吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (1): 79-90.doi: 10.13229/j.cnki.jdxbgxb20200792

SUS301L不锈钢激光焊缝缺陷修复工艺

- 1.吉林大学 材料科学与工程学院,长春 130022

2.中车长春轨道客车股份有限公司,长春 130021

3.常州轩豪机械有限公司,常州 213000

Defects repair technology of SUS301L stainless steel laser weld

Wen-quan WANG1( ),Yan-xin WANG1,Hong-xiao WANG2,Xin LI1(

),Yan-xin WANG1,Hong-xiao WANG2,Xin LI1( ),Peng WU3

),Peng WU3

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.CRRC Changchun Railway Vehicles Co. ,Ltd. ,Changchun 130021,China

3.Changzhou Xuan?hao Machinery Co. ,Ltd. ,Changzhou 213000,China

摘要:

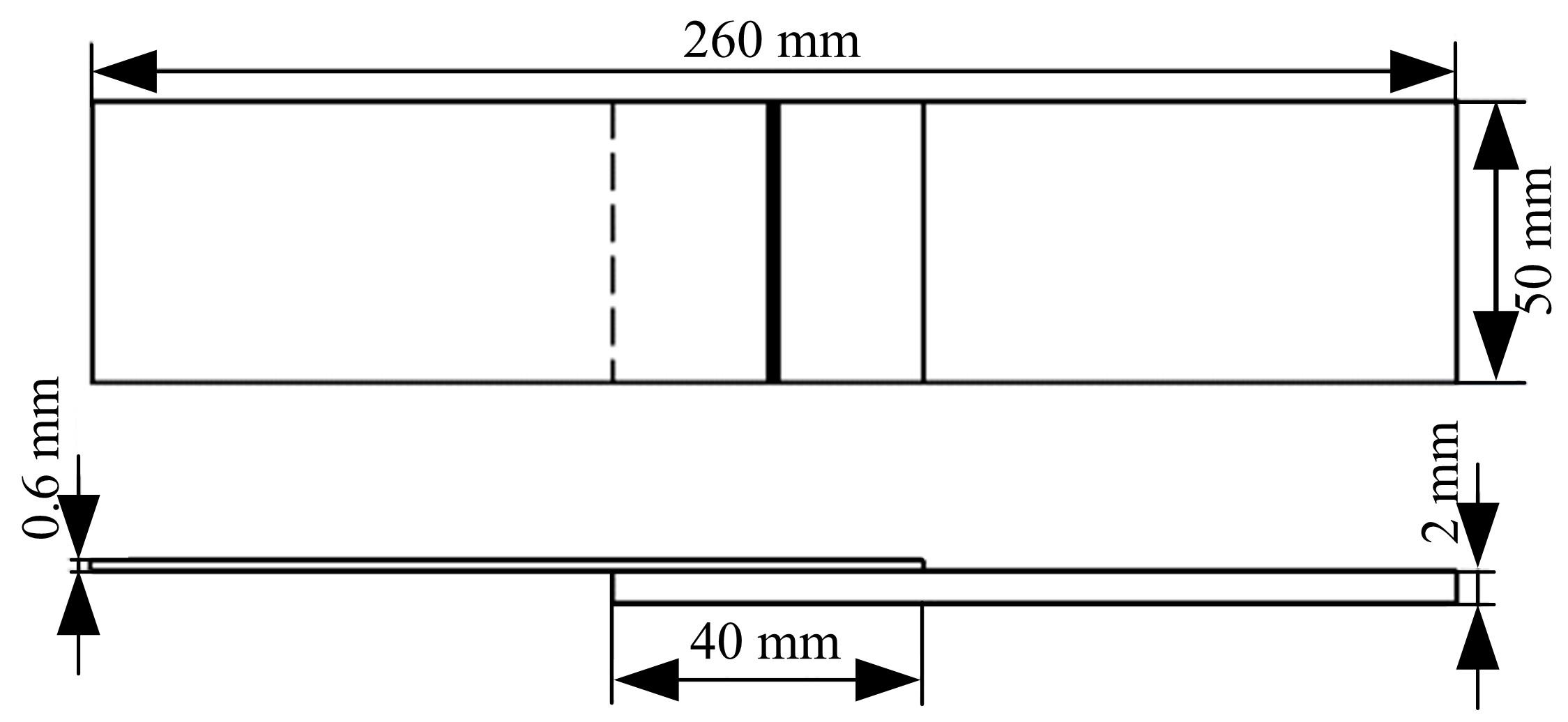

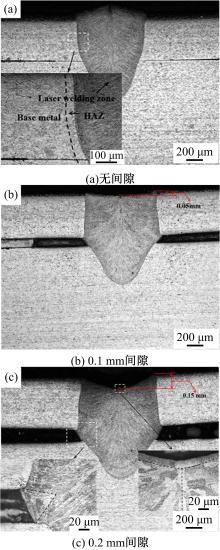

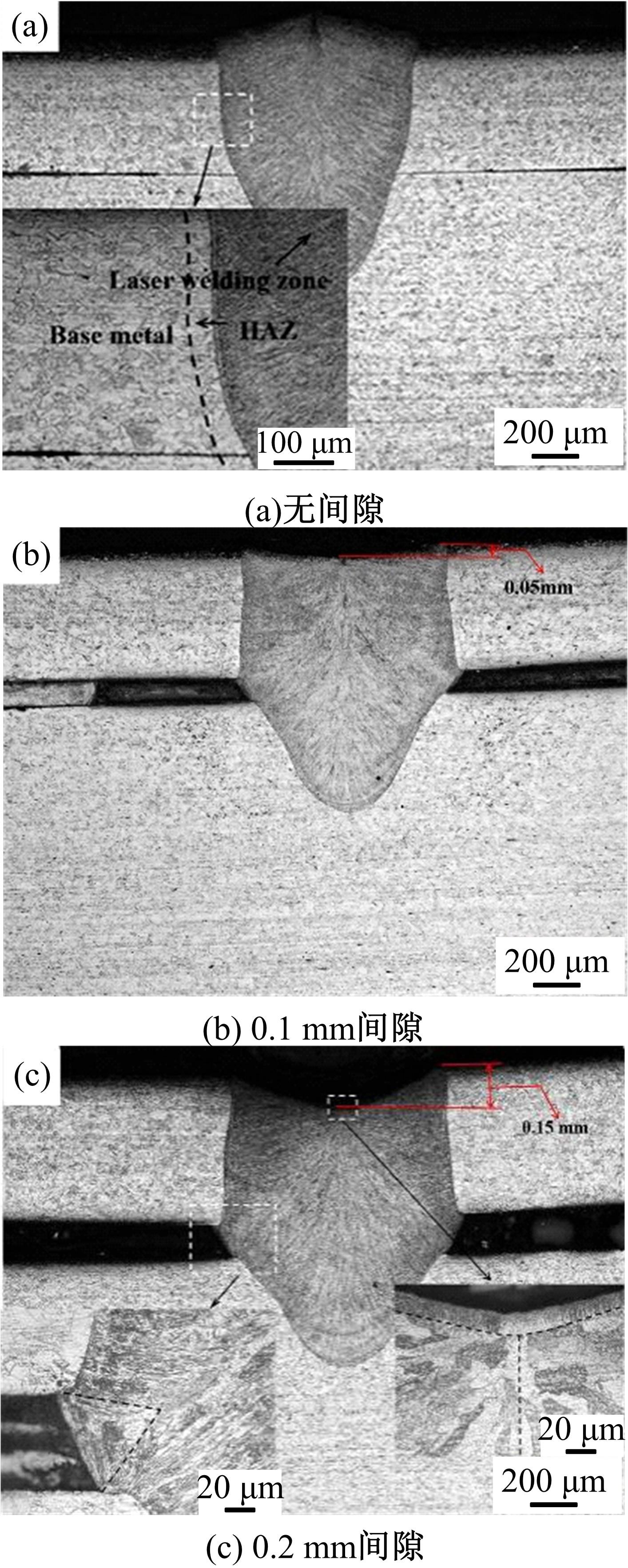

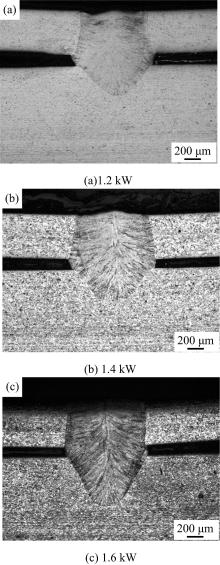

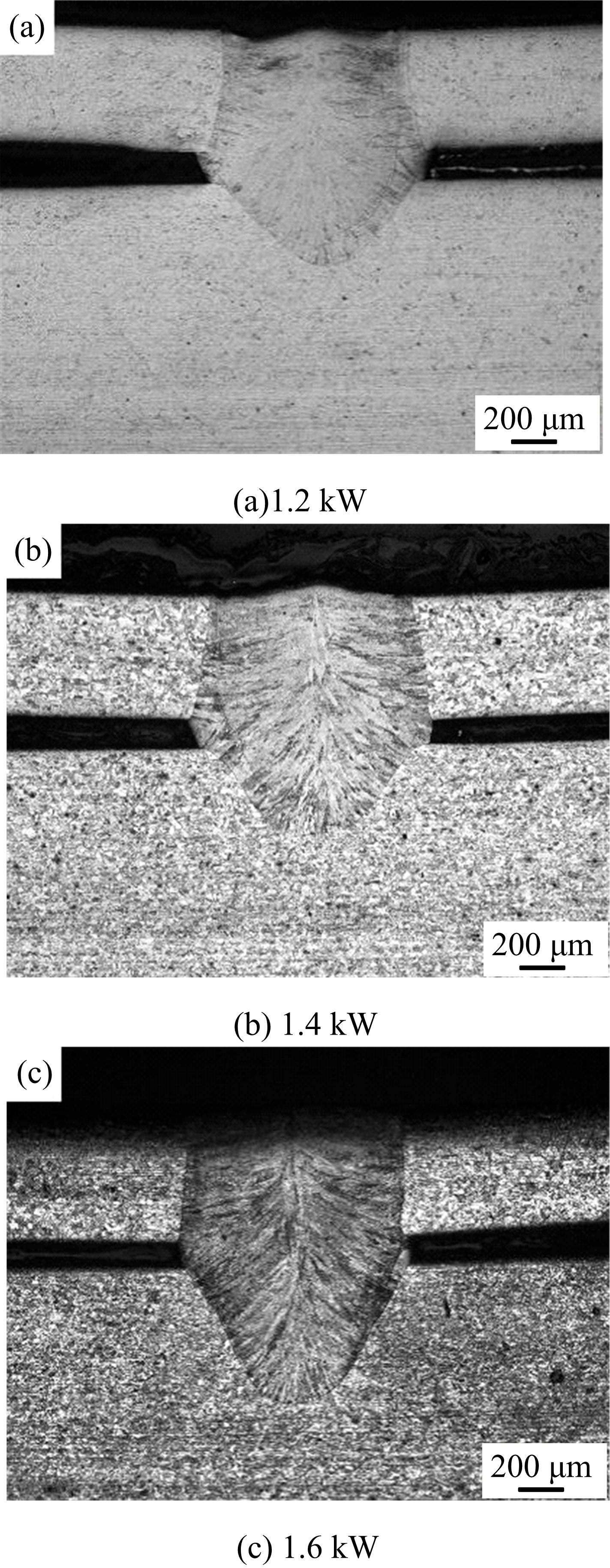

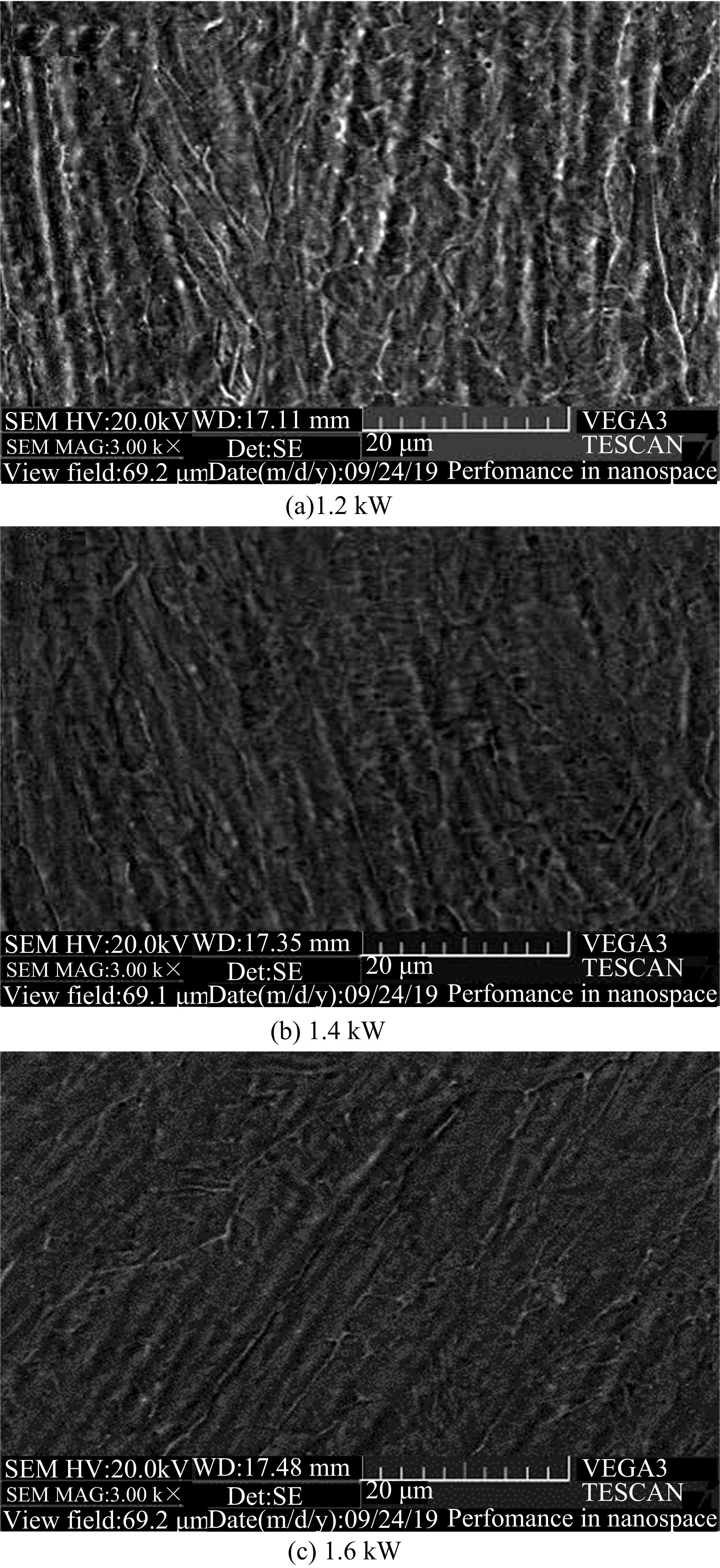

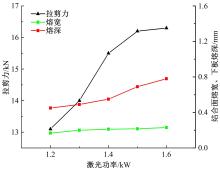

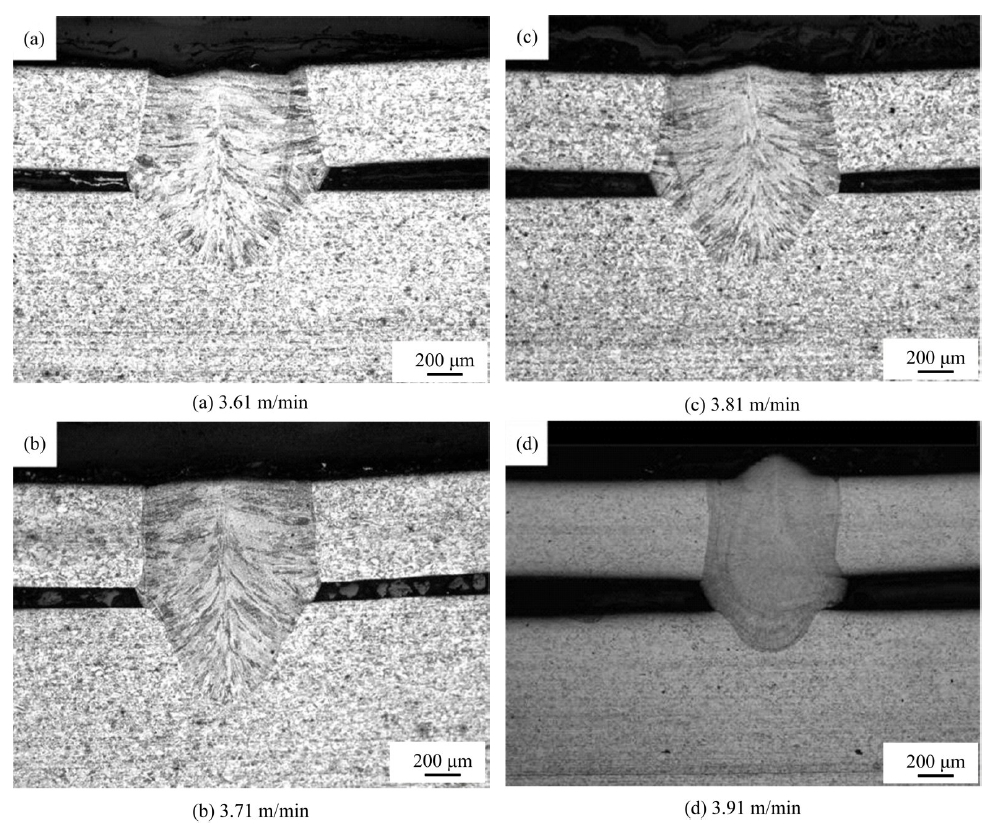

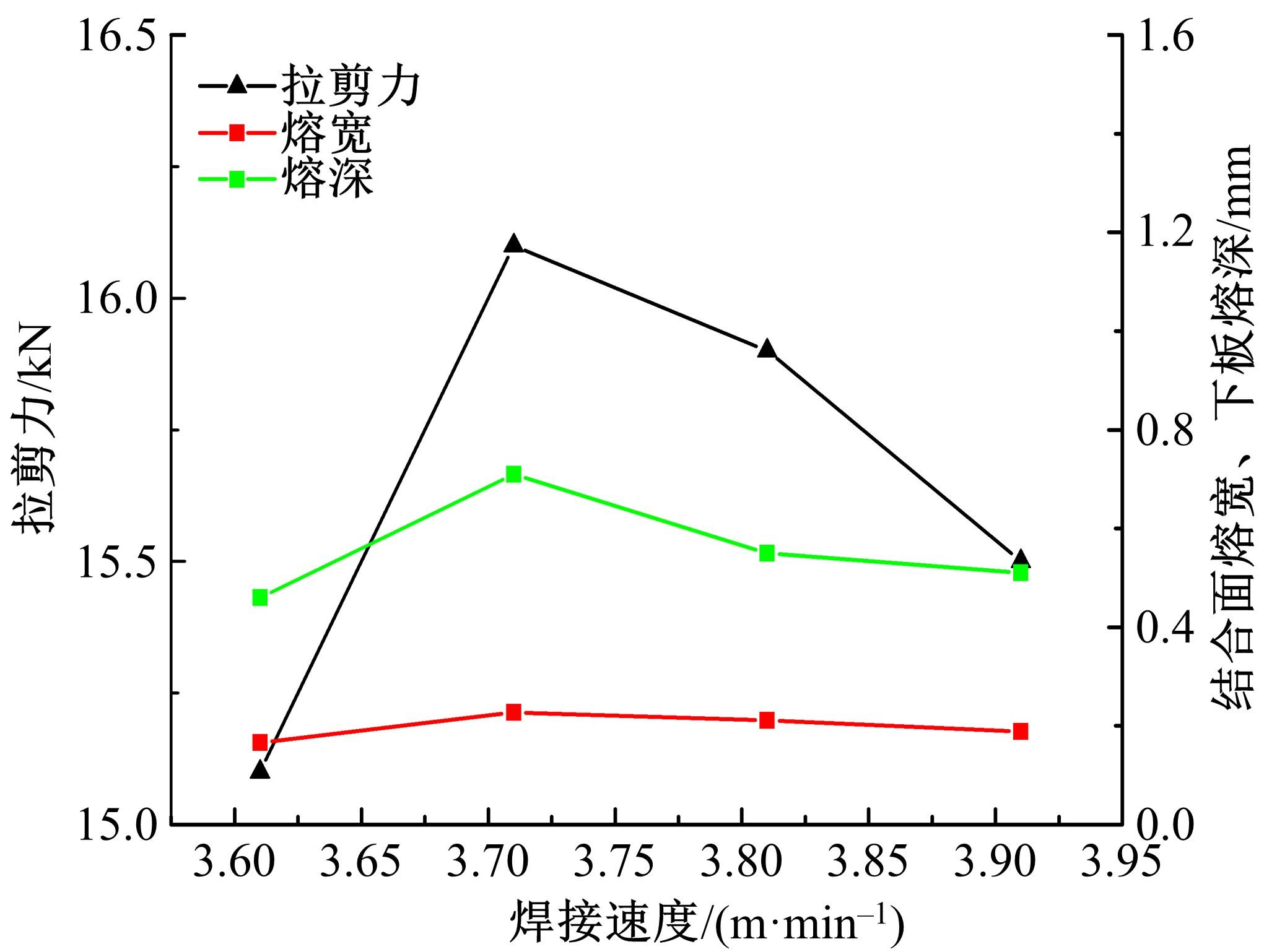

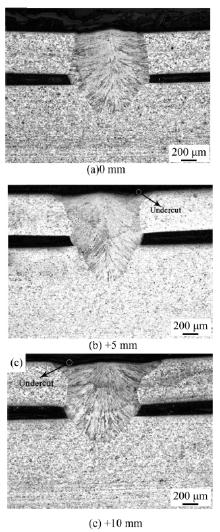

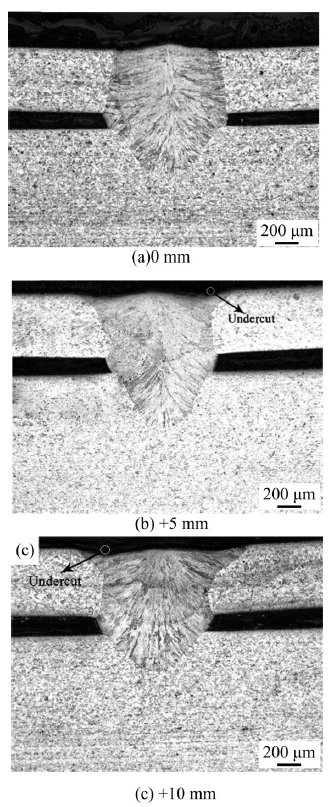

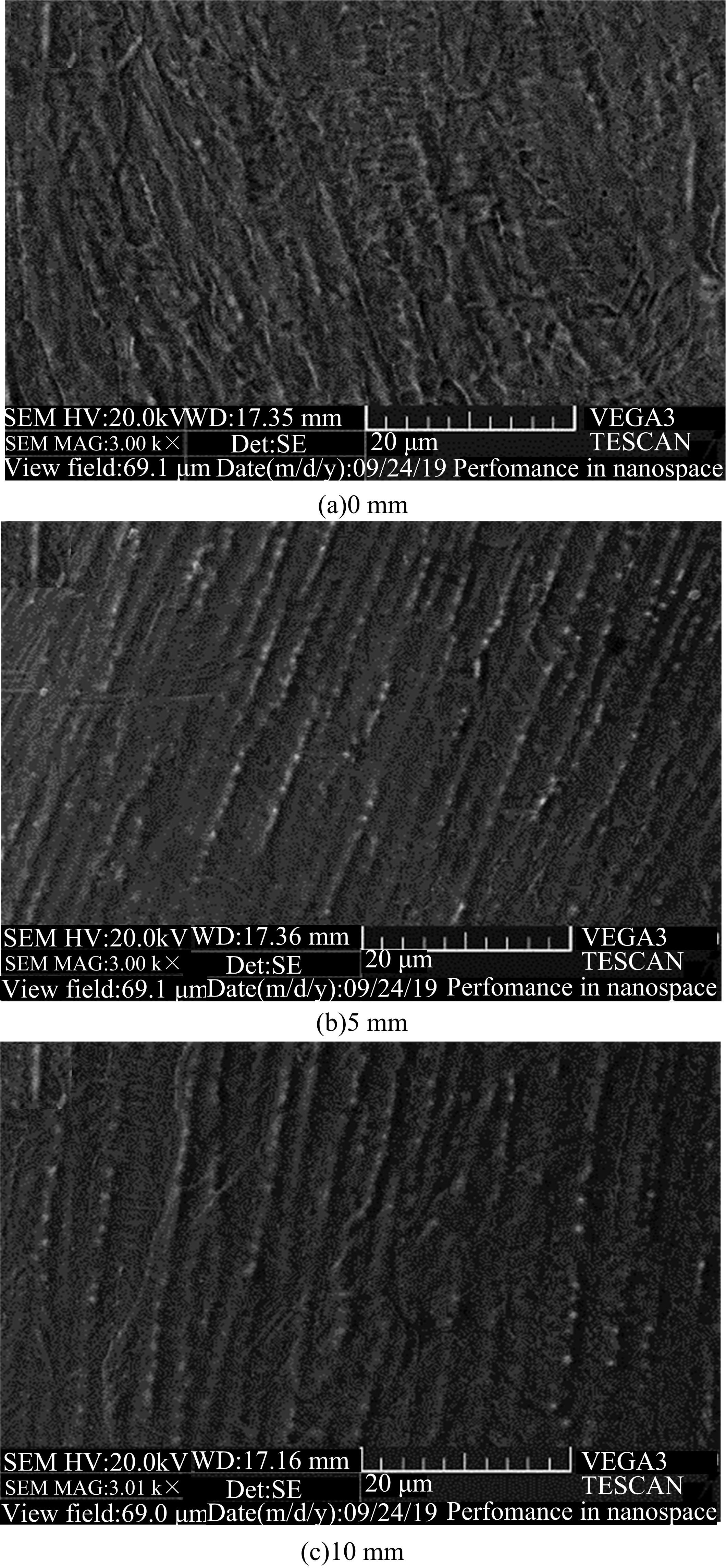

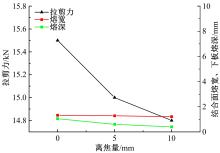

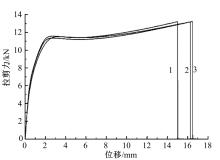

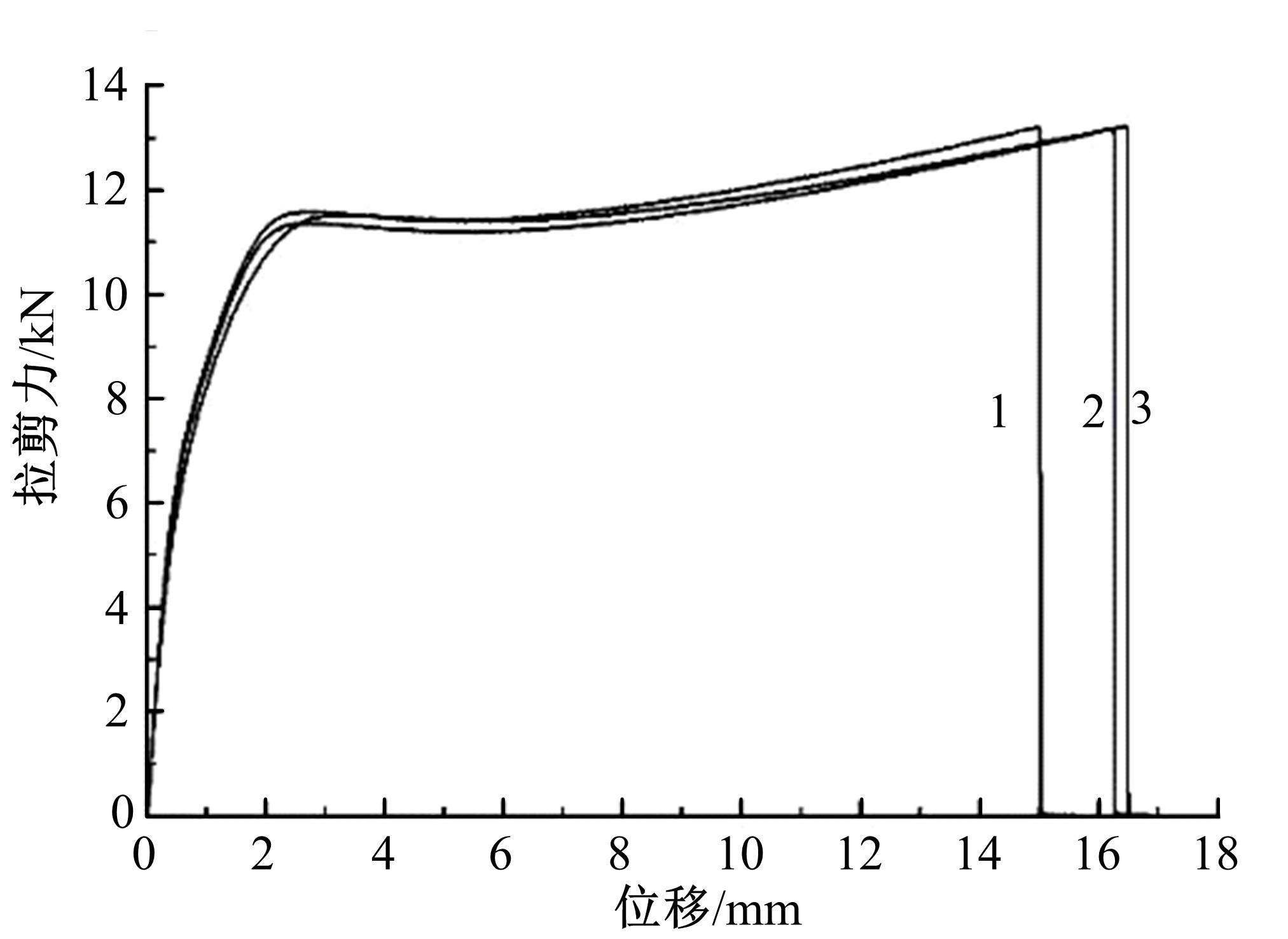

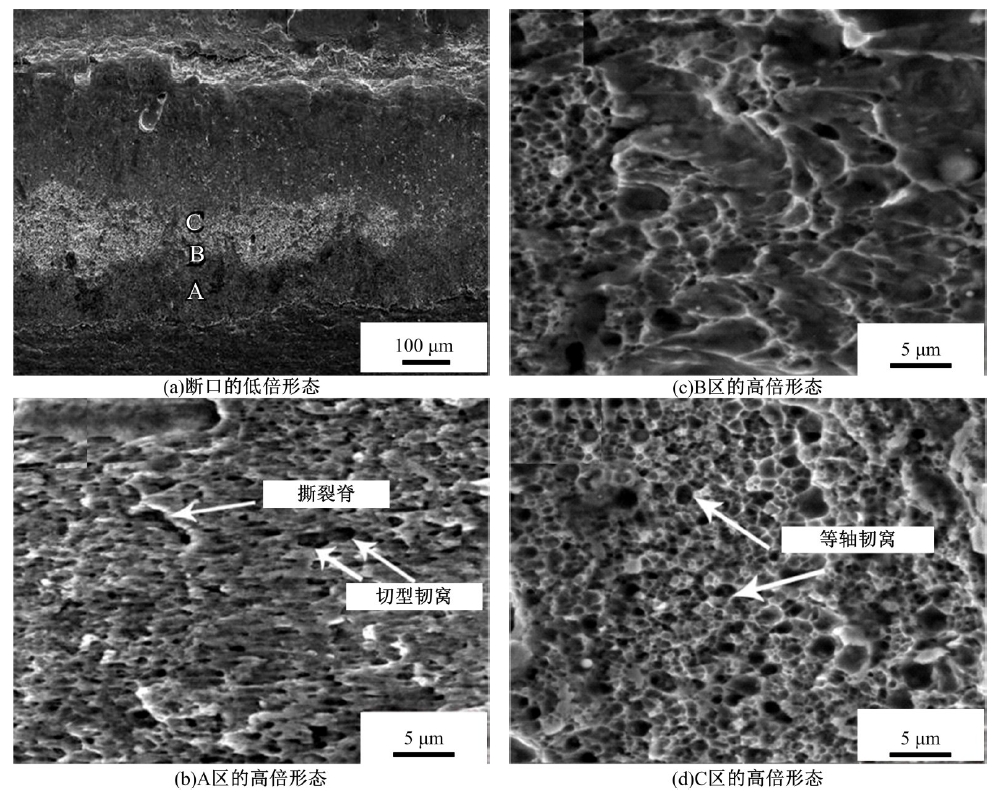

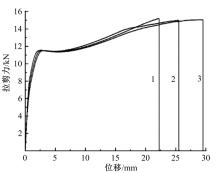

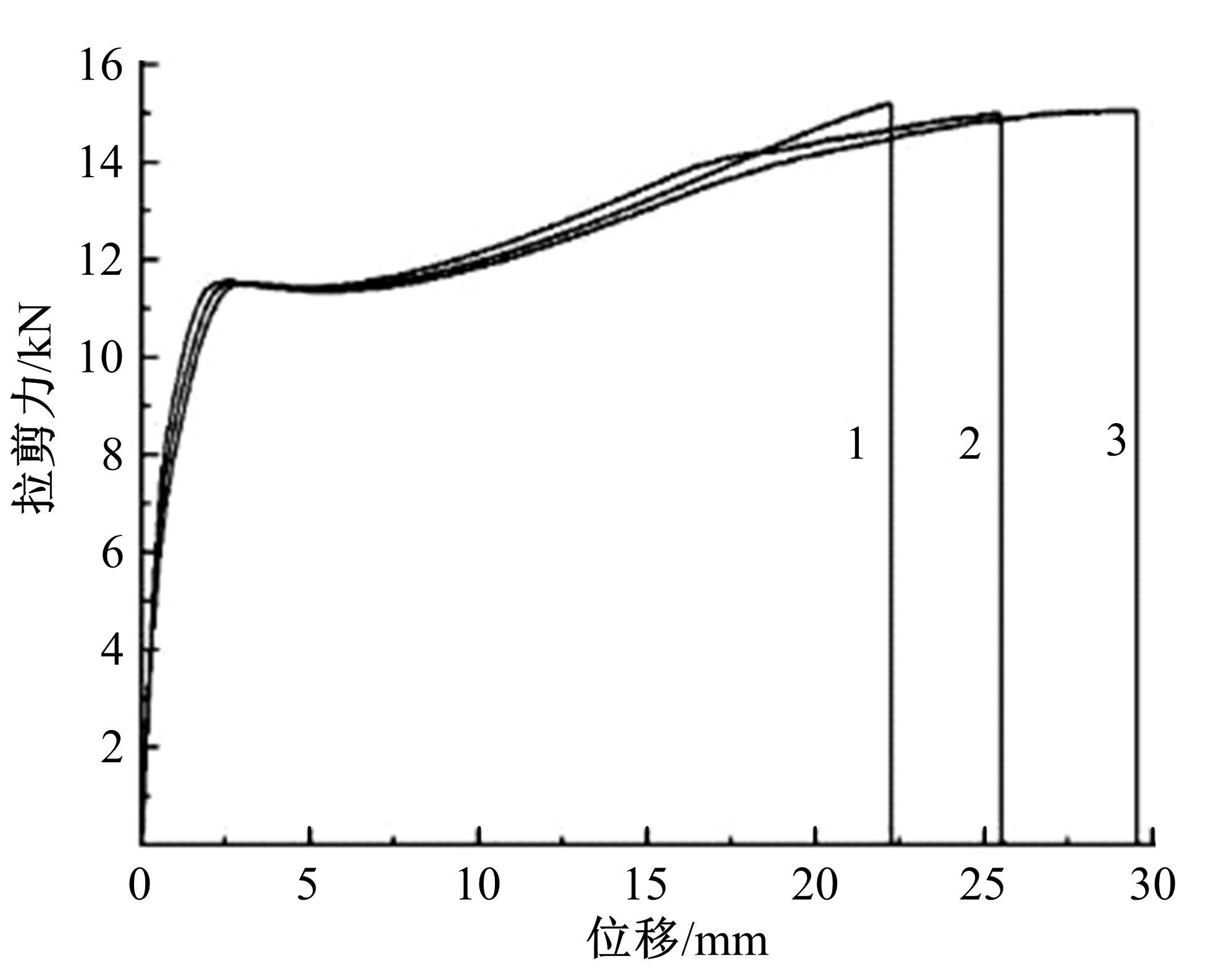

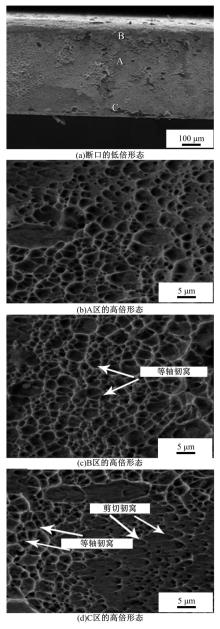

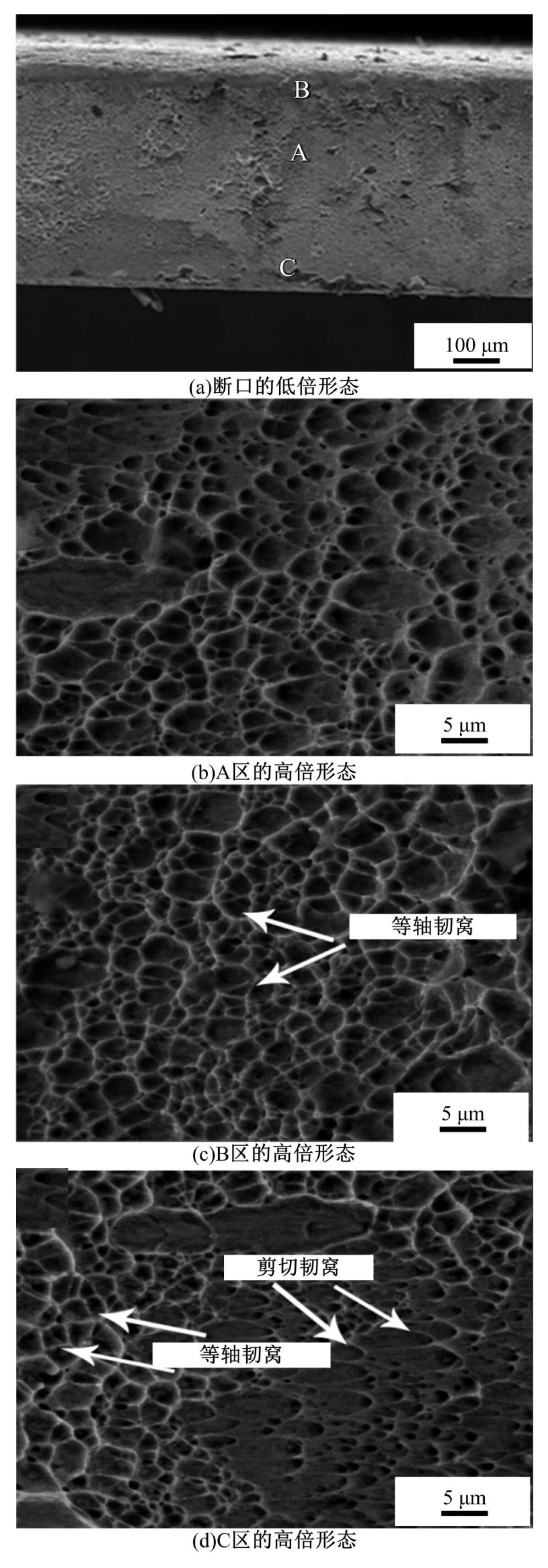

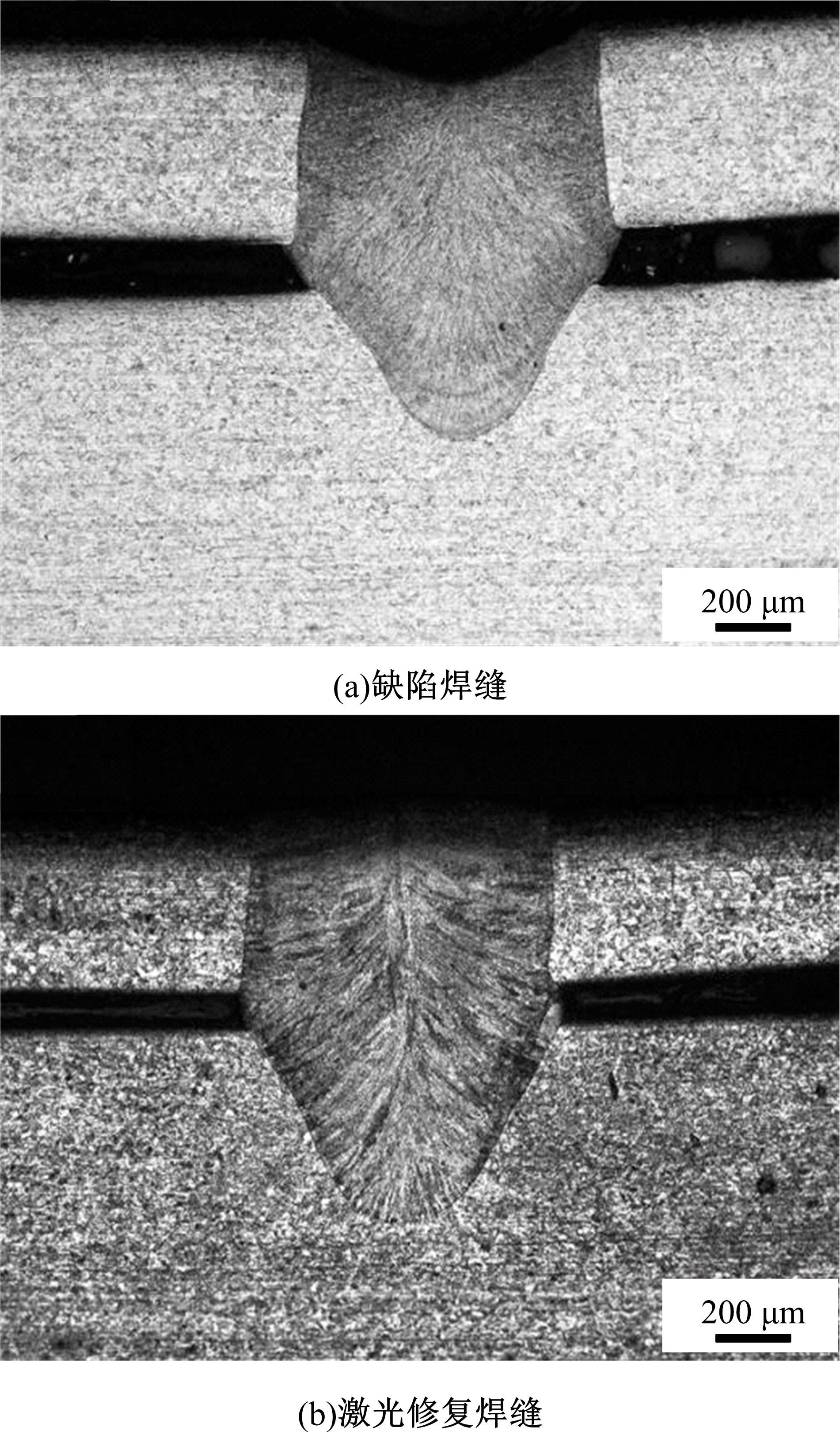

在不锈钢车体侧墙的生产过程中,钢板在装配过程中不可避免会存在间隙。间隙的存在会使得焊缝表面出现下凹、未焊透等缺陷,对焊缝的表面质量和静强度产生不利影响。针对上述问题,采用激光焊对缺陷焊缝进行重熔修复,研究了激光功率、焊接速度、离焦量对修复焊缝表面质量、微观组织及力学性能的影响规律,并采用正交优化试验设计方法进一步优化激光修复工艺参数,得到优化的激光修复工艺最佳参数如下:激光功率为1.6 kW、焊接速度为3.81 m/min,离焦量为0 mm。修复焊缝最大拉剪力为16.3 kN,大于无缺陷焊缝的拉剪力,而且激光修复焊缝晶粒未粗化。研究表明,激光修复技术能够有效修复焊缝表面塌陷,修复焊缝的拉剪力满足实际生产技术要求,该工艺可以应用于实际生产。

中图分类号:

- TG456.7

| 1 | 张兰. 我国不锈钢焊接工艺研究现状及进展[J].山西冶金,2007,30(2): 1-5. |

| Zhang Lan. Present research status and development of welding technology for stainless steel in China[J]. Shanxi Metallurgy,2007,30(2): 1-5. | |

| 2 | Wu Qiang,Gong Jin-ke,Chen Gen-yu,et al. Research on laser welding of vehicle body[J]. Optics & Laser Technology,2008,40(2): 420-426. |

| 3 | 陈树娟,李希勇,郭会生,等. 不锈钢车体制造技术[J]. 信息化建设,2016(2): 239. |

| Chen Shu-juan,Li Xi-yong,Guo Hui-sheng,et al. Manufacturing technology of stainless steel metro vehicle[J]. Informatization Construction,2016(2): 239. | |

| 4 | 张乐乐,李培,刘晨. 焊接缺陷对转向架强度的影响[J]. 中国铁道科学, 2010, 31(2): 67-72. |

| Zhang Le-le, Li Pei, Liu Chen,et al. Influence of the weld defect on the structure strength of the bogie frame[J]. China Railway Science,2010,31(2): 67-72. | |

| 5 | Nimaeh Nitipon,Muangjunburee Prapas. Improvement of welding repair aluminum alloy 6082 T6 by MIG welding process[J]. Materials Science Forum,2016,872: 8-12. |

| 6 | 仲超,刘奋成,程洪茂,等. GH4169镍基高温合金TIG焊接修复组织和性能研究[J]. 热加工工艺,2019,48(3): 28-34. |

| Zhong Chao,Liu Fen-cheng,Cheng Hong-mao,et al. Study on microstructure and mechanical properties of GH4169 nickel based superalloy TIG welding repair zone[J]. Hot Working Technology,2019,48(3): 28-34. | |

| 7 | 徐子法,焦俊科,张正,等. 镍基高温合金激光修复工艺研究[J]. 材料导报,2019,33(19): 3196-3202. |

| Xu Zi-fa,Jiao Jun-ke,Zhang Zheng,et al. Research on laser repair process of ni-based superalloy[J]. Materials Review,2019,33(19) :3196-3202. | |

| 8 | Lu Ching-wen,Wang Huei-sen,Chen Hou-guang,et al. Effects of heat treatment and Nd: YAG laser repair welding parameters on the microstructure and properties of a Cu–Ni–Si–Cr mold alloy[J]. Materials Science and Engineering: A,2021,799: No.140342. |

| 9 | Turichin G,Ⅰ Tsibulskiy,Kuznetsov M,et al. Influence of the gap width on the geometry of the welded joint in hybrid laser-arc welding[J]. Physics Procedia,2015,78: 14-23. |

| 10 | 李磊,王洪潇,史春元. 焊接气氛对奥氏体不锈钢激光焊接接头组织与性能的影响[C]∥中国机械工程学会第八届中国北方焊接学术会议,石家庄,2012: 171-174. |

| 11 | Wang Hong-xiao,Wang Chun-sheng,He Guang-zhong,et al. Application of lap laser welding technology on stainless steel railway[C]∥Advanced Laser Manufacturing Technology,Beijing,China,2011: 2578-2582. |

| 12 | Gao Zhi-guo,Wu Yi-xiong,Huang Jian. Analysis of weld pool dynamic during stationary laser-MIG hybrid welding[J]. International Journal of Advanced Manufacturing Technology, 2009,44(9): 870-879. |

| 13 | Sudnik W,Radaj D,Breitschwerdt S,et al. Numerical simulation of weld pool geometry in laser beam welding[J]. Journal of Physics D: Applied Physics,2000,33(6): 662-671. |

| 14 | 刘成财. 铝合金EBW熔池行为及焊缝成形规律的数值模拟研究[D]. 哈尔滨:哈尔滨工业大学材料科学与工程学院,2017. |

| Liu Cheng-cai. Numerical study on the welding pool behavior and weld formation regularity during electron beam welding of aluminum alloy[D]. Harbin:School of Materials Science and Engineering,Harbin Institute of Technology,2017. | |

| 15 | .电子束及激光焊接接头、欠缺质量分级指南[S]. |

| 16 | 孟威. 高强钢T型搭接接头激光焊接动态过程与成形特征研究[D]. 上海: 上海交通大学材料科学与工程学院,2014. |

| Meng Wei. Studies on the dynamic process and shape characteristic during laser lap welding T-joints for high strength steel[D]. Shanghai: School of Materials Science and Engineering,Shanghai Jiaotong University,2014. | |

| 17 | 温鹏,邬瑞峰,王秀义,等. 不锈钢车体搭接接头激光非熔透焊接工艺及其拉剪性能[J]. 中国机械工程,2017,28(11): 1355-1361. |

| Wen Peng,Wu Rui-feng,Wang Xiu-yi,et al. Laser welding parameters and tensile properties of partial penetration lap joint for stainless train body[J]. China Mechanical Engineering,2017,28(11): 1355-1361. | |

| 18 | 唐舵,王春明,田曼,等. SUS301L-HT不锈钢激光焊接与MIG焊接对比试验研究[J]. 中国激光,2015,42(7): 98-105. |

| Tang Duo,Wang Chun-ming,Tian Man,et al. Contrasting study on quality of SUS301L-HT joints in fiber laser welding and MIG welding[J]. Chinese Journal of Lasers,2015,42(7): 98-105. |

| [1] | 郎利辉, 王耀, 李奎, 孙志莹, 张泉达. 板材充液成形过程反胀效应影响因素[J]. 吉林大学学报(工学版), 2016, 46(5): 1567-1576. |

| [2] | 闻德生, 刘巧燕, 刘忠迅, 高俊峰, 周瑞彬, 吕建森. 滚柱叶片式双定子多速马达的原理与实验验证[J]. 吉林大学学报(工学版), 2015, 45(4): 1130-1138. |

| [3] | 贾洪飞,谭云龙,李强,杨东. 考虑驾驶员特征的快速路合流区间隙接受模型构建[J]. 吉林大学学报(工学版), 2015, 45(1): 55-61. |

| [4] | 朱晓林1, 2, 于鸣3, 高青1, 2, 王有镗1, 2. 地下换热管热变形引起的管-土间隙[J]. 吉林大学学报(工学版), 2014, 44(4): 998-1003. |

| [5] | 左曙光, 韩惠君, 苏虎, 韦开君, 赵愿玲. 燃料电池车用旋涡风机气动噪声及影响因素[J]. 吉林大学学报(工学版), 2013, 43(06): 1453-1458. |

| [6] | 孙智勇, 孙小端. 高速公路施工区车辆汇入的可接受间隙[J]. , 2012, (06): 1470-1474. |

| [7] | 陈永恒,曲昭伟,郑倩. T型交叉口车辆远引掉头评价模型[J]. 吉林大学学报(工学版), 2009, 39(增刊2): 150-0153. |

| [8] | 陈永恒,葛兴, 王殿海 . 双车道路段公交车辆对交通流延误影响模型[J]. 吉林大学学报(工学版), 2009, 39(03): 576-0581. |

| [9] | 岂兴明,朴英,矫津毅 . 高压涡轮叶顶间隙变化的数值分析[J]. 吉林大学学报(工学版), 2009, 39(01): 33-37. |

| [10] | 梁春岩, 王春光, 沈战, 王殿海 . 机非混行交叉口右转机动车行程时间计算方法 [J]. 吉林大学学报(工学版), 2007, 37(05): 1053-1057. |

| [11] | 王殿海,孙锋,金盛 . 两相位交叉口左转车通行能力计算方法[J]. 吉林大学学报(工学版), 2007, 37(04): 767-771. |

| [12] | 张健红,左春柽,钱生君,齐培正 . 基于轴承间隙模型的摆锤碰撞试验台仿真研究[J]. 吉林大学学报(工学版), 2007, 37(03): 553-0557. |

| [13] | 刘畅,王靖宇,桑涛,梁天也,胡兴军 . 大型载货汽车驾驶室与货厢间隙 对气动力特性的影响[J]. 吉林大学学报(工学版), 2007, 37(02): 280-0285. |

|

||