吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1709-1717.doi: 10.13229/j.cnki.jdxbgxb20190611

• 交通运输工程·土木工程 • 上一篇

疏水性纳米白炭黑改性沥青及混合料的粘弹特性

- 1.长吉城际铁路有限责任公司, 长春 130021

2.吉林大学 交通学院, 长春 130022

Viscoelasticity of hydrophobic nano⁃silica modified asphalt and asphalt mixture

Zi-wen WANG1( ),Xue-dong GUO2,Wei GUO2,Meng-yuan CHANG2,Wen-ting DAI2(

),Xue-dong GUO2,Wei GUO2,Meng-yuan CHANG2,Wen-ting DAI2( )

)

- 1.Changji Intercity Railway Co. Ltd. , Changchun 130021, China

2.College of Transportation, Jilin University, Changchun 130022, China

摘要:

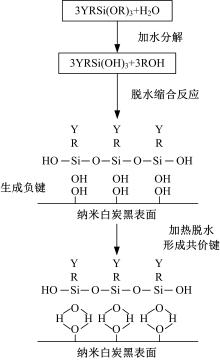

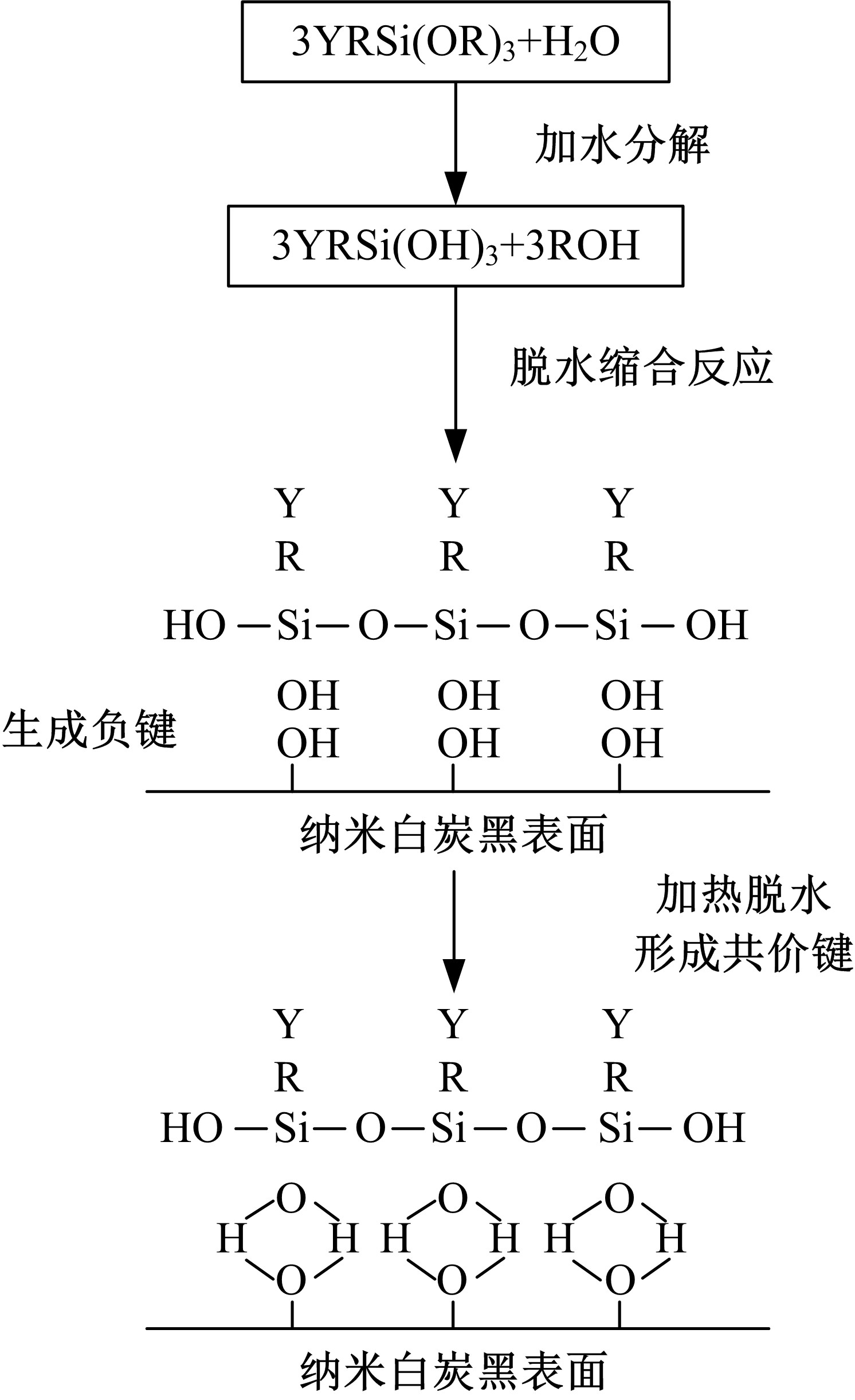

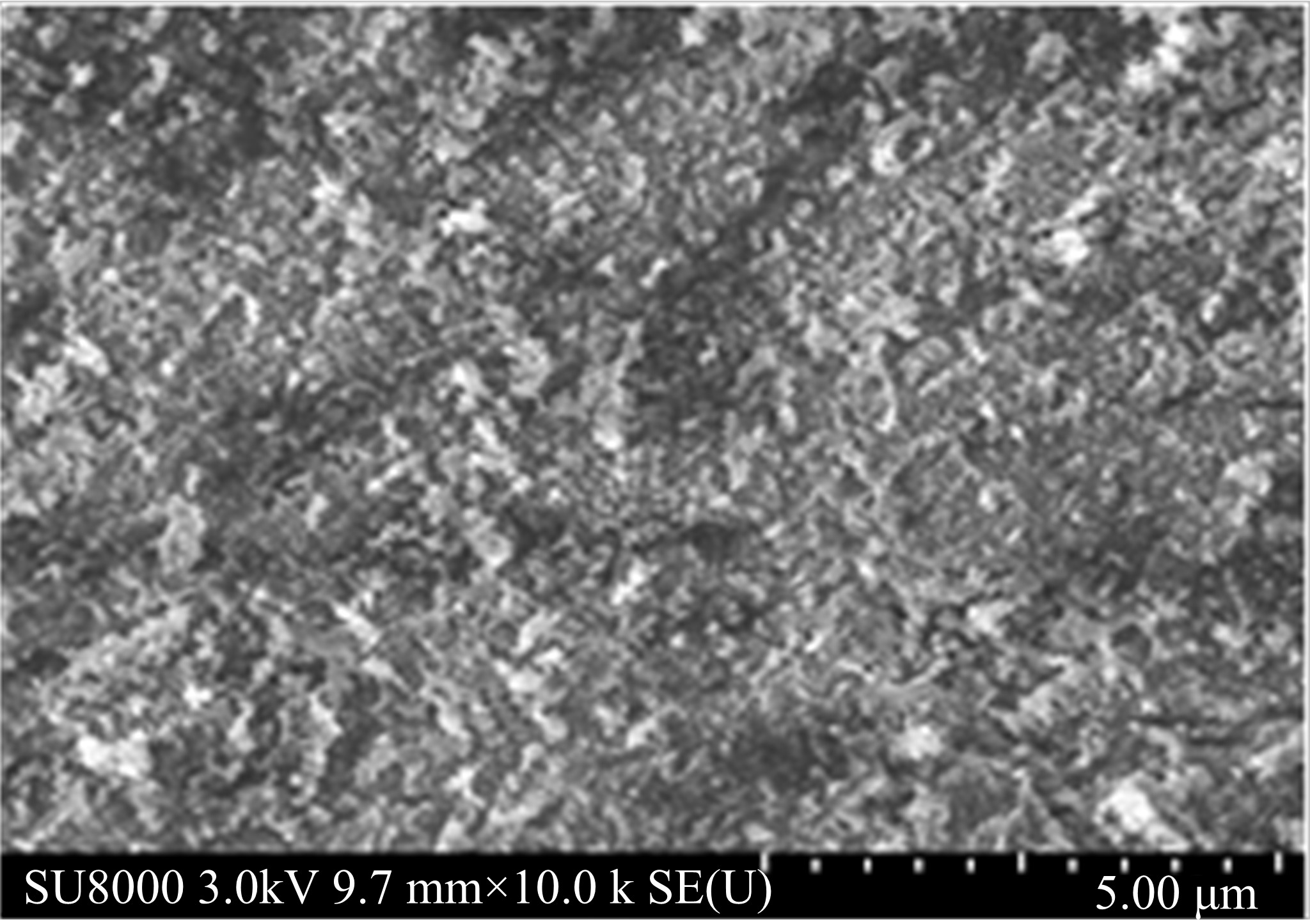

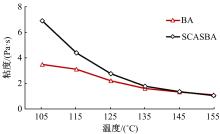

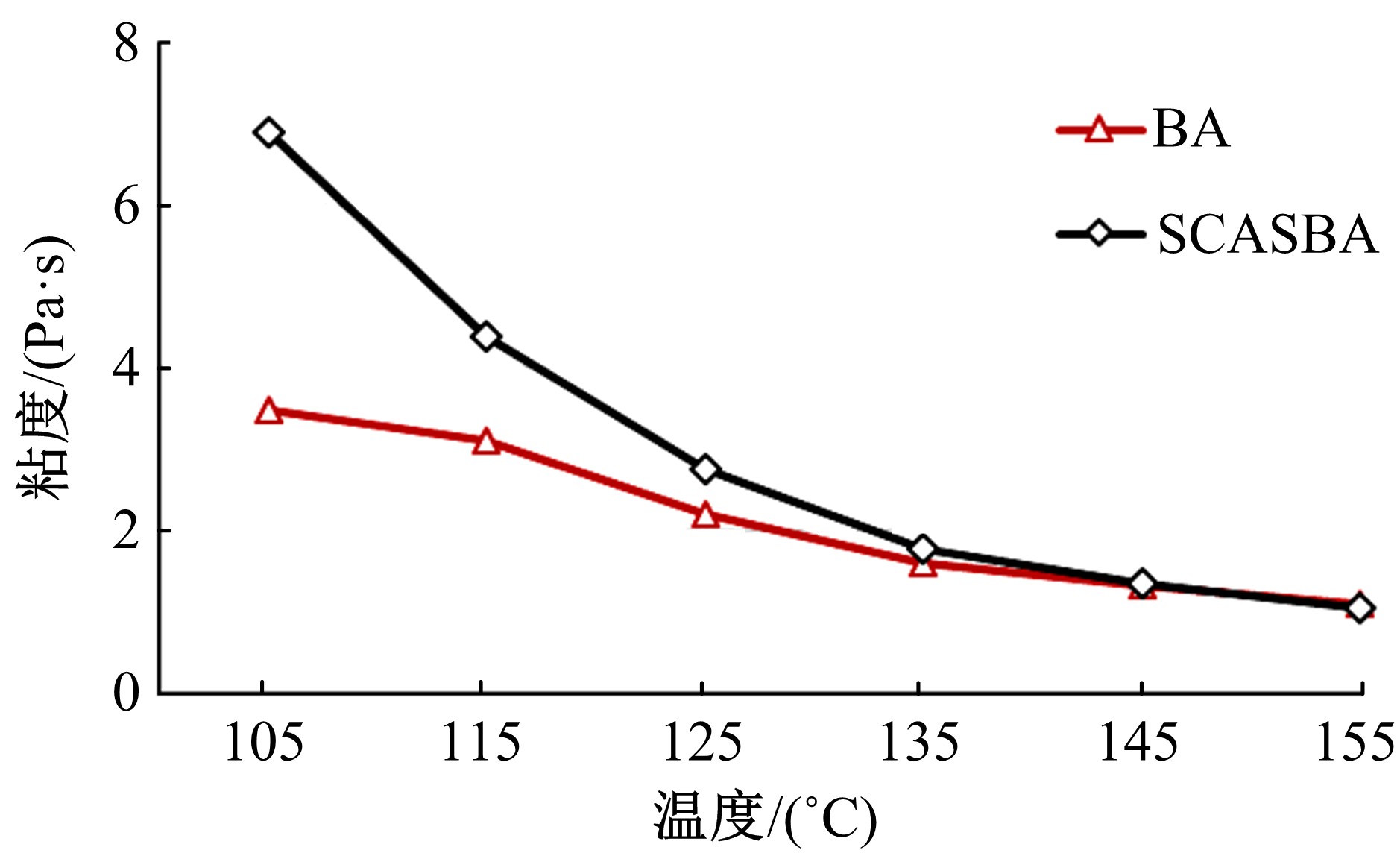

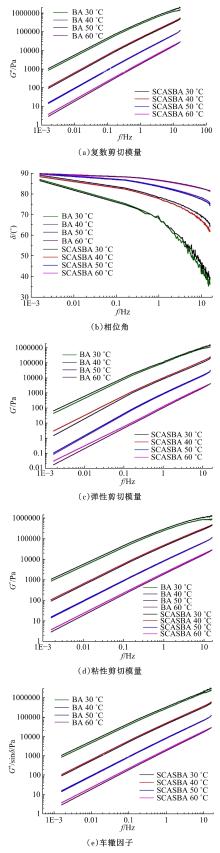

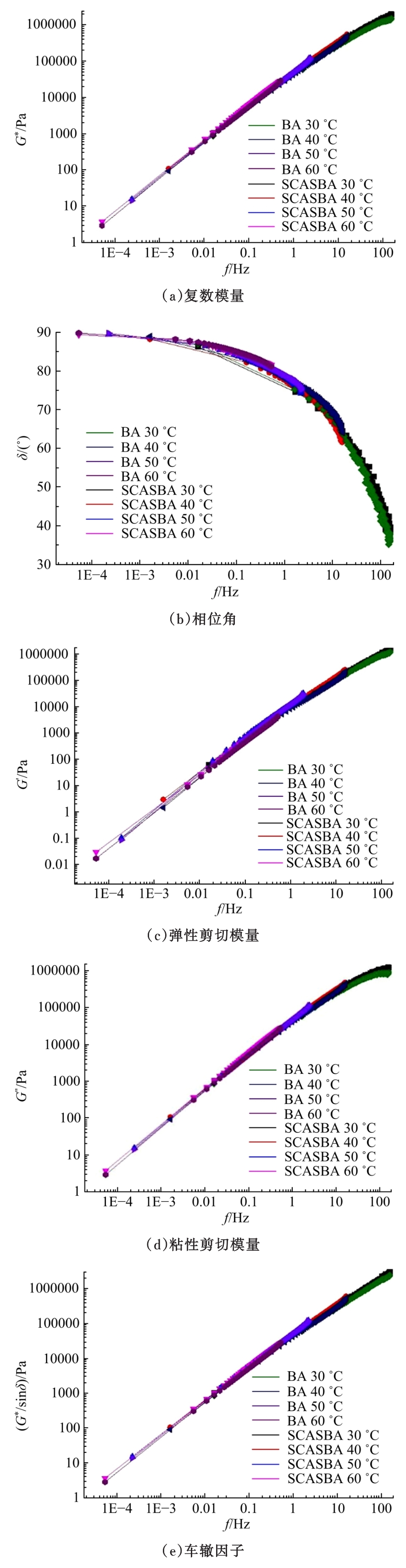

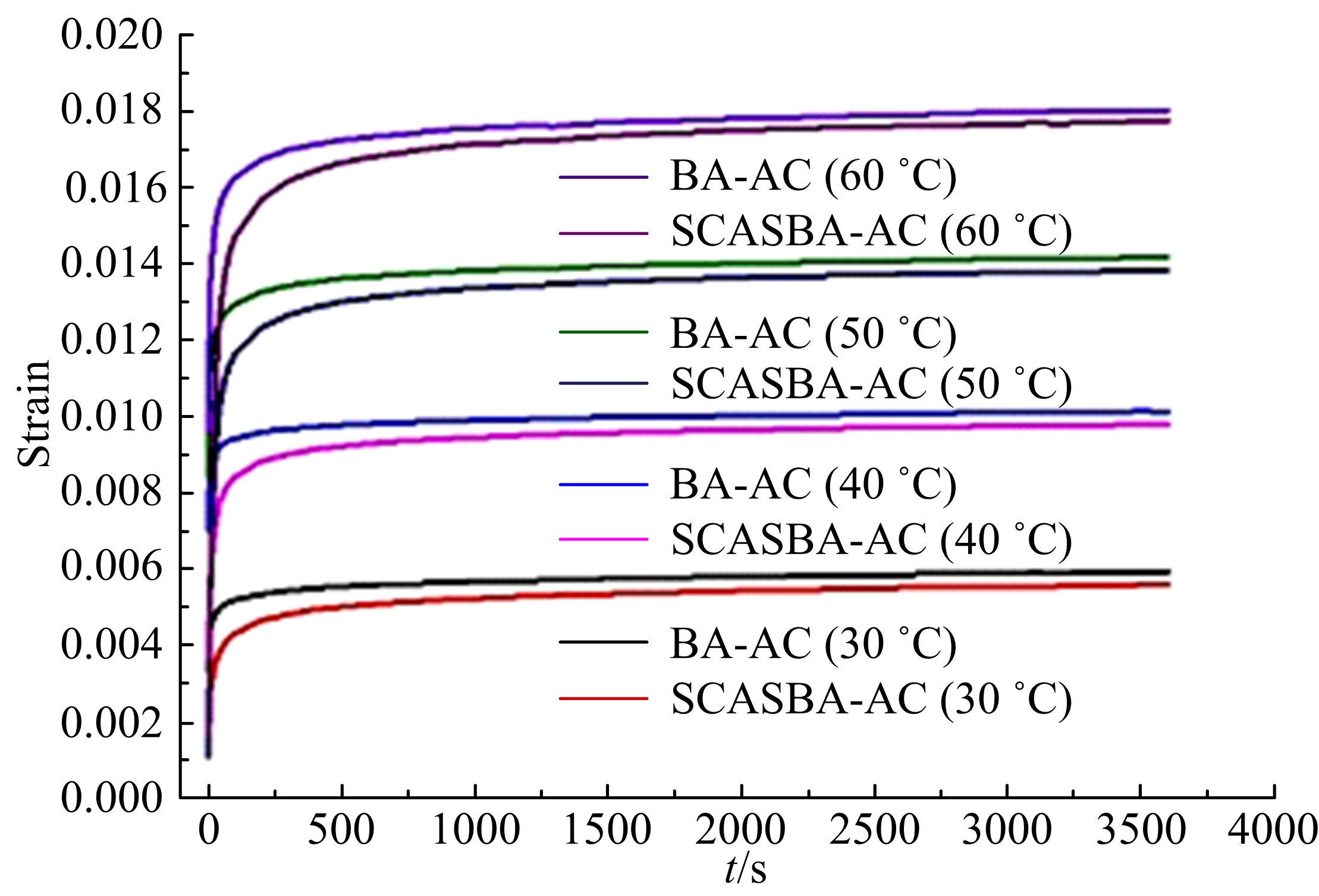

为研究疏水性纳米白炭黑改性沥青及沥青混合料的粘弹特性,选用硅烷偶联剂表面修饰后得到的疏水性纳米白炭黑作为沥青改性剂,对疏水性纳米白炭黑改性沥青及沥青混合料进行了针入度试验、旋转粘度试验、剪切流变试验和静态蠕变试验,并以针入度指数、旋转粘度、复数剪切模量、弹性剪切模量、粘性剪切模量、相位角、车辙因子、应变差以及Burgers粘弹参数为技术指标进行了粘弹性评价。结果表明:加入疏水性纳米白炭黑,可增强沥青混合料的粘弹性能和高温稳定性能,改善沥青的感温性能以及常温状态下的触变性。通过主曲线分析可知,在低频区疏水性纳米白炭黑的掺入可以提高沥青的相位角,增强沥青的弹性性能。通过分析疏水性纳米白炭黑改性沥青的Burgers模型参数,发现疏水性纳米白炭黑的掺入可提高沥青的粘滞系数。由静态蠕变试验结果分析可知,疏水性纳米白炭黑的掺入,可明显降低相同温度下沥青混合料的应变值。此外,疏水性纳米白炭黑改性剂的掺入可增强沥青混合料的弹性部分,增大沥青混合料的粘性流动变形和粘弹性延迟变形。

中图分类号:

- U416

| 1 | 韦大川, 王云鹏, 李世武. 橡胶粉与SBS复合改性沥青路用性能与微观结构[J]. 吉林大学学报: 工学版, 2008, 38(3): 525-529. |

| Wei Da-chuan, Wang Yun-peng, Li Shi-wu. Physical properties and microstructure of waste rubber powder and SBS complex modified asphalt[J]. Journal of Jilin University(Engineering and Technology Edition), 2008, 38(3): 525-529. | |

| 2 | 樊亮, 张玉贞, 刘延军, 等. 纳米材料与技术在沥青路面中的应用研究进展[J]. 材料导报, 2010, 24(23): 72-75. |

| Fan Liang, Zhang Yu-zhen, Liu Yan-jun, et al. Recent application progress of nanometer material & technology in asphalt pavement[J]. Materials Review, 2010, 24(23): 72-75. | |

| 3 | 夏纬通. 白炭黑在灯泡工业中的应用[J]. 江苏化工, 1995(1): 7-11. |

| Xia Wei-tong. Application of silica in light bulb industry[J]. Jiangsu Chemical Industry, 1995(1): 7-11. | |

| 4 | 刘建国, 季桂娟, 郝磊, 等. 油页岩灰渣提取白炭黑的方法[J]. 吉林大学学报: 地球科学版, 2011, 41(4): 1192-1196. |

| Liu Jian-guo, Ji Gui-juan, Hao Lei, et al. Method for extracting white carbon black by oil shale ash[J]. Journal of Jilin University(Earth Science Edition), 2011, 41(4): 1192-1196. | |

| 5 | 张兴友, 谭忆秋, 王哲人. 白炭黑改性沥青及其混合料的路用性能研究[J]. 公路交通科技, 2005, 22(7): 23-40. |

| Zhang Xing-you, Tan Yi-qiu, Wang Zhe-ren. Study on performance of silica modified asphalt and its mixture[J]. Journal of Highway and Transportation Research and Development, 2005, 22(7): 23-40. | |

| 6 | 林桂. 纳米粉体在橡胶基质中的聚集和分散研究[D]. 北京: 北京化工大学材料科学与工程学院, 2004. |

| Lin Gui. Study on aggregation and dispersion of nano powders in rubber matrix[D]. Beijing: School of Materials Science and Engineering, Beijing University of Chemical Technology, 2004. | |

| 7 | 于欣伟, 陈姚. 白炭黑的表面改性技术[J]. 广州大学学报: 自然科学版, 2002, 1(6): 12-16. |

| Yu Xin-wei, Chen Yao. Surface modification technology of silica[J]. Journal of Guangzhou University(Natural Science Edition), 2002, 1(6): 12-16. | |

| 8 | Guo W, Guo X D, Sun M Z, et al. Evaluation of the durability and the property of an asphalt concrete with nano hydrophobic silane silica in spring-thawing Season[J]. Applied Science, 2018, 8(9): 1475-1493. |

| 9 | 赵延庆, 谭忆秋, 王国忠, 等. 粘弹性对沥青路面疲劳开裂的影响[J]. 吉林大学学报: 工学版, 2010, 40(3): 683-687. |

| Zhao Yan-qing, Tan Yi-qiu, Wang Guo-zhong, et al. Effect of viscoelasticity on fatigue cracking of asphalt pavement[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(3): 683-687. | |

| 10 | Gao J F, Wang H N, You Z P, et al. Rheological behavior and sensitivity of wood-derived bio-oil modified asphalt binders[J]. Applied Science, 2018, 8(6): 919-936. |

| 11 | Stefan H. Comments on a priori and a posteriori evaluations of sub-grid scale models for the Burgers’ equation[J]. Computers & Fluids, 2016, 138: 35-37. |

| 12 | Yuan X F, Ma S, Jiang S H. Form-finding of tensegrity structures based on the Levenberg-Marquardt method[J]. Computers & Fluids, 2017, 192: 171-180. |

| [1] | 于海业,乔建磊,肖英奎,王淑杰,张艳萍,. 气雾栽培马铃薯块茎的基本物理特性[J]. 吉林大学学报(工学版), 2011, 41(01): 282-0287. |

| [2] | 赵长福, 高中礼, 马中胜, 马洪顺. 股骨上端松质骨压缩粘弹性实验研究[J]. 吉林大学学报(工学版), 2002, (2): 87-90. |

| [3] | 李洪, 王玉臣, 马洪顺. 腹主动脉粘弹性实验研究[J]. 吉林大学学报(工学版), 2001, (4): 38-41. |

| [4] | 董心, 贺家宁, 罗民, 马洪顺. C3-C7段颈椎粘弹性实验研究[J]. 吉林大学学报(工学版), 2001, (2): 35-39. |

|

||