吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 377-383.doi: 10.13229/j.cnki.jdxbgxb20211088

• 车辆工程·机械工程 • 上一篇

基于模糊耦合的机床零件加工精度可靠性预测方法

- 1.上海工程技术大学 机械与汽车工程学院,上海 201620

2.吉林大学 机械与航空航天学院,吉林 130022

Reliability prediction method of machining precision of machine tool parts based on fuzzy coupling

Xin-tian LIU1( ),Mu-zhou MA1,Jia-long HE2

),Mu-zhou MA1,Jia-long HE2

- 1.School of Mechanical and Automotive Engineering,Shanghai University of Engineering Science,Shanghai 201620,China

2.College of Mechanical and Aerospace,Jilin University,Changchun 130022,China

摘要:

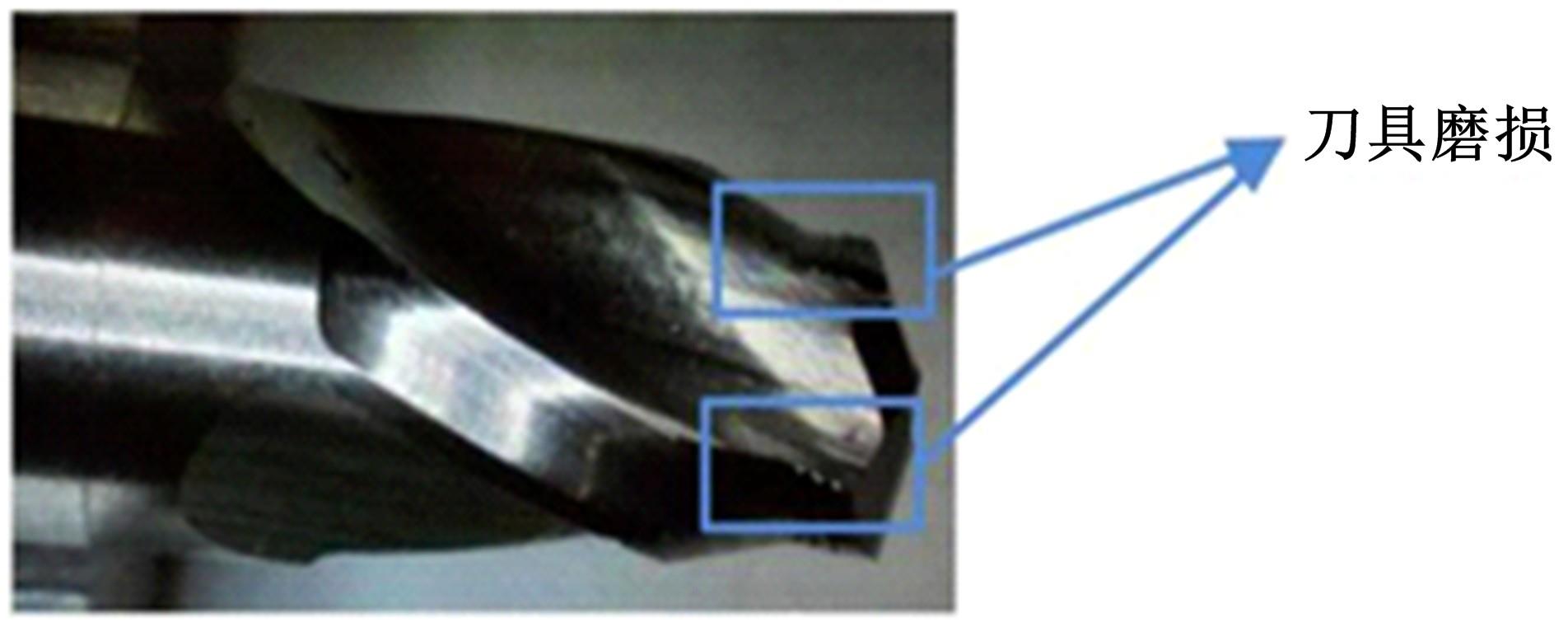

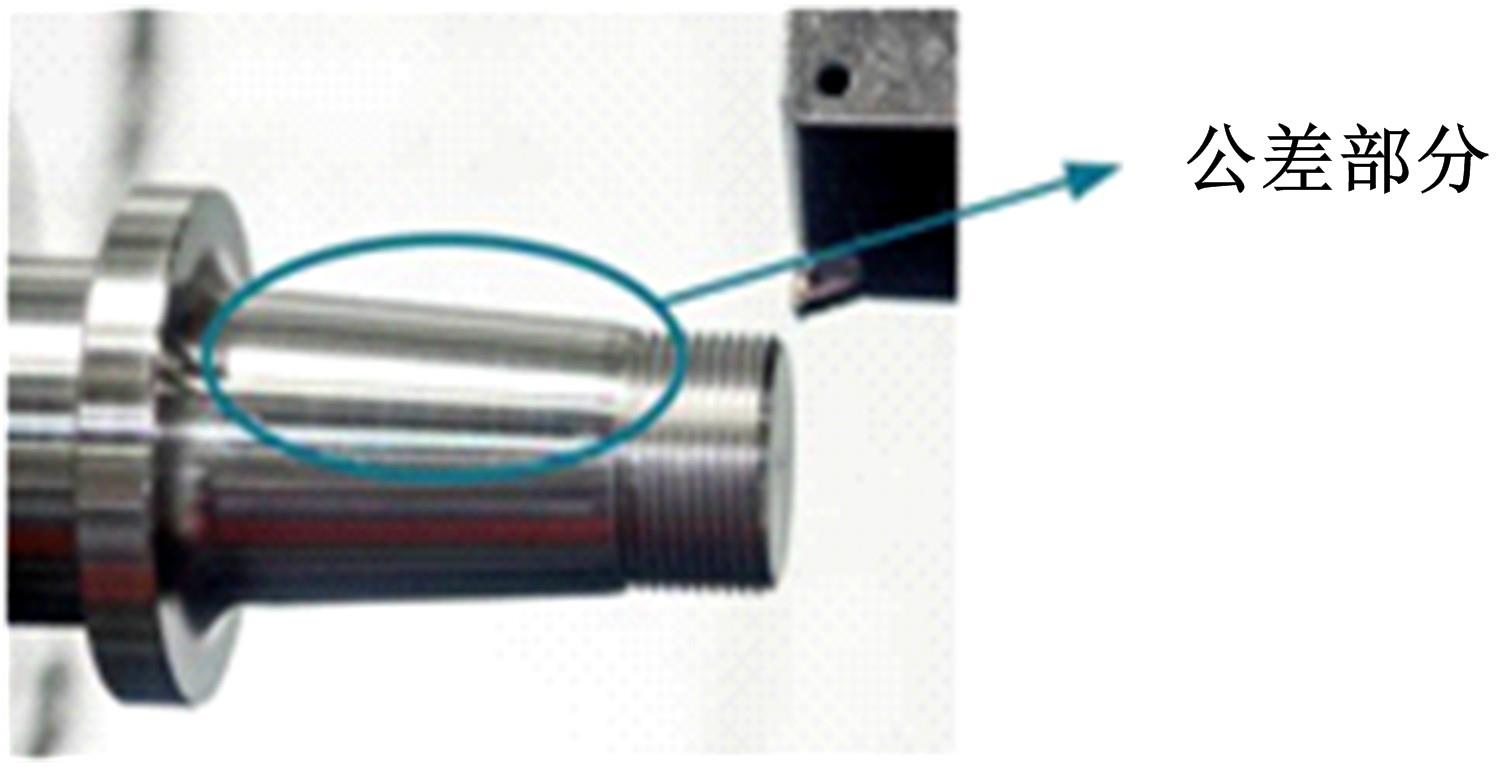

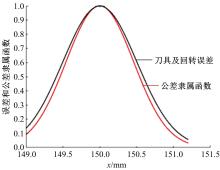

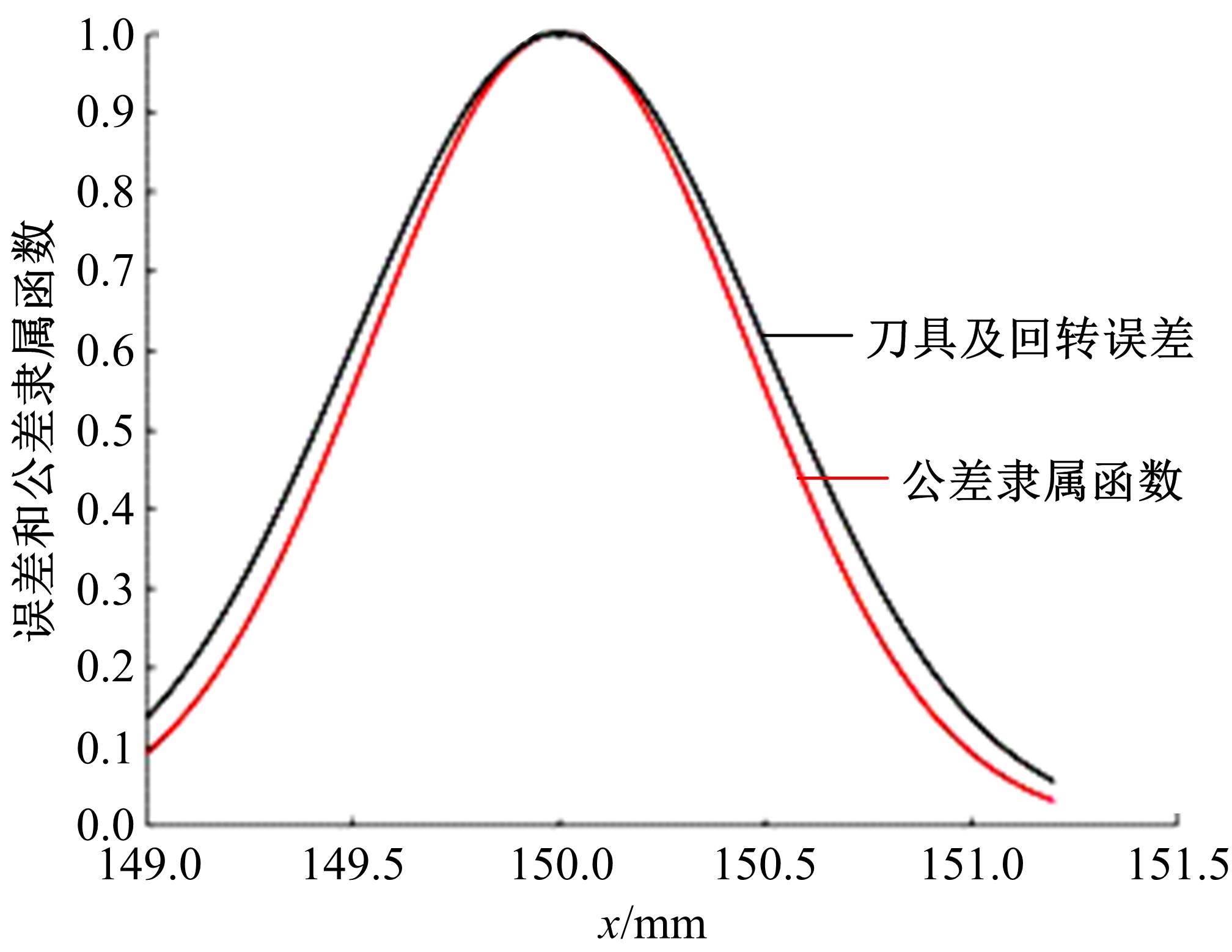

在考虑刀具误差和本身尺寸误差导致加工后零件尺寸精度预测不符合实际使用要求情况的基础上,提出了一种耦合模糊区间和模糊权重的隶属函数模型,该模型考虑了加工过程中各种影响因素占比非固定的情况,还动态表征了多种影响因素在加工过程的贡献变化情况。此外,实际零件加工尺寸的大小多为模糊值,本文将零件尺寸视为一种可能性分布并结合模糊隶属函数构造了新的可靠性预测模型。将预测值与实验数据对比后发现,加工精度可靠性分析的准确度得到显著提升。

中图分类号:

- U463.53

| 1 | 范晋伟, 谢本田, 李晨宝. 数控机床精度优化设计的研究现状[J]. 工具技术, 2021, 55(7): 16-23. |

| Fan Jin-wei, Xie Ben-tian, Li Chen-bao. Current status of research on precision optimization design of CNC machine tools[J]. Tool Technology, 2021, 55(7): 16-23. | |

| 2 | 杨志清. 计数区间的模糊相关系数研究[J]. 统计与决策, 2020, 36(20): 28-32. |

| Yang Zhi-qing. Research on fuzzy correlation coefficients of counting intervals[J]. Statistics and Decision Making, 2020, 36(20): 28-32. | |

| 3 | Wang M L, Liu X T, Wang X L, et al. Research on assembly tolerance allocation and quality control based on fuzzy reliability[J]. Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science, 2016, 230(20): 3755-3766. |

| 4 | 曲兴田, 赵永兵, 刘海忠, 等. 串并混联机床几何误差建模与实验[J]. 吉林大学学报: 工学版, 2017, 47(1): 137-144. |

| Qu Xing-tian, Zhao Yong-bing, Liu Hai-zhong, et al. Modeling and experiments on geometric errors of series-parallel hybrid machine tools[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 137-144. | |

| 5 | Zadeh L A. Fuzzy sets as a basis for a theory of possibility[J]. Fuzzy Sets and Systems, 1978, 1(1): 3-28. |

| 6 | Anotaipaiboon W, Makhanov S S. Minimization of the kinematics error for five-axis machining[J]. Computer-Aided Design, 2011, 43(12): 1740-1757. |

| 7 | 周大勇, 董文龙, 邓海燕. 普通机床加工误差分析[J]. 设备管理与维修, 2020(19): 136-137. |

| Zhou Da-yong, Dong Wen-long, Deng Hai-yan. Analysis of machining errors in general machine tools[J]. Equipment Management and Maintenance, 2020(19): 136-137. | |

| 8 | Yang X F, Liu Y S, Gao Y. An active learning kriging model for hybrid reliability analysis with both random and interval variables[J]. Structural and Multidisciplinary Optimization, 2015, 51(5): 1003-1016. |

| 9 | Liu C, Xiang C T, Lu C W. Dynamic and static error identification and separation method for three-axis CNC machine tools based on feature workpiece cutting[J]. International Journal of Advanced Manufacturing Technology, 2020, 107(5/6): 2227-2238. |

| 10 | Fu C M, Liu Y X, Xiao Z. Interval differential evolution with dimension reduction interval analysis method for uncertain optimization problems[J]. Applied Mathematical Modelling, 2019, 69: 441-452. |

| 11 | 何霞, 刘卫锋, 常娟. 区间值模糊集上的区间值模糊关系[J]. 郑州师范教育, 2018, 7(4): 1-6. |

| He Xia, Liu Wei-feng, Chang Juan. Interval-valued fuzzy relations on interval-valued fuzzy sets[J]. Zhengzhou Teacher Education, 2018, 7(4): 1-6. | |

| 12 | 阮传扬, 韩莉娜. 考虑区间元素个数的区间犹豫模糊决策方法[J]. 计算机科学与探索, 2018, 12(9): 1513-1521. |

| Ruan Chuan-yang, Han Li-na. An interval hesitation fuzzy decision method considering the number of interval elements[J]. Computer Science and Exploration, 2018, 12(9): 1513-1521. | |

| 13 | Zhang Y. Review of theory and technology of mechanical reliability for dynamic and gradual systems[J]. Journal of Mechanical Engineering, 2013, 49(20): 101. |

| 14 | Du X P, Sudjianto A, Huang B Q. Reliability-based design with the mixture of random and interval variables[J]. Journal of Mechanical Design, 2015, 127 (6): 1068-1076. |

| 15 | 杨兆军, 王继利, 李国发. 冲压机床可靠性增长的模糊层次分析预测方法[J]. 吉林大学学报: 工学版, 2014, 44(3): 686-691. |

| Yang Zhao-jun, Wang Ji-li, Li Guo-fa. A fuzzy hierarchical analysis prediction method for the reliability growth of stamping machine tools[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(3): 686-691. | |

| 16 | 宋述稳. 根据位置度公差选择加工机床的方法[J]. 机械制造, 1995(11): 37-38. |

| Cheng Shu-wen. The method of selecting processing machine tools according to the position tolerance[J]. Machinery Manufacturing, 1995(11): 37-38. | |

| 17 | 孙晓玲. 基于区间值相似度的加权模糊推理[J]. 淮阴师范学院学报: 自然科学版, 2016, 15(3): 193-198. |

| Sun Xiao-ling. Weighted fuzzy inference based on interval-valued similarity[J]. Journal of Huaiyin Normal College(Natural Science Edition), 2016, 15(3): 193-198. | |

| 18 | Qiao X Z, Qiu Y Y. A non-probabilistic model for structural reliability analysis[J]. Applied Mechanics and Materials, 2014, 496-500: 2737-2741. |

| 19 | 孙海龙, 姚卫星. 结构区间可靠性分析的可能度法[J]. 中国机械工程, 2008(12): 100-105. |

| Sun Hai-long, Yao Wei-xing. Possibility degree method for structural interval reliability analysis[J]. China Mechanical Engineering, 2008(12): 100-105. |

| [1] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [2] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [3] | 胡东海, 何仁, 顾晓丹. 电涡流缓速器结构参数的节能优化设计[J]. 吉林大学学报(工学版), 2014, 44(5): 1253-1257. |

| [4] | 董伟,于秀敏,张友坤 . 汽车下长坡时发动机制动CVT控制策略 [J]. 吉林大学学报(工学版), 2006, 36(05): 650-0653. |

|

||