吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (6): 1669-1676.doi: 10.13229/j.cnki.jdxbgxb.20230075

• 交通运输工程·土木工程 • 上一篇

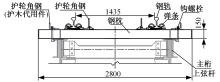

拆装式桁梁新型钢枕桥面竖向荷载分配机制

孙志星1,2( ),陈士通1,2(

),陈士通1,2( ),赵曼3,许宏伟3,陈哲心4

),赵曼3,许宏伟3,陈哲心4

- 1.石家庄铁道大学 省部共建交通工程结构力学行为与系统安全国家重点实验室,石家庄 050043

2.石家庄铁道大学 安全工程与应急管理学院,石家庄 050043

3.石家庄铁道大学 土木工程学院,石家庄 050043

4.济南金曰公路工程有限公司,济南 250101

Vertical load distribution mechanism of new steel sleeper bridge deck used for assembled truss beam

Zhi-xing SUN1,2( ),Shi-tong CHEN1,2(

),Shi-tong CHEN1,2( ),Man ZHAO3,Hong-wei XU3,Zhe-xin CHEN4

),Man ZHAO3,Hong-wei XU3,Zhe-xin CHEN4

- 1.State Key Laboratory of Mechanical Behavior and System Safety of Traffic Engineering Structures,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

2.School of Safety Engineering and Emergency Management,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

3.School of Civil Engineering,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

4.Jinan Kingyue Highway Engineering Company Limited,Jinan 250101,China

摘要:

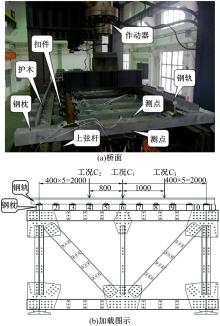

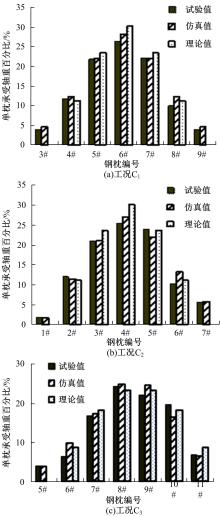

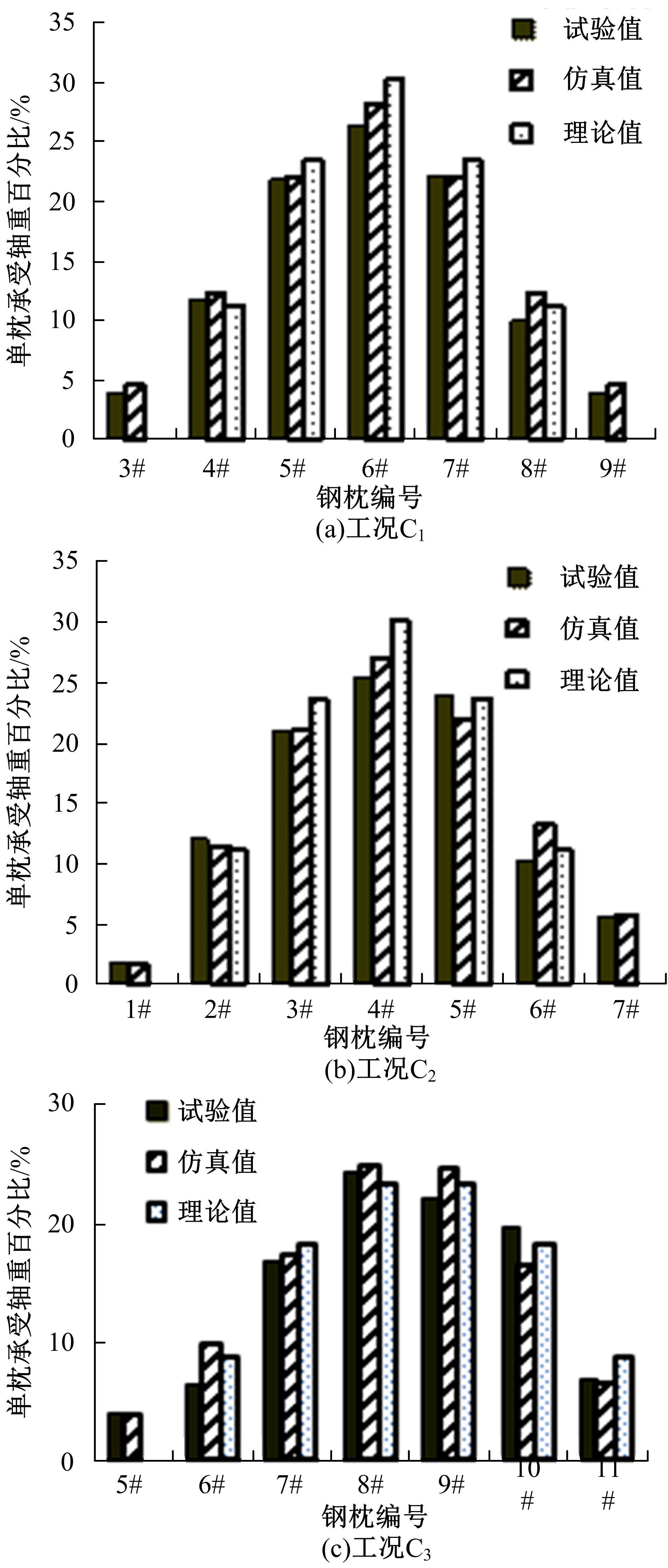

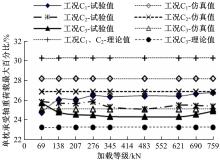

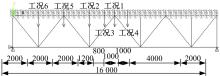

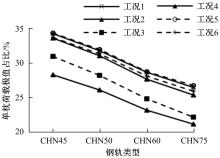

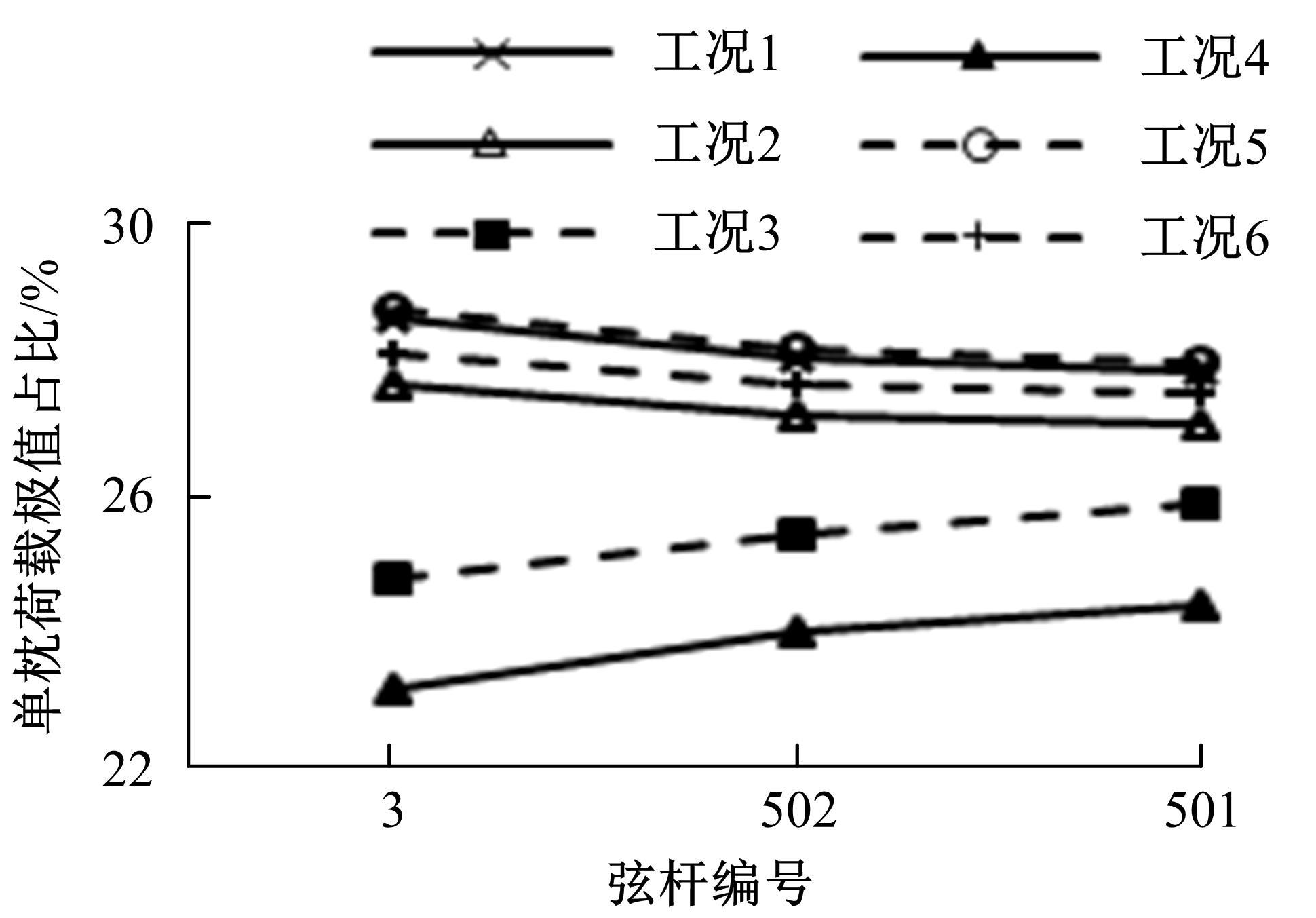

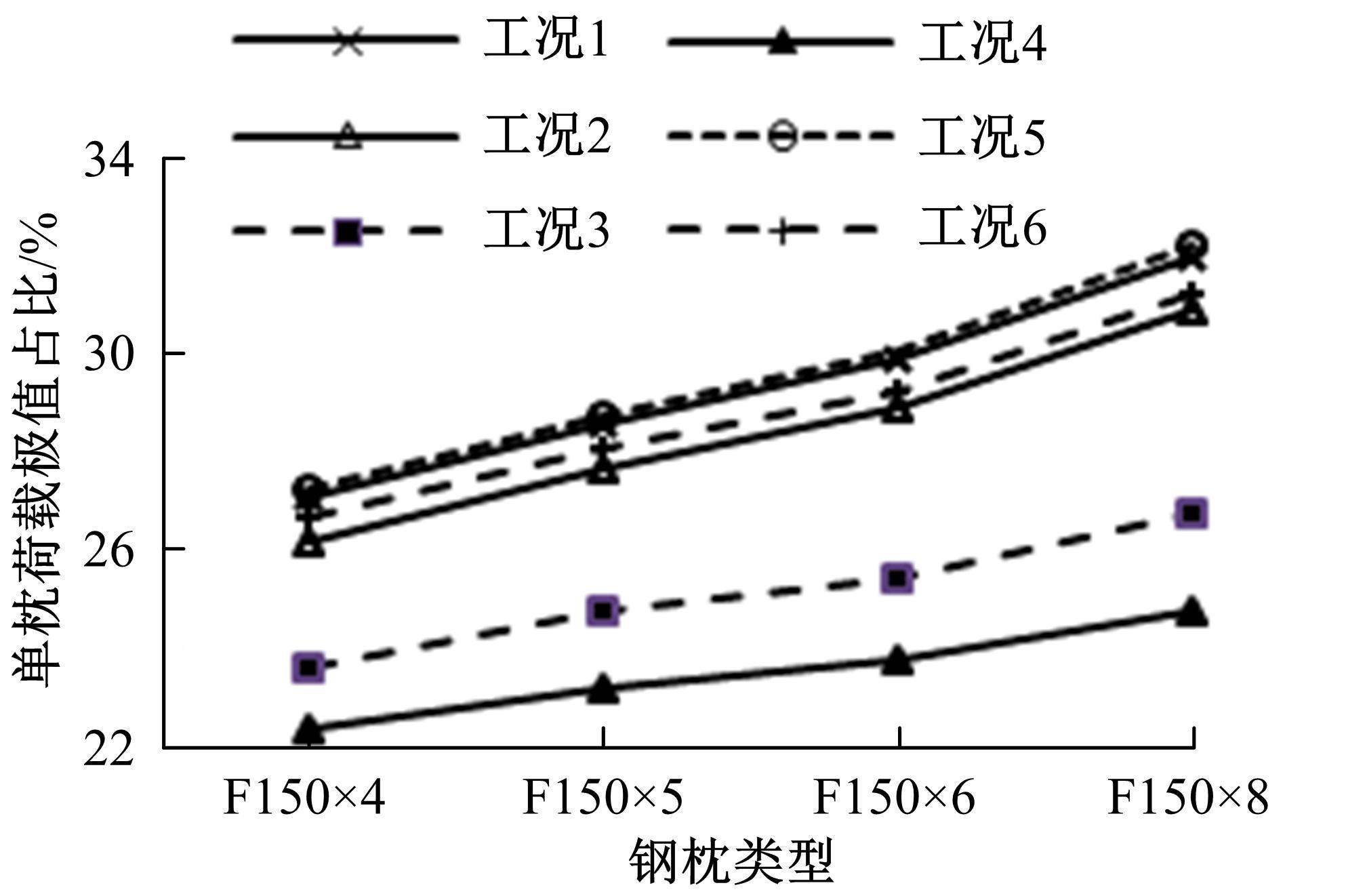

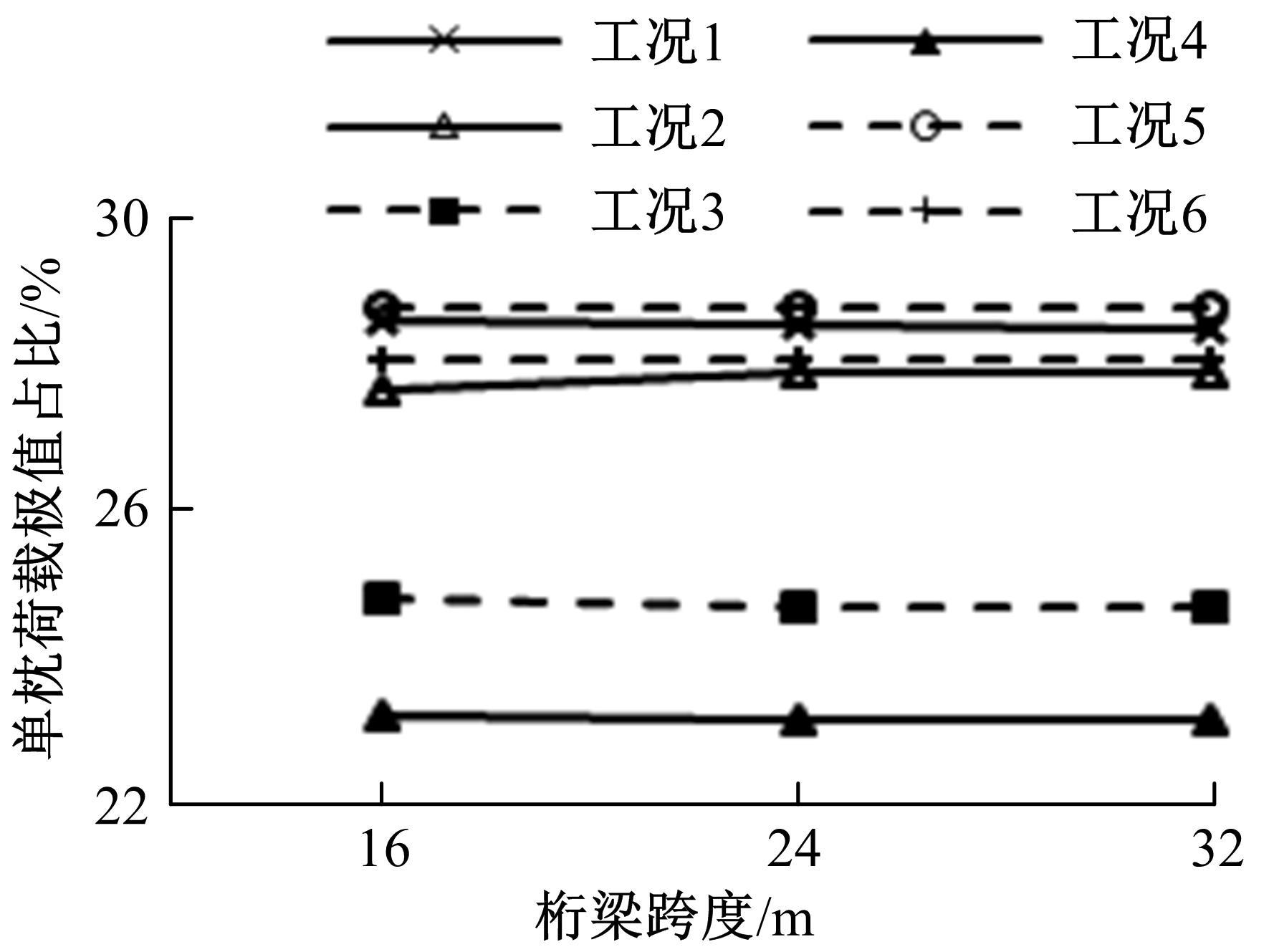

为解决拆装式桁梁既有桥面木枕储备量严重不足、制约其应急使用的问题,研发了一种新型钢枕桥面。为探明新型钢枕桥面用于拆装式桁梁时的竖向荷载分配机制,开展了4 m节段足尺试验及有限元仿真分析研究,在仿真和试验对比研究的基础上,基于实桥有限元模型探讨了加载位置、钢轨刚度、弦杆刚度、钢枕刚度、桁梁竖向刚度等因素对竖向荷载分配的影响规律。结果表明:竖向荷载在钢枕上的实际分布范围较理论计算值大;位于弦杆节点位置的钢枕较位于节间位置的钢枕所承受的荷载比例要大,且支撑刚度越大,所分担的荷载比例越大;单枕荷载极值占比随钢轨刚度的增大而减小,随钢枕刚度的增大而增大,而与桥跨结构竖向刚度关系很小;桁架梁弦杆刚度增大会减弱加载位置对单枕荷载极值占比的影响。新型钢枕可适用于拆装式桁梁对我国铁路常用钢轨线路中16~32 m跨桥梁进行抢通等应急使用的桥面,为拆装式桁梁的抢修抢险提供基础设施保障,并可提高抢通速度。

中图分类号:

- U213.3

| 1 | 曾志斌. 既有铁路木枕替代材料的研究现状及发展趋势[J]. 铁道建筑, 2016(8): 1-9. |

| Zeng Zhi-bin. Research status and development trend of alternative materials of exiting wooden sleepers[J]. Railway Engineering, 2016(8): 1-9. | |

| 2 | 井国庆, 杜文博, 付琪璋. 特殊功能轨枕种类及应用[J]. 中国铁路, 2021(5): 98-102. |

| Jing Guo-qing, Du Wen-bo, Fu Qi-zhang. Types and application of sleepers with special functions[J]. China Railway, 2021(5): 98-102. | |

| 3 | Parvez A, Foster S J. Fatigue of steel-fibre-reinforced concrete prestressed railway[J]. Engineering Structures, 2017(141): 241-250. |

| 4 | Pachideh G, Gholhaki M. Using steel and polypropylene fibres to improve the performance of concrete sleepers[J]. Proceedings of the Institution of Civil Engineers—Structures and Buildings, 2020, 173(9): 690-702. |

| 5 | 刘玉祥, 管吉波, 左一舟, 等. 一种新型钢筋桁架轨枕技术的研究[J]. 铁道工程学报, 2016(12): 88-92, 98. |

| Liu Yu-xiang, Guan Ji-bo, Zuo Yi-zhou, et al. Technical study of a new type of steel bar truss sleeper[J]. Journal of Railway Engineering Society, 2016(12): 88-92, 98. | |

| 6 | 陈成, 李建峰, 段永达, 等. 一种可调间距的X型抗滑动轨枕[P]. 中国: 01910091734.8, 2019-05-07. |

| 7 | 邵壮, 孙井林, 陈学振, 等. 新型臂展式轨枕和Ⅲc型轨枕横向阻力试验和仿真研究[J]. 铁道勘察, 2022(5): 100-103, 124. |

| Shao Zhuang, Sun Jing-lin, Chen Xue-zhen, et al. Experimental and simulation study on the ballast bed lateral resistance of new arm-spread-type sleeper and standard IIIc sleeper[J]. Railway Investigation and Surveying, 2022(5): 100-103, 124. | |

| 8 | 庞玲, 强伟乐, 周强, 等. 新型钢枕道床横向阻力试验与分析[J]. 铁道工程学报, 2020(2): 40-45. |

| Pang Ling, Qiang Wei-le, Zhou Qiang, et al. Test and analysis of lateral resistance of innovated steel sleeper[J]. Journal of Railway Engineering Society, 2020(2): 40-45. | |

| 9 | 张鹏飞, 朱勇, 雷晓燕. 新型钢枕轨道结构受力特性影响因素分析[J]. 铁道标准设计, 2019, 63(9): 1-5. |

| Zhang Peng-fei, Zhu Yong, Lei Xiao-yan. Analysis of influence factors on mechanical characteristics of new steel sleeper track structure[J]. Railway Standard Design, 2019, 63(9): 1-5. | |

| 10 | 李保龙, 曾志斌, 王冬立, 等. 新型明桥面在重载铁路钢梁上的应用[J]. 铁道建筑, 2021, 61(3): 42-45. |

| Li Bao-long, Zeng Zhi-bin, Wang Dong-li, et al. Application of new type open deck on steel girder of heavy haul railway[J]. Railway Engineering, 2021, 61(3): 42-45. | |

| 11 | 井国庆, 杜文博, 尤瑞林, 等. 基于DIC 混凝土轨枕和复合轨枕受弯特征分析[J]. 铁道科学与工程学报, 2021, 18(1): 64-70. |

| Jing Guo-qing, Du Wen-bo, You Rui-lin, et al. Analysis of bending characteristics of FFU composite sleeper and concrete sleeper based on digital image correlation[J]. Journal of Railway Science and Engineering, 2021, 18(1): 64-70. | |

| 12 | 曾志斌. 纤维增强复合材料轨枕的技术参数和试验方法[J]. 铁道建筑, 2021, 61(2): 107-112, 121. |

| Zeng Zhi-bin. Technical parameters and test methods of sleepers made of fiber reinforced polymer[J]. Railway Engineering, 2021, 61(2): 107-112, 121. | |

| 13 | 孙孝红, 肖林, 李俊, 等. 明桥面木枕受力分析[J]. 铁道建筑, 2007(2): 82-83. |

| Sun Xiao-hong, Xiao Lin, Li Jun, et al. Load analysis of wooden sleeper on open deck of bridge[J]. Railway Engineering, 2007(2): 82-83. |

| No related articles found! |

|

||