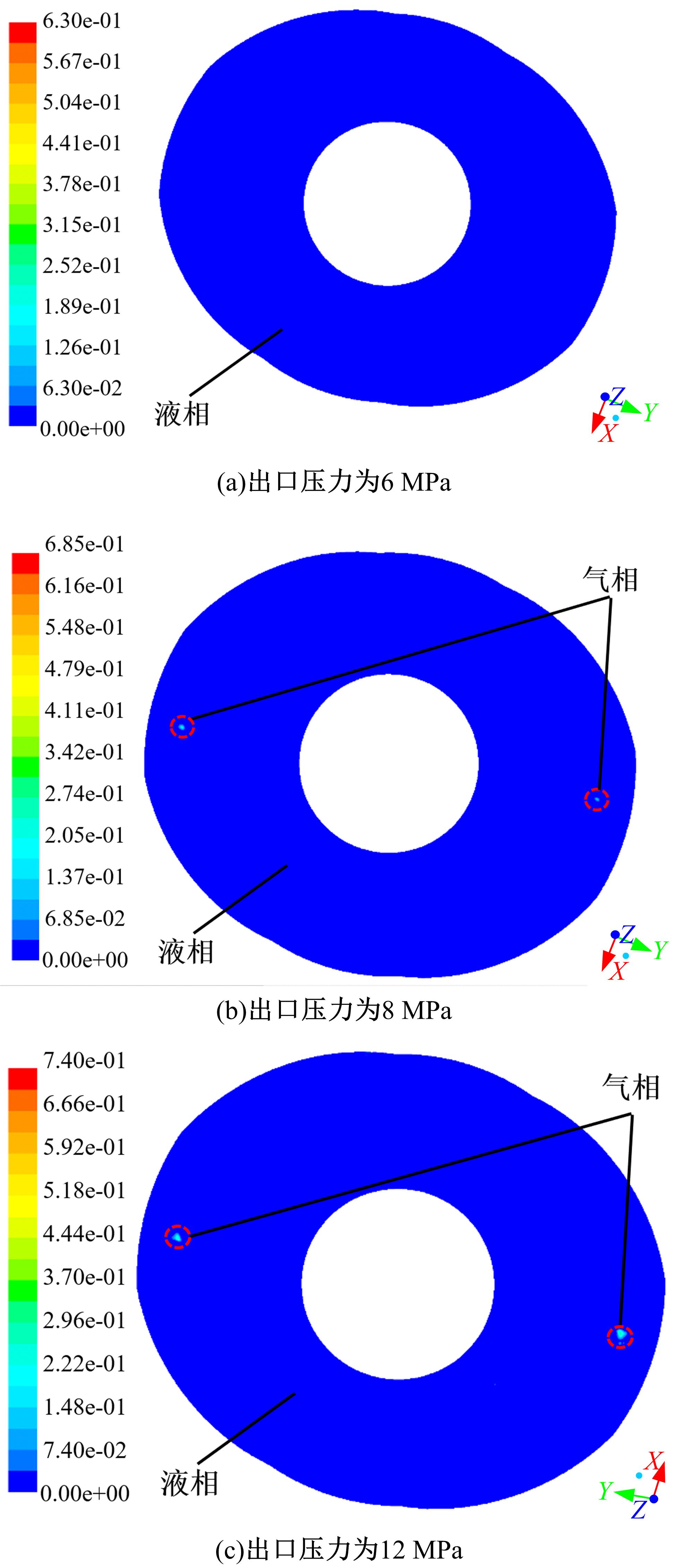

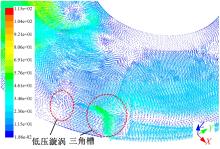

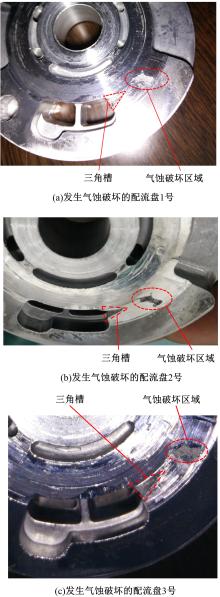

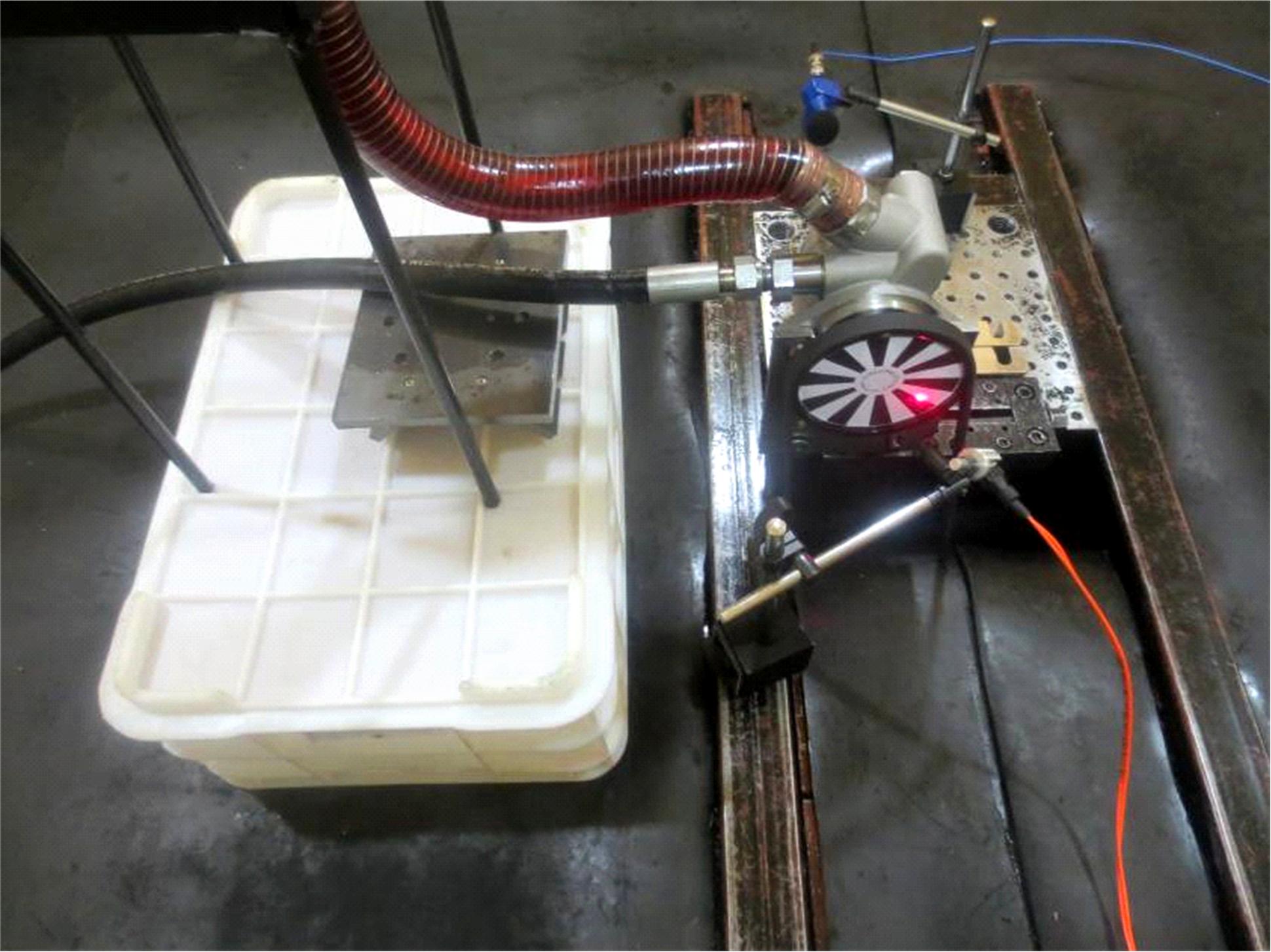

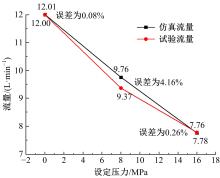

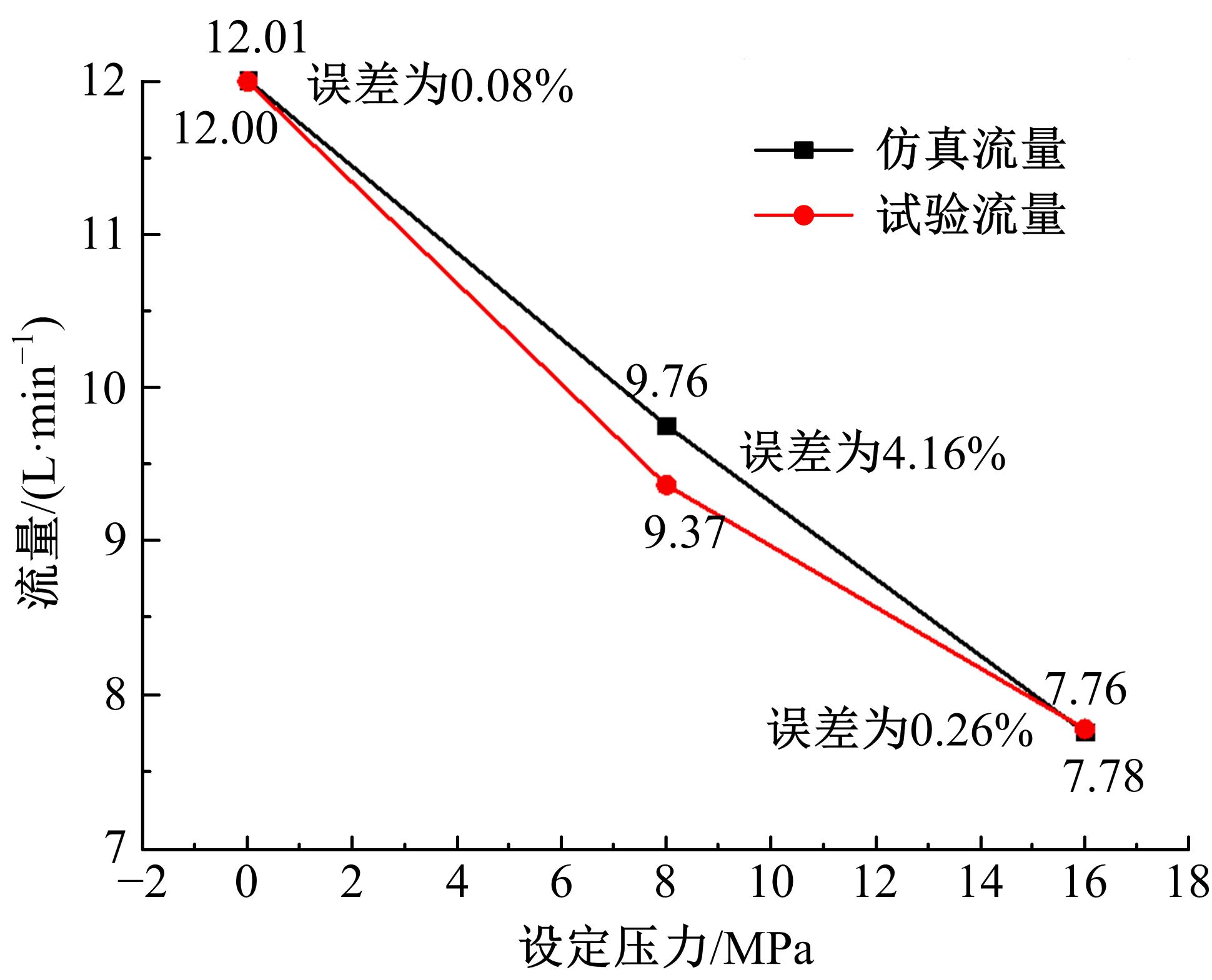

双作用叶片泵在高转速工况下,其高压油液出口三角槽附近易发生空化现象,严重时会发生气蚀,破坏配流盘表面,带来尖锐的噪声并缩短叶片泵的使用寿命。本文针对双作用叶片泵的空化气蚀现象,利用计算流体力学仿真分析,对双作用叶片泵流场进行建模分析。引入动网格技术并通过用户自定义函数对叶片绕定子转动的运动规律进行约束,实现对双作用叶片泵流场动态特性的分析。在不同转速和压力条件下,计算分析双作用叶片泵流场的压力分布及速度矢量分布,得出配流盘发生气蚀的原因是配流副间隙内局部低压流场的存在,其发生位置在配流盘高压出口容腔三角槽前方,与实际试验具有一致性。

中图分类号:

- TQ021.1

| 1 | 朱诗顺,欧阳熙,朱道伟,等. 车辆液压助力转向泵故障模拟实验[J]. 军事交通学院学报,2015,17(3):57-61. |

| Zhu Shi-shun, Ouyang Xi, Zhu Dao-wei, et al. Fault simulation experiment of automotive hydraulic power steering pump[J]. Journal of Military Transportation University, 2015, 17(3): 57-61. | |

| 2 | 刘阳阳. 双作用高压叶片泵内部泄漏分析及流量脉动研究[D]. 兰州:兰州理工大学能源与动力工程学院, 2019. |

| Liu Yang-yang. Internal leakage analysis and flow pulsation study on double-action high pressure vane pump[D]. Lanzhou: School of Energy and Power Engineering, Lanzhou University of Technology, 2019. | |

| 3 | 江帆,陈维平,王一军,等. 基于动网格的离心泵内部流场数值模拟[J]. 流体机械, 2007, 35(7):20-24. |

| Jiang Fan, Chen Wei-ping, Wang Yi-jun, et al. Numerical simulation of flow field inside of centrifugal pump based on dynamics mesh[J]. Fluid Machinery, 2007, 35(7):20-24. | |

| 4 | 王兴坤. 叶片泵流场的数值模拟及性能分析[D]. 洛阳:河南科技大学机电工程学院, 2013. |

| Wang Xing-kun. Numerical simulation and characteristic research on the flow field for vane pump[D]. Luoyang: School of Mechatronics Engineering, Henan University of Science and Technology, 2013. | |

| 5 | 闻德生,王京,高俊峰,等. 双定子单作用叶片泵闭死容腔的压力特性[J]. 吉林大学学报:工学版,2017,47(4):1094-1101. |

| Wen De-sheng, Wang Jing, Gao Jun-feng, et al. Pressure variation characteristics in cavity of double-stator single-action vane pump[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(4): 1094-1101. | |

| 6 | 曹建国,于亮,杨光辉. 基于CAD和CFD技术的高效叶片泵流场仿真与优化分析[J]. 徐州工程学院学报:自然科学版, 2015, 30(2):1-5. |

| Cao Jian-guo, Yu Liang, Yang Guang-hui. Simulation and optimization analys of flow field for efficient centrifugal pumps based on the CAD on the CAD and CFD technologies[J]. Journal of Xuzhou Institute of Technology(Natural Sciences Edition), 2015, 30(2):1-5. | |

| 7 | Sanada K, Yamaguchi N. CFD analysis of inlet flow around an impeller of an oil-hydraulic pump[C]∥Proceedings of the 8th JFPS International Symposium of Fluid Power, Okinawa, 2011:188-195. |

| 8 | 孙正,黄钰期,俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报:工学版,2018,48(3):744-751. |

| Sun Zheng, Huang Yu-qi, Yu Xiao-li. Numerical simulation of flow and heat transfer in journal bearing lubrication[J]. Journal of Jilin University (Engineering and Technology Edition),2018,48(3):744-751. | |

| 9 | Chao Qun, Zhang Jun-hui, Xu Bin, et al. Effects of inclined cylinder ports on gaseous cavitation of high-speed electro-hydrostatic actuator pumps: a numerical study[J]. Engineering Applications of Computational Fluid Mechanics, 2019,13(1):245-253. |

| 10 | Chen Q, Wu M, Kang S, et al. Study on cavitation phenomenon of twin-tube hydraulic shock absorber based on CFD[J]. Engineering Applications of Computational Fluid Mechanics,2019,13(1):1049-1062. |

| 11 | Xie S F, Wang Y, Liu Z C, et al. Optimization of centrifugal pump cavitation performance based on CFD[J]. Materials Science and Engineering, 2015, 72(3):1-6. |

| 12 | Zhang Q F, Xu X Y. Numerical simulation on cavitation in a vane pump with moving mesh[C]∥International Conference on Computational Methods, Cambridge, England, 2014:1-7. |

| 13 | 曹国强,包明宇,荣刚. 计算流体动力学(CFD)中并行分区算法的应用[J]. 机械设计与制造,2005(12):70-72. |

| Cao Guo-qiang, Bao Ming-yu, Rong Gang. The application of parallel district method in computation fluid dynamics[J]. Machinery Design & Manufacture,2005(12):70-72. | |

| 14 | 张凯,王瑞金,王刚. Fluent技术基础与应用实例[M]. 北京:清华大学出版社, 2010. |

| 15 | 王福军. 计算流体力学分析——CFD软件专著与应用[M].北京:清华大学出版社,2004. |

| 16 | 刘春宝,马文星,许睿. 液力变矩器轴向力的CFD计算与分析[J]. 吉林大学学报:工学版,2009,39(5):1181-1185. |

| Liu Chun-bao, Ma Wen-xing, Xu Rui. Calculation and analysis of axial force in hydrodynamic torque converter based on CFD[J]. Journal of Jilin University (Engineering and Technology Edition), 2009,39(5):1181-1185. |

| [1] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [2] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [3] | 孙正, 黄钰期, 俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报(工学版), 2018, 48(3): 744-751. |

| [4] | 张英朝, 韦甘, 张喆. 不同尾翼两厢轿车的气动特性数值模拟[J]. 吉林大学学报(工学版), 2011, 41(01): 1-0005. |

| [5] | 张英朝, 张喆, 李杰. 基于计算流体力学的虚拟风洞试验[J]. 吉林大学学报(工学版), 2010, 40(增刊): 90-0094. |

| [6] | 张英朝,李杰,张喆,胡兴军. 汽车风洞试验段尺寸参数对试验的影响[J]. 吉林大学学报(工学版), 2010, 40(02): 346-0350. |

| [7] | 张英朝,张喆,李杰,韦甘,罗双虎. 基于空气动力学数值模拟的汽车造型设计[J]. 吉林大学学报(工学版), 2009, 39(增刊2): 260-0263. |

| [8] | 刘春宝, 马文星, 许睿. 液力变矩器轴向力的CFD计算与分析[J]. 吉林大学学报(工学版), 2009, 39(05): 1181-1185. |

| [9] | 张君媛,兰海涛,杨秀坤,李红建,唐洪斌 . 汽车正面气囊充气过程仿真技术[J]. 吉林大学学报(工学版), 2008, 38(06): 1262-1266. |

| [10] | 刘春宝,马文星,褚亚旭 . 多流动区域耦合算法在液力元件中的应用[J]. 吉林大学学报(工学版), 2008, 38(06): 1342-1347. |

| [11] | 杨永柏;王靖宇;胡兴军 . 皮卡车外流场的数值模拟[J]. 吉林大学学报(工学版), 2007, 37(06): 1236-1241. |

| [12] | 张英朝,傅立敏. 简单外形汽车隧道中会车过程的瞬态空气动力学数值模拟[J]. 吉林大学学报(工学版), 2006, 36(03): 302-0306. |

| [13] | 王健,葛安林,雷雨龙,田华,杨建华. 基于三维流动理论的液力变矩器设计流程[J]. 吉林大学学报(工学版), 2006, 36(03): 315-0320. |

| [14] | 傅立敏, 沈俊, 王靖宇. 汽车流场及尾部涡系数值模拟[J]. 吉林大学学报(工学版), 2000, 30(02): 6-9. |

|

||