吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2451-2459.doi: 10.13229/j.cnki.jdxbgxb.20221393

• 车辆工程·机械工程 • 上一篇

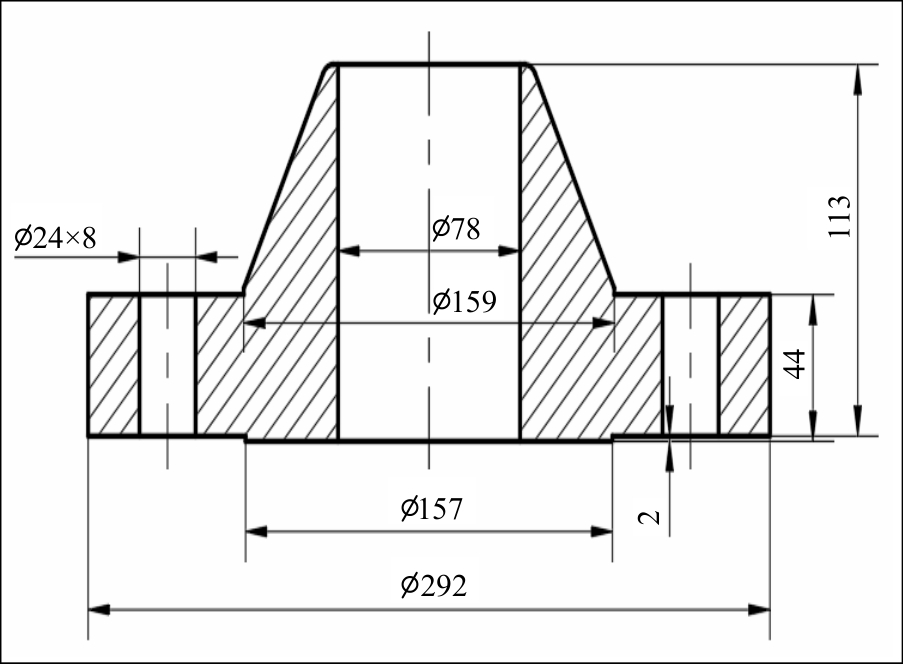

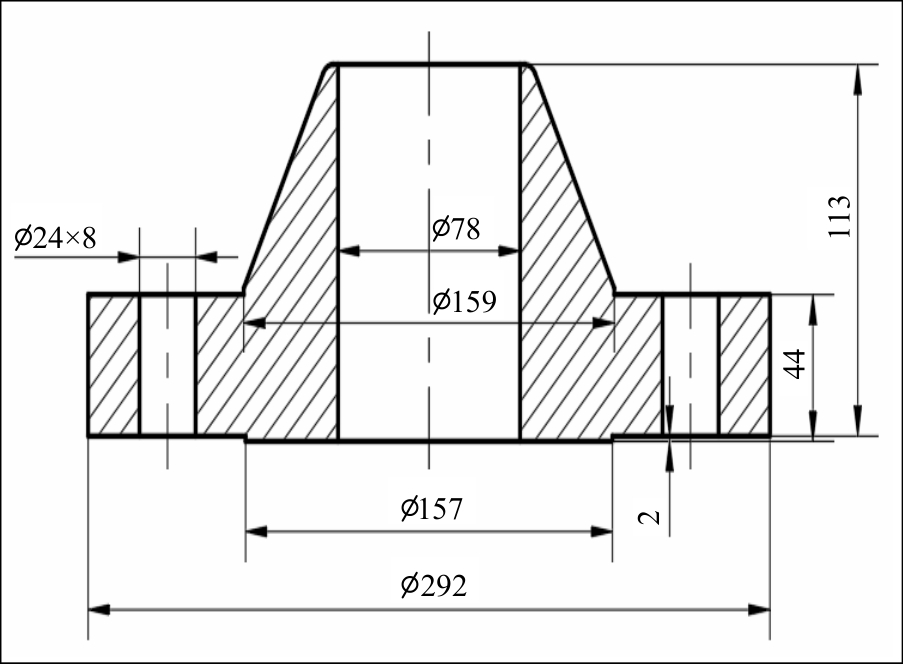

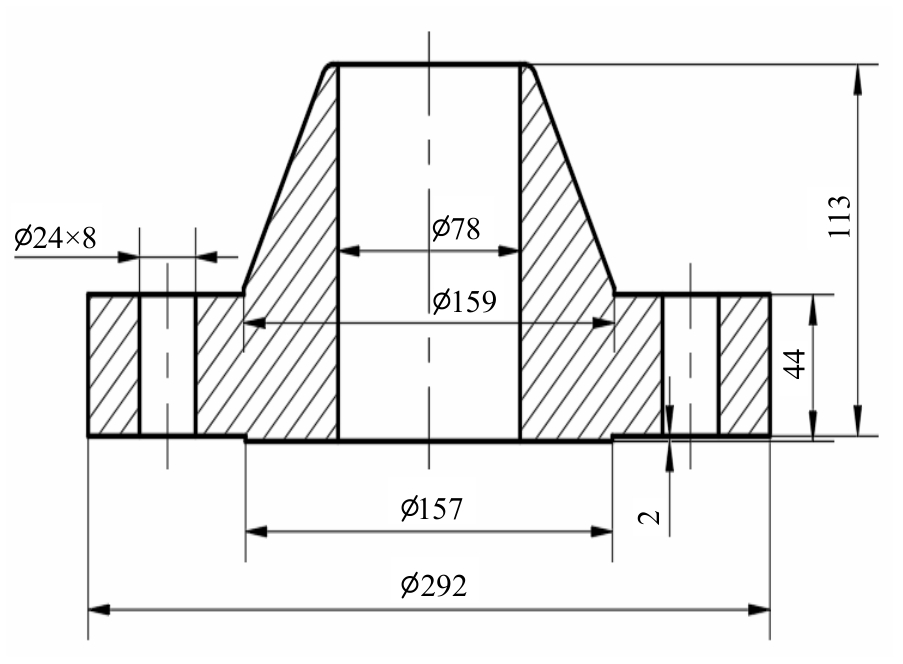

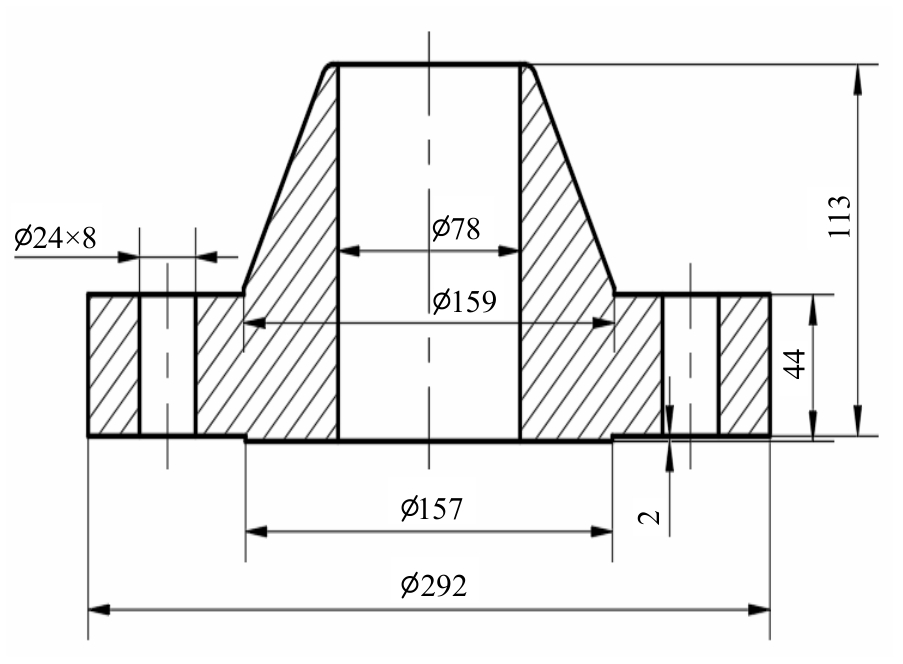

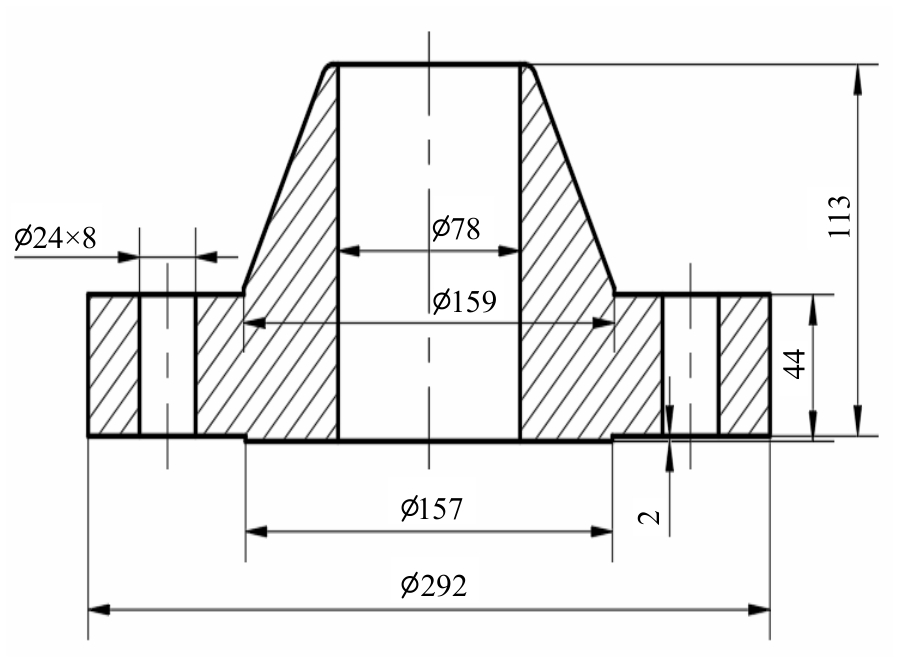

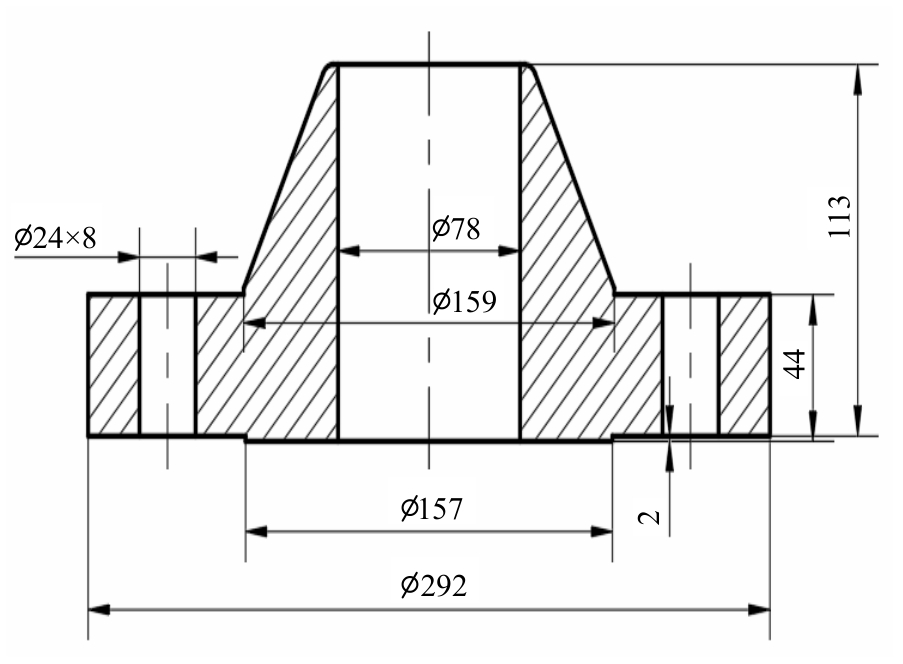

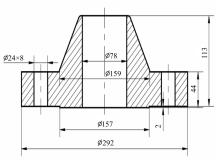

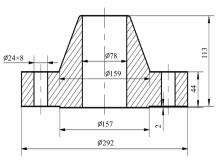

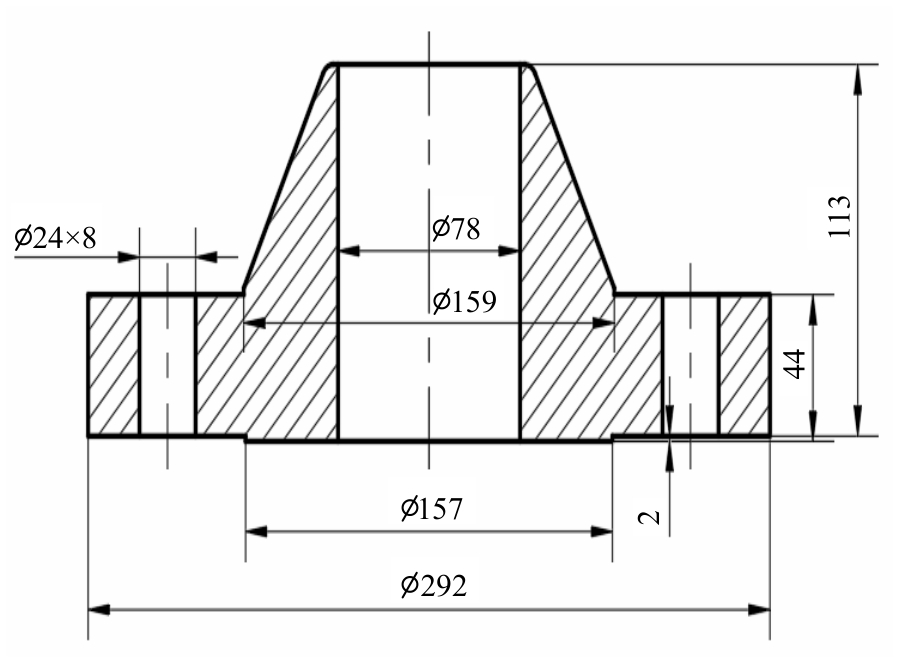

凸面法兰连接下的螺栓载荷均匀性分析

- 西安建筑科技大学 机电工程学院,西安 710055

Analysis of bolt load uniformity under convex flange connection

Ling LI( ),Xu-yang DU,Jing-jing WANG,Xiao-guang RUAN(

),Xu-yang DU,Jing-jing WANG,Xiao-guang RUAN( ),An-jiang CAI

),An-jiang CAI

- School of Mechanical and Electrical Engineering,Xi'an University of Architecture and Technology,Xi'an 710055,China

摘要:

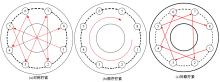

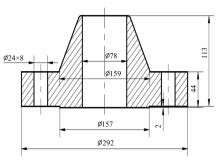

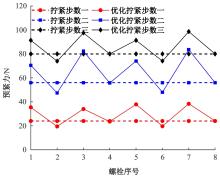

通过构建弹性相互作用模型,优化凸面法兰连接的螺栓预紧力均匀性。将一次弹性相互作用系数法扩展至多次拧紧过程,通过解析模型预测各拧紧步数下所有螺栓的初始预紧力。建立三维有限元模型验证其准确性,并探究拧紧顺序与步数的影响。结果表明:对称拧紧三步法可最小化弹性相互作用,提升预紧力均匀性。考虑弹性相互作用的模型进一步优化了均匀性,更接近目标值。该方法有效解决了预紧力分散问题,为螺栓法兰结构的安全可靠性设计提供了科学依据。

中图分类号:

- TG95

| 1 | 黄贤振,孙楷铂,栾晓刚,等.螺栓预紧连接可靠性灵敏度分析[J]. 吉林大学学报: 工学版, 2023, 53(8):2219-2226. |

| Huang Xian-zhen, Sun Kai-bo, Luan Xiao-gang, et al.Reliability sensitivity analysis of bolt pre-tightening connection[J]. Journal of Jilin University (Engineering and Technology Edition), 2023,53(8):2219-2226. | |

| 2 | Bickford J H. Introduction to the Design and Behavior of Bolted Joints: Non-Gasketed Joints[M]. Florida: CRC Press, 2007. |

| 3 | Bickford J H, Nassar S. Handbook of Bolts and Bolted Joints[M].Florida: CRC Press,1998. |

| 4 | Bibel G D, Ezell R M. Bolted flange assembly: preliminary elastic interaction data and improved bolt-up procedures[J]. Bulletin Welding Research Council, 1996,408:No.379774. |

| 5 | Bibel G D, Ezell R M. An improved flange bolt-up procedure using experimentally determined elastic interaction coefficients[J]. Journal of Pressure Vessel Technology, 1992,114(4):439-443. |

| 6 | Nassar S A, Alkelani A A. Clamp load loss due to elastic interaction and gasket creep relaxation in bolted joints[J]. Journal of Pressure Vessel Technology, 2006, 128(3): 394-401. |

| 7 | Alkelani A A, Nassar S A, Housari B A. Formulation of elastic interaction between bolts during the tightening of flat-face gasketed joints[J]. Journal of Mechanical Design, 2009,131(2): No.21004. |

| 8 | Nassar S A, Yang X. Novel formulation of bolt elastic interaction in gasketed joints[J]. Journal of Pressure Vessel Technology, 2009,131(5):No.3151814. |

| 9 | Fukuoka T, Takaki T. Finite element simulation of bolt-up process of pipe flange connections with spiral wound gasket[J]. Journal of Pressure Vessel Technology, 2003,125(4):371-378. |

| 10 | Takaki T, Fukuoka T. Systematical FE analysis of bolt assembly process of pipe flange connections[C]∥ASME Pressure Vessels and Piping Conference,Atlanta,USA,2002, 19442:147-152. |

| 11 | Takaki T, Fukuoka T. Effective bolting up procedure using finite element analysis and elastic interaction coefficient method[C]∥ASME Pressure Vessels and Piping Conference, Atlanta, USA, 2004, 46733:155-162. |

| 12 | Abid M, Hussain S. Bolt preload scatter and relaxation behavior during tightening a 4 in 900#flange joint with spiral wound gasket[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2008,222(2):123-134. |

| 13 | Nassar S A, Wu Z J, Yang X J.Achieving uniform clamp load in gasketed bolted joints using a nonlinear finite element model[J]. Journal of Pressure Vessel Technology, 2010,132(3): No.031205. |

| 14 | 陈成军, 杨国庆, 常东方, 等.基于有限元法的螺栓组连接弹性相互作用研究[J].武汉理工大学学报, 2011, 33(10): 131-135. |

| Chen Cheng-jun, Yang Guo-qing, Chang Dong-fang, et al. FEM based elastic interaction analysis of assembly and fastening[J]. Journal of Wuhan University of Technology, 2011,33(10): 131-135. | |

| 15 | Abasolo M, Aguirrebeitia J, Aviles R, et al. A tetraparametric metamodel for the analysis and design of bolting sequences for wind generator flanges[J]. Journal of Pressure Vessel Technology, 2011,133(4): No.4002541. |

| 16 | Abasolo M, Aguirrebeitia J, Aviles R, et al. Methodology for the optimization of bolting sequences for wind generator flanges[J]. Journal of Pressure Vessel Technology, 2014, 136(6): No.61202. |

| 17 | Wang Y Q, Wu J K, Liu H B, et al. Modeling and numerical analysis of multi-bolt elastic interaction with bolt stress relaxation[J]. Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science, 2016,230(15): 2579-2587. |

| 18 | Wang Y Q, Wu J K, Liu H B, et al. Analysis of elastic interaction stiffness and its effect on bolt preloading[J]. International Journal of Mechanical Sciences, 2017,130: 307-314. |

| 19 | Zhu L B, Bouzid A, Hong J, et al. Numerical and experimental study of elastic interaction in bolted flange joints[J]. Journal of Pressure Vessel Technology, 2017,139(2): No.21211. |

| 20 | Zhu L B, Bouzid A, Hong J, et al. Elastic interaction in bolted flange joints: an analytical model to predict and optimize bolt load[J]. Journal of Pressure Vessel Technology, 2018,140(4): No.4040421. |

| 21 | Kurfess T R, Saldana C, Saleeby K, et al. A review of modern communication technologies for digital manufacturing processes in industry 4.0[J]. Journal of Manufacturing Science and Engineering, 2020, 142(11): No.110815. |

| 22 | Li B, Chen H, Jin T. Support vector regression for optimal robotic force control assembly[J]. Journal of Manufacturing Science and Engineering, 2020,142(1):No.011007. |

| 23 | Wang Z, Liu P, Xiao Y, et al. A data driven approach for process optimization of metallic additive manufacturing under uncertainty[J]. Journal of Manufacturing Science and Engineering, 2019,141(8): No.081004. |

| [1] | 陶文斌,侯俊领,陈铁林,唐彬. 高预紧力后张法全长锚固支护力学分析[J]. 吉林大学学报(工学版), 2020, 50(2): 631-640. |

| [2] | 王智. 月基二维转台轴承预紧力和系统刚度计算[J]. 吉林大学学报(工学版), 2015, 45(6): 1831-1835. |

| [3] | 杨佐卫,殷国富,尚欣,姜华,钟开英. 高速电主轴热态特性与动力学特性耦合分析模型[J]. 吉林大学学报(工学版), 2011, 41(01): 100-0105. |

|

||