吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1620-1627.doi: 10.13229/j.cnki.jdxbgxb20200538

• 车辆工程·机械工程 • 上一篇

椭圆齿轮传动系统齿面接触与动态磨损分析

- 兰州理工大学 机电工程学院,兰州 730050

Analysis of tooth surface contact and dynamic wear of elliptic gear transmission system

Yong-ping LIU( ),Chang-bin DONG,Yong-qiao WEI

),Chang-bin DONG,Yong-qiao WEI

- School of Mechanical and Electrical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

摘要:

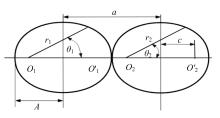

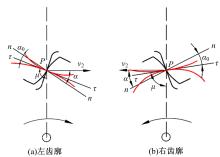

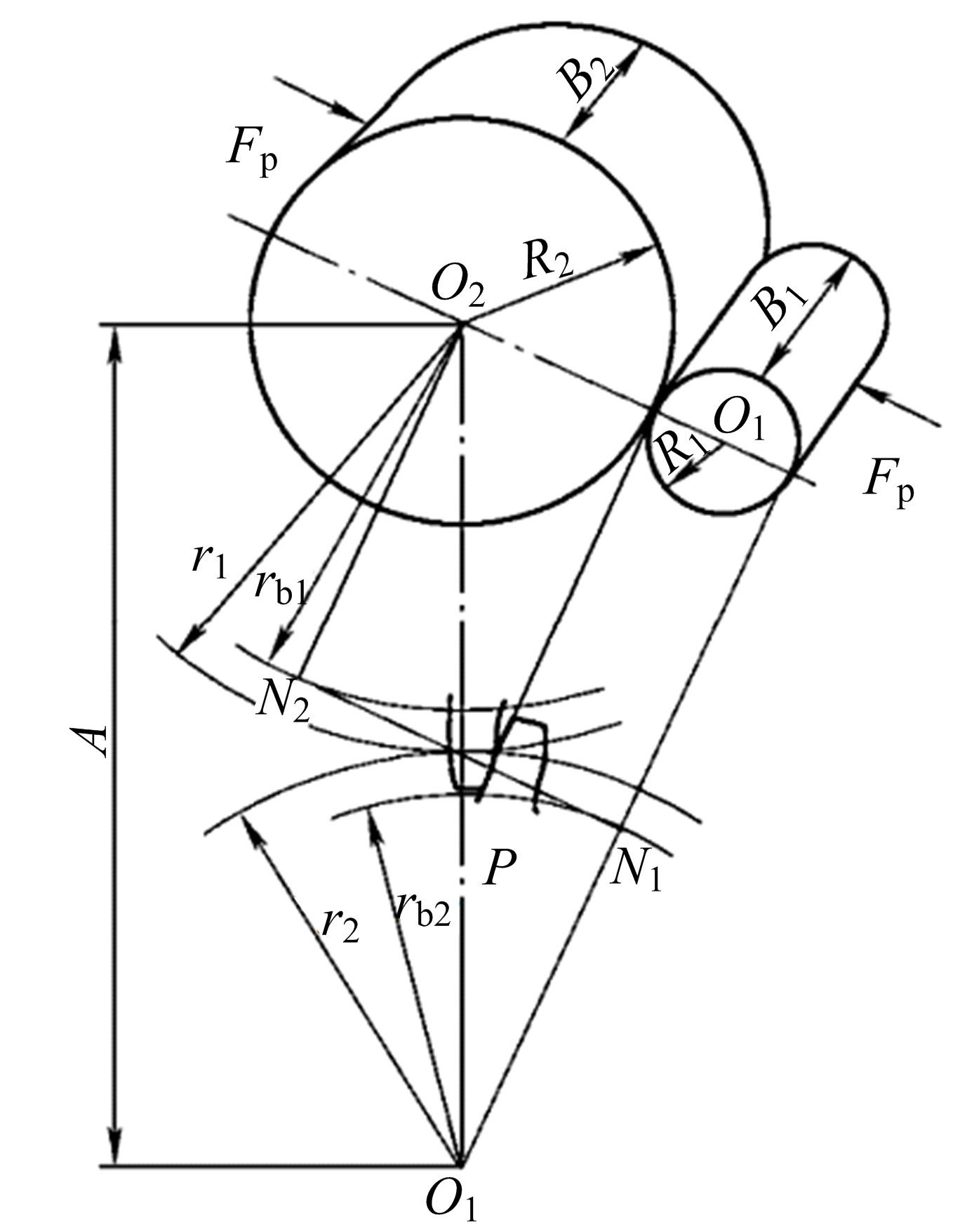

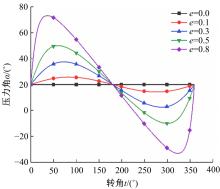

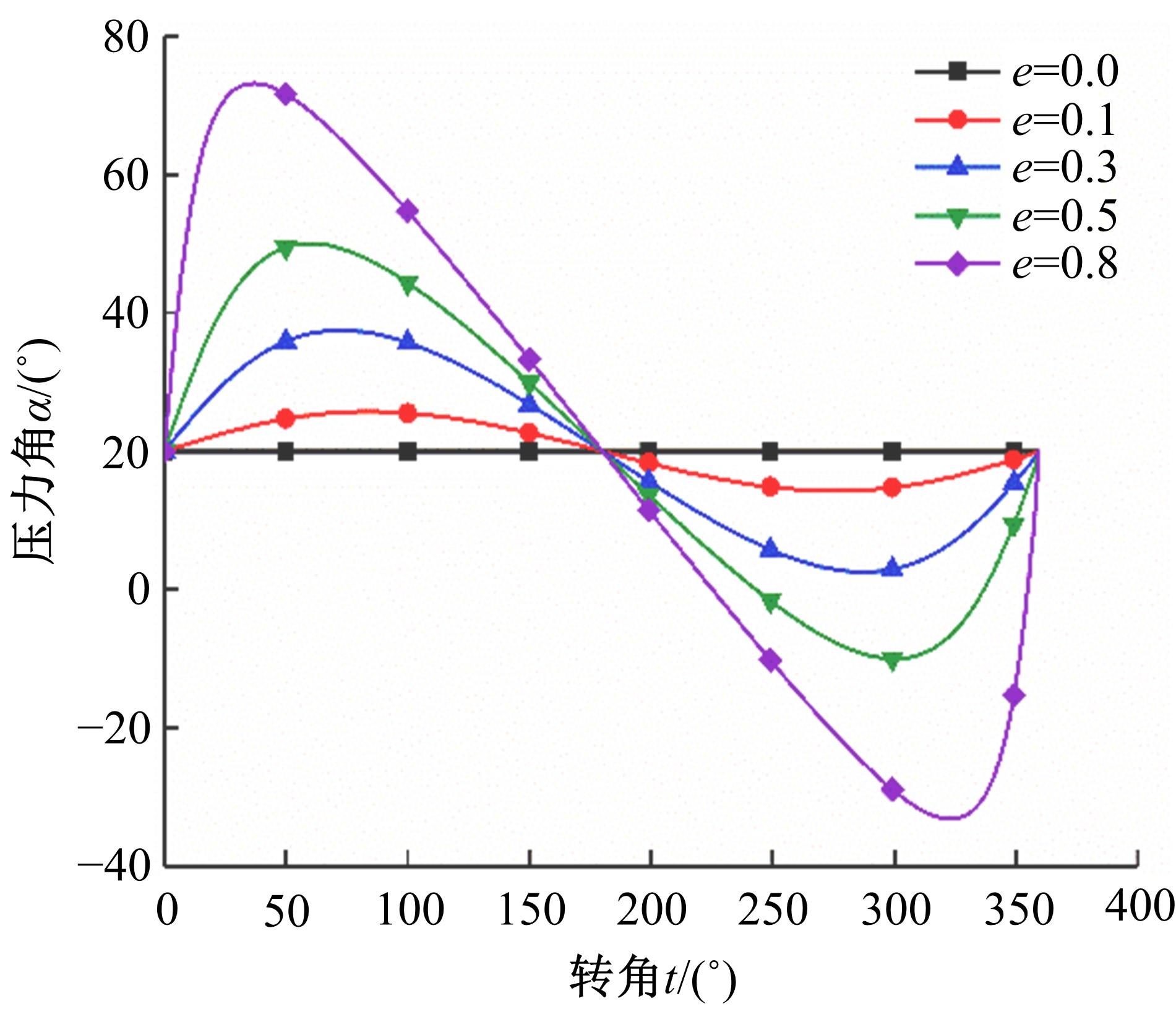

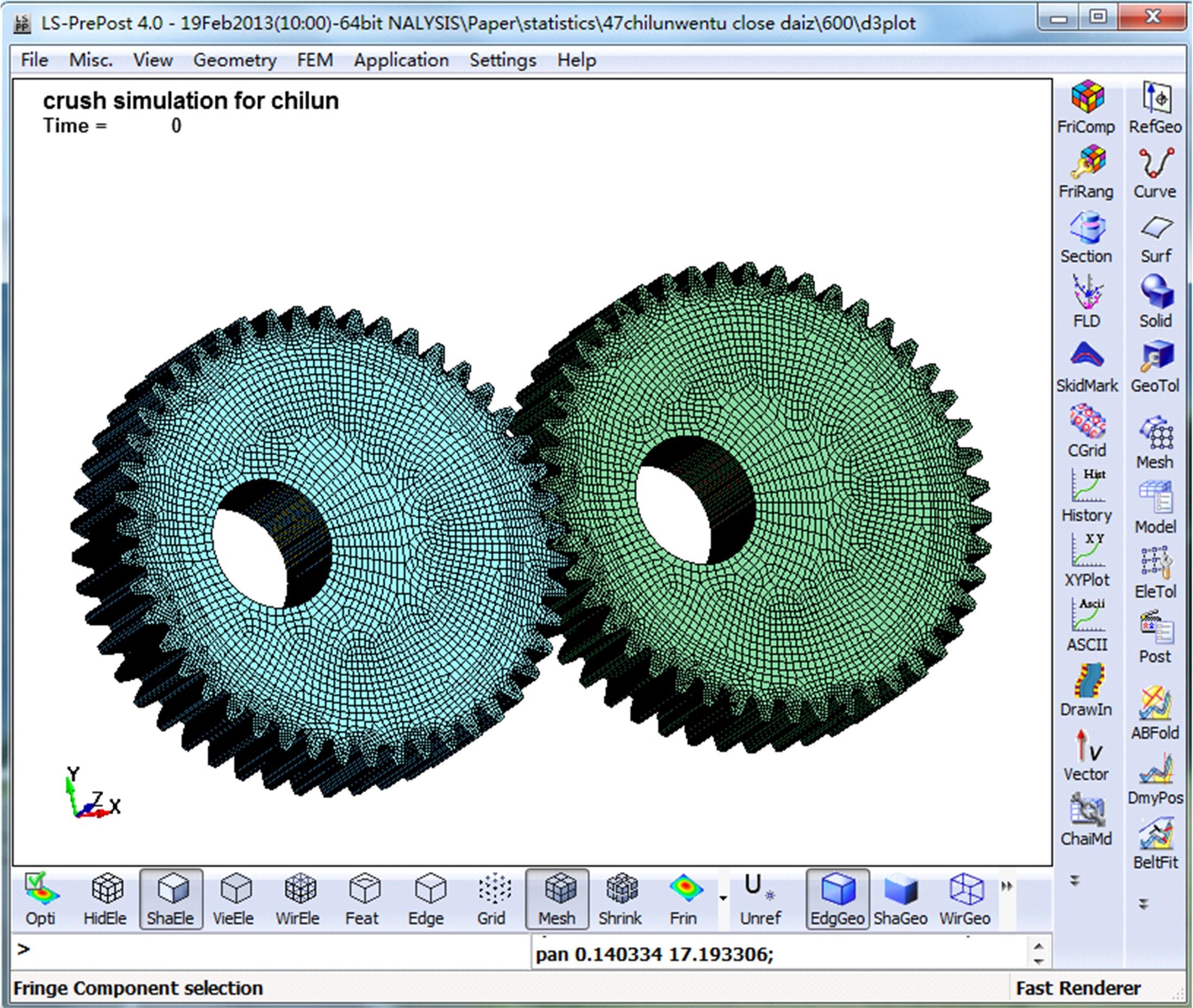

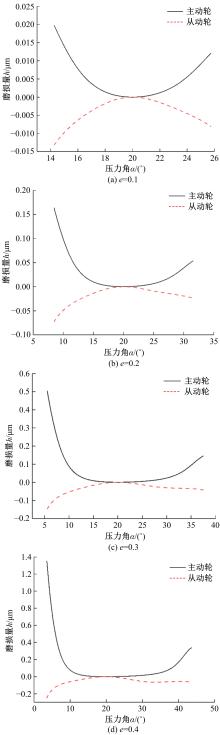

为获取椭圆齿轮齿面动态磨损特性,以一对相互啮合的椭圆齿轮副为研究对象,基于Hertz接触理论和Archard磨损计算通式,建立了椭圆齿轮齿面接触应力和齿面磨损计算模型,运用数值计算方法模拟了齿面接触应力和齿面啮合点处的磨损分布情况,获取了不同设计参数和工况参数条件下齿面接触应力及齿面磨损量随齿廓压力角的分布规律。分析表明:齿面接触应力在单、双齿啮合交替区域会发生突变,随着偏心率和转矩的增大,齿面接触应力呈现出递增趋势。齿面磨损量由齿根到齿顶先减小后增大,在节圆处理论磨损量趋于零;齿面磨损量随着偏心率、输入转矩和转速的增加而呈现出递增趋势。因此,在满足既定要求和运动规律的条件下,减小偏心率、输入转矩及转速有利于降低齿面磨损。研究结果对后续非圆齿轮的动态磨损分析和轮齿修形具有一定的指导意义。

中图分类号:

- TH132.424

| 1 | Smith W C. The math of noncircular gearing[J]. Gear Technology, 2000, 17(4): 18-21. |

| 2 | 董长斌, 刘永平, 魏永峭. 不同载荷条件下椭圆柱齿轮动态接触特性分析[J]. 华中科技大学学报: 自然科学版, 2019, 47(8): 103-107. |

| Dong Chang-bin, Liu Yong-ping, Wei Yong-qiao. Dynamic contact characteristics analysis of elliptic cylinder gear under different load conditions[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2019, 47(8): 103-107. | |

| 3 | 李波涛, 陈定方. 非圆齿轮设计、制造、检测及应用[J]. 机械工程学报, 2020, 56(9): 55-72. |

| Li Bo-tao, Chen Ding-fang. Design, manufacture, inspection and application of non-circular gears[J].Journal of Mechanical Engineering,2020,56(9):55-72. | |

| 4 | 董长斌, 刘永平, 魏永峭, 等. 椭圆齿轮传动系统非线性动态特性分析[J]. 吉林大学学报: 工学版, 2020, 50(2): 483-493. |

| Dong Chang-bin, Liu Yong-ping, Wei Yong-qiao, et al. Analysis of nonlinear dynamic characteristic of elliptic gear transmission system[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 483-493. | |

| 5 | 周长江, 雷玉英, 汪红兵, 等. 准静态与动态载荷下斜齿轮齿面粘着磨损计算[J]. 机械工程学报, 2018, 54(23): 24-36. |

| Zhou Chang-jiang, Lei Yu-ying, Wang Hong-bing, et al. Adhesive wear models for helical gears under quasi-static and dynamic loads[J]. Journal of Mechanical Engineering, 2018, 54(23): 24-36. | |

| 6 | 潘冬, 赵阳, 李娜, 等. 齿轮磨损寿命预测方法[J]. 哈尔滨工业大学学报, 2012, 44(9): 29-33, 39. |

| Pan Dong, Zhao Yang, Li Na, et al. The wear life prediction method of gear system[J]. Journal of Harbin Institute of Technology, 2012, 44(9): 29-33, 39. | |

| 7 | 张俊, 卞世元, 鲁庆, 等. 准静态工况下渐开线直齿轮齿面磨损建模与分析[J]. 机械工程学报, 2017, 53(5): 136-145. |

| Zhang Jun, Bian Shi-yuan, Lu Qing, et al. Quasi-static-model-based wear analysis of spur gears[J]. Journal of Mechanical Engineering, 2017, 53(5): 136-145. | |

| 8 | Archard J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953, 24(8): 981-998. |

| 9 | Wu S, Cheng H S. A sliding wear model for partial-EHL contacts[J]. Journal of Tribology, 1991, 113(1): 134. |

| 10 | Wu S, Cheng H S. Sliding wear calculation in spur gears[J].Journal of Tribology,1993,115(3): 493-500. |

| 11 | Zhang J, Liu X Z. Effects of misalignment on surface wear of spur gears[J]. Proceedings of the Institution of Mechanical Engineers Part J Journal of Engineering Tribology, 2015, 229(9): 1-14. |

| 12 | 王晓笋, 巫世晶, 陈杰, 等. 考虑动载荷与动态磨损系数的直齿轮传动系统动态磨损特性[J]. 中南大学学报: 自然科学版, 2014: 45(2): 408-413. |

| Wang Xiao-sun, Wu Shi-jing, Chen Jie, et al. Dynamic surface wear characteristics in spur gear transmission system with dynamic loads and wear coefficients[J]. Journal of Central South University(Science and Technology), 2014, 45(2): 408-413. | |

| 13 | 何泽银,唐伟迤,林腾蛟,等.增速齿轮副非均匀磨损时变啮合刚度研究[J].机械传动,2019,43(12): 1-6. |

| He Ze-yin, Tang Wei-yi, Lin Teng-jiao, et al. Study on the time-varying mesh stiffness of speed-increasing gear pair with non-uniform wear[J]. Journal of Mechanical Transmission, 2019, 43(12): 1-6. | |

| 14 | 胡波, 黄平. 渐开线直齿圆柱齿轮磨损的数值计算与分析[J]. 润滑与密封, 2017, 42(12): 23-28, 33. |

| Hu Bo, Huang Ping. Numerical calculation and analysis of wear behavior of involute spur gear[J]. Lubrication Engineering, 2017, 42(12): 23-28, 33. | |

| 15 | Litvin F L. Noncircular Gears: Design and Generation[M]. Canbridge: Cambridge University Press, 2009. |

| 16 | 林超, 刘毅, 魏艳群, 等. 端曲面齿轮副复合运动规律及受力分析[J]. 吉林大学学报: 工学版, 2017, 47(1): 157-162. |

| Lin Chao, Liu Yi, Wei Yan-qun, et al. Composite motion law and force condition of curve-face gear pair[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 157-162. |

| [1] | 赵云伟,耿德旭,刘晓敏,刘齐. 气动柔性六足机器人定半径转弯实现方法与稳定性[J]. 吉林大学学报(工学版), 2020, 50(2): 472-482. |

| [2] | 董长斌,刘永平,魏永峭,邓海青,许杰. 椭圆齿轮传动系统非线性动态特性分析[J]. 吉林大学学报(工学版), 2020, 50(2): 483-493. |

| [3] | 徐涛, 赵玉洁, 邵晴, 张友鹤, 徐天爽, 于征磊. 联合载荷下角接触球轴承静态接触特性分析[J]. 吉林大学学报(工学版), 2017, 47(4): 1114-1120. |

| [4] | 曲兴田, 赵永兵, 刘海忠, 王昕, 杨旭, 陈行德. 串并混联机床几何误差建模与实验[J]. 吉林大学学报(工学版), 2017, 47(1): 137-144. |

| [5] | 任书楠, 杨向东, 王国磊, 刘志, 陈恳. 大部件喷涂中的移动机械臂站位规划[J]. 吉林大学学报(工学版), 2016, 46(6): 1995-2002. |

| [6] | 沈志煌, 姚斌, 陆如升, 冯伟, 张祥雷, 王萌萌. 精密螺杆转子齿廓成形磨削的误差分析[J]. 吉林大学学报(工学版), 2016, 46(3): 831-838. |

| [7] | 王延忠, 侯良威, 吕庆军, 赵兴福, 吴灿辉. 基于总线控制的面齿轮复杂曲面加工技术[J]. 吉林大学学报(工学版), 2015, 45(6): 1836-1843. |

| [8] | 陈健, 葛连正, 李瑞峰. 考虑摩擦特性的机器人柔性关节鲁棒控制器设计[J]. 吉林大学学报(工学版), 2015, 45(6): 1906-1912. |

| [9] | 郭黎滨, 张彬, 崔海, 张志航. 微细电火花线切割表面三维粗糙度的结构性参数[J]. 吉林大学学报(工学版), 2015, 45(3): 851-856. |

| [10] | 王继利, 杨兆军, 李国发, 朱晓翠. EM算法的多重威布尔可靠性建模[J]. 吉林大学学报(工学版), 2014, 44(4): 1010-1015. |

| [11] | 杨兆军,王继利,李国发,张新戈. 冲压机床可靠性增长的模糊层次分析预测方法[J]. 吉林大学学报(工学版), 2014, 44(3): 686-691. |

| [12] | 董立春, 韩志武, 张雷, 牛士超, 马荣峰, 任露泉. 凹坑型仿生形态环块样件接触问题有限元数值模拟[J]. 吉林大学学报(工学版), 2013, 43(增刊1): 543-546. |

| [13] | 佟金, 王亚辉, 卢纪生, 张书军, 陈东辉. 基于CCD的大型台阶轴锻件同轴度测量[J]. 吉林大学学报(工学版), 2013, 43(04): 945-950. |

| [14] | 江晟, 王殿海, 赵莹莹, 胡宏宇. 混合交通特征表达及快速检测算法[J]. , 2012, (06): 1459-1464. |

| [15] | 张雷, 赵云伟, 杨卓, 赵继. 电流变抛光液剪切屈服特性[J]. , 2012, 42(05): 1145-1150. |

|

||