Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (12): 3367-3378.doi: 10.13229/j.cnki.jdxbgxb.20220075

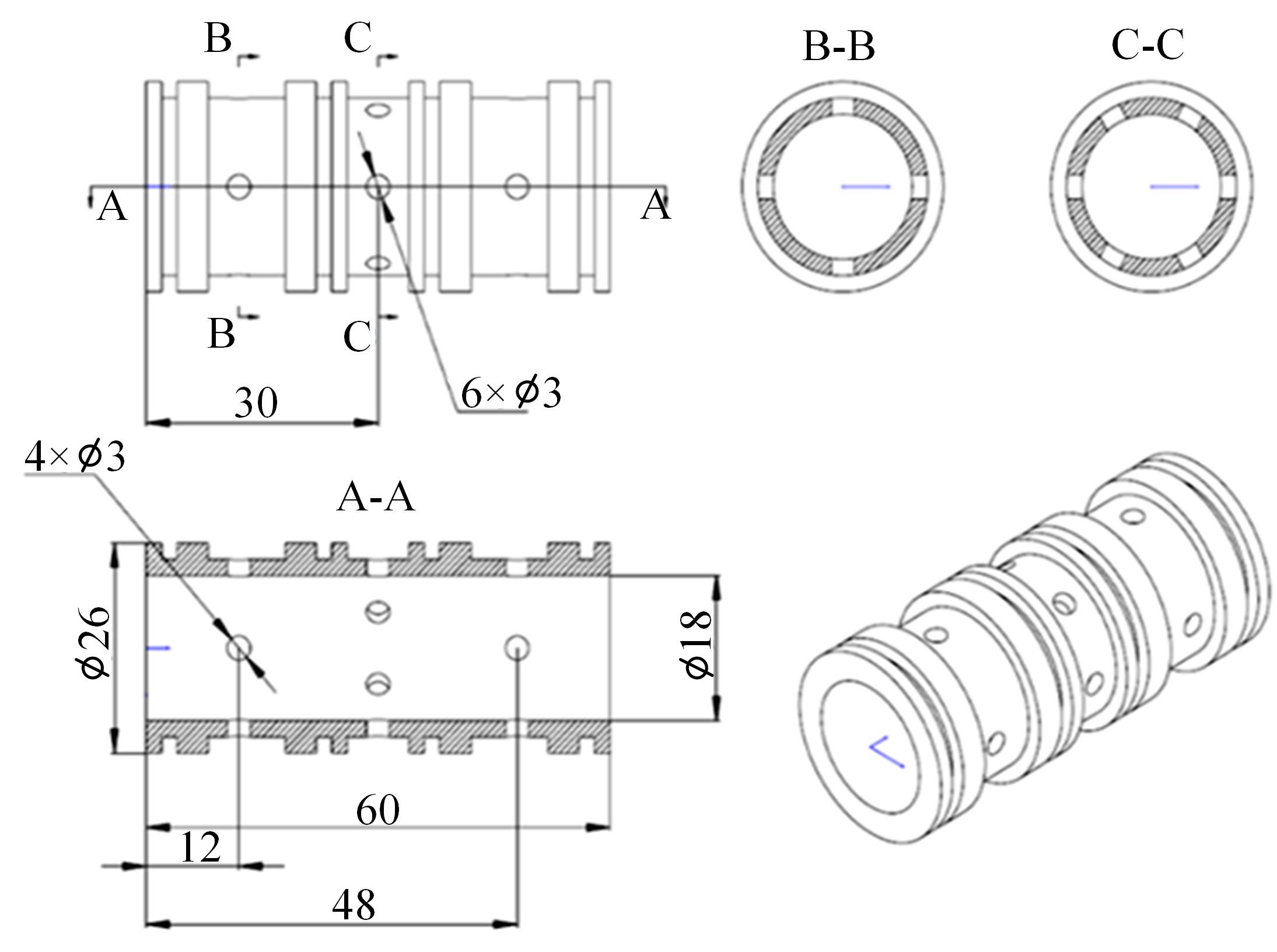

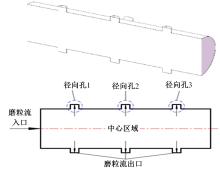

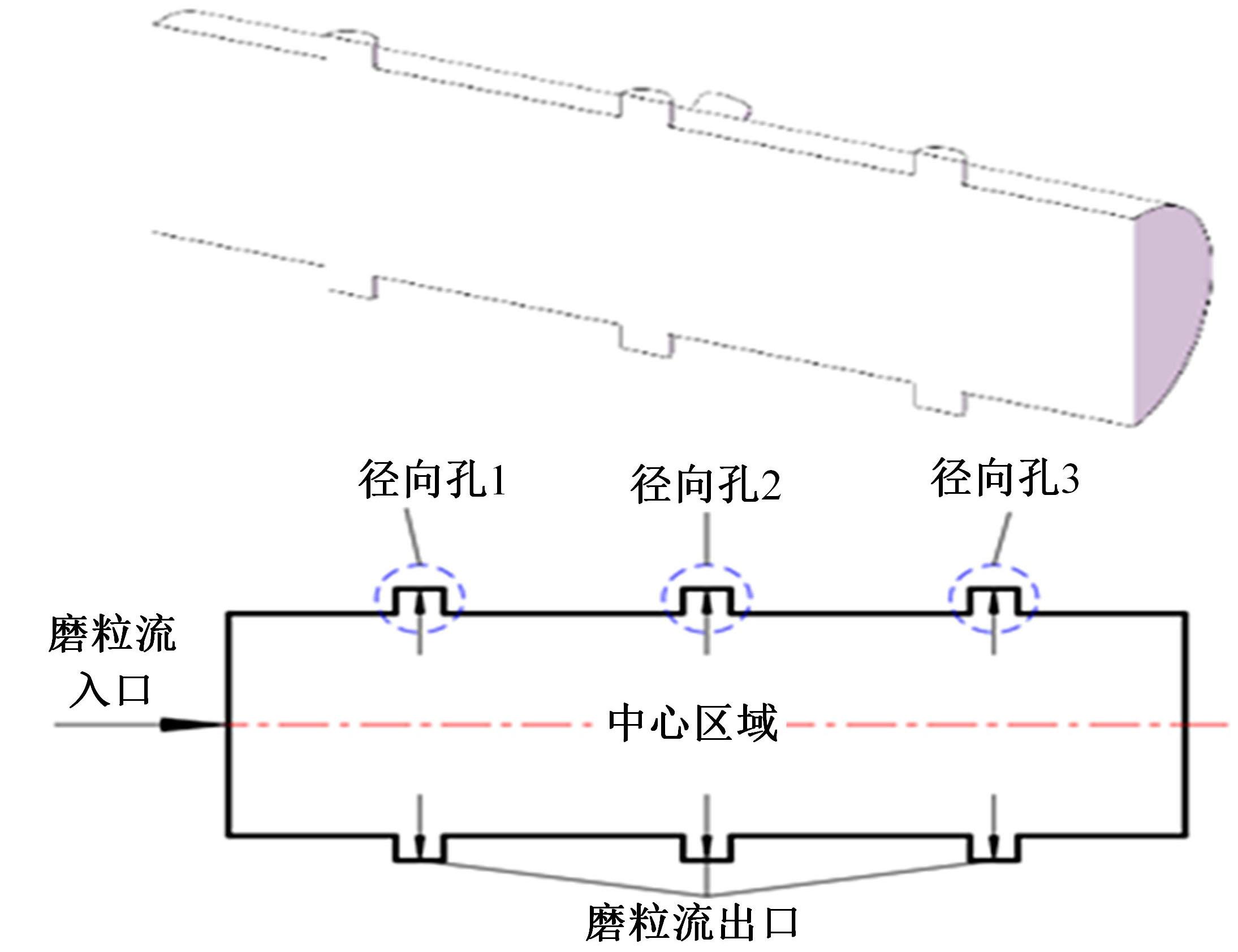

Quality analysis of abrasive flow precision machining of cross hole of valve sleeve

Jing GUO1( ),Lin GUI1,Wei HOU1,Jun-ye LI2(

),Lin GUI1,Wei HOU1,Jun-ye LI2( ),Zhi-bao ZHU2,Li-wei SUN2

),Zhi-bao ZHU2,Li-wei SUN2

- 1.Key Laboratory of Vehicle Transmission,China North Vehicle Research Institute,Beijing 100072,China

2.Ministry of Education Key Laboratory for Cross-Scale Micro and Nano Manufacturing,Changchun University of Science and Technology,Changchun 130022,China

CLC Number:

- TH161.1

| 1 | 孙振贵, 邢天羿, 邵铭, 等. 超精密阀套内孔的珩磨工艺研究[J]. 航空精密制造技术,2019,55(2):53-56. |

| Sun Zhen-gui, Xing Tian-yi, Shao Ming, et al. Honing process research about ultra-precision valve sleeve bore[J]. Aviation Precision Manufacturing Technology, 2019, 55(2): 53-56. | |

| 2 | 朱西薇, 车飞, 方兵, 等. 电液伺服阀自动化配研磨技术研究[J]. 液压气动与密封, 2020, 40(3): 80-84. |

| Zhu Xi-wei, Che Fei, Fang Bing, et al. Research on auto-matching grinding technology of electro-hydraulic servo valve[J]. Hydraulics Pneumatics & Seals, 2020, 40(3): 80-84. | |

| 3 | 张静, 朱春江, 赵龙. 航空精密偶件去毛刺方法的研究[J]. 航空精密制造技术, 2014, 50(2): 54-55. |

| Zhang Jing, Zhu Chun-jiang, Zhao Long. Research on deburring approach of aviation precision matching parts[J]. Aviation Precision Manufacturing Technology, 2014, 50(2): 54-55. | |

| 4 | Gillespie L K. Deburring precision miniature parts[J]. Precision Engineering, 1979, 1(4): 189-198. |

| 5 | Kotte G. Precision machining: technology and machine development and improvement[J]. Precision Engineering, 2012, 15(4): 455-460. |

| 6 | Fu Y, Gao H, Yan Q, et al. Rheological characterisation of abrasive media and finishing behaviours in abrasive flow machining[J]. The International Journal of Advanced Manufacturing Technology, 2020, 107(7): 3569-3580. |

| 7 | Kumar S S, Hiremath S S. A review on abrasive flow machining (AFM)[J]. Procedia Technology, 2016, 25: 1297-1304. |

| 8 | Cheema M S, Venkatesh G, Dvivedi A, et al. Developments in abrasive flow machining: a review on experimental investigations using abrasive flow machining variants and media[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(12): 1951-1962. |

| 9 | Fu Y, Gao H, Yan Q, et al. An efficient approach to improving the finishing properties of abrasive flow machining with the analyses of initial surface texture of workpiece[J]. The International Journal of Advanced Manufacturing Technology, 2020, 107(5): 2417-2432. |

| 10 | Suzuki H, Ohashi K. Special issue on precision abrasive technology of difficult-to-machine materials[J]. International Journal of Automation Technology, 2018, 12(6): 861. |

| 11 | Dixit N, Sharma V, Kumar P. Research trends in abrasive flow machining: a systematic review[J]. Journal of Manufacturing Processes, 2021, 64: 1434-1461. |

| 12 | Kim K J, Kim Y G, Kim K H. Characterization of deburring by abrasive flow machining for AL6061[J]. Applied Sciences, 2022, 12(4): No. 2048. |

| 13 | Li Jun-ye, Zhu Zhi-bao, Hu Jing-lei, et al. Particle collision-based abrasive flow mechanisms in precision machining[J]. International Journal of Advanced Manufacturing Technology, 2020, 110(7): 1819-1831. |

| 14 | 李俊烨, 胡敬磊, 杨兆军, 等. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报:工学版, 2018, 48(2): 492-499. |

| Li Jun-ye, Hu Jing-lei, Yang Zhao-jun, et al. Effect on the quality of abrasive flow polishing the common rail pipe in size of discrete phase abrasive particle[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(2): 492-499. | |

| 15 | Li Jun-ye, Meng Wen-qing, Dong Kun, et al. Numerical analysis of solid-liquid two-phase abrasive flow in microcutting polycrystalline materials based on molecular dynamics[J]. International Journal of Precision Engineering and Manufacturing, 2018, 19(11): 1597-1610. |

| 16 | Wei H, Peng C, Gao H, et al. On establishment and validation of a new predictive model for material removal in abrasive flow machining[J]. International Journal of Machine Tools and Manufacture, 2019, 138: 66-79. |

| 17 | Guo J, Song C, Fu Y, et al. Internal surface quality enhancement of selective laser melted inconel 718 by abrasive flow machining[J]. Journal of Manufacturing Science and Engineering, 2020, 142(10): No. 101003. |

| 18 | Yuan Q, Qi H, Wen D. Numerical and experimental study on the spiral-rotating abrasive flow in polishing of the internal surface of 6061 aluminium alloy cylinder[J]. Powder Technology, 2016, 302: 153-159. |

| 19 | Furumoto T, Ueda T, Amino T, et al. A study of internal face finishing of the cooling channel in injection mold with free abrasive grains[J]. Journal of Materials Processing Technology, 2011, 211(11): 1742-1748. |

| 20 | 李俊烨, 朱旭, 杨兆军, 等. 固液两相磨料流的微小孔精密研抛行为[J].吉林大学学报: 工学版, 2020, 50(3): 903-913. |

| Li Jun-ye, Zhu Xu, Yang Zhao-jun, et al. Micro-hole precision grinding and polishing behavior of solid-liquid two-phase abrasive flow[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(3): 903-913. | |

| 21 | 李忠新. 精密复杂微小型构件车铣复合加工技术研究[D]. 北京: 北京理工大学机械与车辆学院, 2014. |

| Li Zhong-xin. Research on turning and milling compound machining technology of precise and complex micro-miniature components[D]. Beijing: School of Machinery and Vehicles, Beijing Institute of Technology, 2014. |

| [1] | LI Jun-ye, HU Jing-lei, YANG Zhao-jun, ZHANG Xin-ming, ZHOU Zeng-wei. Effect of the size of discrete phase abrasive particles on the abrasive flow polishing quality of common rail pipe [J]. 吉林大学学报(工学版), 2018, 48(2): 492-499. |

| [2] | LI Jun-ye, QIAO Ze-min, YANG Zhao-jun, ZHANG Xin-ming. Influence of abrasive concentration on processing quality of abrasive flow in mesoscopic scale [J]. 吉林大学学报(工学版), 2017, 47(3): 837-843. |

| [3] | GUO Zhe-feng, TANG Wen-cheng. Stress analysis of cup-shaped parts in secondary deep drawing [J]. 吉林大学学报(工学版), 2016, 46(2): 494-499. |

| [4] | LI Song-sheng, ZHAO Yan-wei, GU Xi-ren. Application of improved FUP algorithm on hardware product quality analysis system [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 251-254. |

|

||