Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1665-1676.doi: 10.13229/j.cnki.jdxbgxb.20221039

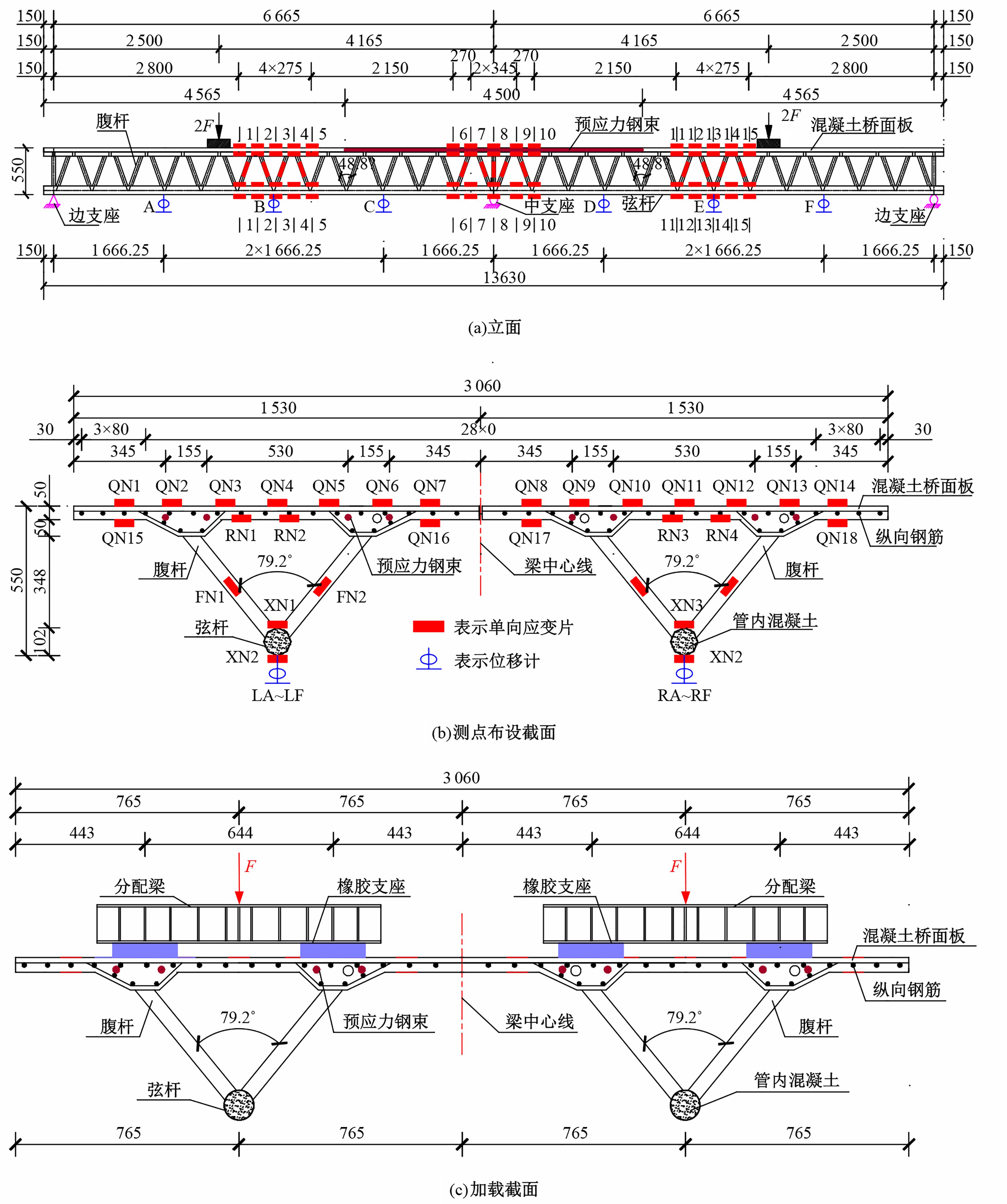

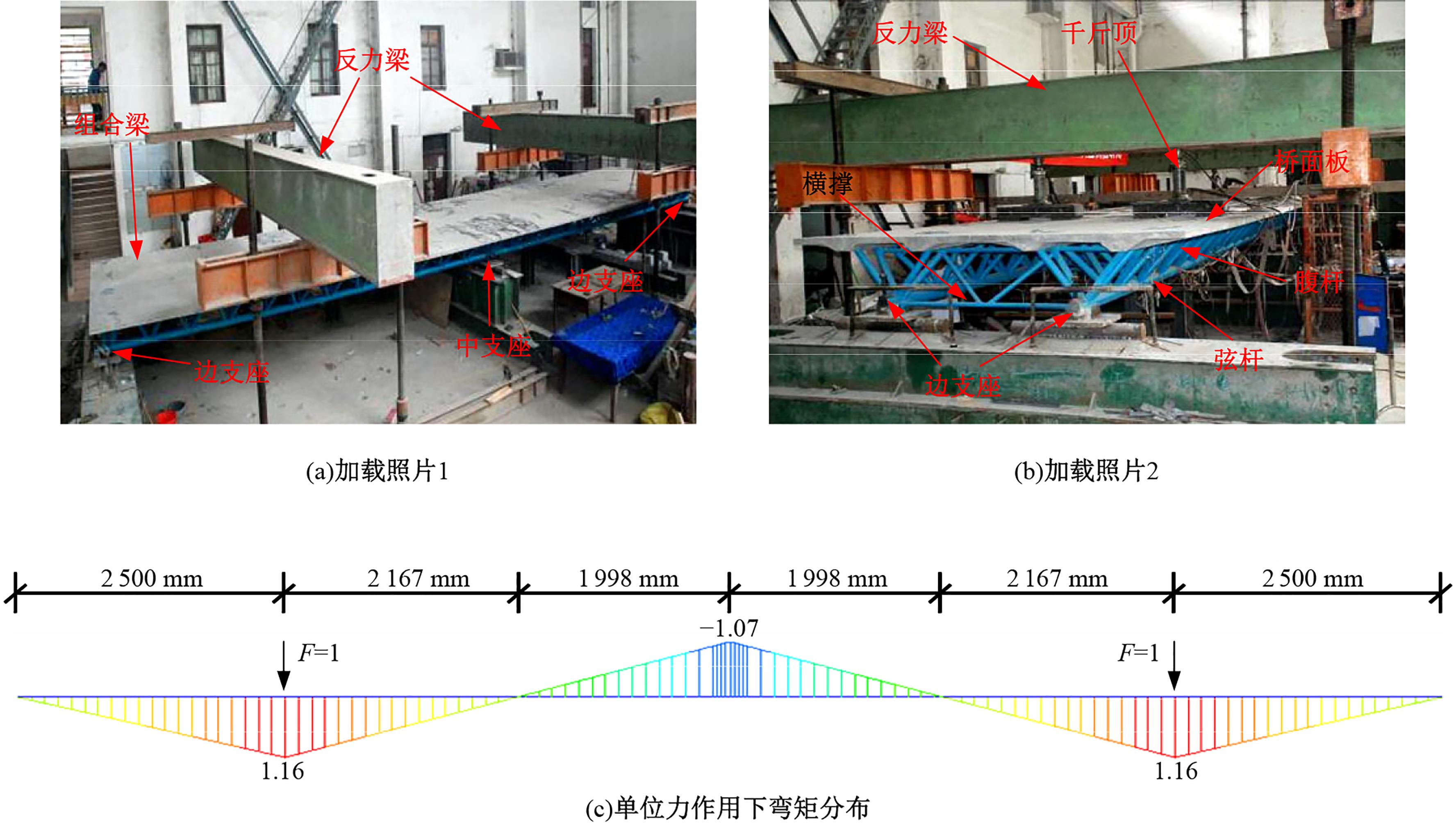

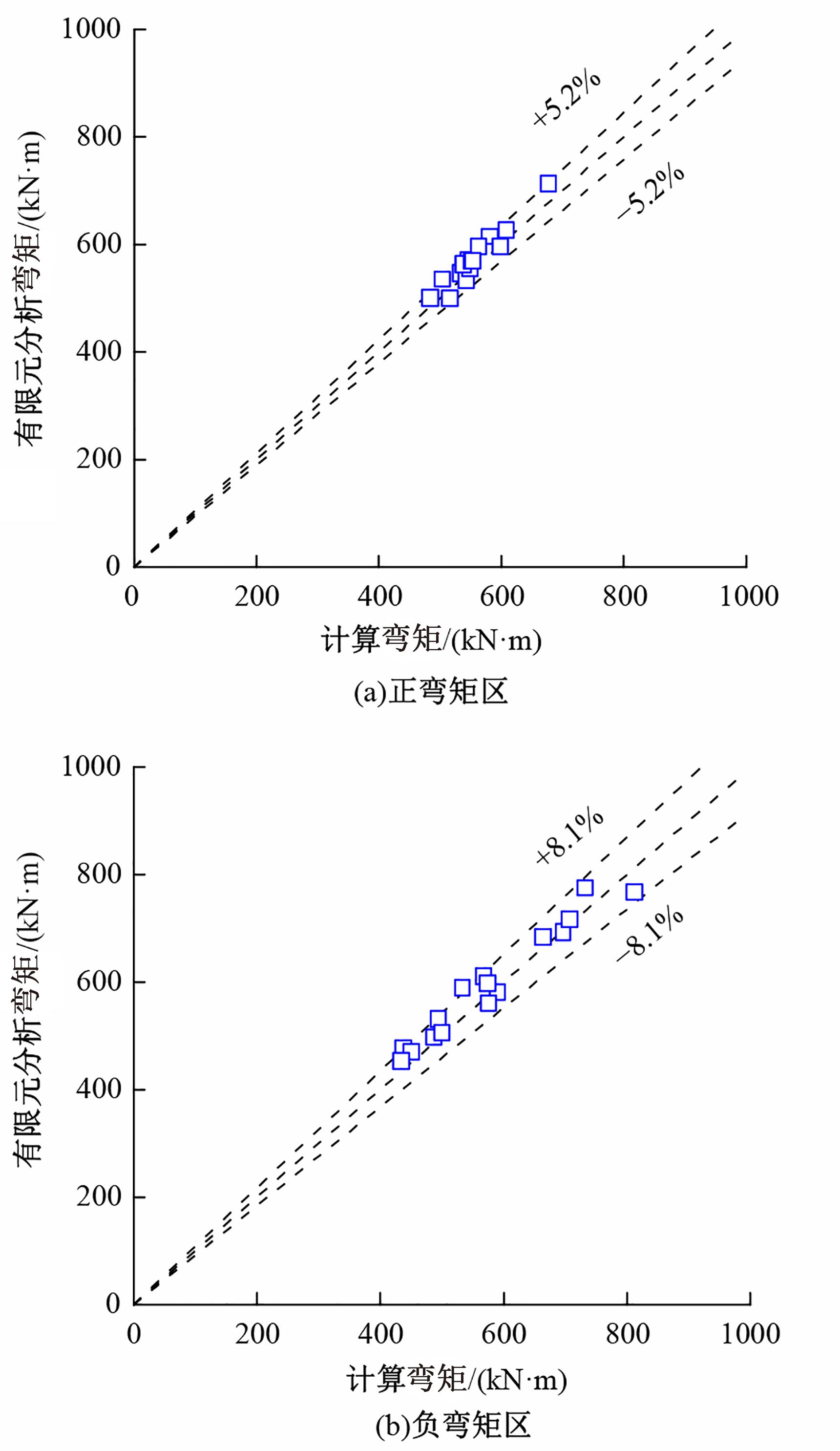

Flexural behavior of composite continuous girders with concrete-filled steel tubular truss chords

Han-hui HUANG1( ),Kang-ming CHEN2,Qing-xiong WU2

),Kang-ming CHEN2,Qing-xiong WU2

- 1.College of Civil Engineering,Fujian Chuanzheng Communication College,Fuzhou 350007,China

2.College of Civil Engineering,Fuzhou University,Fuzhou 350116,China

CLC Number:

- U441

| 1 | Jung K H, Kim J H J, Yi J W, et al. Development and evaluation of new connection systems for hybrid truss bridges[J]. Journal of Advanced Concrete Technology, 2013, 11(2): 61-79. |

| 2 | Tian Z J, Liu Y J, Jiang L, et al. A review on application of composite truss bridges composed of hollow structural section members[J]. Journal of Traffic and Transportation Engineering (English Edition), 2019, 6(1): 94-108. |

| 3 | Xu F, Chen J, Chan T M. Mechanical behaviour of concrete-filled CHS connections subjected to in-plane bending[J]. Engineering Structures, 2017, 148: 101-112. |

| 4 | Song S S, Chen J, Xu F. Mechanical behaviour and design of concrete-filled K and KK CHS connections [J]. Journal of Constructional Steel Research, 2022, 188: 107000. |

| 5 | Hou C, Han L H, Mu T M. Behaviour of CFDST chord to CHS brace composite K-joints: experiments [J]. Journal of Constructional Steel Research, 2017, 135: 97-109. |

| 6 | Xie K Z, Wang H W, Pang J H, et al. Study of the ultimate bearing capacity of concrete-filled steel tube K-joints[J]. KSCE Journal of Civil Engineering, 2019, 23(5): 2254-2262. |

| 7 | Xu F, Chen J, Jin W L. Punching shear failure of concrete-filled steel tubular CHS connections[J]. Journal of Constructional Steel Research, 2016, 124: 113-121. |

| 8 | Xu F, Chen J, Jin W L. Experimental investigation of SCF distribution for thin-walled concrete-filled CHS joints under axial tension loading[J]. Thin-walled Structures, 2015, 93: 149-157. |

| 9 | Wei X, Wen Z Y, Xiao L, et al. Review of fatigue assessment approaches for tubular joints in CFST trusses[J]. International Journal of Fatigue, 2018, 113: 43-53. |

| 10 | Tong L W, Chen K P, Xu G W, et al. Formulae for hot-spot stress concentration factors of concrete-filled CHS T-joints based on experiments and FE analysis [J]. Thin-walled Structures, 2019, 136: 113-128. |

| 11 | Huang W J, Fenu L, Chen B C, et al. Experimental study on K-joints of concrete-filled steel tubular truss structures[J]. Journal of Constructional Steel Research, 2015, 107: 182-193. |

| 12 | Zheng J, Nakamura S, Ge Y J, et al. Extended formulation of stress concentration factors for CFST T-joints[J]. Journal of Bridge Engineering, 2020, 25(1): 06019006. |

| 13 | Zheng J, Nakamura S, Okumatsu T, et al. Formulation of stress concentration factors for concrete-filled steel tubular (CFST) K-joints under three loading conditions without shear forces[J]. Engineering Structures, 2019, 190: 90-100. |

| 14 | Musa I A, Mashiri F R. Stress concentration factor in concrete-filled steel tubular K-joints under balanced axial load[J]. Thin-walled Structures, 2019, 139: 186-195. |

| 15 | Hou C, Han L H, Mu T M, et al. Analytical behaviour of CFST chord to CHS brace truss under flexural loading[J]. Journal of Constructional Steel Research, 2017, 134: 66-79. |

| 16 | Huang W J, Fenu L, Chen B C, et al. Experimental study on joint resistance and failure modes of concrete filled steel tubular (CFST) truss girders[J]. Journal of Constructional Steel Research, 2018, 141: 241-250. |

| 17 | Han L H, Xu W, He S H, et al. Flexural behaviour of concrete filled steel tubular (CFST) chord to hollow tubular brace truss: experiments[J]. Journal of Constructional Steel Research, 2015, 109: 137-151. |

| 18 | Huang Y H, Liu A R, Fu J Y, et al. Experimental investigation of the flexural behavior of CFST trusses with interfacial imperfection[J]. Journal of Constructional Steel Research, 2017, 137: 52-65. |

| 19 | Zhou W B, Chen Y, Wang K, et al. Experimental research on circular concrete filled stainless steel tubular truss[J]. Thin-walled Structures, 2017, 117: 224-238. |

| 20 | Chen Y, Feng R, Gao S W. Experimental study of concrete-filled multiplanar circular hollow section tubular trusses[J]. Thin-walled Structures, 2015, 94: 199-213. |

| 21 | Xu W, Han L H, Tao Z. Flexural behaviour of curved concrete filled steel tubular trusses[J]. Journal of Constructional Steel Research, 2014, 93: 119-134. |

| 22 | Chen S L, Hou C, Zhang H, et al. Structural behaviour and reliability of CFST trusses with random initial imperfections[J]. Thin-walled Structures, 2019, 143: 106192. |

| 23 | . 混凝土物理力学性能试验方法标准 [S]. |

| 24 | . 金属材料 拉伸试验 第1部分: 室温试验方法 [S]. |

| 25 | 曾明根, 武彧, 苏庆田. 钢纤维混凝土组合桥面板负弯矩区开裂性能试验[J]. 吉林大学学报:工学版, 2023, 53(11): 3176-3185. |

| Zeng Ming-gen, Wu Yu, Su Qing-tian. Experimental studies on cracking behavior of steel fiber reinforced concrete slab in negative moment region of orthotropic composite bridge deck[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(11): 3176-3185. | |

| 26 | . 混凝土结构设计规范 [S]. |

| 27 | 刘威. 钢管混凝土局部受压时的工作机理研究[D]. 福州: 福州大学土木工程学院, 2005. |

| Liu Wei. Research on mechanism of concrete-filled steel tubes subjected to local compression[D]. Fuzhou: College of Civil Engineering, Fuzhou University, 2005. | |

| 28 | 王彤, 谢旭, 王渊, 等. 桁腹式组合桁梁结构计算理论[J]. 浙江大学学报:工学版, 2014, 48(4): 711-720. |

| Wang Tong, Xie Xu, Wang Yuan, et al. Analysis of prestressed composite truss girders with steel truss webs[J]. Journal of Zhejiang University (Engineering Science), 2014, 48(4): 711-720. | |

| 29 | . 钢管混凝土结构技术规范 [S]. |

| [1] | Chun-lei ZHANG,Chang-yu SHAO,Qing-tian SU,Chang-yuan DAI. Experimental on positive bending behaviour of composite bridge decks with steel-fiber-reinforced concrete and longitudinal bulb-flat ribs [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1634-1642. |

| [2] | Chang-jiang SHAO,Hao-meng CUI,Qi-ming QI,Wei-lin ZHUANG. Longitudinal seismic mitigation of near⁃fault long⁃span RC soft⁃lighten arch bridge based on viscous damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1355-1367. |

| [3] | Qiu ZHAO,Peng CHEN,Yu-wei ZHAO,Ao YU. Overall mechanical performance of jointless bridges with arch structure behind abutment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1016-1027. |

| [4] | Hong ZHANG,Zhi-wei ZHU,Tian-yu HU,Yan-feng GONG,Jian-ting ZHOU. Bridge bolt defect identification method based on improved YOLOv5s [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 749-760. |

| [5] | Zhi-qiang HAN,Gang XIE,Ya-juan ZHUO,Zuo-long LUO,Hua-teng LI. Vibration response of continuous girder bridge based on wheel⁃deck coherent excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 436-444. |

| [6] | Guo-jun YANG,Ya-hui QI,Xiu-ming SHI. Review of bridge crack detection based on digital image technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 313-332. |

| [7] | Guo-jin TAN,Ji OU,Yong-ming AI,Run-chao YANG. Bridge crack image segmentation method based on improved DeepLabv3+ model [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 173-179. |

| [8] | Guan-xu LONG,Xiu-shi ZHANG,Gong-feng XIN,Tao WANG,Gan YANG. Bridge weigh-in-motion combined with machine version [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 188-197. |

| [9] | Xing WEI,Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO. Numerical simulation of residual stress field of stud girth weld in low temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 198-208. |

| [10] | Ran AN,You-zhi WANG. Shear properties of shear stud connectors under combined tension and shear loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2554-2562. |

| [11] | Xin-dai ZUO,Jin-quan ZHANG,Shang-chuan ZHAO. Fatigue stiffness degradation and life prediction method of in⁃service concrete T⁃beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2563-2572. |

| [12] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [13] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [14] | Guo-jin TAN,Qing-wen KONG,Xin HE,Pan ZHANG,Run-chao YANG,Yang-jun CHAO,Zhong YANG. Bridge scour depth identification based on dynamic characteristics and improved particle swarm optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1592-1600. |

| [15] | Hui JIANG,Xin LI,Xiao-yu BAI. Review on development of bridge seismic structural systems: from ductility to resilience [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1550-1565. |

|

||