吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1601-1611.doi: 10.13229/j.cnki.jdxbgxb20200850

• 车辆工程·机械工程 • 上一篇

考虑离心膨胀的双级串联轴承油膜刚度和阻尼

胡晶1,2( ),李聪3,张邦成4,乔晓利1,2,张心明1,2,5(

),李聪3,张邦成4,乔晓利1,2,张心明1,2,5( ),周笑平1,2

),周笑平1,2

- 1.长春理工大学 机电工程学院,长春 130022

2.吉林省空气动力科技创新中心,长春 130022

3.中国航空工业空气动力研究院,哈尔滨 150001

4.长春工业大学 机电工程学院,长春 130022

5.佛山科学技术学院 机电工程与自动化学院,广东 佛山 528225

Oil film stiffness and damping of double⁃decker ball bearing in consideration of centrifugal expansion

Jing HU1,2( ),Cong LI3,Bang-cheng ZHANG4,Xiao-li QIAO1,2,Xin-ming ZHANG1,2,5(

),Cong LI3,Bang-cheng ZHANG4,Xiao-li QIAO1,2,Xin-ming ZHANG1,2,5( ),Xiao-ping ZHOU1,2

),Xiao-ping ZHOU1,2

- 1.College of Mechanical and Electrical Engineering,Changchun University of Science and Technology,Changchun 130022,China

2.Jilin Province Innovation Center of Aerodynamic Science and Technology,Changchun 130022,China

3.AVIC Aerodynaiviics Research Institute,Harbin 150001,China

4.College of Mechanical and Electrical Engineering,Changchun University of Technology,Changchun 130022,China

5.School of Mechatronic Engineering and Automation,Foshan University,Foshan 528225,China

摘要:

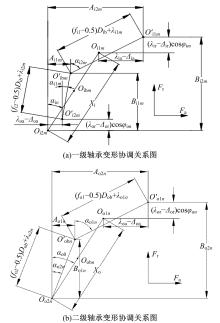

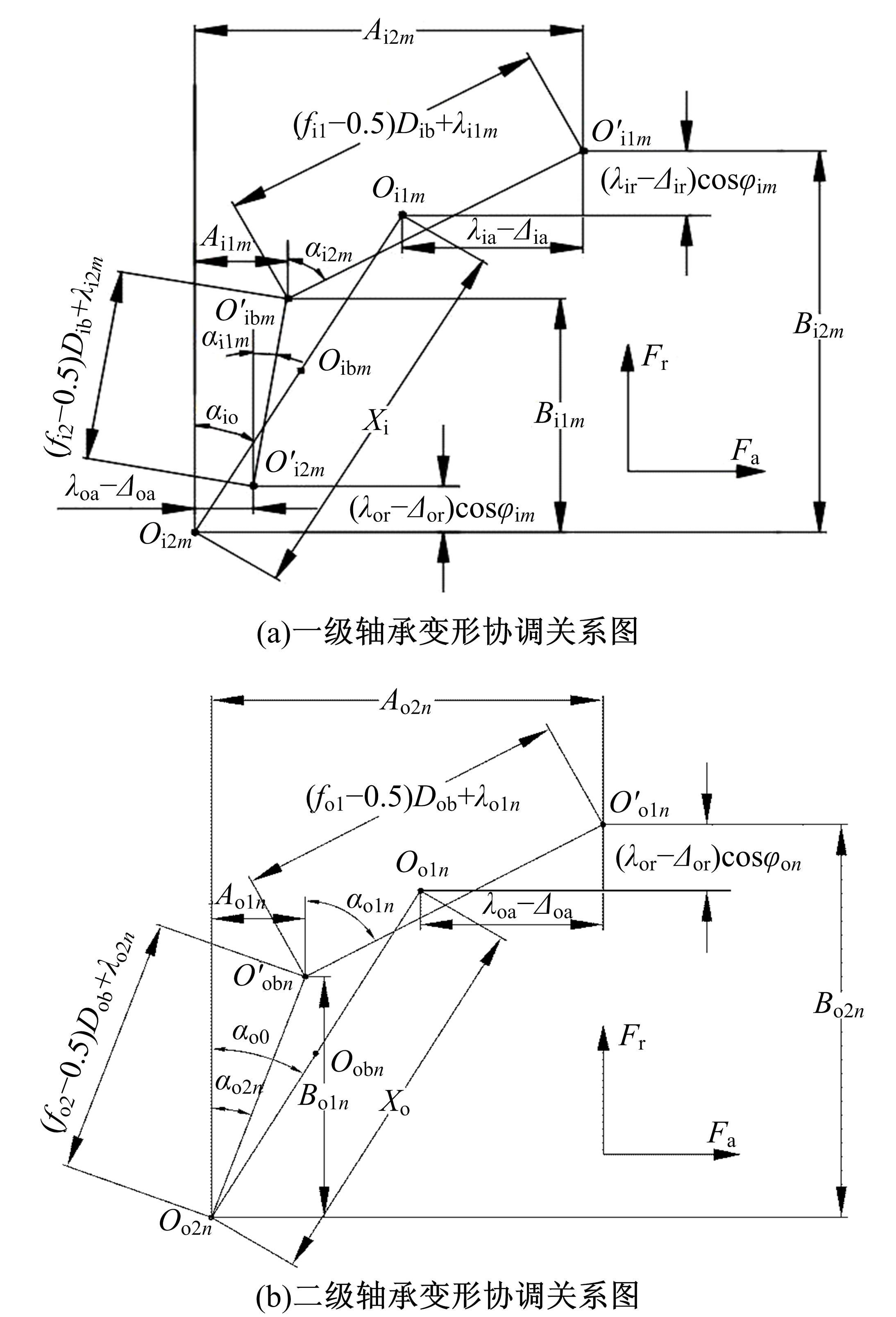

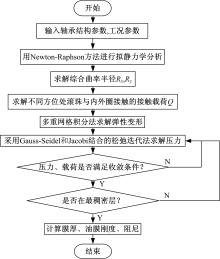

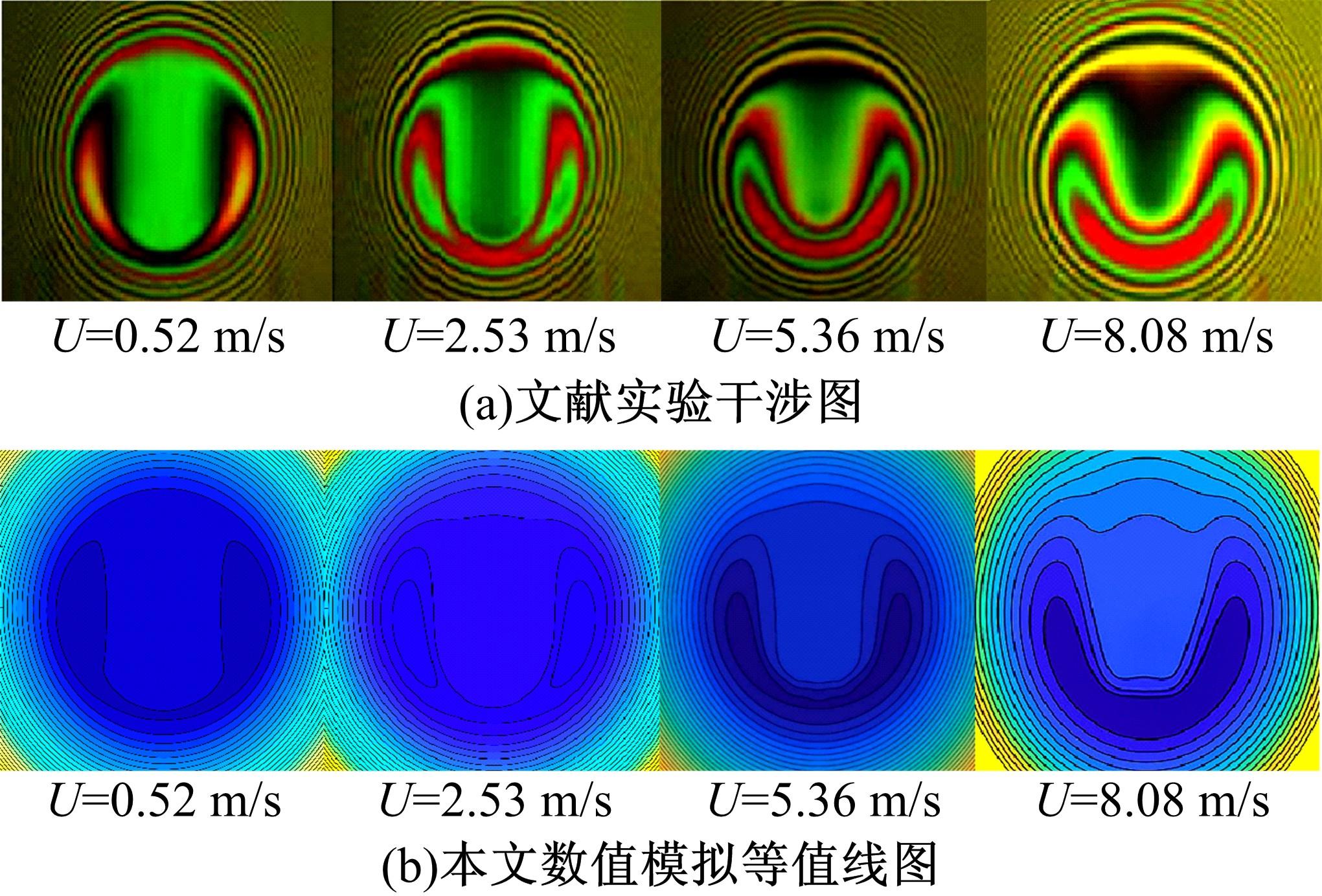

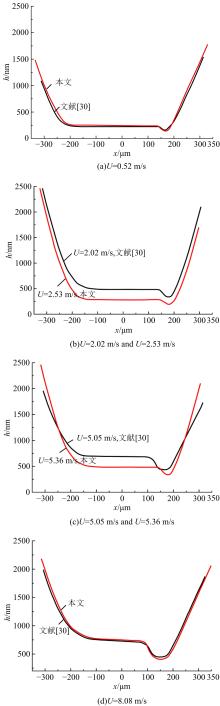

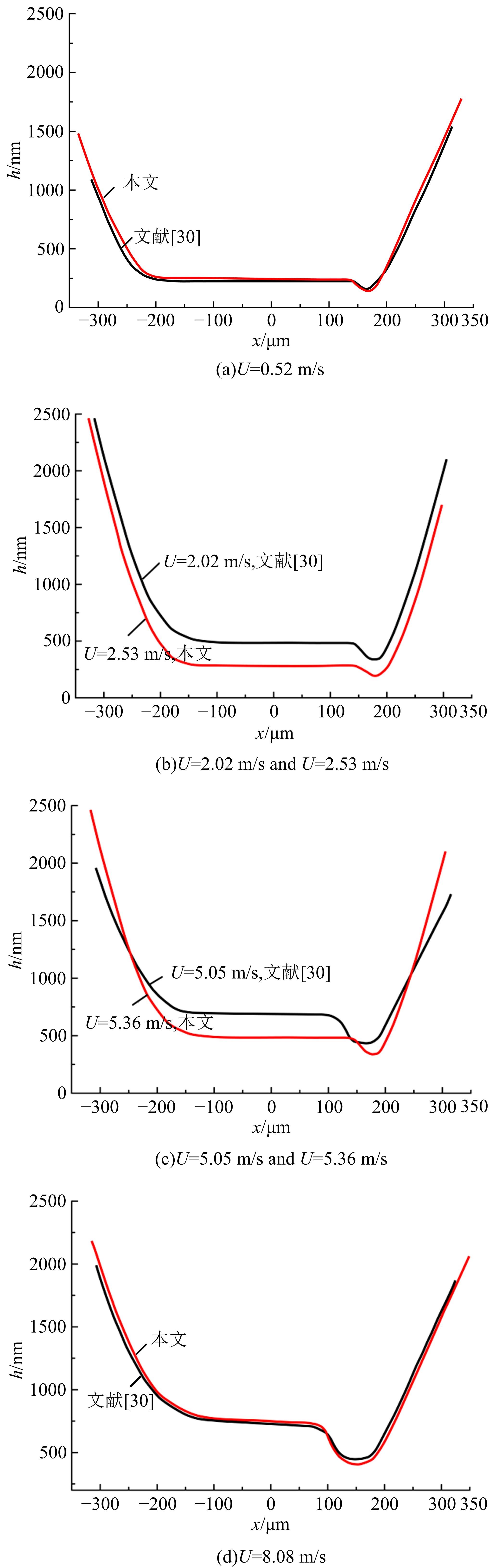

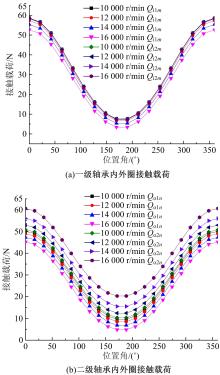

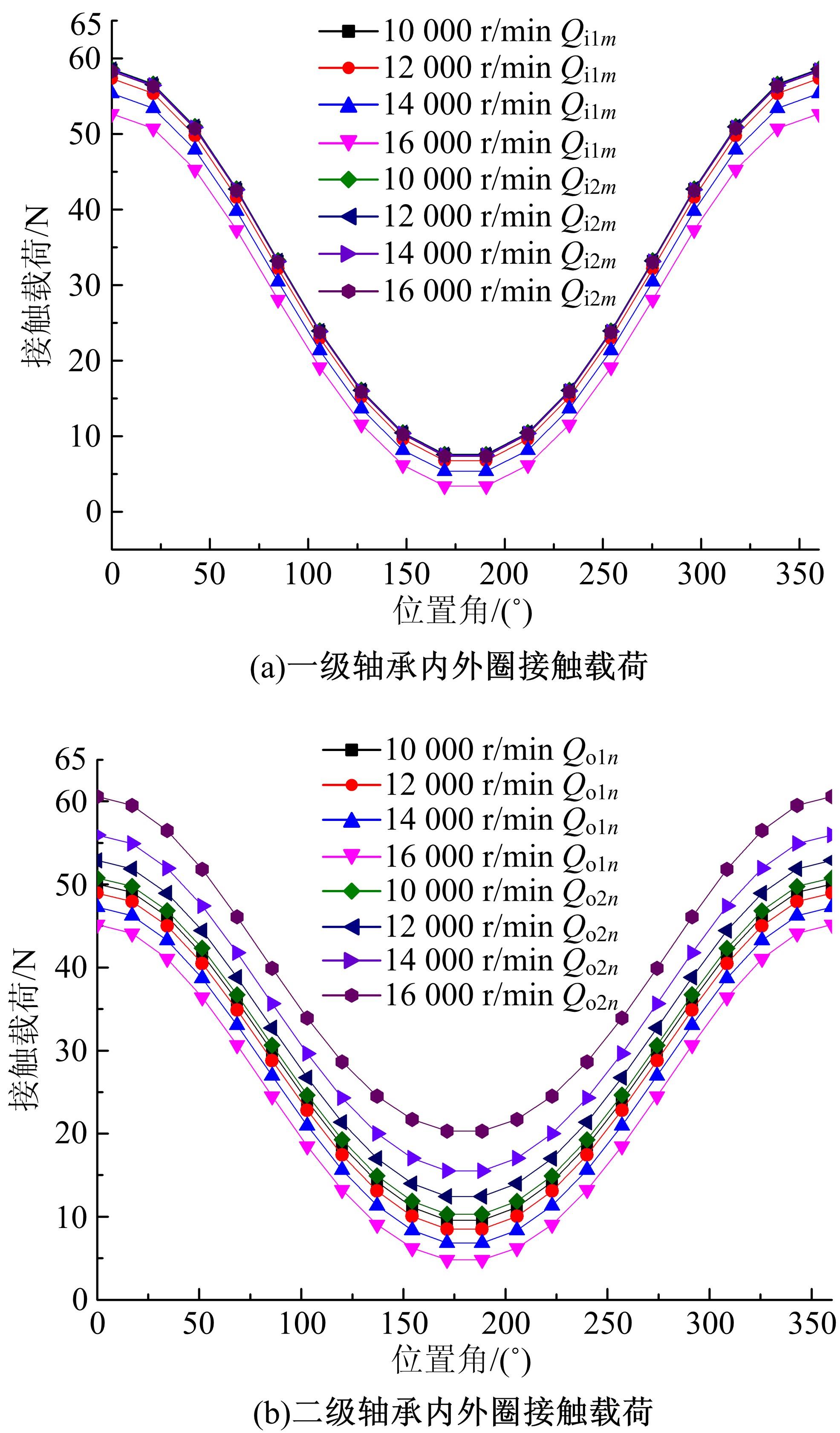

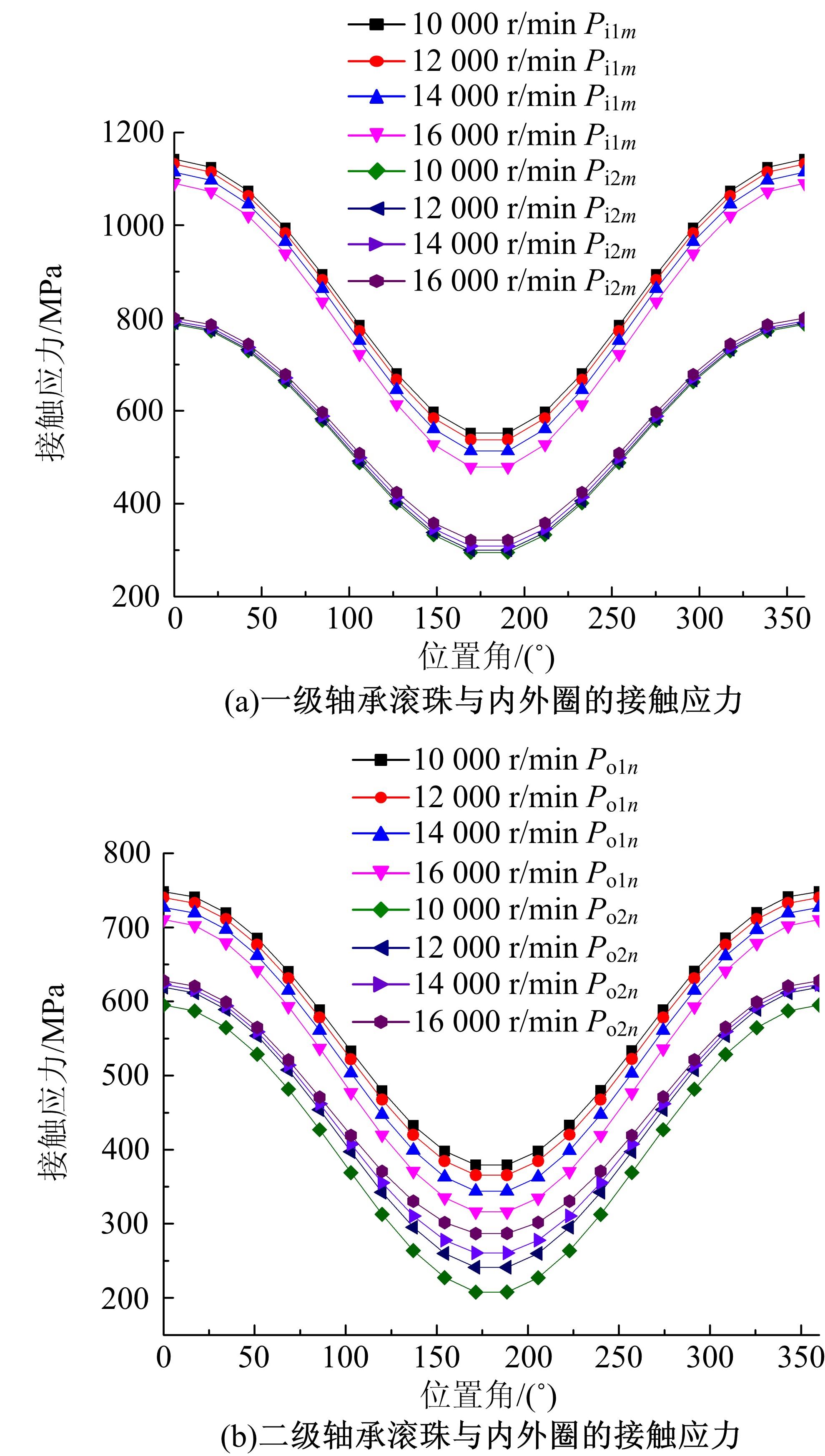

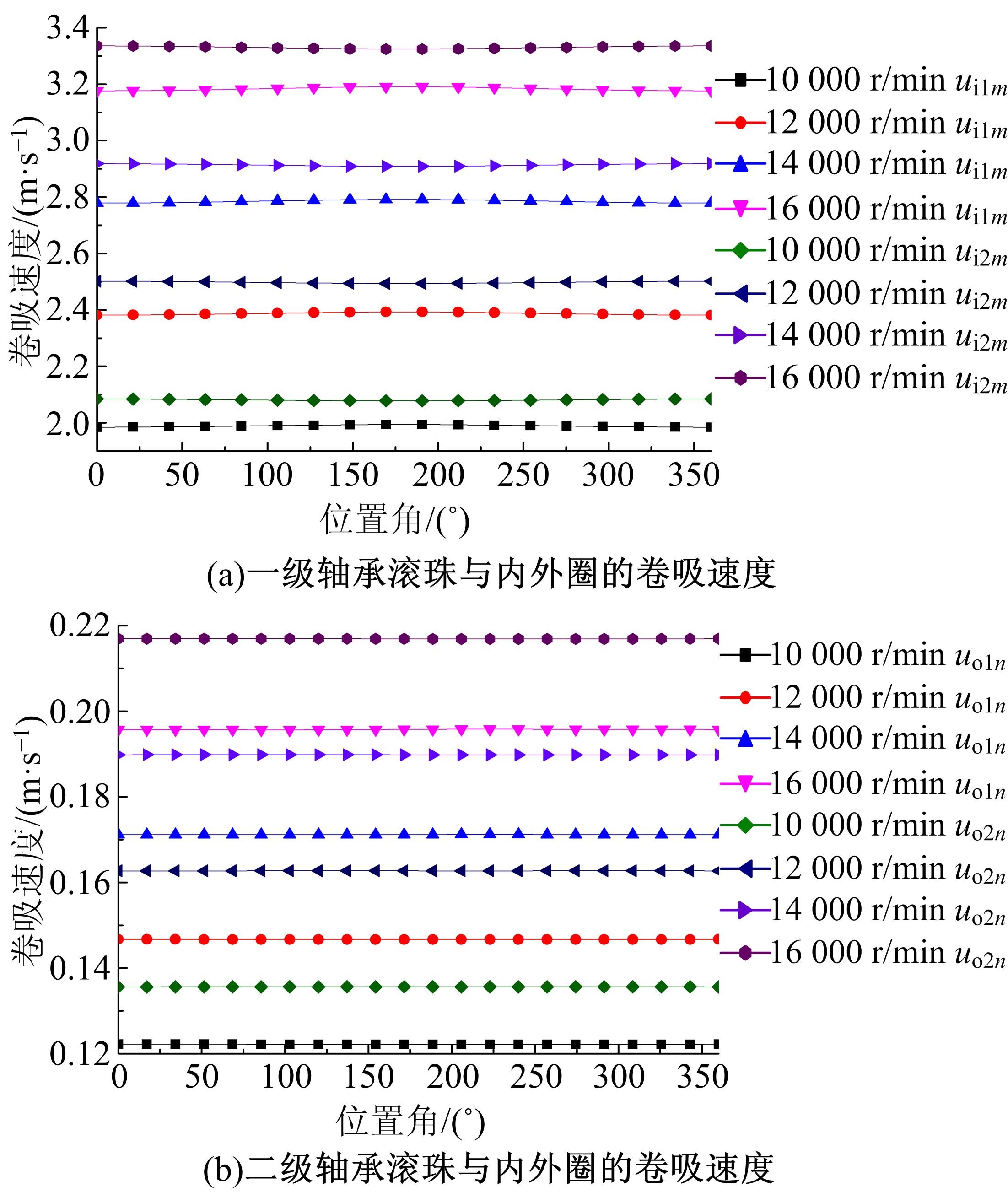

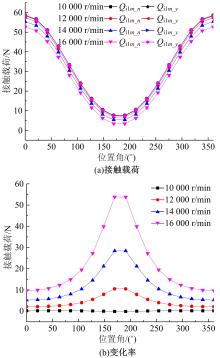

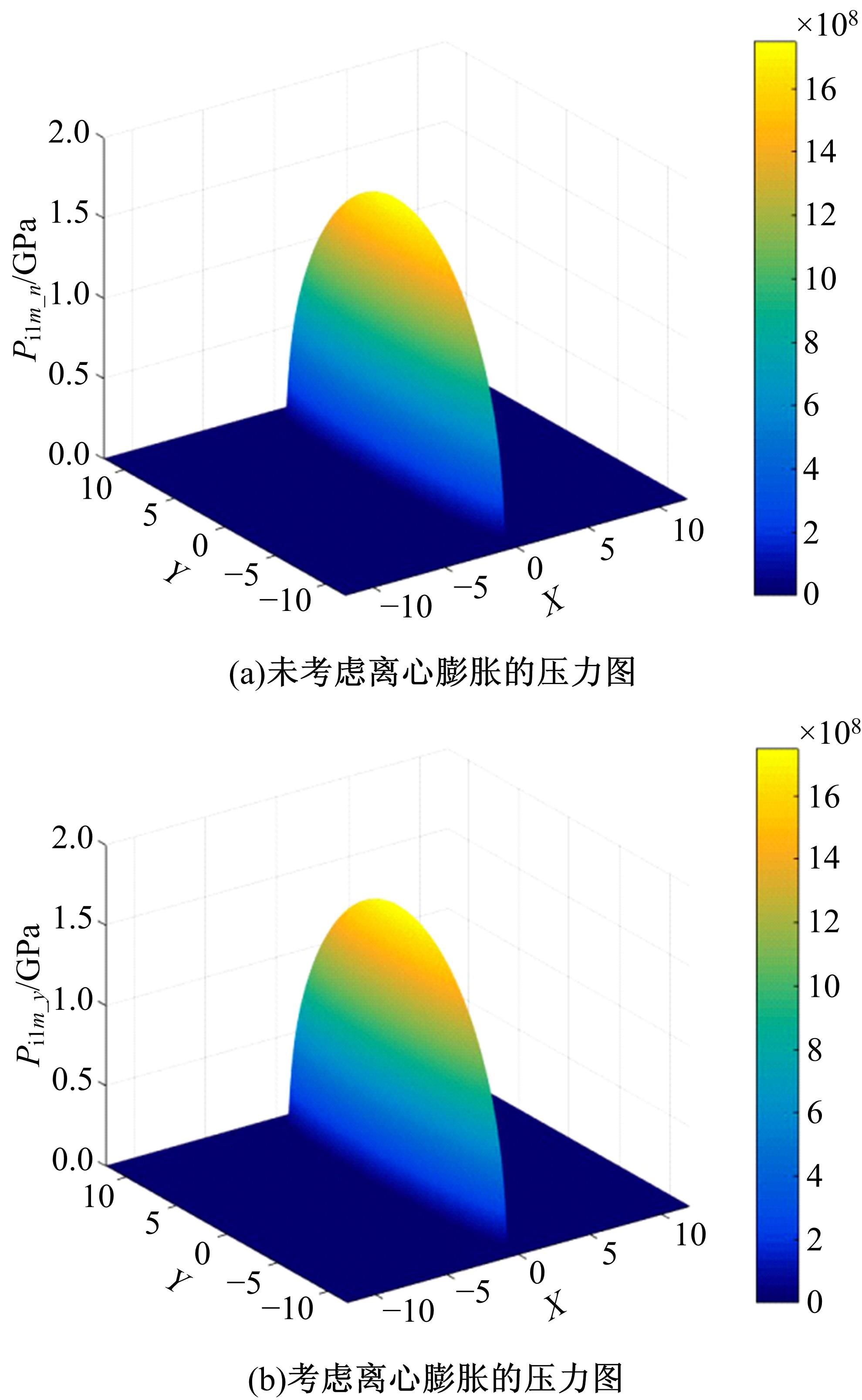

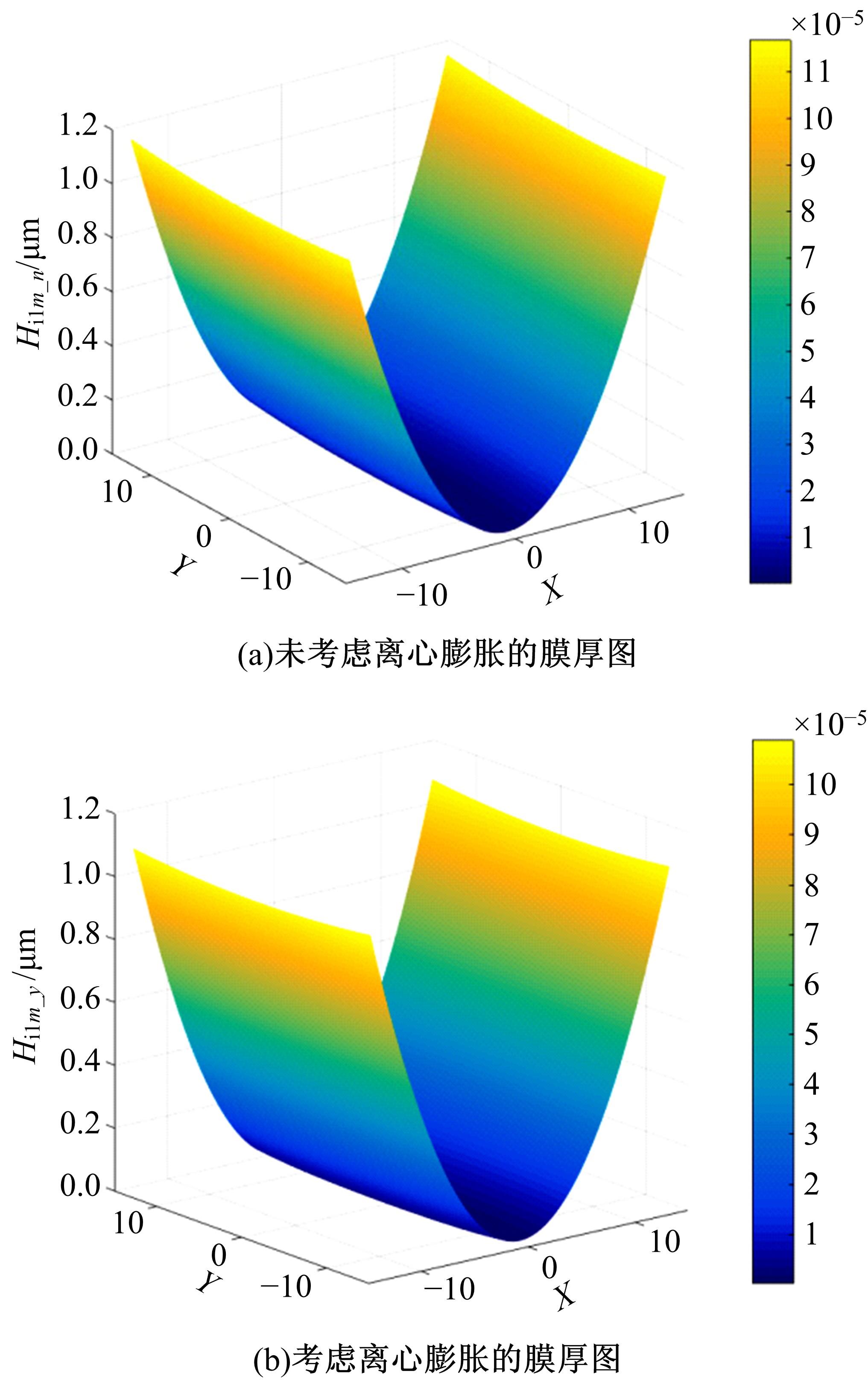

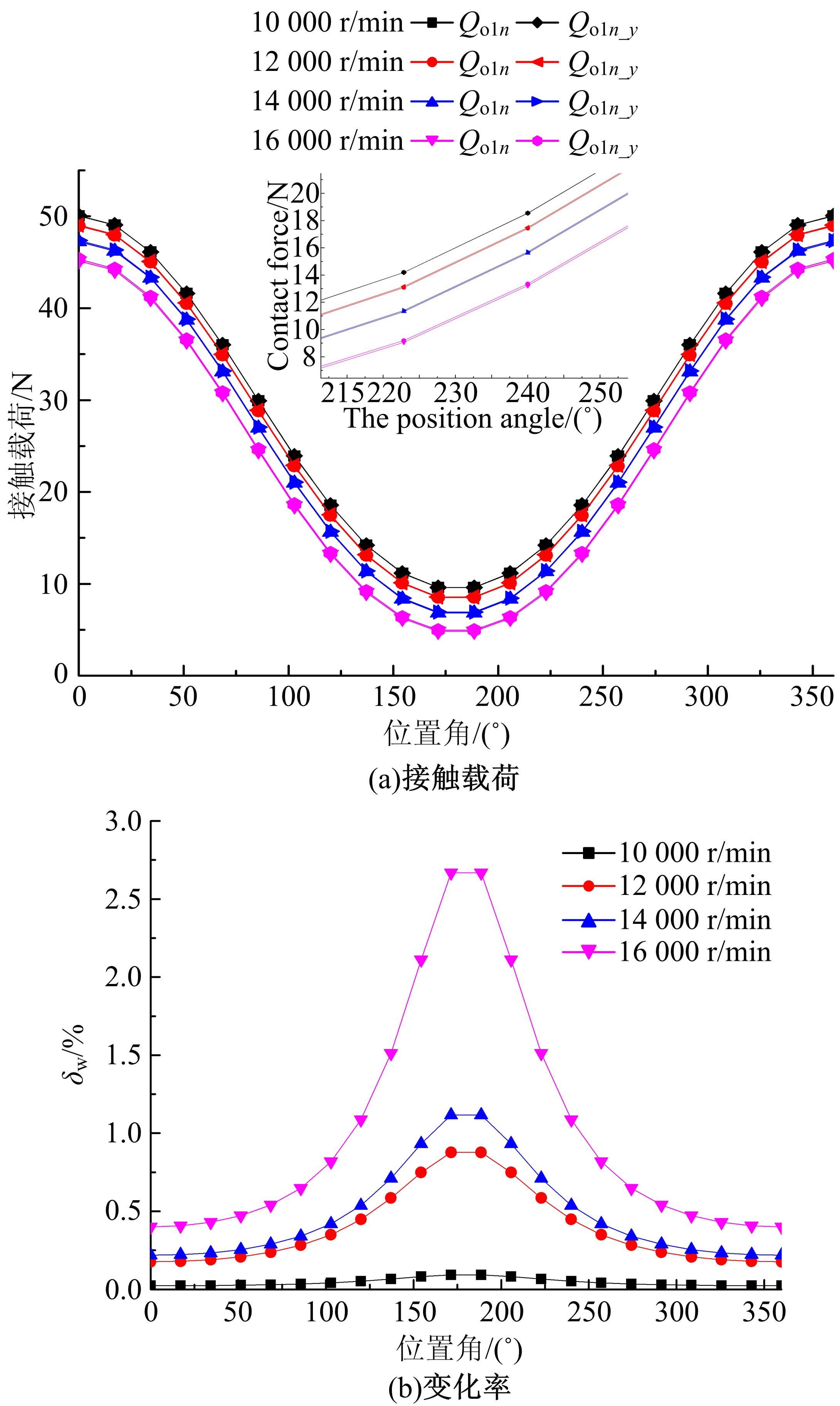

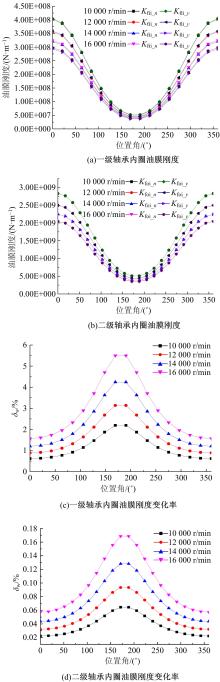

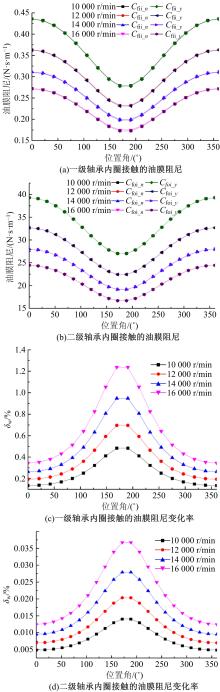

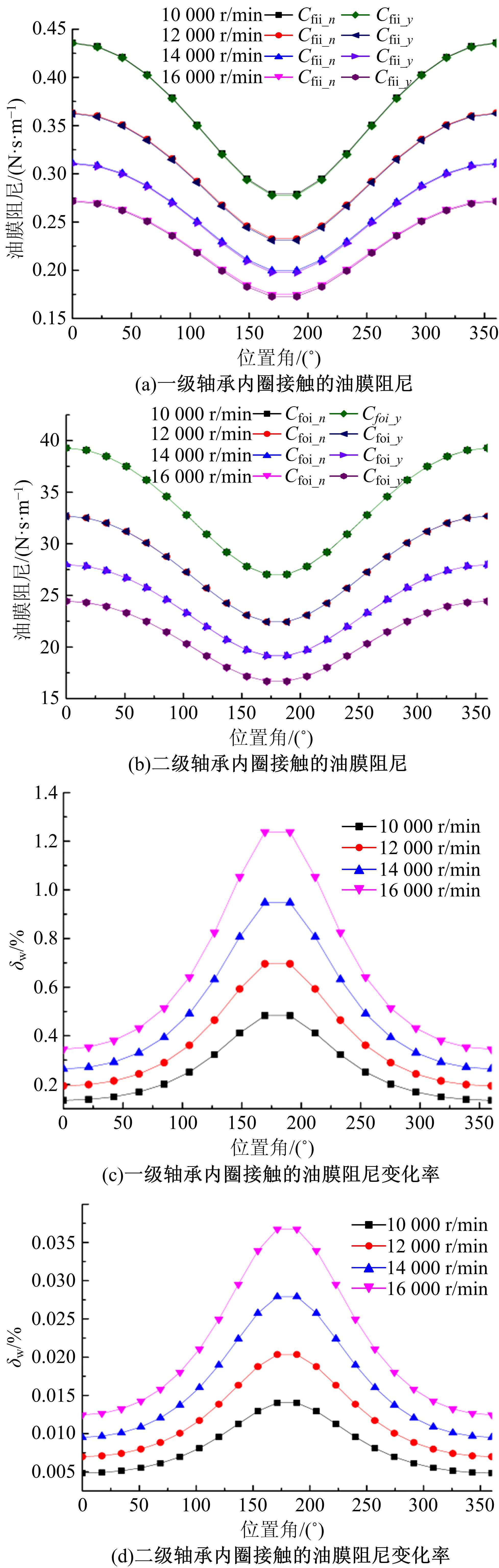

轴承的弹流润滑状况与其动态性能有着密切的关系,对轴承弹流润滑特性的精准计算是轴承转速分析及可靠性设计的关键。为探究双级串联轴承的油膜刚度和阻尼特性,建立了考虑离心膨胀效应后的双级串联轴承拟静力学与弹流润滑分析模型,即离心膨胀影响模型,分析了离心膨胀效应对双级串联球轴承油膜刚度和阻尼的影响规律。研究结果表明:双级串联轴承一、二级轴承的内接触油膜刚度和阻尼随转速的增加而减小;考虑离心膨胀后,油膜刚度有所增加,阻尼减小,且变化率的幅度随转速增加而增大。在邻近高速工况时,考虑离心膨胀的因素能提高计算精度,而一旦转速达到高速区域,离心膨胀效应的影响几乎是不可忽略的。

中图分类号:

- TH133.33

| 1 | 徐涛, 赵玉洁, 邵晴, 等. 联合载荷下角接触球轴承静态接触特性分析[J]. 吉林大学学报: 工学版,2017, 47(4): 1114-1120. |

| Xu Tao, Zhao Yu-jie, Shao Qing, et al. Analysis of static contact characteristics of angular contact ball bearing under combined loads[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(4): 1114-1120. | |

| 2 | Anderson W J. Tribology for Aerospace Application[M]. 1973. |

| 3 | Prashad H. A new generation double decker high precision rolling element bearing-concept, development and investigations[J]. ASLE Transactions, 2001, 44(2): 203-208. |

| 4 | Prashad H. Relative comparison of stiffness and damping properties of double decker high precision and conventional rolling-element bearings[J]. Tribology International, 2002, 35: 265-269. |

| 5 | Prashad H. A theoretical approach to evaluating the performance characteristics of double-decker high-precision bearings[J]. Lubrication Science, 2010, 10(3): 251-263. |

| 6 | Prashad H. A new generation of rolling-element bearing with an outline of its performance advantages[J]. Solving Tribology Problems in Rotating Machines, 2006: 228-242. |

| 7 | Prashad H. An analysis of axial deflection of double-decker high-precision bearings vis-à-vis conventional ball bearings[J]. Lubrication Science, 2006, 18(2): 119-128. |

| 8 | 许磊. 新型滚动轴承的力学性能研究[D]. 南京: 南京航空航天大学机电学院, 2010. |

| Xu Lei. Research on mechanical characteristics of a new type ball bearings[D]. Nanjing: College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics & Astronautics, 2010. | |

| 9 | 朱益利, 徐龙祥. 双层滚珠轴承力学特性分析[J]. 航空动力学报, 2011, 26(8): 1914-1920. |

| Zhu Yi-li, Xu Long-xiang. Mechanical research of double-decker ball bearing[J]. Journal of Aerospace Power, 2011, 26(8): 1914-1920. | |

| 10 | 蒋鹏. 双层滚动轴承运动学研究[D]. 南京: 南京航空航天大学机电学院, 2011. |

| Jiang Peng. Research on motion-characteristics of double-decker rolling-element bearings[D]. Nanjing: College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics & Astronautics, 2011. | |

| 11 | 郑衍通. 新型保护轴承热学特性研究[D]. 南京: 南京航空航天大学机电学院, 2010. |

| Zheng Yan-tong. Research on thermal characteristics of type auxiliary bearing[D]. Nanjing: College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics & Astronautics, 2010. | |

| 12 | 金超武, 余旭东, 朱益利, 等. 双层轴承的载荷分布研究[J]. 机械科学与技术, 2014, 33(2): 204-207. |

| Jin Chao-wu,Yu Xu-dong,Zhu Yi-li, et al. Research on the load distribution of a double-decker ball bearing[J]. Mechanical Science and Technology for Aerospace Engineering, 2014, 33(2): 204-207. | |

| 13 | Xu L X, Yu C T, Yu X D. Research on the Mechanical properties of "Z" type double-decker ball bearings[J]. Journal of Tribology, 2014, 136(1): 011102. |

| 14 | Zhu Y L, Zhang Y C, Jin C W. Research on the mechanical properties of a new "I" type double-decker ball bearing[J]. Journal of Tribology, 2015, 138(2): 021102. |

| 15 | Zhu Y L, Zheng Z Q. The use of double-decker catcher bearing with face-to-face installed inner layer bearings[J]. Modern Physics Letters B, 2017, 31(19-21): 1740012. |

| 16 | 俞成涛, 徐龙祥, 蒋鹏, 等. 双层轴承转速分配比[J]. 南京航空航天大学学报, 2012, 44(3): 285-289. |

| Yu Cheng-tao, Xu Long-xiang, Jiang Peng, et al. Speed distribution ratio of double-decker rolling-element bearings[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2012, 44(3): 285-289. | |

| 17 | Wu J Q, Wang L Q, He T, et al. Investigation on the angular contact ball bearings under low speed and heavy load with coupled mixed lubrication and quasi dynamic analysis[J]. Lubrication Science, 2020(2): 108-120. |

| 18 | Wang B M, Yun X L, Liao X Y, et al. Analysis of thermal effect on elastohydrodynamic lubrication in angular contact ball bearing[J]. Applied Mechanics & Materials, 2015, 741: 443-448. |

| 19 | 史修江. 航空发动机主轴轴承动态性能和热弹流润滑状态耦合分析[D].哈尔滨: 哈尔滨工业大学机电工程学院, 2018. |

| Shi Xiu-jiang. Coupling analysis of dynamic performance and TEHL state of aeroengine main shaft bearing[D]. Harbin: School of Mechatronics Engineering, Harbin Institute of Technology, 2018. | |

| 20 | 吴明星, 吴维, 胡纪滨, 等. 考虑自旋的高速角接触球轴承油膜刚度计算[J]. 振动与冲击, 2014, 33(10): 38-42. |

| Wu Ming-xing, Wu Wei, Hu Ji-bin, et al. Calculation of oil film stiffness of high speed angular contact ball bearing considering spin[J]. Vibration and Impact, 2014, 33(10): 38-42. | |

| 21 | Zhang Y Y. Influence of lubrication starvation and surface waviness on the oil film stiffness of elastohydrodynamic lubrication line contact[J]. Journal of Vibration and Control, 2018, 24(5): 924-936. |

| 22 | Bizarre L, Nonato F, Cavalca K L. Formulation of five degrees of freedom ball bearing model accounting for the nonlinear stiffness and damping of elastohydrodynamic point contacts[J]. Mechanism & Machine Theory, 2018, 124: 179-196. |

| 23 | Lei C L, Li F H, Guo J F, et al. Analysis on the oil film stiffness of rolling bearings based on multi parameter coupling[J]. Journal of Vibration and Shock, 2018, 37(10): 225-232. |

| 24 | 杨佐卫, 殷国富, 尚欣, 等. 高速电主轴热态特性与动力学特性耦合分析模型[J]. 吉林大学学报: 工学版, 2011, 41(1): 100-105. |

| Yang Zuo-wei, Yin Guo-fu, Shang Xin, et al. Coupling analysis model of thermal and dynamic characteristic for high-speed motorized spindle[J]. Journal of Jilin University(Engineering and Technology Edition), 2011, 41(1): 100-105. | |

| 25 | Lu Z Y, Lv Y J, Zhang Y F, et al. Micro thermal elastohydrodynamic lubrication analysis of angular contact ball bearing considering thermal elastic deformation[J]. Tribology, 2018, 38(3): 299-308. |

| 26 | Zivkovic A, Zeljkovic M, Tabakovic S, et al. Mathematical modeling and experimental testing of high-speed spindle behavior[J]. International Journal of Advanced Manufacturing Technology, 2015, 77(5-8): 1071-1086. |

| 27 | Zhu Y L, Xu L X. The radial stiffness and application of double-decker ball bearing[J]. Key Engineering Materials, 2011, 450: 353-356. |

| 28 | Feng G, Yang P R, Qu S Y. On the theory of thermal elastohydrodynamic lubrication at high slide-roll ratios—circular glass-steel contact solution at opposite sliding[J]. Journal of Tribology, 2001, 123(4): 816-821. |

| 29 | Walford T L H, Stone B J. The sources of damping in rolling element bearings under oscillating conditions[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 1983, 197(4): 225-232. |

| 30 | Zhang Y G, Wang W Z, Zhang S G, et al. Experimental study of EHL film thickness behaviour at high speed in ball-on-ring contacts[J]. Tribology International, 2017, 113: 216-223. |

| 31 | Abele E, Altintas Y, Brecher C. Machine tool spindle units[J]. CIRP Annals—Manufacturing Technology, 2010, 59(2): 781-802. |

| [1] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [2] | 关健, 王黎钦. 考虑载荷大小变化次序的球轴承寿命修正模型[J]. 吉林大学学报(工学版), 2016, 46(4): 1182-1189. |

| [3] | 李常有,徐敏强,郭耸,王跃武. 基于模型的转子弯曲程度识别方法[J]. 吉林大学学报(工学版), 2010, 40(04): 1019-1024. |

| [4] | 徐进永, 张子达, 陆爽. 基于K-L变换和支持向量机的[J]. 吉林大学学报(工学版), 2005, 35(05): 500-0504. |

|

||