吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 310-317.doi: 10.13229/j.cnki.jdxbgxb20211207

• 车辆工程·机械工程 • 上一篇

基于1D⁃RSCNN的嵌入式轴承故障实时检测

- 东北石油大学 电气信息工程学院,黑龙江 大庆 163318

Real⁃time detection of embedded bearing faults based on 1D⁃RSCNN

Xiu-fang WANG( ),Shuang SUN,Chun-yang DING

),Shuang SUN,Chun-yang DING

- School of Electrical Information Engineering,Northeast Petroleum University,Daqing 163318,China

摘要:

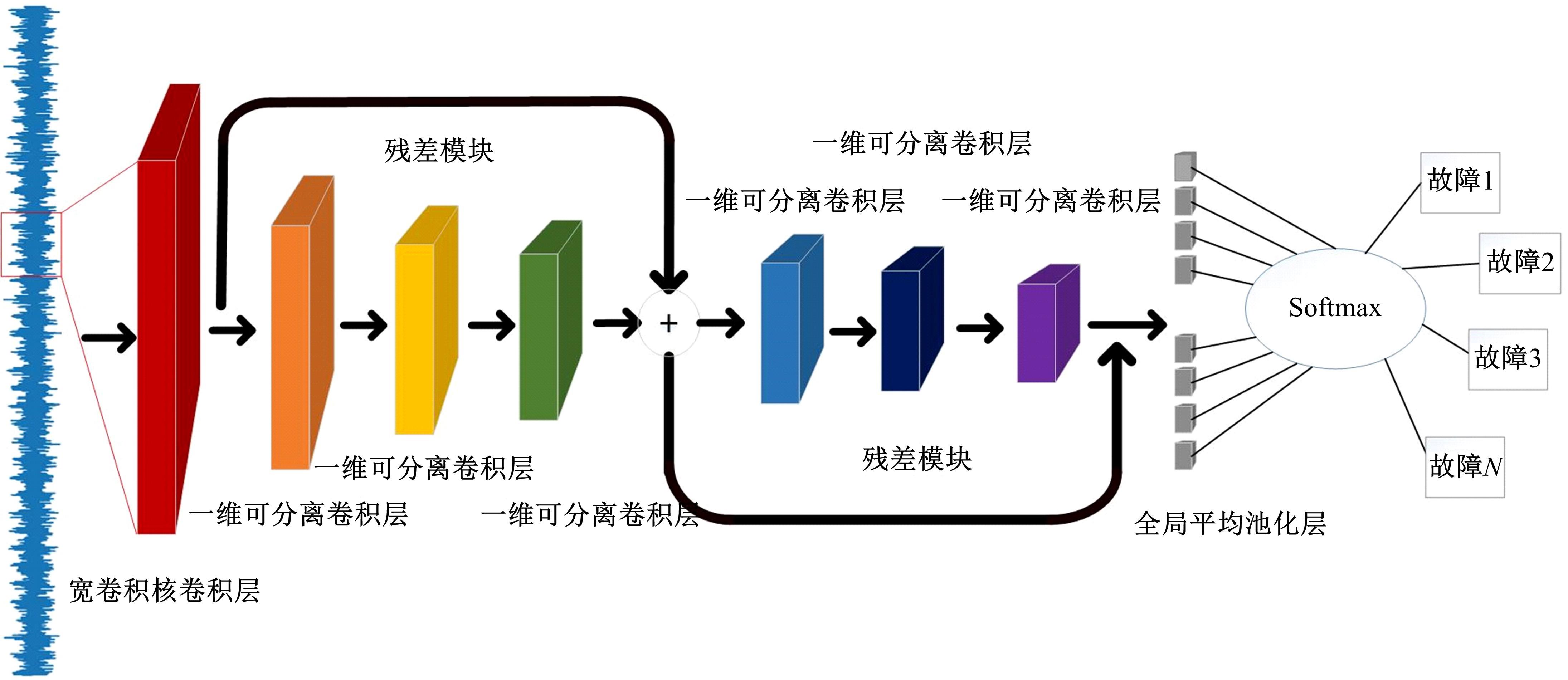

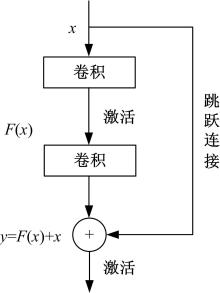

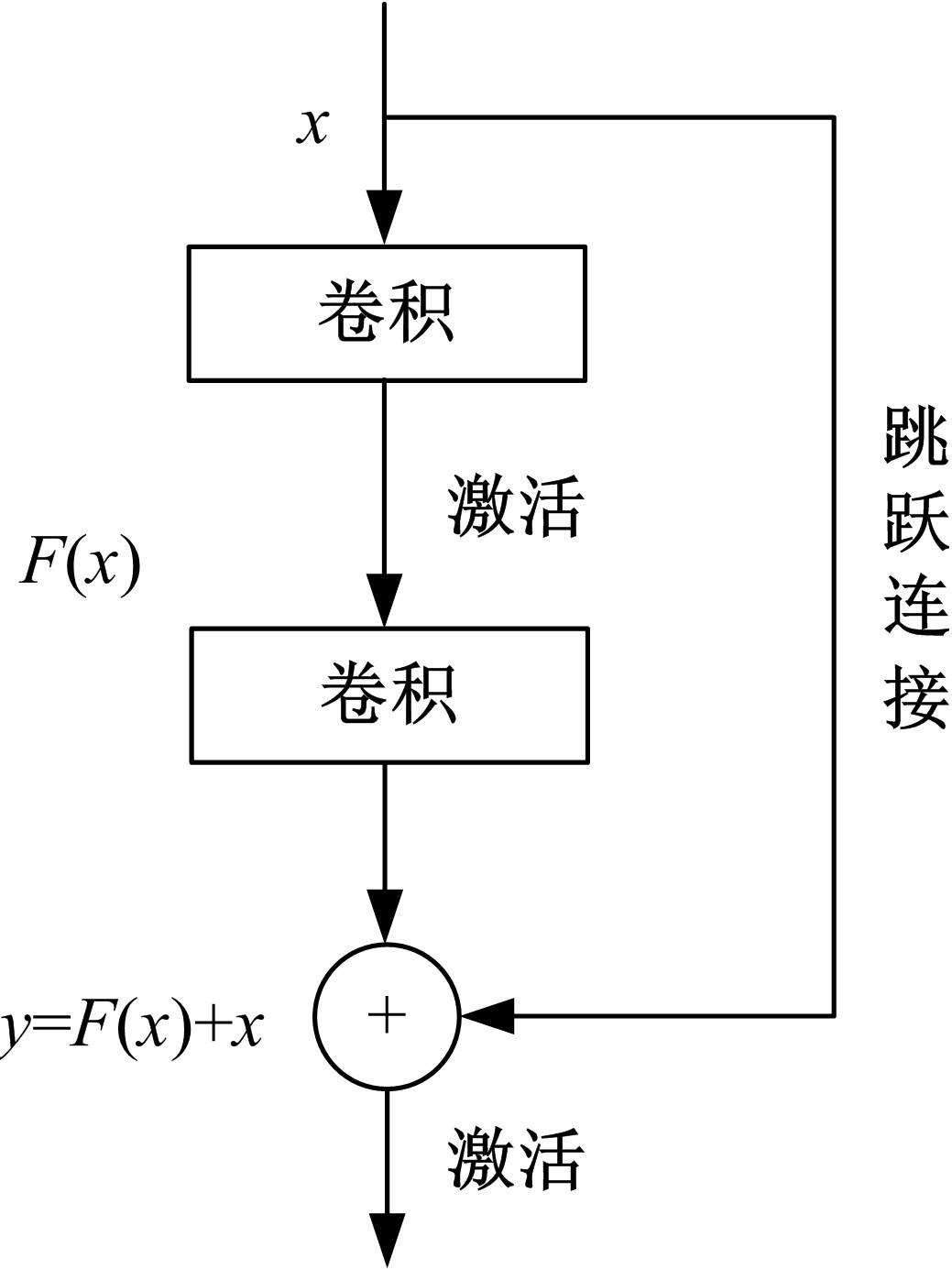

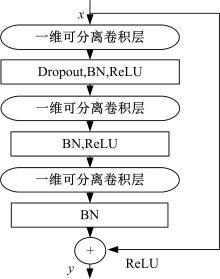

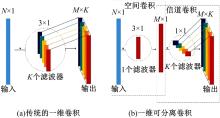

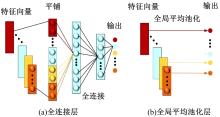

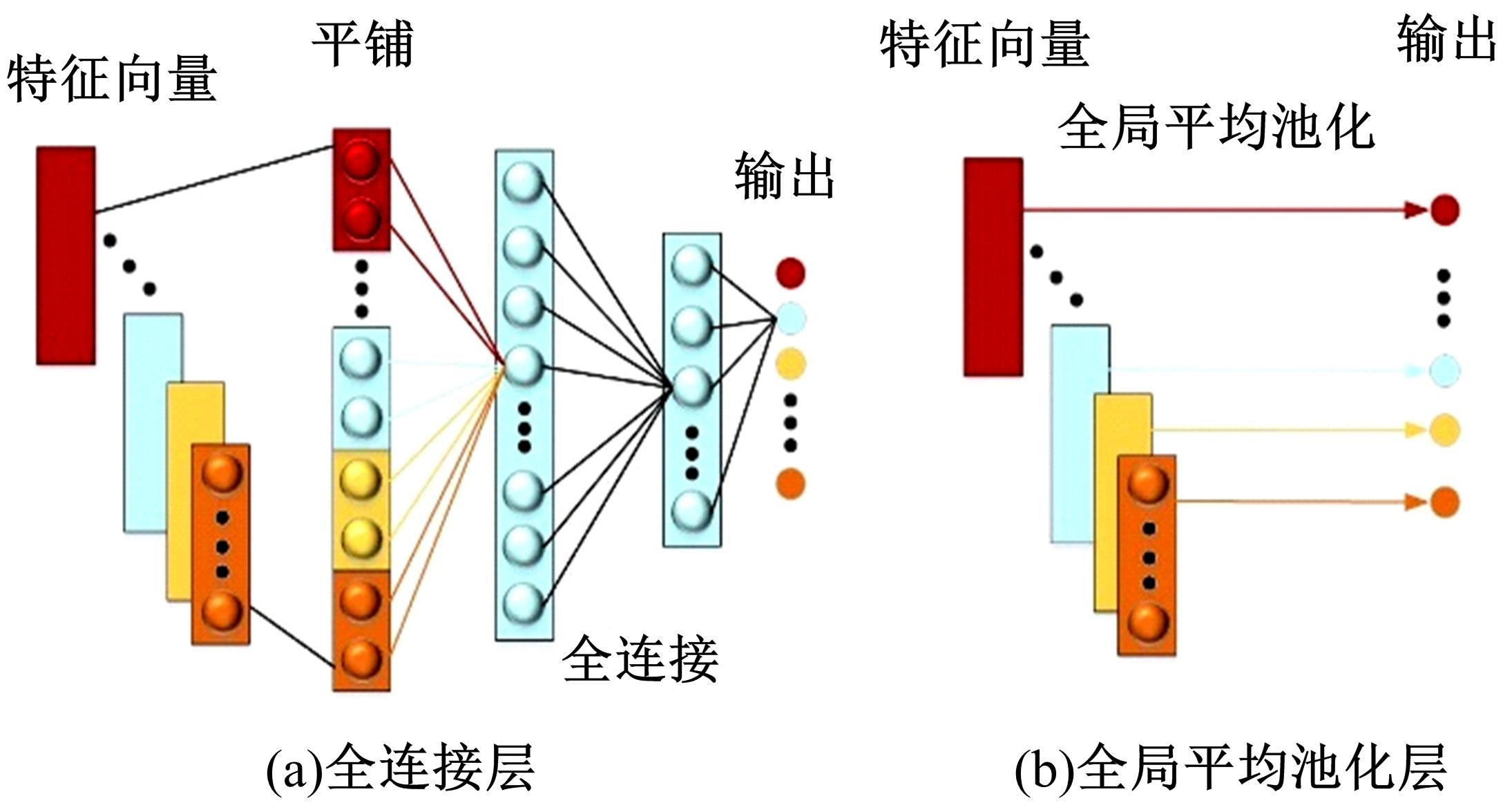

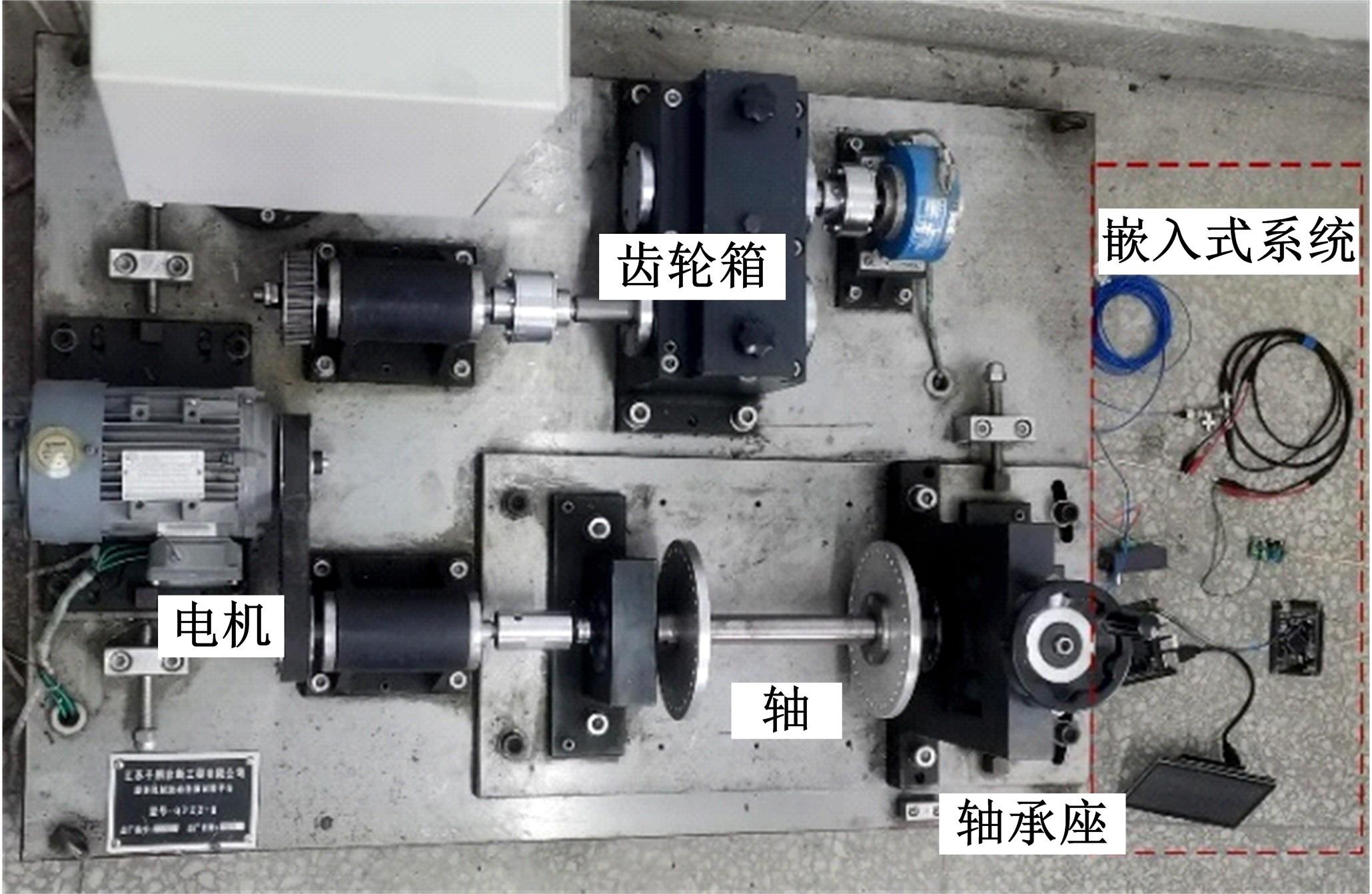

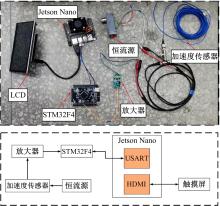

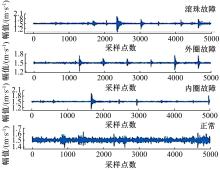

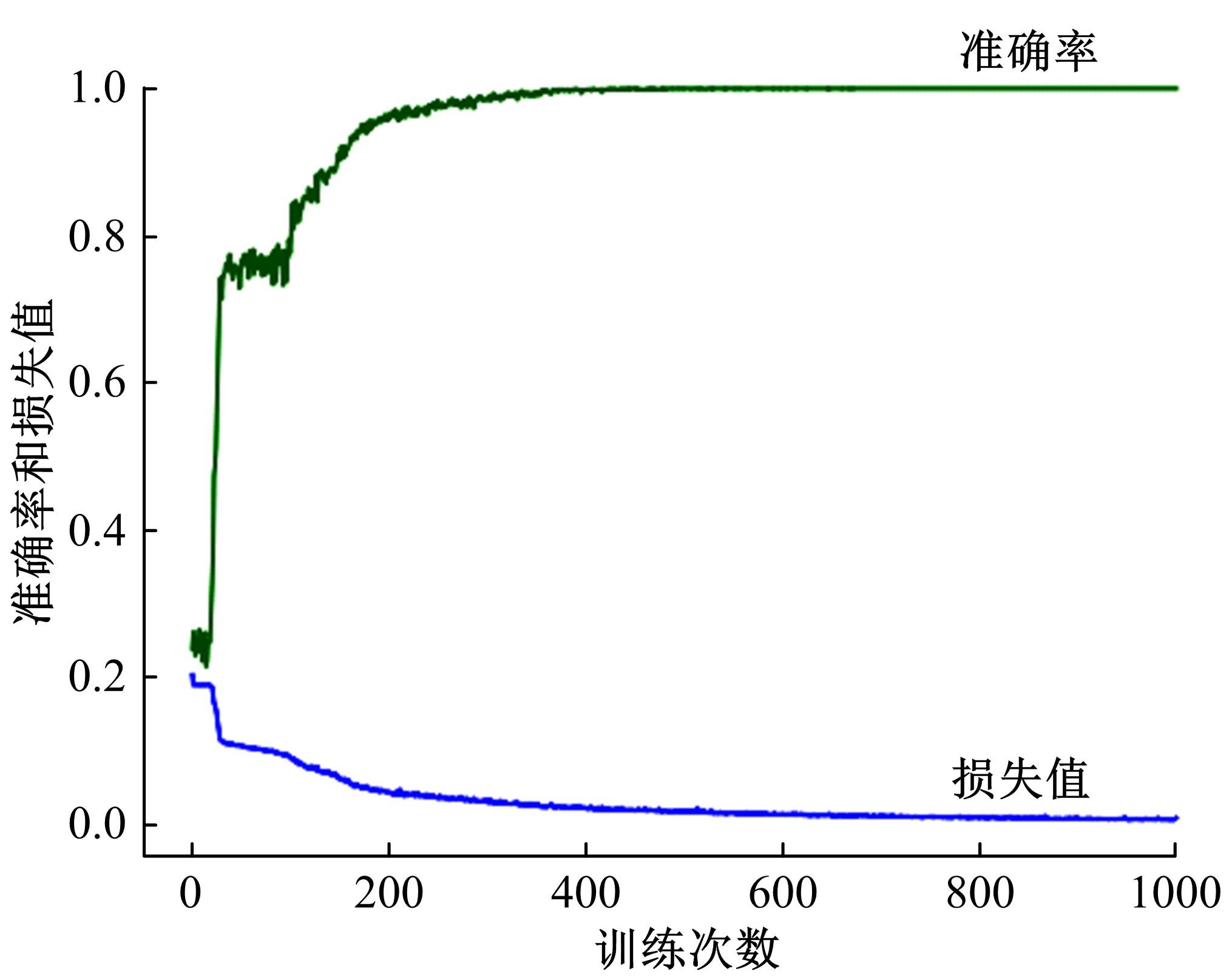

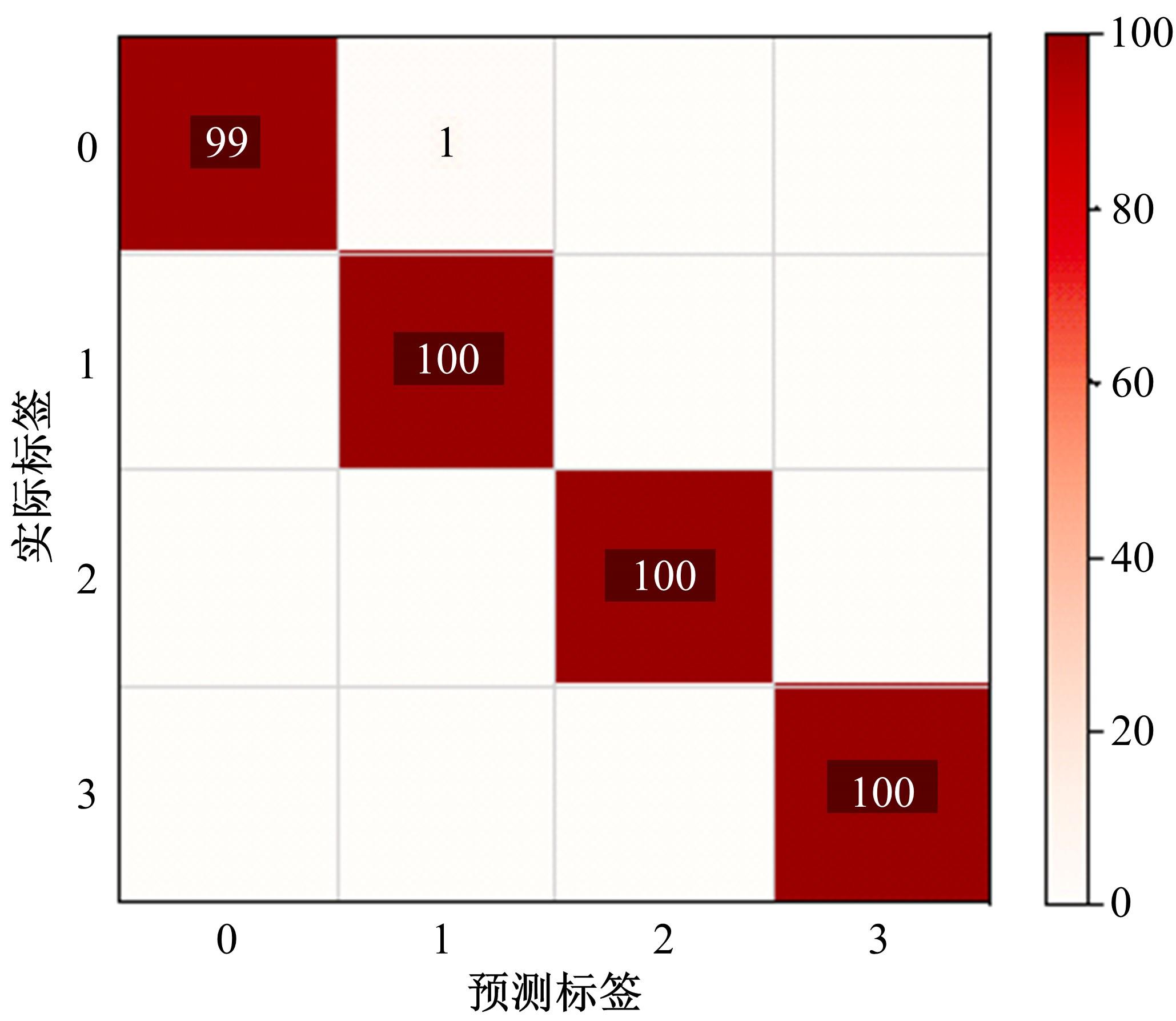

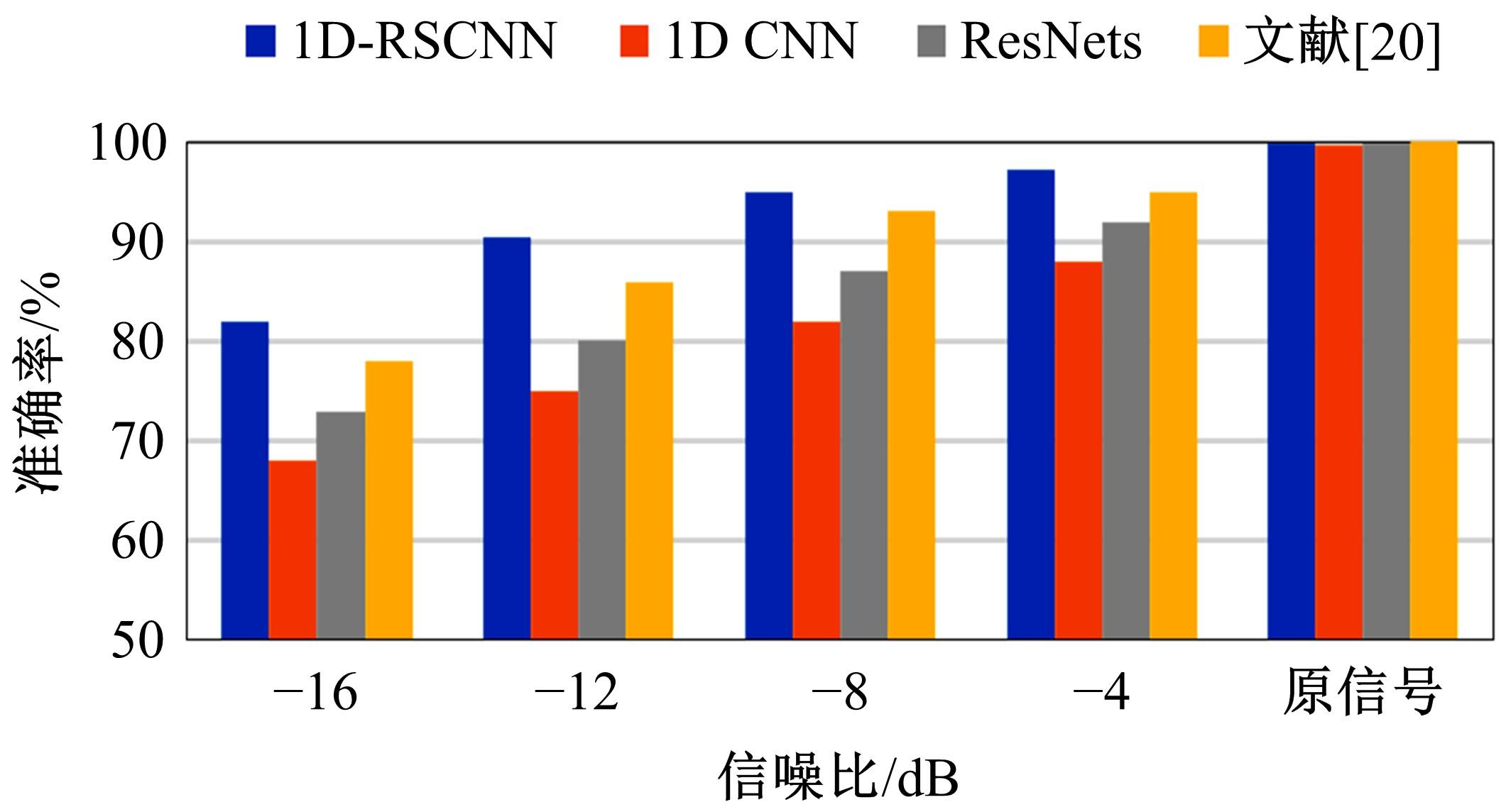

针对传统故障诊断模型参数多,训练、检测时间长,抗噪性差,不适用于在线实时诊断的问题,提出了基于残差连接和一维可分离卷积(1D-RSCNN)的滚动轴承故障诊断方法,构建了由Jetson Nano和信号采集电路组成的嵌入式系统。利用一维可分离卷积和全局平均池化对模型尺寸进行压缩,改善传统卷积的运算效率;通过宽卷积核,残差网络中引入Dropout提高对噪声的容忍度。试验结果表明,该方法诊断准确率高达99.92%,与其他模型相比,诊断精度高,实时性好,抗干扰能力强,适用于电机轴承故障的实时检测。

中图分类号:

- TP277

| 1 | Lee C Y, Cheng Y H. Motor fault detection using wavelet transform and improved PSO-BP neural network[J]. Processes, 2020, 8(10): 1322. |

| 2 | Pandarakone S E, Mizuno Y, Nakamura H. Evaluating the progression and orientation of scratches on outer-raceway bearing using a pattern recognition method[J]. IEEE Transactions on Industrial Electronics, 2019, 66(2): 1307-1314. |

| 3 | Cao H, Fan F, Zhou K, et al. Wheel-bearing fault diagnosis of trains using empirical wavelet transform [J]. Measurement, 2016, 82: 439-449. |

| 4 | Nikolaou N G, Antoniadis I A. Rolling element bearing fault diagnosis using wavelet packets[J]. NDT & E International, 2009, 35(3): 197-205. |

| 5 | 武哲, 杨绍普, 刘永强. 基于多元经验模态分解的旋转机械早期故障诊断方法[J]. 仪器仪表学报, 2016, 37(2): 241-248. |

| Wu Zhe, Yang Shao-pu, Liu Yong-qiang. Early fault diagnosis method of rotating machinery based on multiple empirical mode decomposition[J]. Journal of Instrumentation, 2016, 37(2): 241-248. | |

| 6 | Dragomiretskiy K, Zosso D. Variational mode decomposition [J]. IEEE Transactions on Signal Processing, 2014, 62(3): 531-544. |

| 7 | 姚德臣, 杨建伟, 程晓卿, 等. 基于多尺度本征模态排列熵和SA-SVM的轴承故障诊断研究[J]. 机械工程学报, 2018, 54(9): 168-176. |

| Yao De-chen, Yang Jian-wei, Cheng Xiao-qing, et al. Railway rolling bearing fault diagnosis based on muti-scale IMF permutation entropy and SA-SVM classifier[J]. Journal of Mechanical Engineering, 2018, 54(9): 168-176. | |

| 8 | Krishnakumari A, Elayaperumal A, Saravanan M. et al. Fault diagnostics of spur gear using decision tree and fuzzy classifier[J]. Int J Adv Manuf Technol,2017, 89: 3487-3494. |

| 9 | Chen S Z, Yang R, Zhong M Y. Graph-based semi-supervised random forest for rotating machinery gearbox fault diagnosis[J]. Control Engineering Practice, 2021, 117: 104952. |

| 10 | Yang Y, Yu D, Cheng J. A roller hearing fault diagnosis method baesd on EMD energy entropy and ANN[J]. Journal of Sound and Vibration, 2006, 294(1): 269-277 |

| 11 | Li H W, Zhao X P, Wu J X, et al. Motor fault diagnosis based on short-time fourier transform and convolutional neural network[J]. Chinese Journal of Mechanical Engineering, 2017, 30(6): 1357-1368. |

| 12 | Li G Q, Deng C, Wu J, et al. Sensor data-driven bearing fault diagnosis based on deep convolutional neural networks and s-transform[J]. Sensors, 2019, 19(12): 2750-2764. |

| 13 | Ding X X, He Q B. Energy-fluctuated multiscale feature learning with deep convnet for intelligent spindle bearing fault diagnosis[J]. IEEE Transactions on InStrumentation and Measurement, 2017, 66(8): 1926-1935. |

| 14 | Xia M, Li T, Xu L, et al. Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks[J]. IEEE/ASME Transactions on Mechatronics, 2018, 23(1): 101-110. |

| 15 | 吴晨芳, 杨世锡, 黄海舟, 等. 一种基于改进的LeNet-5模型滚动轴承故障诊断方法研究[J]. 振动与冲击, 2021, 40(12): 55-61. |

| Wu Chen-fang, Yang Shi-xi, Huang Hai-zhou, et al. Research on a fault diagnosis method of rolling bearing based on improved lenet-5 model[J]. Vibration and Shock, 2021,40(12): 55-61. | |

| 16 | 曲建岭, 余路, 袁涛, 等. 基于一维卷积神经网络的滚动轴承自适应故障诊断算法[J]. 仪器仪表学报, 2018, 39(7): 134-143. |

| Qu Jian-ling, Yu Lu, Yuan Tao, et al. Adaptive fault diagnosis algorithm of rolling bearing based on one-dimensional convolutional neural network[J]. Journal of Instrumentation, 2018, 39(7): 134-143. | |

| 17 | 宫文峰, 陈辉, 张美玲, 等. 基于深度学习的电机轴承微小故障智能诊断方法[J]. 仪器仪表学报, 2020, 41(1): 195-205. |

| Gong Wen-feng, Chen Hui, Zhang Mei-ling, et al. Intelligent fault diagnosis method of motor bearing based on deep learning[J]. Journal of Instrumentation, 2020, 41(1): 195-205. | |

| 18 | Li X Y, Li J L, Zhao C Y, et al. Gear pitting fault diagnosis with mixed operating conditions based on adaptive 1D separable convolution with residual connection[J]. Mechanical Systems and Signal Processing, 2020, 142: 106740. |

| 19 |

邓飞跃, 吕浩洋, 顾晓辉, 等. 基于轻量化神经网络Shuffle-SENet的高速动车组轴箱轴承故障诊断方法[J]. 吉林大学学报: 工学版. DOI: 10.13229/j.cnki.jdxbgxb20210644.

doi: 10.13229/j.cnki.jdxbgxb20210644 |

|

Deng Fei-yue, Hao-yang Lyu, Gu Xiao-hui, et al. High-speed locomotive set axle box bearing troubleshooting method based on lightweight neural network Shuffle-SENet[J]. Journal of Jilin University(Engineering and Technology Edition). DOI: 10.13229/j.cnki.jdxbgxb20210644.

doi: 10.13229/j.cnki.jdxbgxb20210644 |

|

| 20 | Lu S, Qian G, He Q, et al. In situ motor fault diagnosis using enhanced convolutional neural network in an embedded system[J]. IEEE Sensors Journal, 2020, 20(15): 8287-8296. |

| 21 | He K, Zhang X, Ren S, et al. Deep residual learning for image recognition[C]∥Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, 2016: 770-778. |

| 22 | 赵敬娇, 赵志宏, 杨绍普. 基于残差连接和1D-CNN的滚动轴承故障诊断研究[J]. 振动与冲击, 2021, 40(10): 1-6. |

| Zhao Jing-jiao, Zhao Zhi-hong, Yang Shao-pu. Research on fault diagnosis of rolling bearing based on residual connection and 1D-CNN[J]. Vibration and Shock, 2021, 40(10): 1-6. | |

| 23 | 董绍江, 裴雪武, 吴文亮, 等. 改进抗干扰CNN的变负载滚动轴承损伤程度识别[J]. 振动,测试与诊断, 2021, 41(4): 715-722, 831. |

| Dong Shao-jiang, Pei Xue-wu, Wu Wen-liang, et al. Identification of damage degree of variable load rolling bearing based on improved anti-interference CNN[J]. Vibration, Test and Diagnosis, 2021, 41(4): 715-722, 831. | |

| 24 | Ioffe S, Szegedy C. Batch normalization: accelerating deep network training by reducing internal covariate shift[C]∥International Conference on International Conference on Machine Learning, Miami, 2015: 448-456. |

| 25 | Lin M, Chen Q, Yan S C. Network in network[C]∥International Conference on Learning Representations, Vancouver, Canada, 2014: 1-10. |

| [1] | 郭继昌,吴洁,郭春乐,朱明辉. 基于残差连接卷积神经网络的图像超分辨率重构[J]. 吉林大学学报(工学版), 2019, 49(5): 1726-1734. |

| [2] | 宋大凤, 李广含, 张琳, 潘冰, 曾小华, 彭宇君, 王庆年. 模糊逻辑在混合动力汽车电机故障检测中的应用[J]. 吉林大学学报(工学版), 2016, 46(2): 354-359. |

| [3] | 马喜强,刘维亚,郑喜凤,程鹏. 非平稳多任务下的动态功耗管理随机策略[J]. 吉林大学学报(工学版), 2014, 44(3): 776-781. |

| [4] | 陈大伟, 刘海龙, 李金屏. 复杂静态背景下多移动目标实时检测系统的FPGA实现[J]. 吉林大学学报(工学版), 2013, 43(增刊1): 287-290. |

| [5] | 金玉善, 郭凯, 杨书范, 黄永平. 嵌入式系统测量中的指数平滑滤波新算法[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 314-316. |

| [6] | 周宝余, 臧雪柏, 赵浩宇, 包环宇. 基于QT的无线多路视频监控系统[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 204-207. |

| [7] | 曲良东, 刘衍珩, 魏达. 基于VPN的车载网关异构无线网络切换系统[J]. 吉林大学学报(工学版), 2010, 40(05): 1292-1297. |

| [8] | 李秀红,黄天戍,孙忠富,肖春华 . 基于GPRS/SMS的嵌入式环境监测系统[J]. 吉林大学学报(工学版), 2007, 37(06): 1409-1414. |

| [9] | 张海涛,艾云峰 . 基于Petri网的分布式实时嵌入式系统的调度分析[J]. 吉林大学学报(工学版), 2007, 37(03): 616-0620. |

| [10] | 刘久富,杨忠,孙德敏,李志宇. 基于模型的飞行控制软件测试用例的生成[J]. 吉林大学学报(工学版), 2006, 36(04): 543-547. |

| [11] | 辛华峰, 于 枫, 谭 健,王文丽. 嵌入式USB主/从机应用模块[J]. 吉林大学学报(工学版), 2005, 35(02): 166-0169. |

| [12] | 赵宏伟, 陈鹏, 刘大有, 王庆年. 混合动力汽车多能源动力总成嵌入式系统[J]. 吉林大学学报(工学版), 2003, (3): 35-37. |

|

||