吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1724-1733.doi: 10.13229/j.cnki.jdxbgxb20200491

• 交通运输工程·土木工程 • 上一篇

新型异形钢管混凝土柱⁃钢梁节点抗震性能试验

刁延松1,2( ),郭荡1,屠康1,焦圣伦1,刘芸1,2,刘秀丽1,2

),郭荡1,屠康1,焦圣伦1,刘芸1,2,刘秀丽1,2

- 1.青岛理工大学 土木工程学院,山东 青岛 266033

2.青岛理工大学 蓝色经济区工程建设与安全协同创新中心,山东 青岛 266033

Experiment of seismic behavior of new joints between concrete filled special⁃shaped steel tube column and steel beams

Yan-song DIAO1,2( ),Dang GUO1,Kang TU1,Sheng-lun JIAO1,Yun LIU1,2,Xiu-li LIU1,2

),Dang GUO1,Kang TU1,Sheng-lun JIAO1,Yun LIU1,2,Xiu-li LIU1,2

- 1.School of Civil Engineering,Qingdao University of Technology,Qingdao 266033,China

2.Collaborative Innovation Center of Engineering Construction and Safety in Shandong Blue Economic Zone,Qingdao University of Technology,Qingdao 266033,China

摘要:

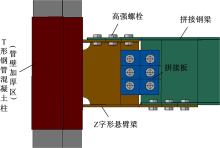

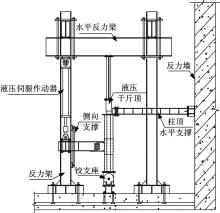

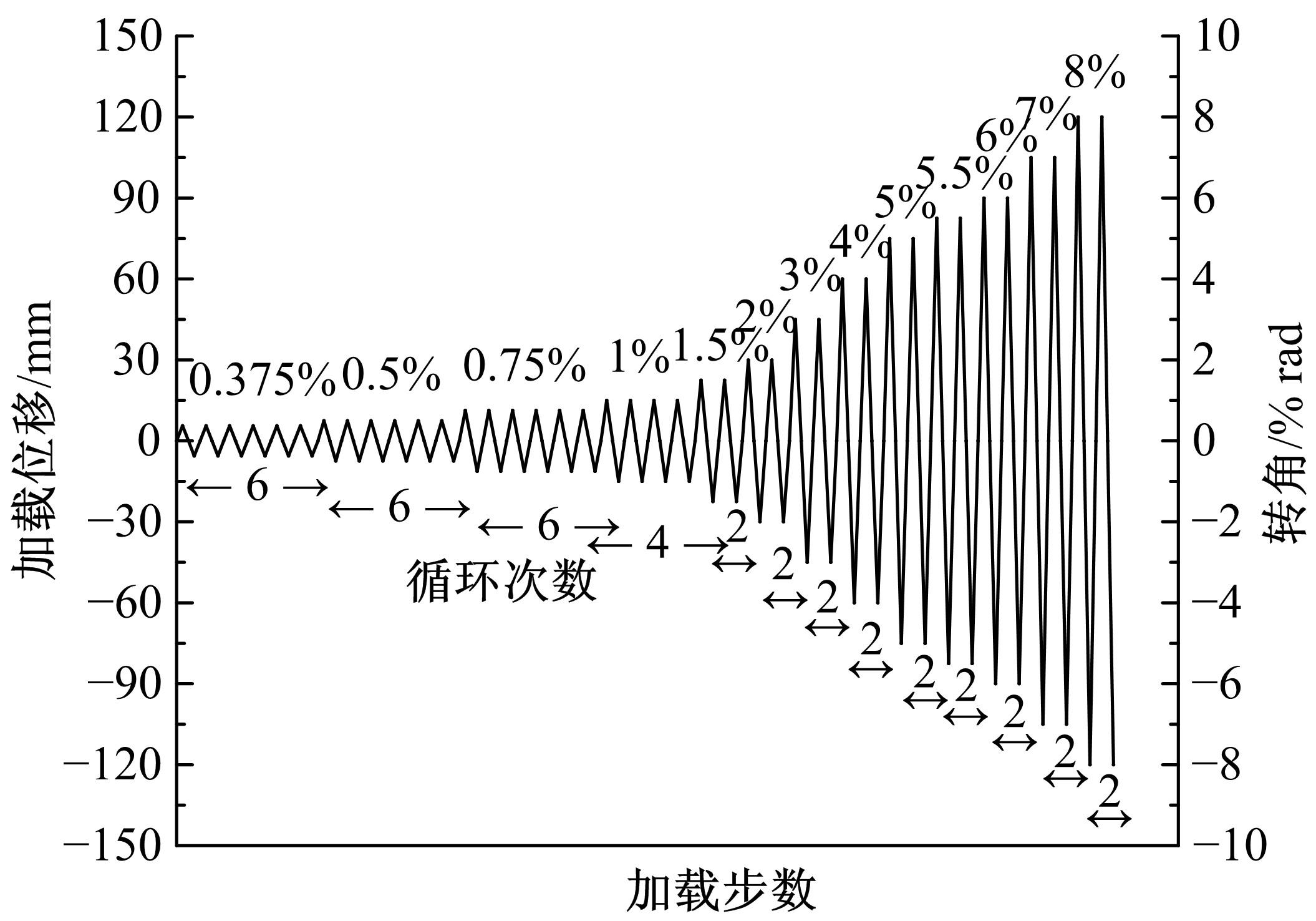

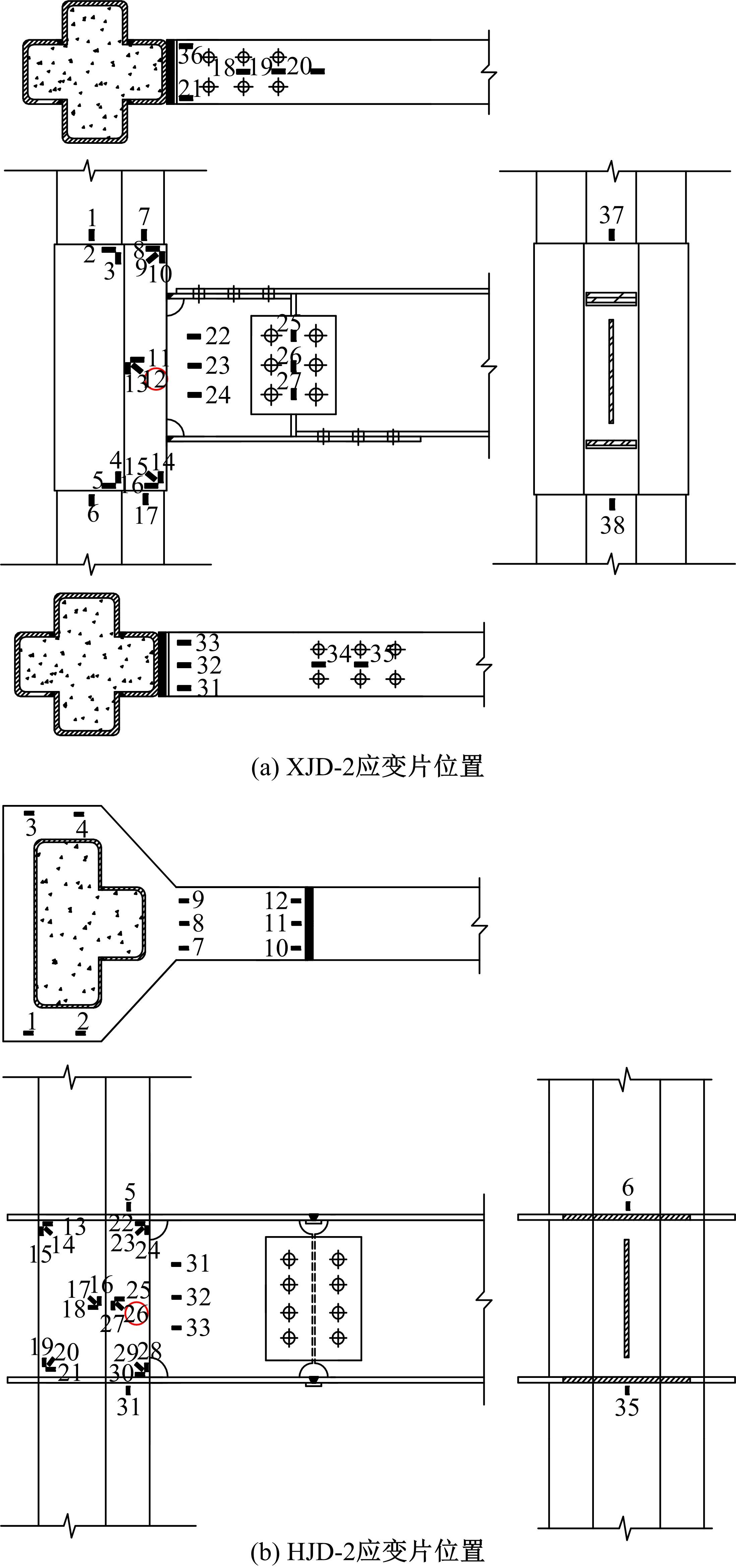

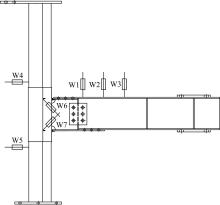

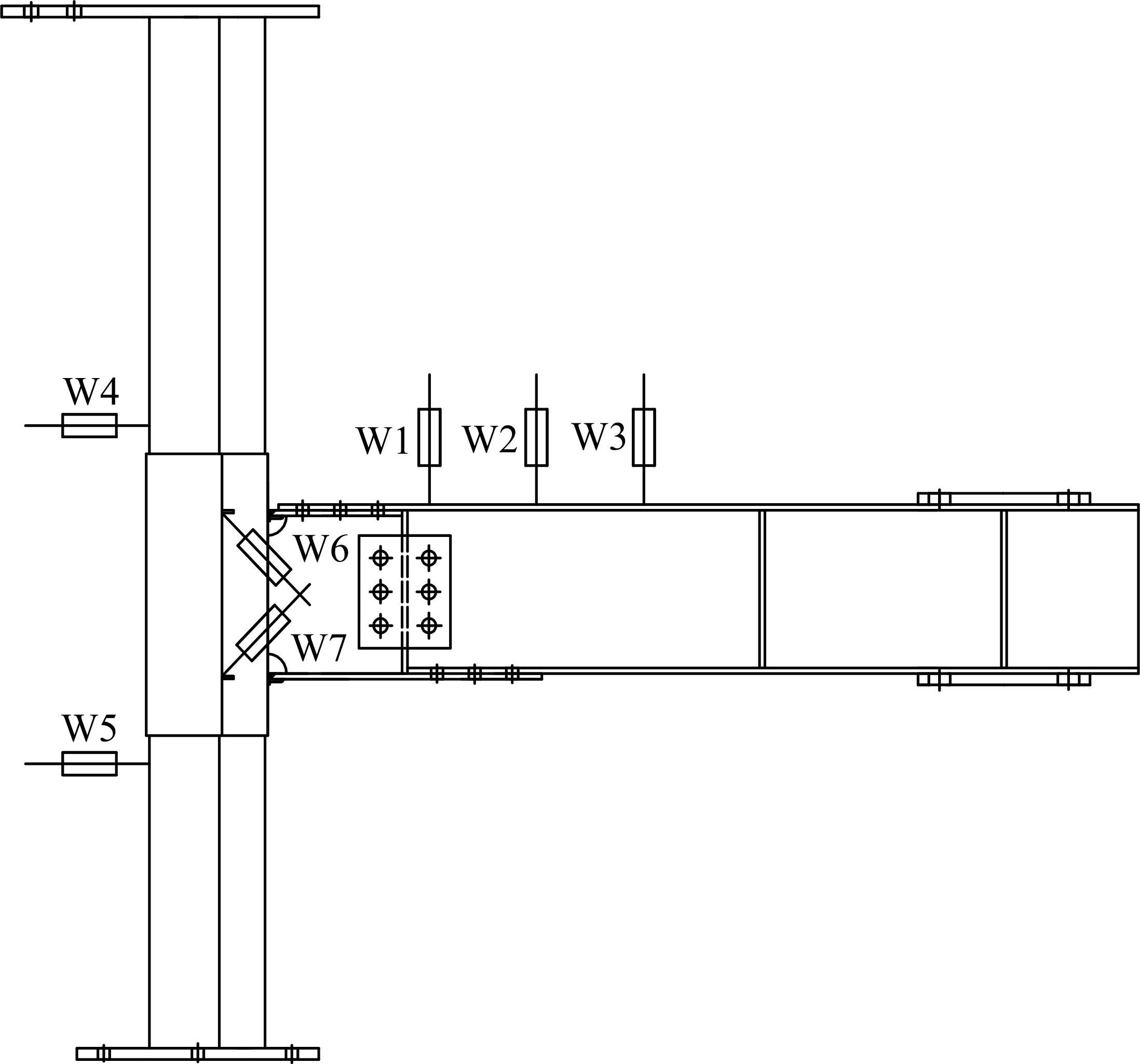

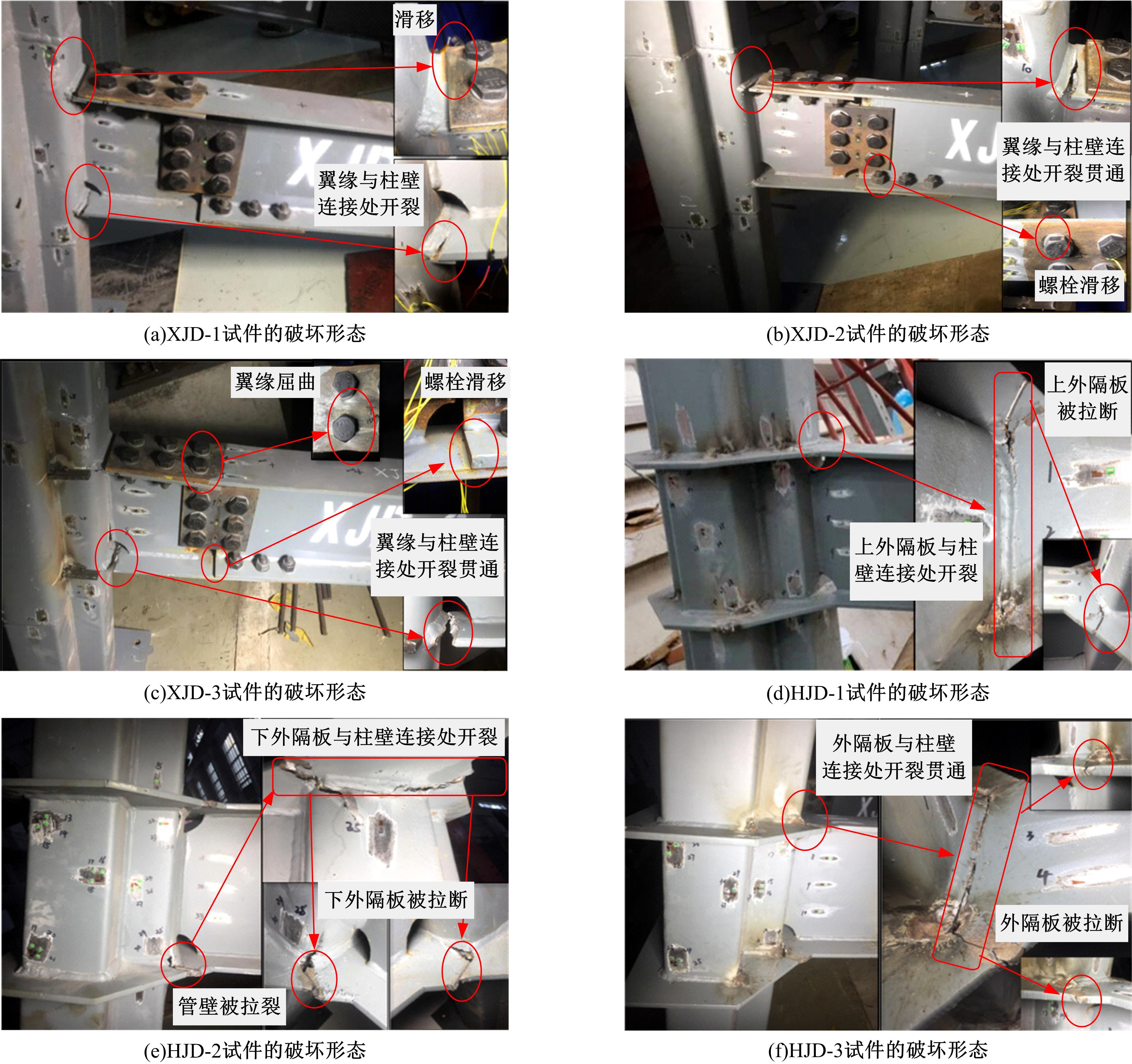

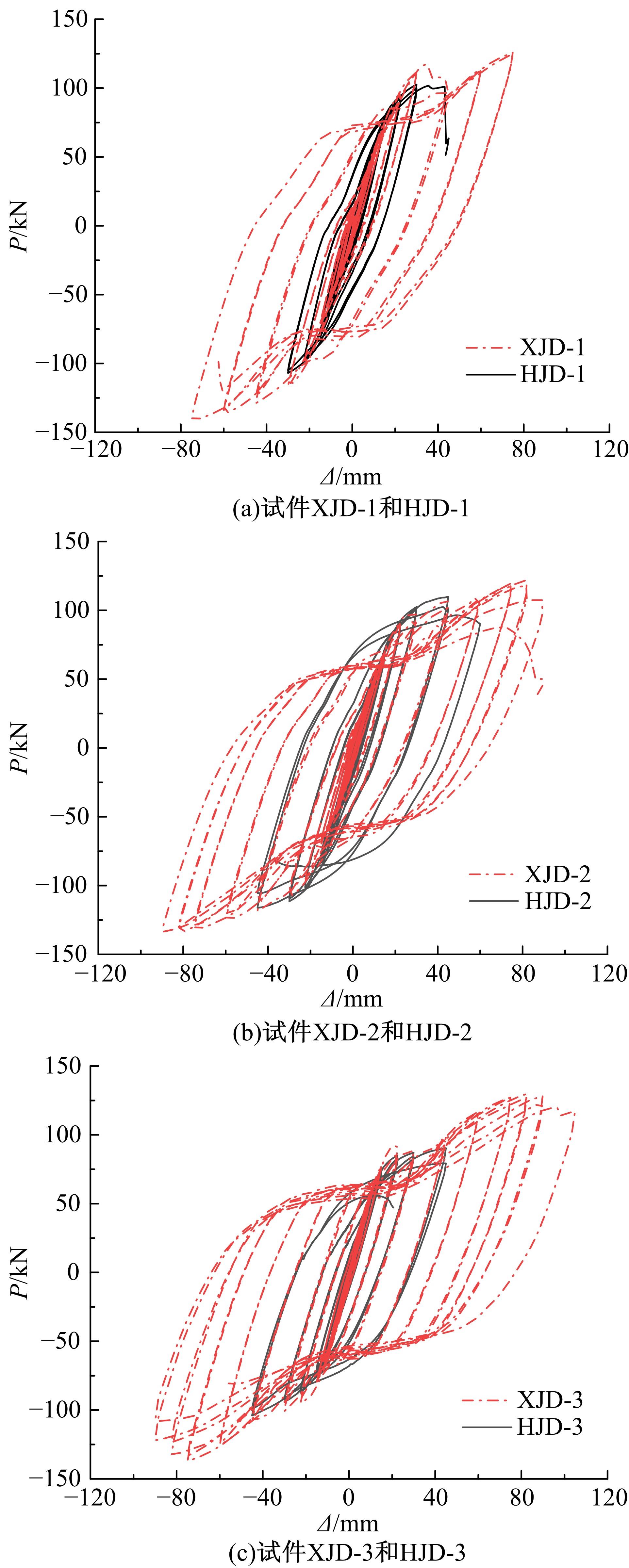

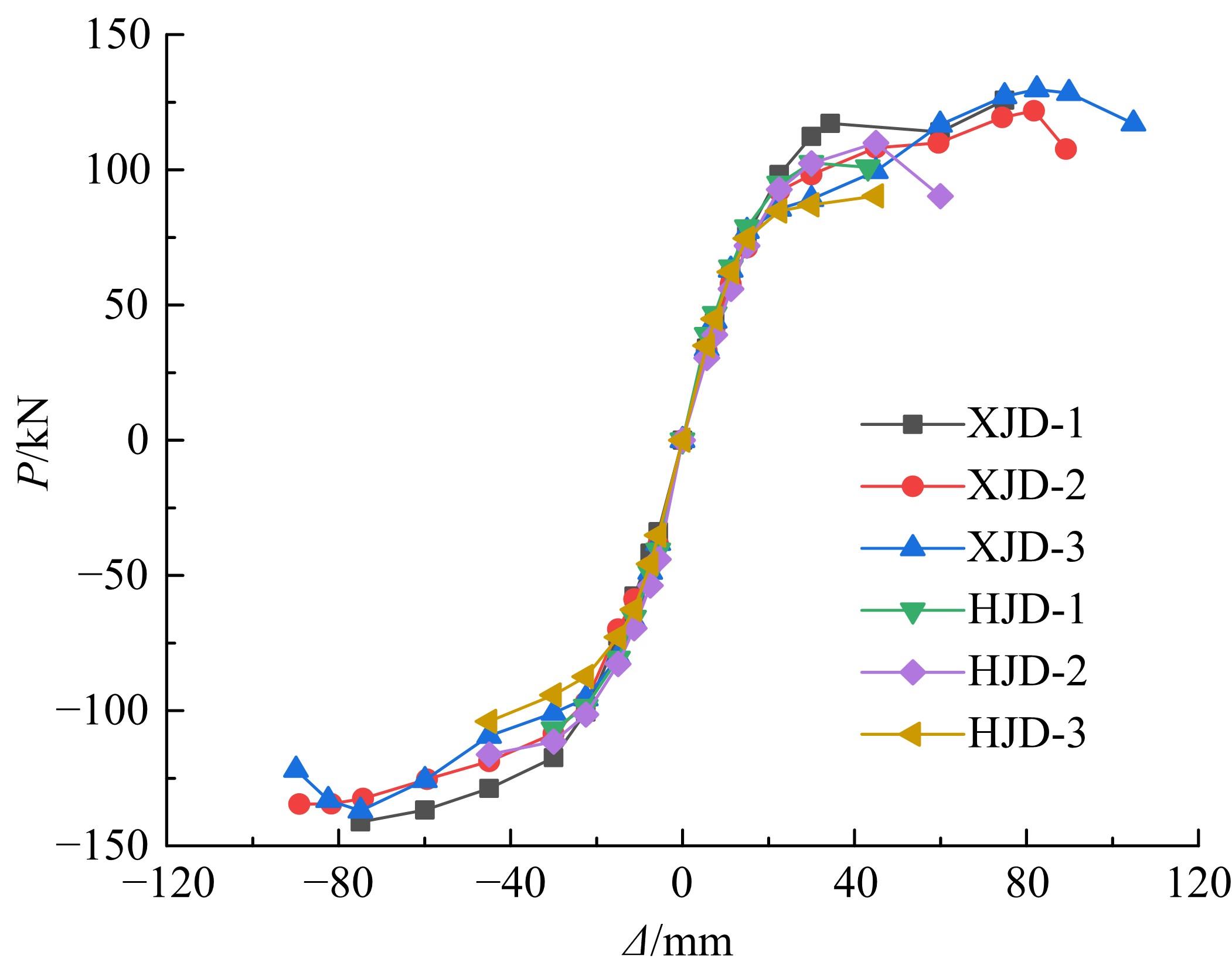

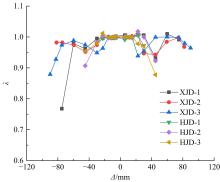

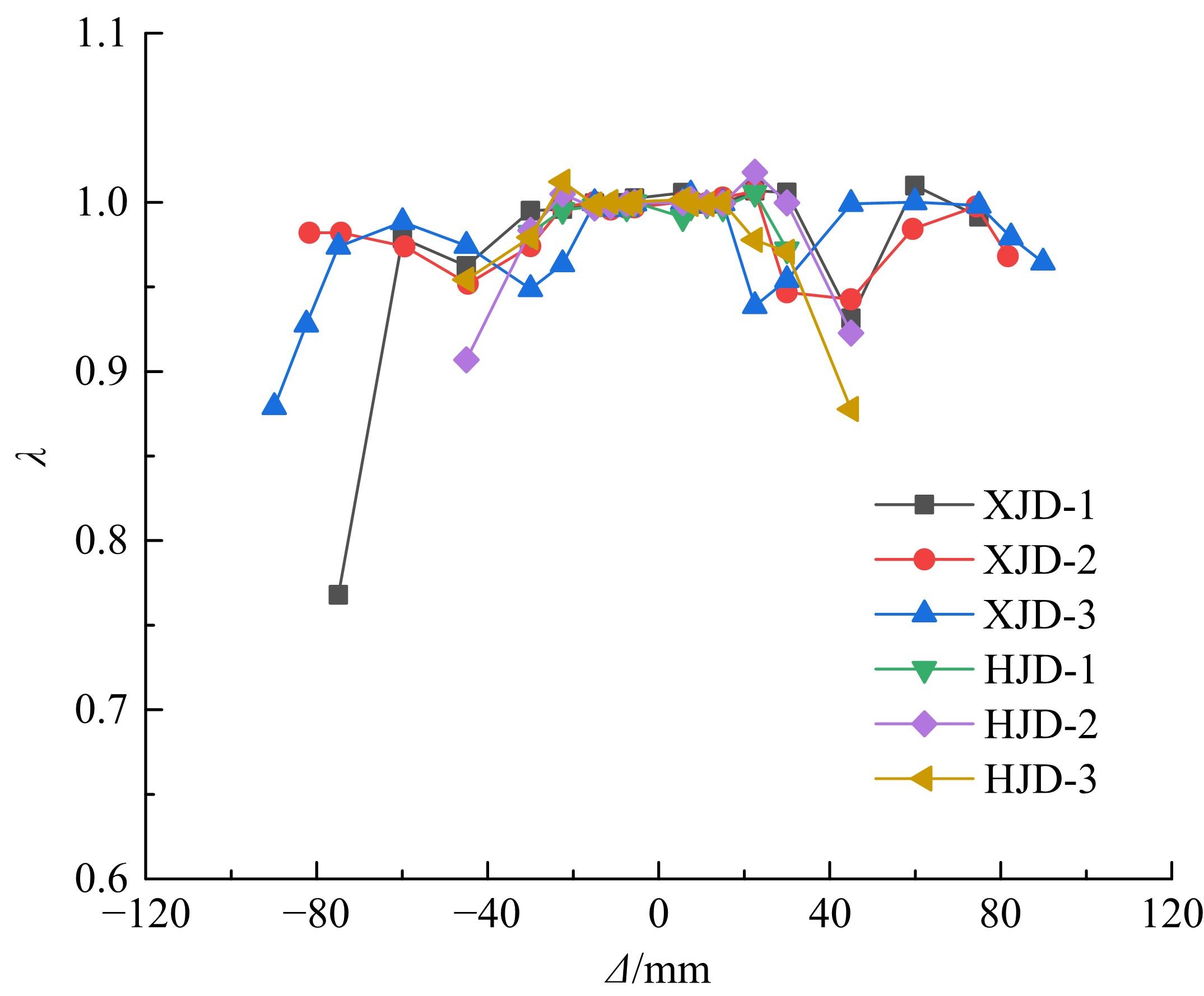

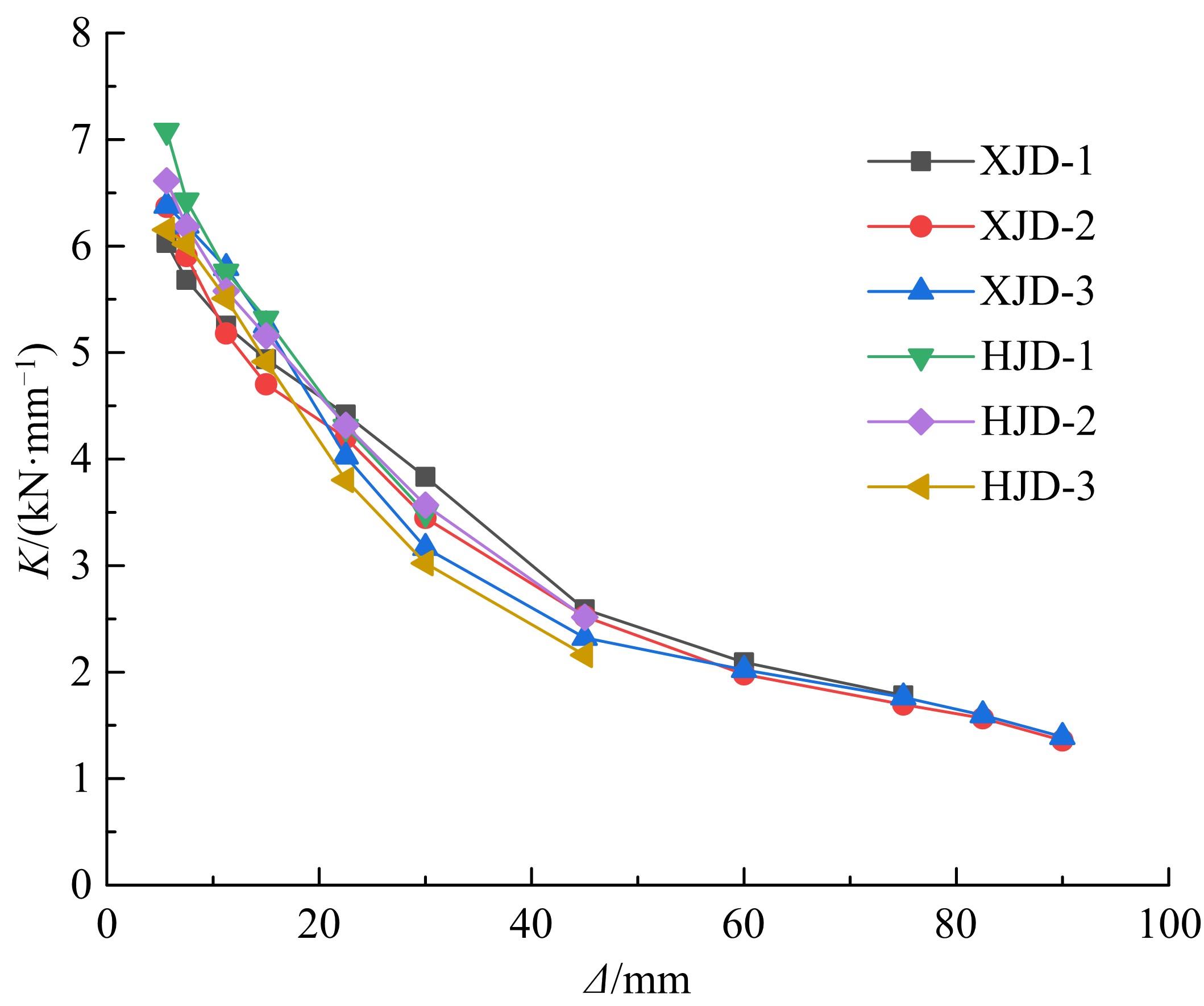

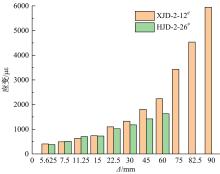

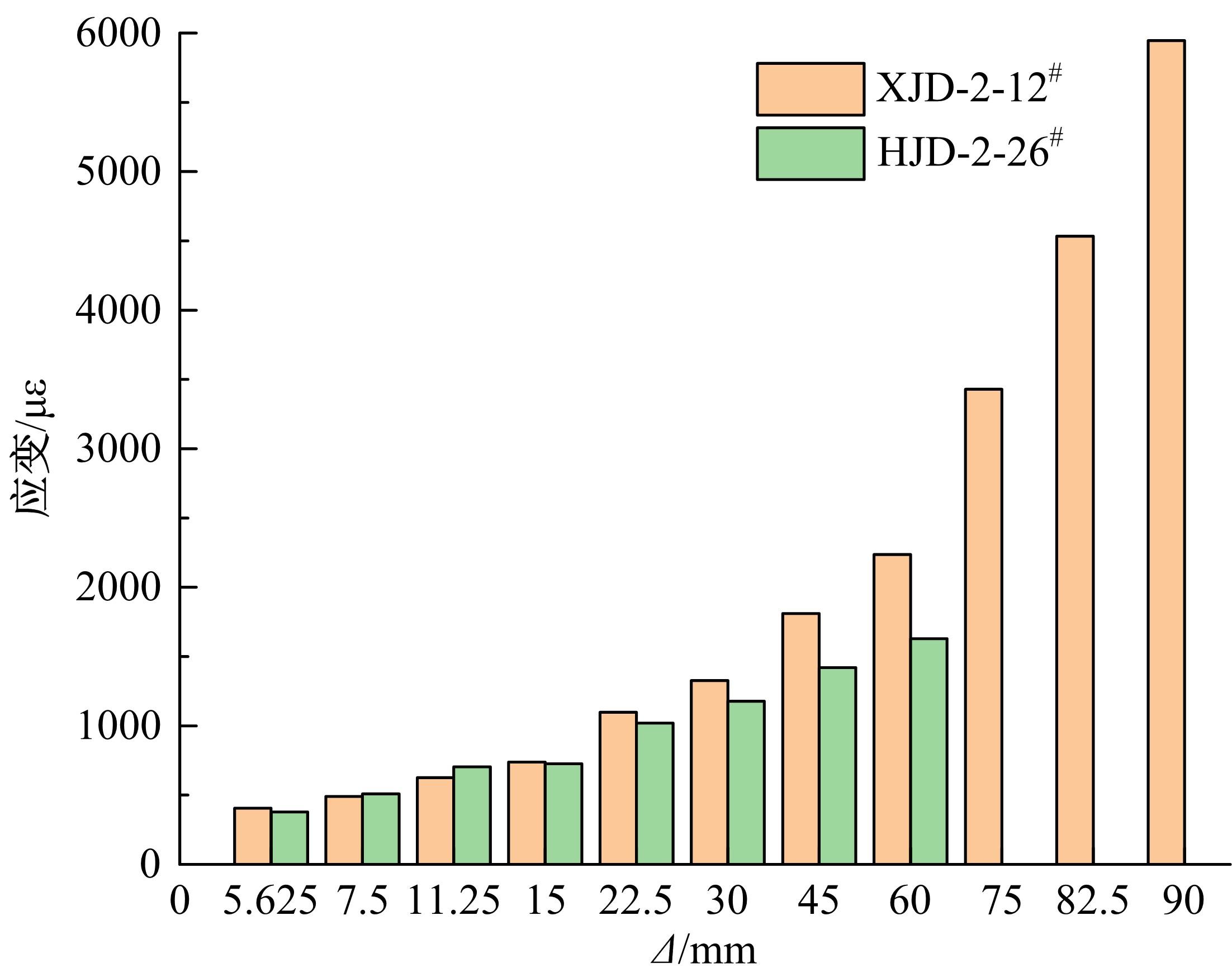

异形钢管混凝土柱-钢梁节点通常采用内隔板或外隔板,针对外隔板的存在会影响建筑的使用功能、内隔板加工不便且会影响混凝土的浇筑质量的不足,提出了节点区管壁局部加厚带Z字形悬臂梁段的新型节点。首先,取消外隔板,代之以节点区管壁局部加厚;然后,将钢梁与异形钢管混凝土柱通过Z字形悬臂梁段进行连接。按照“强柱弱梁”原则设计制作了6个缩尺比例为1∶2的异形钢管混凝土柱-钢梁节点试件,新型节点和外隔板式节点试件各3个,柱截面分别为L、T、十字形。对上述节点试件分别进行了低周往复荷载作用下的试验研究,得到了其破坏模式和滞回曲线、骨架曲线、强度退化曲线、刚度退化曲线、延性因数、总耗能以及等效黏滞阻尼系数等抗震性能指标。结果表明:与外隔板式节点相比,新型节点具有较高的承载力、较好的延性和耗能能力。新型节点的耗能包含材料屈服耗能和Z字形悬臂梁与钢梁拼接区板件间的滑移耗能两部分,滑移段的出现显著提高了节点的延性。

中图分类号:

- TU398.9

| 1 | 许成祥. 异形截面钢管混凝土结构研究现状与分析[J]. 长江大学学报: 自然科学版, 2010, 7(3): 126-130. |

| Xu Cheng-xiang. Research status and analysis of concrete-filled steel tube structures with special sections[J]. Journal of Yangtze University(Natural Science Edition), 2010, 7(3): 126-130. | |

| 2 | 徐礼华, 杜国锋, 温芳, 等. 组合T形截面钢管混凝土柱正截面受压承载力试验研究[J]. 土木工程学报, 2009, 42(6): 14-21. |

| Xu Li-hua, Du Guo-feng, Wen Fang, et al. Experimental study on normal section compression bearing capacity of composite T-shaped concrete-filled steel tubular columns[J]. China Civil Engineering Journal, 2009, 42(6): 14-21. | |

| 3 | 葛广全. T形钢管混凝土异形柱-钢梁框架节点性能研究[J]. 福建建材, 2011, 121(2): 11-13. |

| Ge Guang-quan. The performances research of T-shaped steel tubular reinforced concrete filled special-shaped column and steel beam frame shaped nodes[J]. Fujian Building Materials, 2011, 121(2): 11-13. | |

| 4 | 万波. 异形钢管混凝土柱-钢梁框架中柱节点受力性能试验研究[D]. 荆州: 长江大学城市建设学院, 2012. |

| Wan Bo. Experimental study on seismic behavior of interior joints in the composite frame consisting of CFST special-shaped section columns and steel beam[D]. Jingzhou: College of Urban Construction, Yangtze University, 2012. | |

| 5 | Du G F, Ma C, Xu C X. Experimental research on seismic behavior of exterior frame joints with T-shaped CFST column and steel beam[J]. Advanced Materials Research, 2011, 368-373: 183-188. |

| 6 | 许成祥, 万波, 张继承, 等. 十字形钢管混凝土柱框架中节点抗震性能试验研究[J]. 建筑结构, 2012, 42(3): 80-83. |

| Xu Cheng-xiang, Wan Bo, Zhang Ji-cheng, et al. Experimental research on seismic behavior of interior joints in the composite frame consisting of CFST crisscross section columns and steel beams[J]. Building Structure, 2012, 42(3): 80-83. | |

| 7 | 周鹏, 薛建阳, 陈茜, 等. 矩形钢管混凝土异形柱-钢梁框架节点抗震性能试验研究[J]. 建筑结构学报, 2012, 33(8): 41-50. |

| Zhou Peng, Xue Jian-yang, Chen Qian,et al. Experimental study on seismic performance of joints between concrete-filled square steel tubular special-shaped columns and steel beams[J]. Journal of Building Structures, 2012, 33(8): 41-50. | |

| 8 | 陈茜, 梁斌, 刘小敏. 新型异形钢管混凝土节点破坏机理[J]. 河南科技大学学报: 自然科学版, 2016, 37(1): 58-63. |

| Chen Qian, Liang Bin, Liu Xiao-min. Failure mechanism of new-type shaped concrete-filled steel tube joints[J]. Journal of Henan University of Science & Technology(Natural Science Edition), 2016, 37(1): 58-63. | |

| 9 | 林明森, 戴绍斌, 刘记雄, 等. T形钢管混凝土柱与钢梁外伸端板连接节点抗震性能试验研究[J]. 地震工程与工程振动, 2012, 32(2): 114-119. |

| Lin Ming-sen, Dai Shao-bin, Liu Ji-xiong, et al. Experimental study on seismic performance of end-plate connections of concrete-filled steel tube T-section column and steel beam[J]. Earthquake Engineering and Engineering Vibration, 2012, 32(2): 114-119. | |

| 10 | 刘记雄, 戴绍斌, 霍凯成, 等. 异形钢管混凝土组合柱-钢梁顶底角钢连接节点抗震性能研究[J]. 四川大学学报: 工程科学版, 2015, 47(1): 128-137. |

| Liu Ji-xiong, Dai Shao-bin, Huo Kai-cheng, et al. Study on earthquake resistance behavior of top and seat angle joint of special-shaped concrete-filled rectangular composite tubular column with steel beam[J]. Journal of Sichuan University(Engineering Science Edition), 2015, 47(1): 128-137. | |

| 11 | 王亚楠. 侧板连接T形钢管混凝土柱-钢梁节点受力性能研究[D]. 郑州: 中原工学院建筑工程学院, 2017. |

| Wang Ya-nan. Study on the mechanical behavior of T-shaped concrete filled steel tubular columns beam with steel side joints[D]. Zhengzhou: Architecture & Civil Engineering, Zhongyuan Institute of Technology, 2017. | |

| 12 | 王培又. 侧板连接带约束拉杆异形钢管混凝土柱-钢梁节点抗震性能有限元分析[D]. 郑州: 中原工学院建筑工程学院, 2019. |

| Wang Pei-you. Finite element analysis of seismic behavior of special-shaped concrete filled steel tubular column-steel beam joints with side plate connections[D]. Zhengzhou: Architecture & Civil Engineering, Zhongyuan Institute of Technology, 2019. | |

| 13 | 吴一然, 石永久, 孟令野. T形钢管混凝土异形柱和工形钢梁节点承载力性能试验[J]. 沈阳建筑大学学报: 自然科学版, 2019, 35(5): 769-778. |

| Wu Yi-ran, Shi Yong-jiu, Meng Ling-ye. Experimental studies of joints strength performance with T-shape concrete filled steel tubular columns and I-shape steel beams[J]. Journal of Shenyang Jianzhu University(Natural Science), 2019, 35(5): 769-778. | |

| 14 | 张爱林, 郭志鹏, 刘学春, 等. 带Z字形悬臂梁段拼接的装配式钢框架节点抗震性能试验研究[J]. 工程力学, 2017, 34(8): 31-41. |

| Zhang Ai-lin, Guo Zhi-peng, Liu Xue-chun, et al. Experimental study on aseismic behavior of prefabricated steel frame joints with Z-shaped cantilever beams splicing[J]. Engineering Mechanics, 2017, 34(8): 31-41. | |

| 15 | . 钢管混凝土结构技术规范[S]. |

| 16 | AI. Seismic provisions for structural steel buildings[S]. |

| 17 | . 金属材料拉伸试验 第1部分: 室温试验方法[S]. |

| 18 | .建筑抗震试验规程[S]. |

| 19 | 施刚, 袁锋, 霍达, 等. 钢框架梁柱节点转角理论模型和测量计算方法[J]. 工程力学, 2012, 29(2): 52-59. |

| Shi Gang, Yuan Feng, Huo Da, et al. The theoretical model and measuring calculation method of the beam-to-column joint rotation in steel frames[J]. Engineering Mechanics, 2012, 29(2): 52-59. |

| [1] | 张广泰,张路杨,邢国华,曹银龙,易宝. 钢-聚丙烯混杂纤维混凝土剪力墙抗震性能[J]. 吉林大学学报(工学版), 2021, 51(3): 946-955. |

| [2] | 苏迎社, 杨媛媛. 高温对建筑混凝土材料抗震抗压的作用及原理[J]. 吉林大学学报(工学版), 2015, 45(5): 1436-1442. |

| [3] | 高欣, 吴晓伟, 田俊. 轻骨料混凝土剪力墙非线性有限元模型的构成及影响其抗震性能的因素[J]. 吉林大学学报(工学版), 2015, 45(5): 1428-1435. |

| [4] | 李黎明,陈以一,李宁,蔡玉春. 外套管式冷弯方钢管与H型钢梁连接节点的抗震性能[J]. 吉林大学学报(工学版), 2010, 40(01): 67-0071. |

| [5] | 孙绪杰,潘景龙,郑文忠 . 玻璃纤维增强聚合物混凝土小型空心 砌块复合墙片的抗震性能[J]. 吉林大学学报(工学版), 2008, 38(05): 1054-1059. |

| [6] | 李黎明,,李宁3,陈志华4,姜忻良4 . 方钢管混凝土柱的抗震性能试验研究[J]. 吉林大学学报(工学版), 2008, 38(04): 817-822. |

|

||