吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1221-1227.doi: 10.13229/j.cnki.jdxbgxb20180703

• • 上一篇

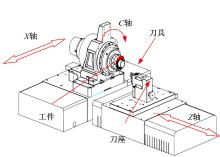

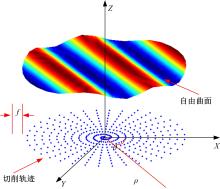

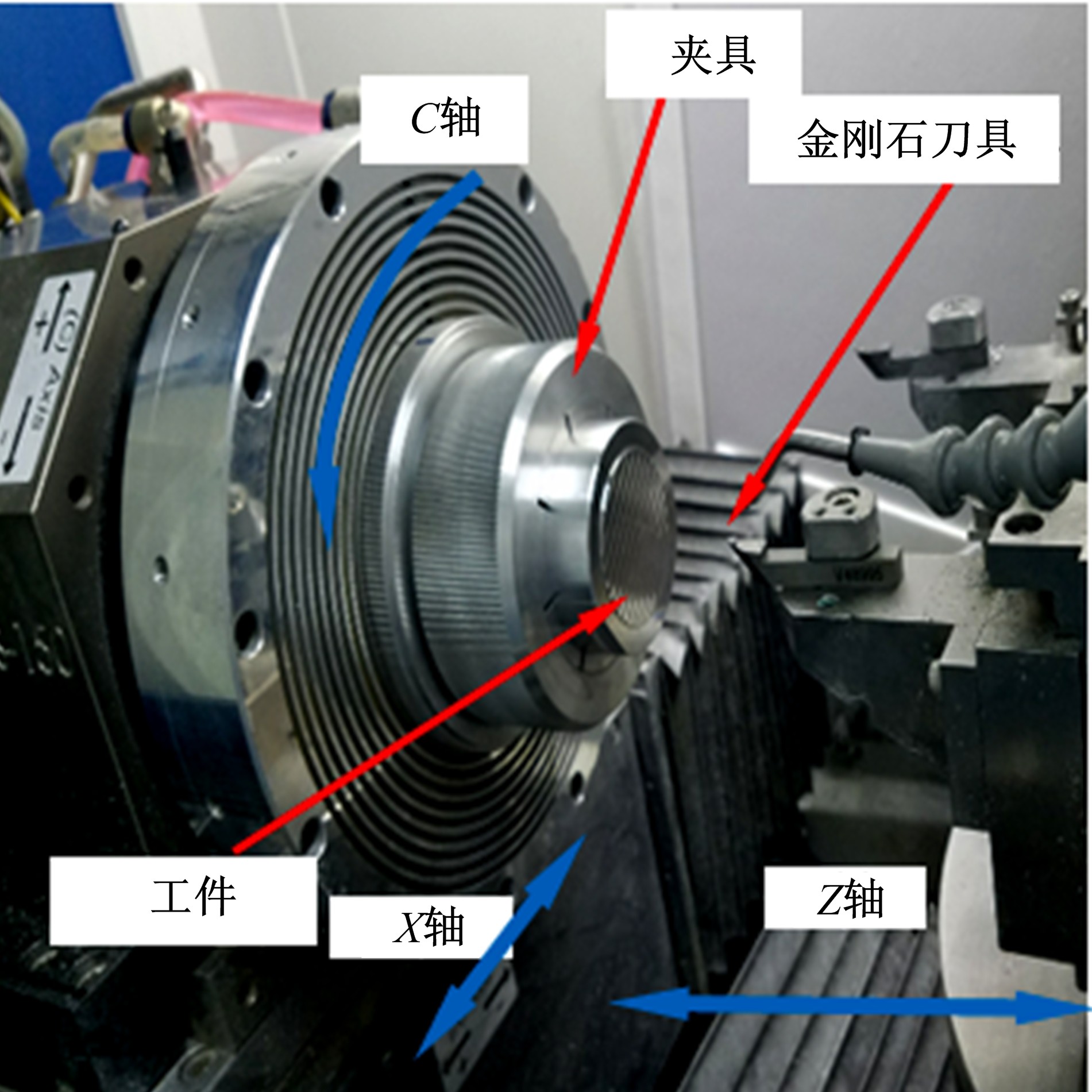

主动控制加工误差慢刀伺服车削轨迹生成方法

- 长春理工大学 机电工程学院,长春 130022

Tool path generation of slow tool servo for active control machining error

- College of Mechanical and Electric Engineering,Changchun University of Science and Technology,Changchun 130022,China

摘要:

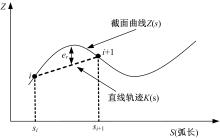

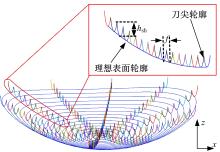

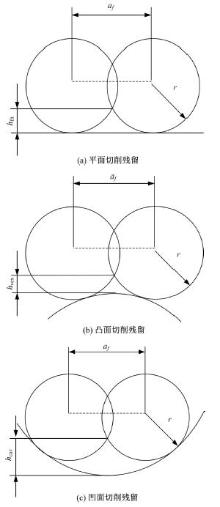

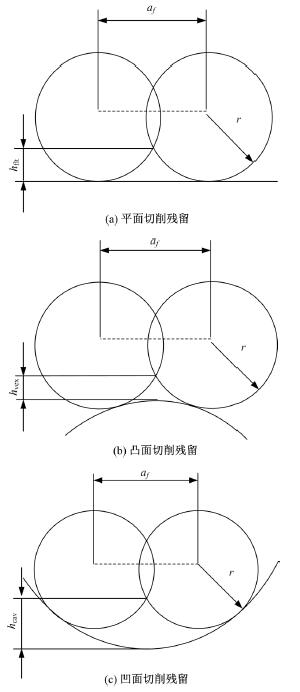

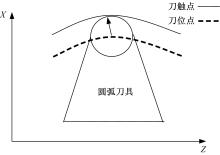

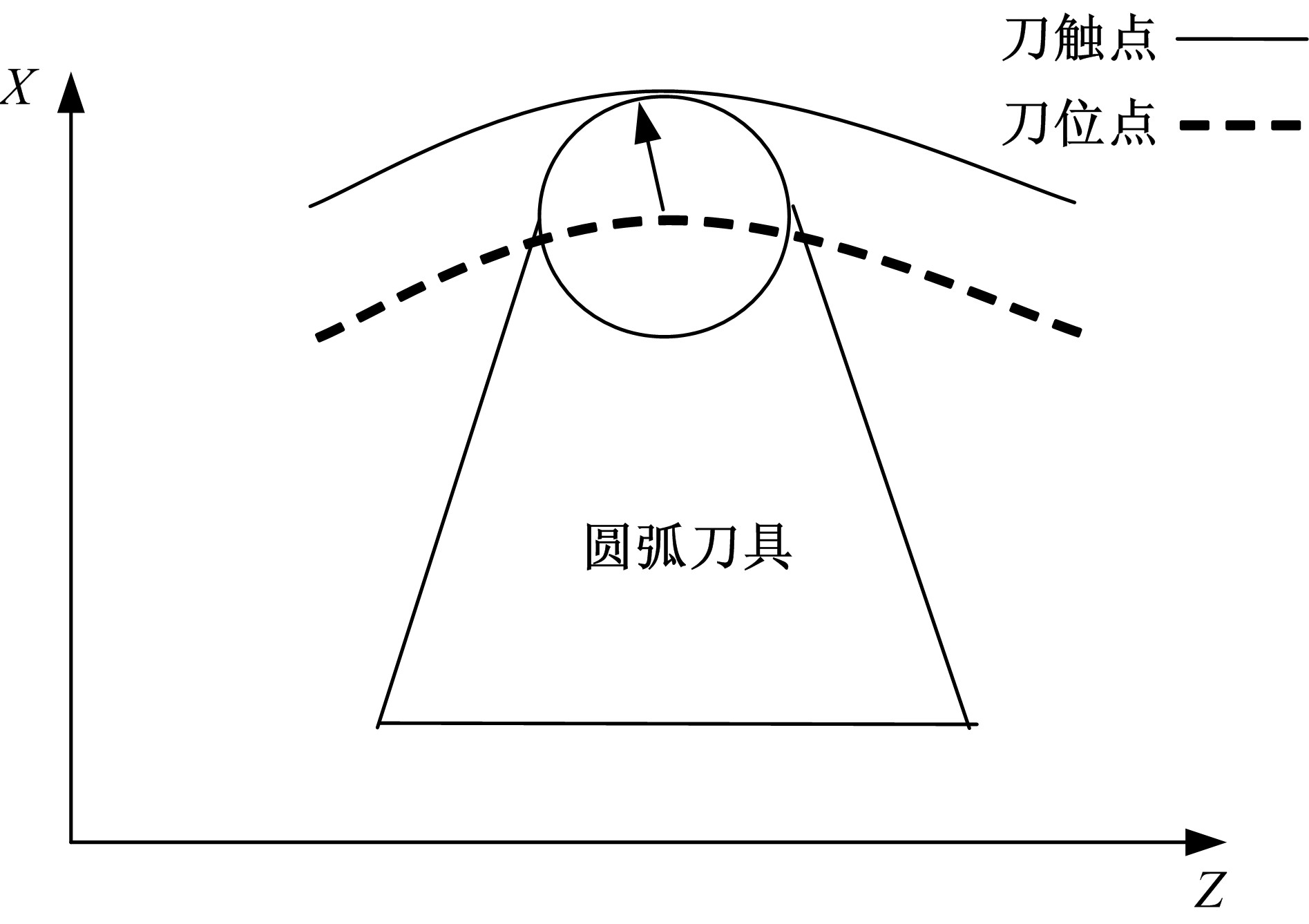

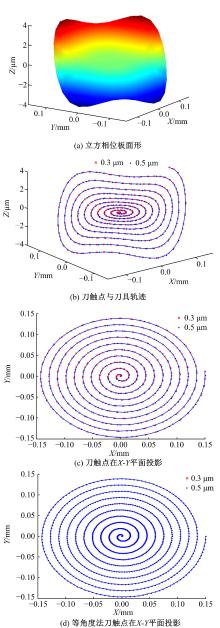

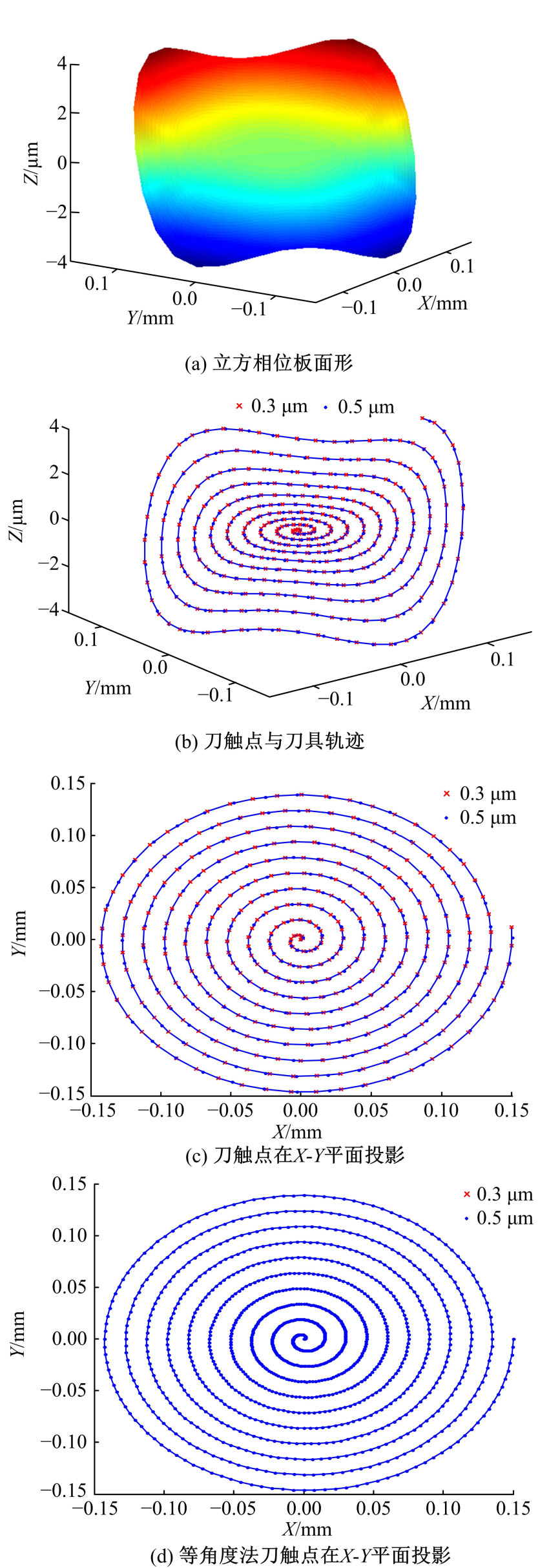

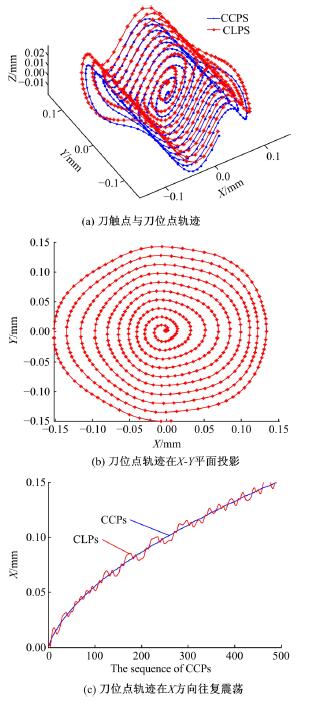

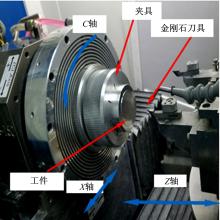

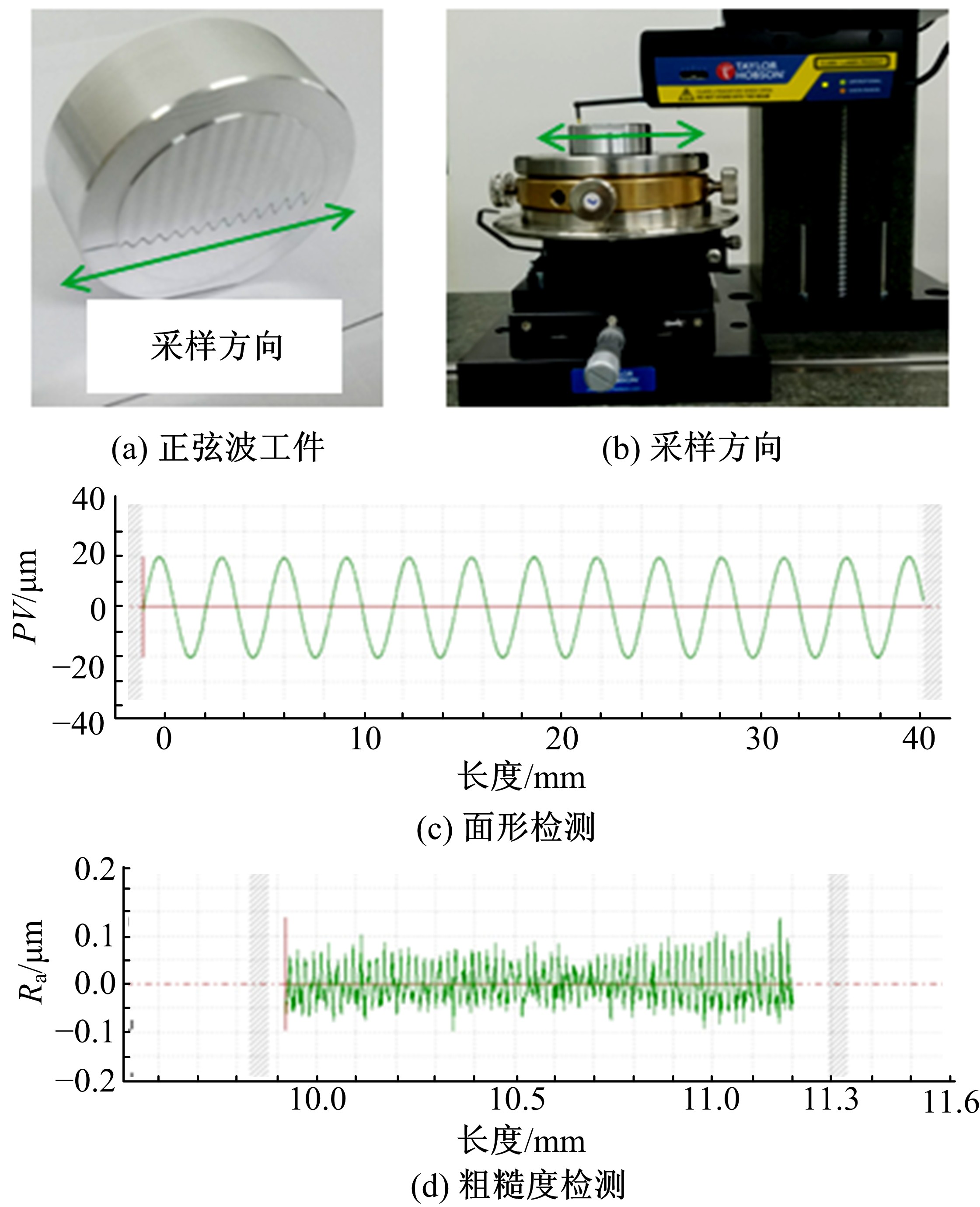

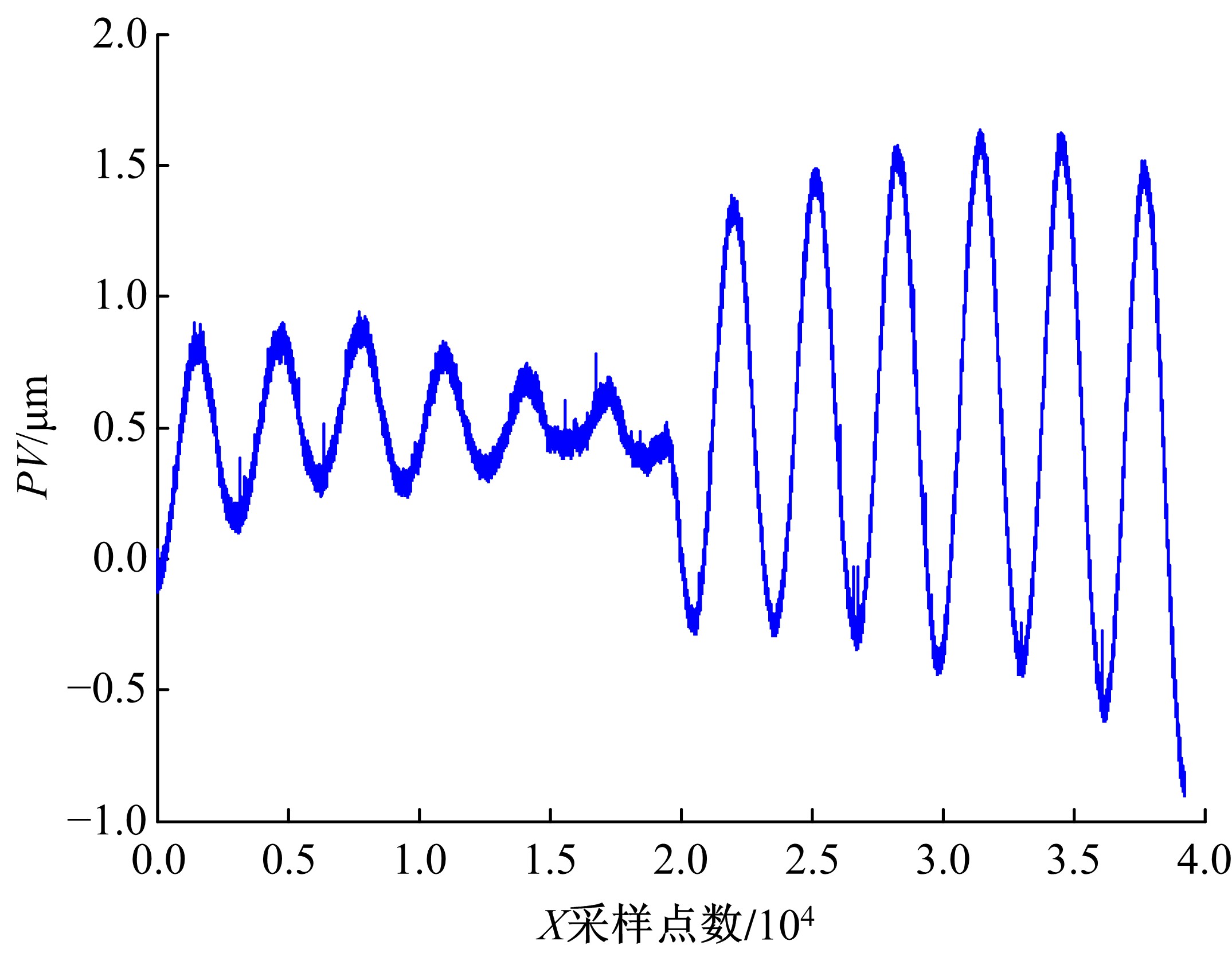

考虑到光学自由曲面慢速刀具伺服车削缺乏切削轨迹点选取位置和数量的依据,提出了主动控制加工误差的刀具路径生成方法。进行了刀触点、刀位点轨迹分析和慢刀伺服车削正弦波面试验,结果表明,本文方法可以预测加工表面精度并可以显著降低切削点数量。

中图分类号:

- TH161

| 1 | 周晓勤, 侯强, 刘强, 等 . 微纳结构几何特征检测技术的研究现状与发展趋势[J]. 北京工业大学学报, 2015, 41(3): 327⁃339. |

| Zhou Xiao⁃qin , Hou Qiang , Liu Qiang , et al . Research status and tendency of measurement techniques for geometric features of micro/nano structures[J]. Journal of Beijing University of Technology, 2015, 41(3): 327⁃339. | |

| 2 | 樊成, 赵继, 张雷, 等 . 移动抛光自由曲面材料去除的理论建模与试验研究[J]. 机械工程学报, 2014, 50(5): 173⁃181. |

| Fan Cheng , Zhao Ji , Zhang Lei , et al . Modeling and experimental study on the material removal in the velocity⁃dwell⁃mode polishing process[J]. Journal of Mechanical Engineering, 2014, 50(5): 173⁃181. | |

| 3 | 刘源, 曹喜滨, 王永章, 等 . 具有自光顺功能的五坐标样条插补控制器[J]. 吉林大学学报: 工学版, 2011, 41(4): 1010⁃1014. |

| Liu Yuan , Cao Xi⁃bin , Wang Yong⁃zhang , et al . Spline interpolation controller with fairing function for five⁃axis machining[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(4): 1010⁃1014. | |

| 4 | 王兴盛, 康敏 . 基于Hermite插值的复杂光学曲面车削加工路径规划[J]. 机械工程学报, 2012, 48(11): 191⁃198. |

| Wang Xing⁃sheng , Kang Min . Cutting path planning for complex optical surface using hermite interpolation[J]. Journal of Mechanical Engineering, 2012, 48(11): 191⁃198. | |

| 5 | 车翔玖, 刘大有, 王钲旋 . 两张 NURBS 曲面间G1光滑过渡曲面的构造[J]. 吉林大学学报: 工学版, 2007, 37(4): 838⁃841. |

| Che Xiang⁃jiu , Liu Da⁃you , Wang Zheng⁃xuan . Construction of joining surface with G1 continuity for two NURBS surfaces[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(4): 838⁃841. | |

| 6 | Chrisp M P , Primeau B , Echter M A . Imaging freeform optical systems designed with NURBS surfaces[J]. Optical Engineering, 2016, 55(7): 071208. |

| 7 | 李荣彬, 张志辉, 杜雪, 等 . 自由曲面光学的超精密加工技术及其应用[J]. 红外与激光工程, 2010, 39(1): 110⁃115. |

| Li Rong⁃bin , Zhang Zhi⁃hui , Du Xue , et al . Ultra⁃precision machining technology of freeform optics and its applications[J]. Infrared and Laser Engineering, 2010, 39(1): 110⁃115. | |

| 8 | 田欣, 丁辉, 程凯 . 光学自由曲面机床检测系统静态几何误差快速辨识方法研究[J]. 航空精密制造技术, 2018(3): 11⁃15. |

| Tian Xin , Ding Hui , Cheng Kai . Swift identification method for identifying static geometric errors of ultraprecision machine tool[J]. Aviation Precision Manufacturing Technology, 2018(3): 11⁃15. | |

| 9 | 姚红兵, 丁勇, 辛忠华, 等 . 独立自由曲面LED汽车前雾灯的光学设计[J]. 应用光学, 2018, 39(3):423⁃428. |

| Yao Hong⁃bing , Ding Yong , Xin Zhong⁃hua , et al . Optical design of independent freeform surface LED automotive front fog lamp[J]. Journal of Applied Optics, 2018, 39(3): 423⁃428. | |

| 10 | Tan Gao⁃shan , Zhang Li⁃yuan , Liu Sheng⁃lan , et al . A fast and differentiated localization method for complex surfaces inspection[J]. International Journal of Precision Engineering and Manufacturing, 2015, 16(13): 2631⁃2639. |

| 11 | Kawabata K , Tanaka F , Onosato M . A study on tool path generation for freeform surface by iso⁃scallop strategy using tensor analysis[C]∥JSPE Semestrial Meeting, Osaka, Japan, 2017. |

| 12 | Yang T , Zhu J , Wu X F , et al . Direct design of freeform surfaces and freeform imaging systems with a point⁃by⁃point three⁃dimensional construction⁃iteration method[J]. Optics Express, 2015, 23(8): 10233⁃10246. |

| 13 | Yu D P , Gan S W , Wong Y S , et al . Optimized tool path generation for fast tool servo diamond turning of micro⁃structured surfaces[J]. International Journal of Advanced Manufacturing Technology, 2012, 63(9): 1137⁃1152. |

| 14 | Wang Xing⁃sheng , Fu Xiu⁃qing , Li Chun⁃lin , et al . Tool path generation for slow tool servo turning of complex optical surfaces[J]. The International Journal of Advanced Manufacturing Technology, 2015, 79(1): 437⁃448. |

| 15 | Ji Shi⁃jun , Yu Hui⁃juan , Zhao Ji , et al . Ultra⁃precision machining of a large amplitude sinusoidal ring surface based on slow tool servo[J]. Strojniski Vestnik, 2016, 62(4): 213⁃219. |

| 16 | Neo D W K , Kumar A S , Rahman M . A novel surface analytical model for cutting linearization error in fast tool/slow slide servo diamond turning[J]. Precision Engineering, 2014, 38(4): 849⁃860. |

| 17 | Kong L B , Cheung C F , To S , et al . A theoretical and experimental investigation of design and slow tool servo machining of freeform progressive addition lenses (PALs) for optometric applications[J]. International Journal of Advanced Manufacturing Technology, 2014, 72(1):33⁃40. |

| 18 | Liu Qiang , Zhou Xiao⁃qin , Xu Peng⁃zi . A new tool path for optical freeform surface fast tool servo diamond turning[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2014, 228(12): 1721⁃1726. |

| [1] | 郑玉彬, 杨斌, 王晓峰, 申桂香, 赵宪卓, 秦猛猛. 基于威布尔分布的电主轴加速寿命试验时间设计[J]. 吉林大学学报(工学版), 2018, 48(3): 767-772. |

| [2] | 申桂香, 曾文彬, 张英芝, 吴茂坤, 郑玉彬. 最小故障率下数控组合机床平均维修时间确定[J]. 吉林大学学报(工学版), 2017, 47(5): 1519-1526. |

| [3] | 曲兴田, 赵永兵, 刘海忠, 王昕, 杨旭, 陈行德. 串并混联机床几何误差建模与实验[J]. 吉林大学学报(工学版), 2017, 47(1): 137-144. |

| [4] | 张英芝, 刘津彤, 申桂香, 戚晓艳, 龙哲. 基于故障相关性分析的数控机床系统可靠性建模[J]. 吉林大学学报(工学版), 2017, 47(1): 169-173. |

| [5] | 孟书, 申桂香, 张英芝, 龙哲, 曾文彬. 基于时间相关的数控机床系统组件更换时间[J]. 吉林大学学报(工学版), 2016, 46(6): 1946-1952. |

| [6] | 李洪洲, 杨兆军, 许彬彬, 王彦鹍, 贾玉辉, 侯超. 数控机床可靠性评估试验周期设计[J]. 吉林大学学报(工学版), 2016, 46(5): 1520-1527. |

| [7] | 王健健, 冯平法, 张建富, 吴志军, 张国斌, 闫培龙. 卡盘定心精度建模及其保持特性与修复方法[J]. 吉林大学学报(工学版), 2016, 46(2): 487-493. |

| [8] | 杨兆军, 杨川贵, 陈菲, 郝庆波, 郑志同, 王松. 基于PSO算法和SVR模型的加工中心可靠性模型参数估计[J]. 吉林大学学报(工学版), 2015, 45(3): 829-836. |

| [9] | 王晓燕,申桂香,张英芝,孙曙光,戚晓艳,荣峰. 基于故障链的复杂系统故障相关系数建模[J]. 吉林大学学报(工学版), 2015, 45(2): 442-447. |

| [10] | 赵帼娟, 张雷, 卢磊, 韩飞飞, 赵继. 四轴抛光平台综合误差建模及分析[J]. 吉林大学学报(工学版), 2014, 44(6): 1676-1683. |

| [11] | 王继利, 杨兆军, 李国发, 朱晓翠. EM算法的多重威布尔可靠性建模[J]. 吉林大学学报(工学版), 2014, 44(4): 1010-1015. |

| [12] | 杨兆军,王继利,李国发,张新戈. 冲压机床可靠性增长的模糊层次分析预测方法[J]. 吉林大学学报(工学版), 2014, 44(3): 686-691. |

| [13] | 杨兆军, 杨川贵, 陈菲, 王东亮, 马帅, 刘博. 基于最小二乘算法和SVDUKF算法的电液伺服加载优化[J]. 吉林大学学报(工学版), 2014, 44(2): 392-397. |

| [14] | 陈传海, 杨兆军, 陈菲, 郝庆波, 许彬彬, 阚英男. 基于Bootstrap-Bayes的加工中心主轴可靠性建模[J]. 吉林大学学报(工学版), 2014, 44(01): 95-100. |

| [15] | 申桂香, 孟书, 张英芝, 戚小艳, 栾兰, 宋琪. 平均秩次法在子系统可靠性建模中的应用[J]. 吉林大学学报(工学版), 2014, 44(01): 101-105. |

|

||