吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (8): 2348-2354.doi: 10.13229/j.cnki.jdxbgxb.20230307

基于时序模型和深度学习的设备故障上限评估算法

- 1.新疆师范大学 计算机科学技术学院,乌鲁木齐 830054

2.新疆大学 软件工程学院,乌鲁木齐 830046

3.新疆大学 机械工程学院,乌鲁木齐 830046

Device fault ceiling evaluation algorithm based on timing model and deep learning

Guang-he ZHU1( ),Zhi-qiang ZHU2,Yi-ping YUAN3

),Zhi-qiang ZHU2,Yi-ping YUAN3

- 1.College of Computer Science and Technology,Xinjiang Normal University,Urumqi 830054,China

2.College of Software Engineering,Xinjiang University,Urumqi 830046,China

3.College of Mechanical Engineering,Xinjiang University,Urumqi 830046,China

摘要:

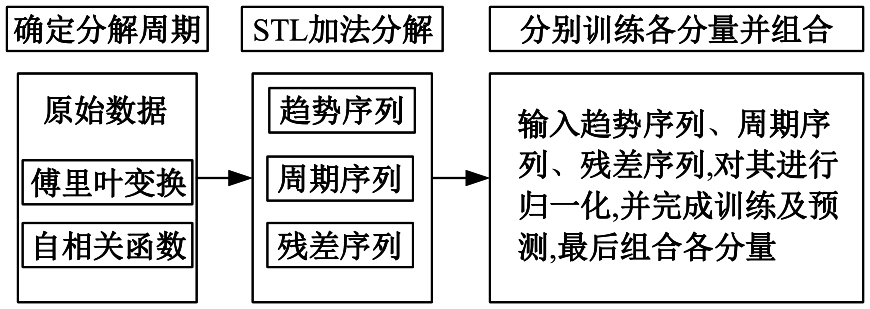

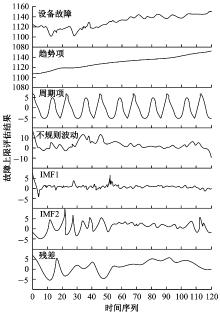

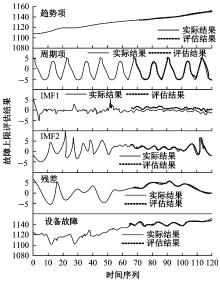

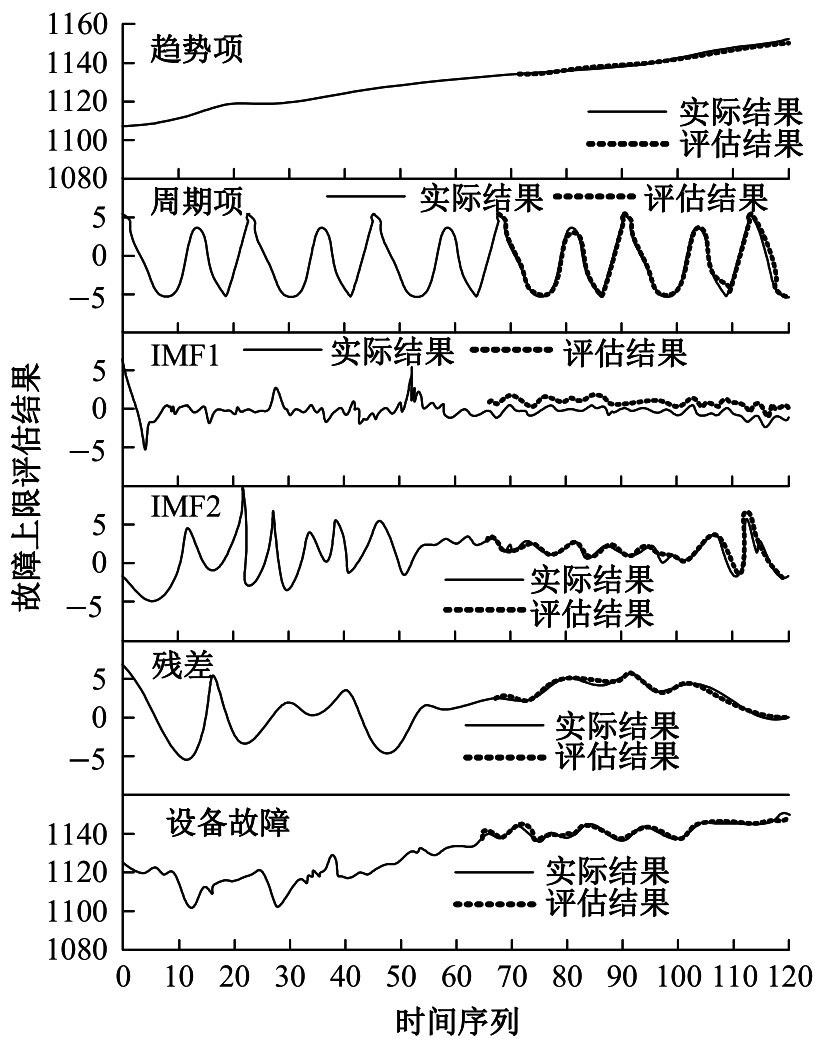

为保障气体绝缘开关设备稳定运行,提出基于时序模型和深度学习的设备故障上限评估算法。该方法利用经验模态分解平稳化时间序列的不规则波动,结合长短期记忆网络构建联立算法;然后,通过该算法处理设备故障数据,提取敏感的本征模函数分量,进而完成故障特征的提取;最后,构建深度学习模型,并确定折射、反射系数,实现设备故障上限评估。测试结果表明:本文算法具有理想的故障上限评估结果,所得曲线与实际结果曲线之间具有较高的拟合度。由此可证明,本文算法可对设备故障上限进行科学评估,具有一定应用价值。

中图分类号:

- TV632

| 1 | 王硕禾, 巩方超, 古晓东, 等. 基于特征融合的变电设备类型及故障识别算法研究[J]. 铁道学报, 2021, 43(4):95-100. |

| Wang Shuo-he, Gong Fang-chao, Gu Xiao-dong, et al. Research on types of substation equipment and fault identification algorithm based on feature fusion [J]. Journal of Railway Studies, 2021,43(4): 95-100. | |

| 2 | 耿苏杰, 王秀利. 基于模糊贝叶斯网络的电力设备故障诊断和状态评估[J]. 计算机集成制造系统, 2021, 27(1): 63-71. |

| Geng Su-jie, Wang Xiu-li. Fault diagnosis and state estimation of power equipment based on fuzzy Bayesian network[J]. Computer Integrated Manufacturing System, 2021,27(1): 63-71. | |

| 3 | 梁天辰. 基于多深度置信网络融合的航空电子设备故障预测[J]. 电讯技术, 2021, 61(2): 248-253. |

| Liang Tian-chen. Fault prognostics of avionics equipment based on multi-deep belief network fusion[J]. Telecommunications Technology, 2021, 61(2): 248-253. | |

| 4 | 段翔兮, 高艺文, 孙永超, 等. 基于kNN算法的电力系统设备隐患在线识别方法研究[J]. 电气传动, 2021, 51(22): 69-73. |

| Duan Xiang-xi, Gao Yi-wen, Sun Yong-chao, et al. Research on on-line identification method of power system equipment based on kNN algorithm[J]. Electrical Transmission, 2021, 51(22): 69-73. | |

| 5 | 郭文军, 张自来, 陈丽君. EMD-AR和GRNN算法下的航空液压泵多模态故障诊断分析[J]. 液压与气动, 2022, 46(6): 151-158. |

| Guo Wen-jun, Zhang Zi-lai, Chen Li-jun. Multimodal fault diagnosis analysis of aviation hydraulic pump based on EMD-AR model and GRNN algorithm [J]. Hydraulic and Pneumatic, 2022, 46(6): 151-158. | |

| 6 | 张朝刚, 侍中楼, 李敏. 基于多状态时间序列预测学习的超精密机床主轴故障诊断仿真[J]. 吉林大学学报: 工学版, 2023, 53 (11): 3056-3061. |

| Zhang Chao-gang, Shi Zhong-lou, Li Min. Simulation of ultra-precision machine tool spindle fault diagnosis based on multi-state time series predictive learning[J]. Journal of Jilin University (Engineering and Technology Edition), 2023,53(11): 3056-3061. | |

| 7 | 柴榕敏, 崔明亮, 王友清, 等.基于多标签学习的旋转机械分级复合故障诊断[J]. 控制与决策, 2022, 37(7): 1772-1778. |

| Chai Rong-min, Cui Ming-liang, Wang You-qing, et al. Hierarchical compound fault diagnosis of rotating machinery based on multi-label learning[J]. Control and Decision-making, 2022,37(7): 1772-1778. | |

| 8 | 门茂琛, 段石磊, 郭磊. 基于多特征融合的电压致热型设备故障检测[J]. 电瓷避雷器, 2022(4): 228-235. |

| Mao-chen Men, Duan Shi-lei, Guo Lei. Fault detection of voltage heating equipment based on multi-feature fusion[J]. Electric Porcelain Lightning Arrester, 2022(4): 228-235. | |

| 9 | 陈晓雷, 孙永峰, 李策, 等. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报: 工学版, 2022, 52(2): 296-309. |

| Chen Xiao-lei, Sun Yong-feng, Li Ce, et al. Stable anti-noise fault diagnosis of rolling bearing based on CNN-BiLSTM[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 296-309. | |

| 10 | 付文秀, 周晓勇, 李弘扬, 等. 基于PSO-SVM的车载ATC设备故障诊断[J]. 北京交通大学学报, 2022, 46(2): 98-107. |

| Fu Wen-xiu, Zhou Xiao-yong, Li Hong-yang, et al. PSO-SVM-Based fault diagnosis of vehicle ATC equipment[J]. Journal of Beijing Jiaotong University, 2022,46(2): 98-107. | |

| 11 | Nguyen T N, Ponciroli R, Bruck P, et al. A digital twin approach to system-level fault detection and diagnosis for improved equipment health monitoring[J]. Annals of Nuclear Energy, 2022, 170(6): 1-14. |

| 12 | Lemos T, Campos L F, Melo A, et al. Echo state network based soft sensor for monitoring and fault detection of industrial processes[J]. Computers & Chemical Engineering, 2021, 155: 1-12. |

| 13 | Yurtseven K, Karatepe E, Deniz E. Sensorless fault detection method for photovoltaic systems through mapping the inherent characteristics of PV plant site: simple and practical[J]. Solar Energy, 2021, 216: 96-110. |

| 14 | Haq M U, Din S U, Dan B. Low-temperature detection of sulfur-hexafluoride decomposition products using octahedral Co3O4-Modified NiSnO3 nanofibers[J]. ACS Applied Materials & Interfaces, 2022,14(7):9292-9306. |

| 15 | Zhou X, Liu G, Zhang X, et al. Re2FAD: a differential image registration and robust image fusion method framework for power thermal anomaly detection[J]. Optik, 2022, 259: 17-30. |

| 16 | Chen D, Tang T, Yao Y. Research on prediction algorithm of ship equipment heath condition[J]. Ocean Engineering, 2022, 249(4): 1-11. |

| 17 | Fischer A, Degener S, Liehr A, et al. Evaluation of extremely steep residual stress gradients based on a combined approach using laboratory‐scale equipment[J]. Journal of Applied Crystallography, 2021, 54(6):1793-1798. |

| 18 | Rodriguez A A, Miller C M, Monty C N. Field testing and cost–benefit evaluation of corrosion-protective coatings on winter maintenance equipment in the state of ohio[J]. Journal of Cold Regions Engineering, 2021, 35(1): 1-11. |

| 19 | Radatz H, Kragl A, Kampwerth J, et al. Application and evaluation of preselection approaches to decide on the use of equipment modules[J]. Chemical Engineering Research and Design, 2021, 173:89-107. |

| 20 | 余孟阳, 杨帆. 信息链接技术下自动化设备现场故障运维仿真[J]. 计算机仿真, 2021, 38(12): 475-479. |

| Yu Meng-yang, Yang Fan. Field failure operation and maintenance simulation of automation equipment based on information link technology[J]. Computer Simulation, 2021,38 (12): 475-479. |

| [1] | 翁渊瀚,李南. 基于时间序列模型的文本数据压缩存储算法[J]. 吉林大学学报(工学版), 2023, 53(7): 2109-2114. |

| [2] | 冀汶莉,田忠,柴敬,张丁丁,王斌. 多属性融合分布式光纤导水裂隙带高度预测方法[J]. 吉林大学学报(工学版), 2023, 53(4): 1200-1210. |

| [3] | 吴剑,许斌. 基于CEEMDAN理论的堆积层滑坡位移区间预测模型及仿真[J]. 吉林大学学报(工学版), 2023, 53(2): 562-568. |

| [4] | 杜睿山,陈雨欣,孟令东. 可信云计算平台多源大数据时间序列调度算法[J]. 吉林大学学报(工学版), 2023, 53(11): 3194-3200. |

| [5] | 李志慧,孙雅倩,陶鹏飞,李海涛,刘昕. 交通事故后的交通运行风险状态等级预测方法[J]. 吉林大学学报(工学版), 2022, 52(1): 127-135. |

| [6] | 李雄飞,王婧,张小利,范铁虎. 基于SVM和窗口梯度的多焦距图像融合方法[J]. 吉林大学学报(工学版), 2020, 50(1): 227-236. |

| [7] | 刘薇娜, 周小龙, 姜振海, 马风雷. 基于最优特征的改进经验模态分解方法[J]. 吉林大学学报(工学版), 2017, 47(6): 1957-1963. |

| [8] | 姜万录,卢传奇,朱勇. 基于HHT和模糊C均值聚类的轴向柱塞泵故障识别[J]. 吉林大学学报(工学版), 2015, 45(2): 429-436. |

| [9] | 李世武, 姚雪萍, 孙文财, 王琳虹, 赖祥翔, 王德强. 体现悬架特性的车辆载荷状态监测技术[J]. 吉林大学学报(工学版), 2014, 44(2): 335-342. |

| [10] | 雷达, 钟诗胜. 基于奇异值分解和经验模态分解的航空发动机健康信号降噪[J]. 吉林大学学报(工学版), 2013, 43(03): 764-770. |

| [11] | 李欢利, 郭立红, 陈涛, 杨丽梅, 王心醉, 董月芳. 基于改进的经验模态分解的虹膜识别方法[J]. 吉林大学学报(工学版), 2013, 43(01): 198-205. |

| [12] | 林玉荣,王强. 基于一维经验模态分解的图像细节提取方法[J]. 吉林大学学报(工学版), 2011, 41(6): 1766-1770. |

| [13] | 刘柏森,卢志茂,申丽然,金辉. 基于希尔伯特-黄变换的低信噪比语音端点检测[J]. 吉林大学学报(工学版), 2011, 41(03): 844-848. |

| [14] | 王国光;王树勋;何丽桥 . 提取混沌中谐波信号的时频方法[J]. 吉林大学学报(工学版), 2006, 36(06): 963-0966. |

|