吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 105-110.doi: 10.13229/j.cnki.jdxbgxb20210589

• 材料科学与工程 • 上一篇

热处理对TC4钛合金激光双束焊接接头疲劳性能的影响

回丽1,2( ),陆家琛1,周松1(

),陆家琛1,周松1( ),安金岚2,周冠妍3,刘小鹏1

),安金岚2,周冠妍3,刘小鹏1

- 1.沈阳航空航天大学 机电工程学院,沈阳 110136

2.沈阳航空航天大学 航空制造工艺数字化国防重点学科实验室,沈阳 110136

3.中国航空工业集团公司 沈阳飞机设计研究所,沈阳 110136

Effect of heat treatment on fatigue properties of TC4 titanium alloy by laser double beam welded joint

Li HUI1,2( ),Jia-chen LU1,Song ZHOU1(

),Jia-chen LU1,Song ZHOU1( ),Jin-lan AN2,Guan-yan ZHOU3,Xiao-peng LIU1

),Jin-lan AN2,Guan-yan ZHOU3,Xiao-peng LIU1

- 1.School of Mechanical and Electrical Engineering,Shenyang Aerospace University,Shenyang 110136,China

2.National Defense Key Discipline Laboratory of Aerospace Manufacturing Process Digitization,Shenyang Aerospace University,Shenyang 110136,China

3.Shenyang Aircraft Design and Research Institute,Aviation Industry Corporation of China,Shenyang 110136,China

摘要:

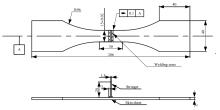

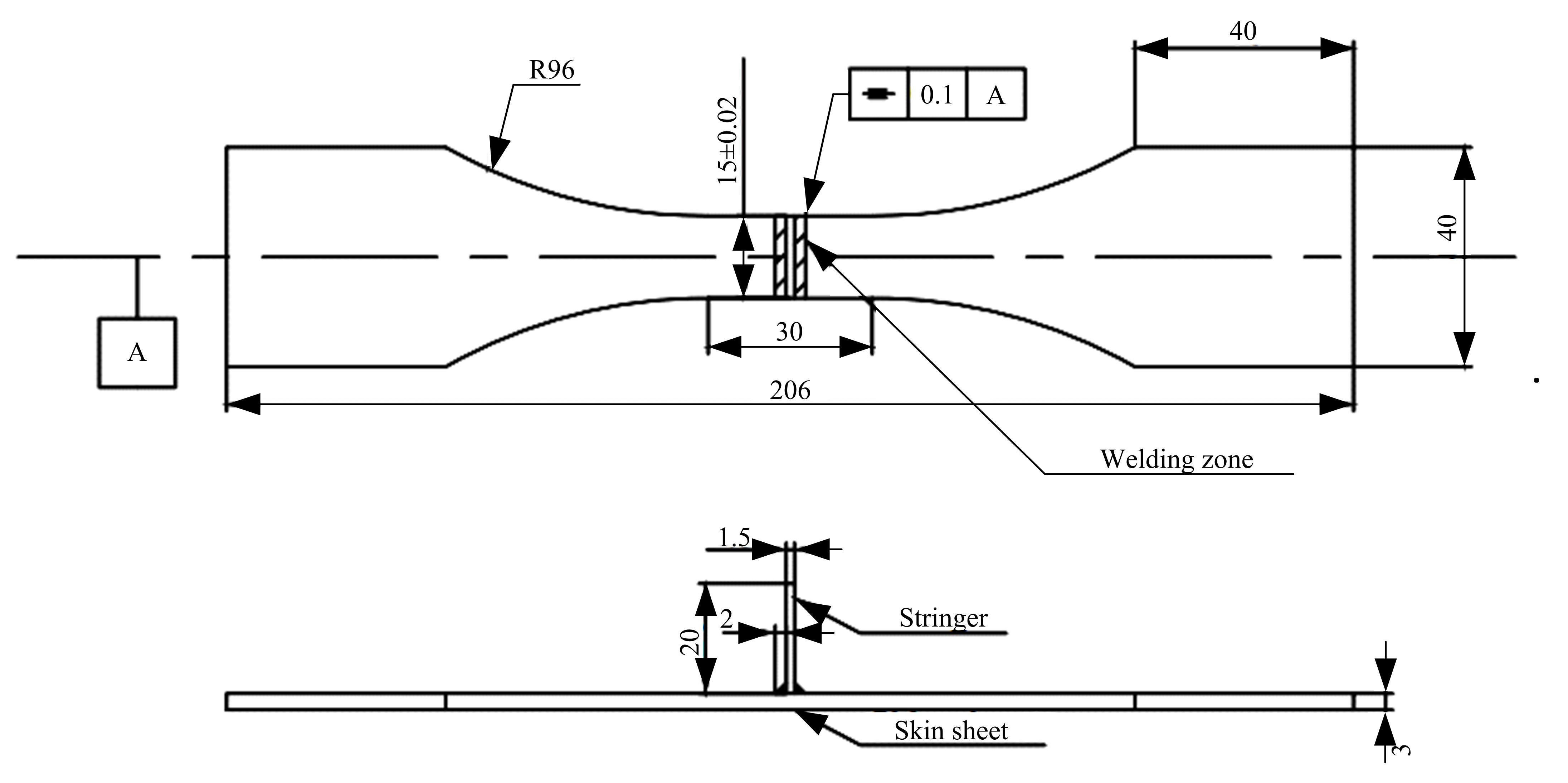

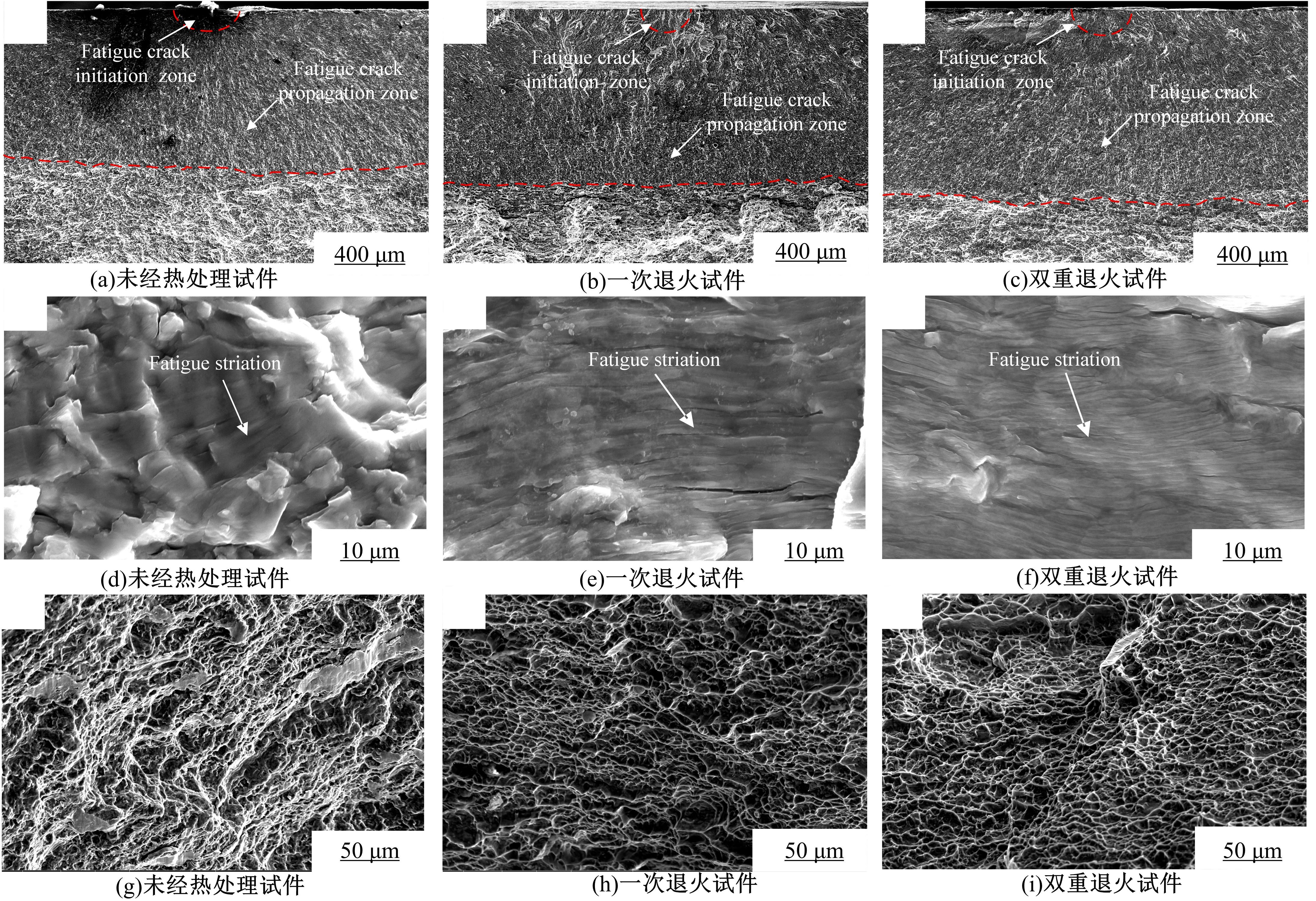

基于飞机金属整体进气道典型件的T形接头在服役过程中因承受空气循环阻力而导致疲劳断裂的问题,利用激光双光束焊接技术对TC4钛合金进行T形焊接后进行热处理,研究不同热处理方法对焊接接头显微组织特征、疲劳性能及断裂机理的影响。结果表明:双重退火热处理试件疲劳寿命是未经热处理试件的1.89倍,一次退火热处理试件疲劳寿命是未经热处理试件的1.43倍。疲劳断口分析表明,与未经热处理试件相比,热处理后试件疲劳裂纹稳定扩展区疲劳条纹间距降低,表明疲劳裂纹扩展速率降低,因此疲劳寿命增大。热处理后网篮组织中析出针状α'马氏体,试件抵抗裂纹萌生和扩展的抗力增强,促进试件疲劳寿命增大。

中图分类号:

- TG407

| 1 | Liu W, Lin Y, Chen Y. Effect of different heat treatments on microstructure and mechanical properties of Ti6Al4V titanium alloy[J]. Rare Metal Materials and Engineering, 2017, 46(3): 634-639. |

| 2 | Logesh M, Selvabharathi R, Thangeeswari T, et al. Influence of severe double shot peening on microstructure properties of Ti 6Al-4V and titanium grade 2 dissimilar joints using laser beam welding[J]. Journal of Technology,2020,123:No.105883. |

| 3 | 关庆丰,姚欣雯,杨洋,等. 强流脉冲电子束作用下TC4钛合金表面Cr合金层制备及性能[J].吉林大学学报:工学版,2019,49(6):2002-2009. |

| Guan Qing-feng, Yao Xin-wen, Yang Yang, et al.Preparation and properties of Cr alloy layer on TC4 titanium alloy surface under the action of high current pulsed electron beam[J].Journal of Jilin University (Engineering and Technology Edition),2019,49(6): 2002-2009. | |

| 4 | 赵耀邦,徐爱杰,姜勇,等. 激光焊接技术研究进展及其在航天领域的应用[J].航天制造技术,2013(3):55-58. |

| Zhao Yao-bang, Xu Ai-jie, Jiang Yong, et al.Research progress of laser welding technology and its application in aerospace field [J]. Aerospace Manufacturing Technology,2013(3):55-58. | |

| 5 | 谷晓燕,隋成龙,狄星,等. 焊接能量对铜/钛超声波焊接接头性能的影响[J].吉林大学学报:工学版,2020,50(5):1669-1676. |

| Gu Xiao-yan, Sui Cheng-long, Di Xing, et al. The effect of welding energy on the properties of copper/titanium ultrasonic welded joints[J]. Journal of Jilin University(Engineering and Technology Edition),2020,50(5):1669-1676. | |

| 6 | Hong X C, Li C, Dong Q L, et al. Microstructure and mechanical properties of aluminum alloy/high strength steel double beam laser deep penetration welded joint[J]. Materials Science Forum, 2019,28:448-457. |

| 7 | 许良,苏居季,周松, 等. TC4钛合金激光双光束焊T形接头疲劳性能及断裂机理[J].中国有色金属学 报,2019,29(7):1408-1416. |

| Xu Liang, Su Ju-ji, Zhou Song, et al. Fatigue properties and fracture mechanism of TC4 titanium alloy t-joint by laser dual beam welding[J]. The Chinese Journal of Nonferrous Metals,2019,29(7):1408-1416. | |

| 8 | 马国龙,李俐群,陈彦宾. 单/双光束激光焊接熔池行为及焊缝成形特性比较[J]. 中国激光,2017,44(2):225-233. |

| Ma Guo-long, Li Li-qun, Chen Yan-bin. Comparative study of molten pool behavior and weld formation characteristic in single/dual beam laser welding[J]. Chinese Journal of Lasers,2017,44(2):225-233. | |

| 9 | Omoniyi P O, Akinlabi E T, Mahamood R M. Heat treatments of Ti6Al4V alloys for industrial applications: an overview[J]. IOP Conference Series: Materials Science and Engineering,2021,1107(1):No. 012094. |

| 10 | 李昌健,刘昕,雷永平. 新型Ti-650合金电子束焊接头组织及性能研究[J]. 材料科学与工艺,2018,26(6):16-22. |

| Li Chang-jian, Liu Xin, Lei Yong-ping. Microstructure and properties of electron beam welded joints of novel Ti-650 alloy [J]. Materials Science and Technology,2018,26(6):16-22. | |

| 11 | Long Wei, Zhang Song, Liang Yi-long,et al.Influence of multi-stage heat treatment on the microstructure and mechanical properties of TC21 titanium alloy[J].International Journal of Minerals Metallurgy and Materials,2021,28(2):296-304. |

| 12 | 王可,赵永庆,贾蔚菊,等. 热处理对Ti90钛合金显微组织及性能的影响[J]. 稀有金属材料与工程,2021,50(2):552-561. |

| Wang Ke, Zhao Yong-qing, Jia Wei-ju, et al. Effect of heat treatment on microstructure and properties of Ti90 titanium alloy[J]. Rare Metal Materials and Engineering, 2021,50(2):552-561. | |

| 13 | Elshaer R N, Ibrahim K M. Effect of cold deformation and heat treatment on microstructure and mechanical properties of TC21 Ti alloy[J]. Transactions of Nonferrous Metals Society of China,2020,30(5):1290-1299. |

| 14 | 赵彦蕾,李伯龙,朱知寿,等. 热处理温度对TC21钛合金微观组织的影响[J]. 材料热处理学报,2011,32(1):14-18. |

| Zhao Yan-lei, Li Bo-long, Zhu Zhi-shou, et al. Effect of heattreatment temperature on microstructure of TC21 titanium alloy[J]. Journal of Materials and Heat Treatment,2011,32(1):14-18. | |

| 15 | Sheng Jin-wen, Wang Zhen-yu, Wu Di, et al. Effect of heat treatment on microstructure and properties of novel high strength titanium alloy[J]. Rare Metal Materials and Engineering,2020,49(3):825-832. |

| 16 | 杨武林,杨晓华,李晓延,等. TC4钛合金薄板激光焊接接头的疲劳寿命及断口分析[J]. 焊接学报,2012,33(3):105-108, 118. |

| Yang Wu-lin, Yang Xiao-hua, Li Xiao-yan, et al. Fatigue life and fracture analysis of laser welded joints of TC4 titanium alloy sheet[J]. Transactions of the China Welding Institution,2012,33(3):105-108, 118. | |

| 17 | 闻雅. TC4钛合金球壳体电子束焊接接头性能及应力分析[D]. 哈尔滨:哈尔滨工业大学材料科学与工程学院,2014. |

| Wen Ya. Performance and stress analysis of electron beam welded joints of TC4 titanium alloy spherical shell[D]. Harbin: School of Materials Science and Engineering, Harbin University of Technology, 2014. | |

| 18 | 马英杰,刘建荣,雷家峰,等. 钛合金疲劳裂纹扩展速率Paris区中的转折点[J]. 金属学报,2008(8):973-978. |

| Ma Ying-jie, Liu Jian-rong, Lei Jia-feng, et al.Fracture point of fatigue crack growth rate in titanium alloy in paris region[J]. Acta Metall Sin,2008(8):973-978. | |

| 19 | Duan Ai-qin, Wang Zhen-su, Peng Huan, et al. Deformation behavior of TC4 titanium alloy laser welded butt joint under static tensile loading[J]. Rare Metal Materials and Engineering,2019,48(8):2432-2440. |

| 20 | 赵锡龙,宋旭,张建勋. TC4钛合金激光焊接接头力学行为的原位研究[J]. 中国有色金属学报,2012,22(2):388-393. |

| Zhao Xi-long, Song Xu, Zhang Jian-xun. In-situ study on mechanical behavior of laser welded joins of TC4 titanium alloy[J]. The Chinese Journal of Nonferrous Metals,2012,22(2):388-393. |

| [1] | 孟广伟,任传鑫,李锋,魏彤辉. 随机载荷作用下的结构疲劳寿命区间分析[J]. 吉林大学学报(工学版), 2022, 52(1): 46-52. |

| [2] | 彭勇,杨汉铎,陆学元,李彦伟. 基于离散元法的空隙特征对沥青混合料虚拟剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 956-964. |

| [3] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [4] | 关庆丰,姚欣雯,杨洋,张凌燕,刘迪,李晨,吕鹏. 强流脉冲电子束作用下TC4钛合金表面Cr合金层制备及性能[J]. 吉林大学学报(工学版), 2019, 49(6): 2002-2009. |

| [5] | 吴娜,庄健,张克松,王慧鑫,马云海. 毛蚶贝壳曲面承压力学特性及断裂机理[J]. 吉林大学学报(工学版), 2019, 49(3): 897-902. |

| [6] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [7] | 王春生, 邹丽, 杨鑫华. 基于邻域粗糙集的铝合金焊接接头疲劳寿命影响因素分析[J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [8] | 王国林, 孙砚田, 梁晨, 杨建, 周海超. 应用满应力理论的轮胎轮廓设计[J]. 吉林大学学报(工学版), 2017, 47(2): 365-372. |

| [9] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [10] | 曹珊珊, 雷俊卿. 考虑区间不确定性的钢结构疲劳寿命分析[J]. 吉林大学学报(工学版), 2016, 46(3): 804-810. |

| [11] | 蒋荣超, 王登峰, 秦民, 蒋永峰. 基于疲劳寿命的轿车后悬架扭转梁轻量化设计[J]. 吉林大学学报(工学版), 2016, 46(1): 35-42. |

| [12] | 邢保英, 何晓聪, 王玉奇, 邓成江. 多铆钉自冲铆接头力学性能机理[J]. 吉林大学学报(工学版), 2015, 45(5): 1488-1494. |

| [13] | 邓成江,何晓聪,邢保英,王玉奇,曾凯,丁燕芳. 铝与铜异质板材自冲铆搭接接头的力学性能[J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

| [14] | 闫楚良, 郝云霄, 刘克格. 基于遗传算法优化的BP神经网络的材料疲劳寿命预测[J]. 吉林大学学报(工学版), 2014, 44(6): 1710-1715. |

| [15] | 韩志武,吕尤,牛士超,张俊秋,马荣峰,任露泉. 仿生表面形态对齿轮弯曲疲劳性能的影响[J]. 吉林大学学报(工学版), 2011, 41(03): 702-705. |

|

||