Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1657-1664.doi: 10.13229/j.cnki.jdxbgxb.20220856

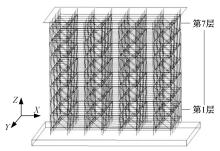

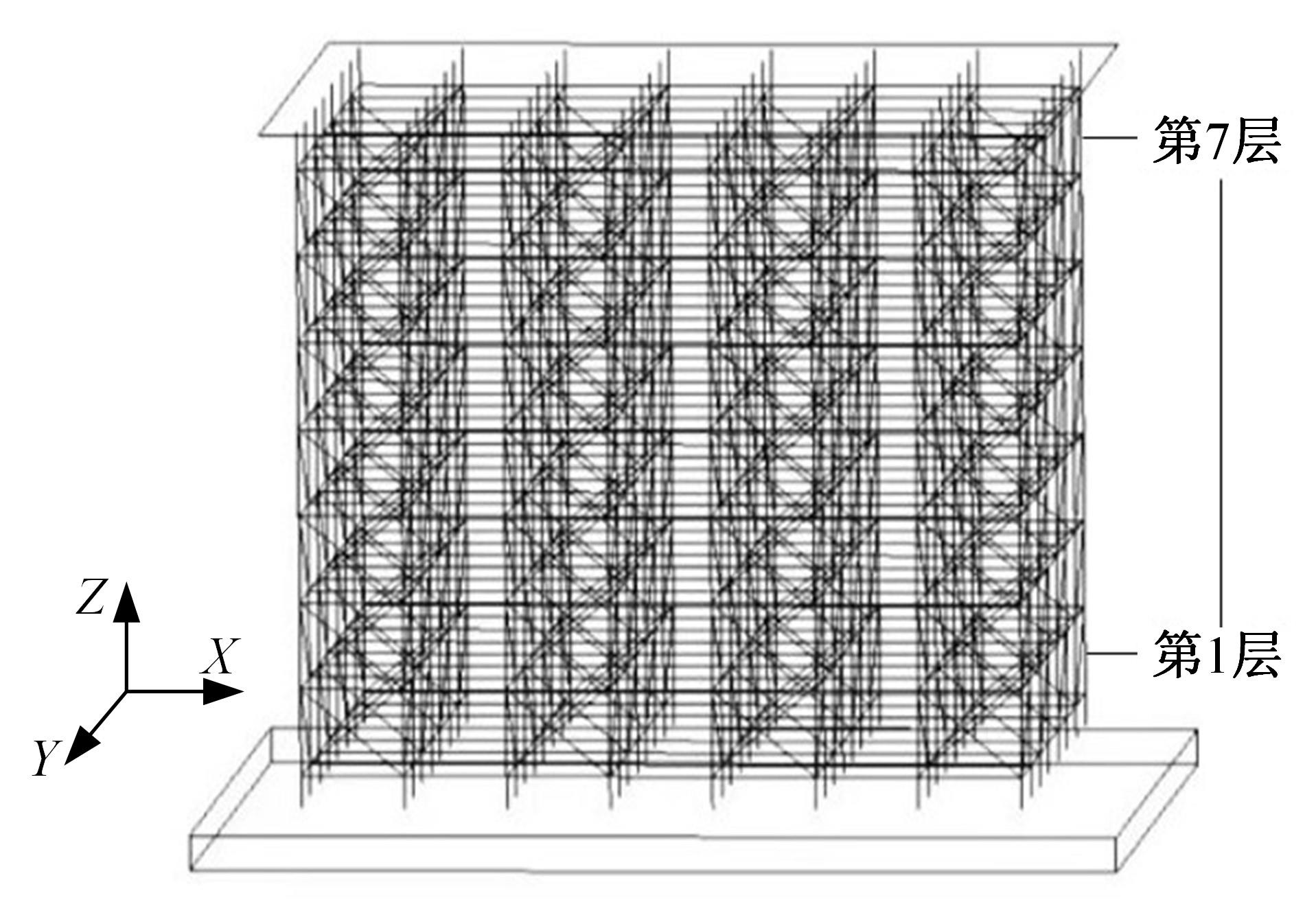

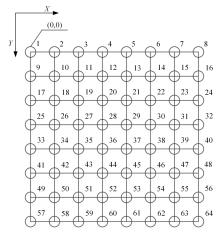

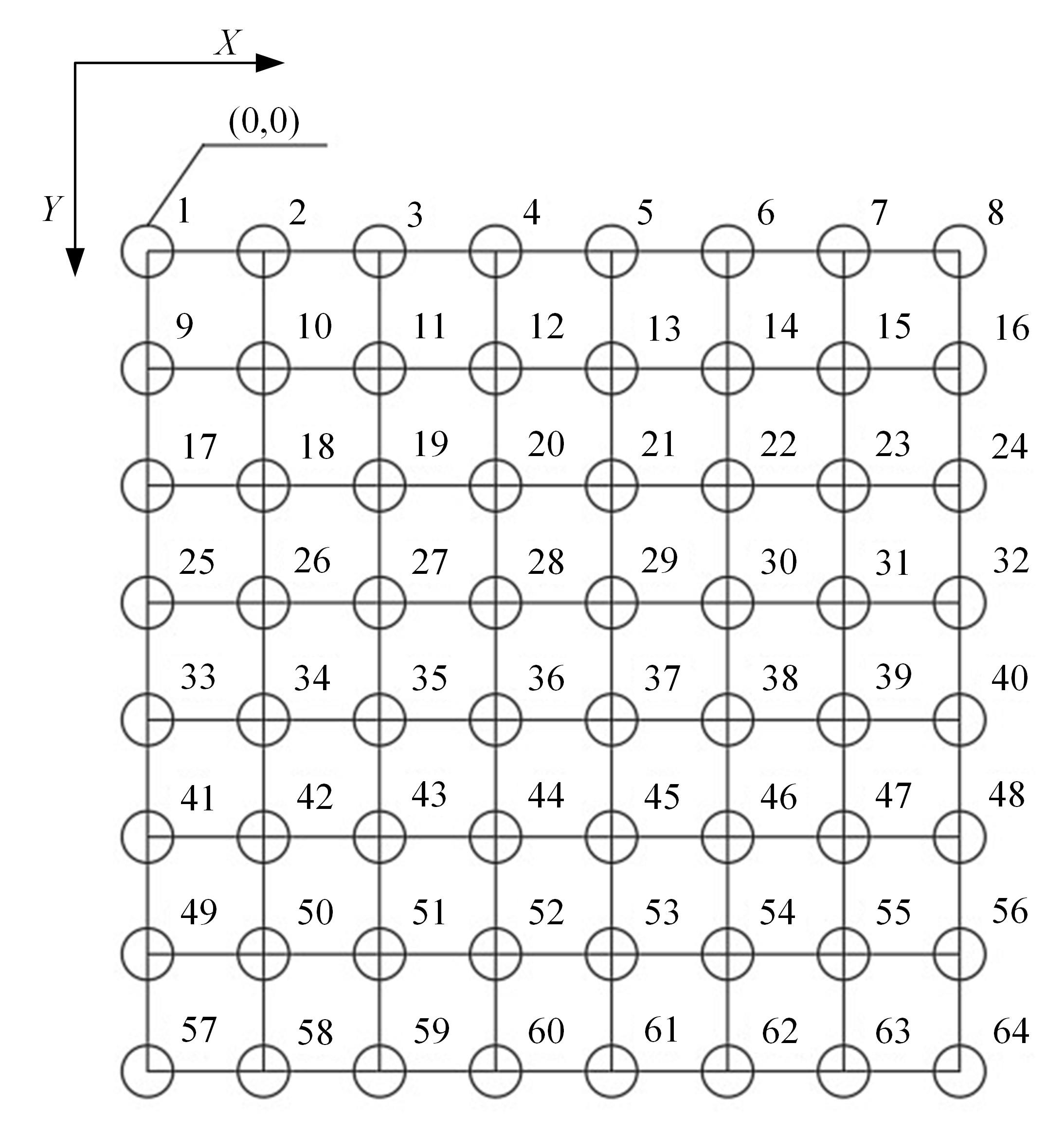

Influence of diagonal brace layout scheme on collapse resistance of high formwork

Xin GAO1,2( ),Jian HE1,Chun-guang LAN2,Ze-qiang WANG2

),Jian HE1,Chun-guang LAN2,Ze-qiang WANG2

- 1.College of Construction Engineering,Jilin University,Changchun 130021,China

2.Beijing Construction Engineering Research Institute Co. ,Ltd. ,Beijing 100039,China

CLC Number:

- TU318

| 1 | 时炜. 承插型盘扣式脚手架在高大模板支撑中的应用[J]. 建筑施工,2005,37(9):1091-1093. |

| Shi Wei. Application of bell-sigot bearing-insertion scaffold to high and large formwork support system[J]. Building Construction, 2005, 37(9): 1091-1093. | |

| 2 | 葛元辉. 高支模施工技术在房建土建工程中的应用研究[J]. 施工技术,2021,48(7):30-32. |

| Ge Yuan-hui. Research on the application of high formwork construction technology in housing construction and civil engineering[J]. Construction Technology, 2021, 48(7):30-32. | |

| 3 | 孙世梅. 2010~2016年建筑施工脚手架坍塌事故统计分析[J]. 吉林建筑大学学报, 2018, 35(4):33-36. |

| Sun Shi-mei. Statistical analysis of collapse accidents of construction scaffolding in 2010~2016[J]. Journal of Jilin Jianzhu University, 2018, 35(4): 33-36. | |

| 4 | 庄金平,蔡雪峰,郑永乾,等. 高大模板扣件式钢管支撑系统整体受力性能研究[J]. 土木工程学报, 2016, 49(10): 57-63, 87. |

| Zhuang Jin-ping, Cai Xue-feng, Zheng Yong-qian, et al. Study on the overall stability of high and large formwork support system with fastening style steel pipe[J]. China Civil Engineering Journal, 2016, 49(10): 57-63, 87. | |

| 5 | 龚照森. 扣件式钢管模板支架抗连续性倒塌理论分析[D]. 重庆: 重庆大学土木工程学院, 2013. |

| Gong Zhao-sen. Theoretical study about resisting progressive collapse of fastener steel tubular formwork supports[D]. Chongqing: College of Civil Engineering, Chongqing University, 2013. | |

| 6 | 韩源彬. 盘扣式模板支撑架承载性能研究与应用[D]. 北京: 清华大学土木工程系, 2018. |

| Han Yuan-bin. Research and application on load-bearing capacity of socket plate fastener type scaffold [D]. Beijing: Department of Civil Engineering, Tsinghua University, 2018. | |

| 7 | 刘莉,王萌,吴金国,等. 现浇混凝土模板体系可调支托伸出长度[J]. 沈阳建筑大学学报:自然科学版, 2015, 31(3): 466-473. |

| Liu Li, Wang Meng, Wu Jin-guo, et al. Study on the extended length of adjustable bearing bracket in cast-inplace concrete formwork system[J]. Journal of Shenyang Jianzhu University (Natural Science), 2015, 31(3): 466-473. | |

| 8 | 袁庆凯. 扣件式满堂支撑体系垮塌机理数值模拟[D]. 秦皇岛: 燕山大学建筑工程与力学学院, 2015. |

| Yuan Qing-kai. The numerical simulation on collapse mechanism of fastener type full framing support system[D]. Qinghuangdao: School of Civil Engineering and Mechanics, Yanshan University, 2015. | |

| 9 | 唐柱才. 应用有限元程序ANSYS/LS-DYNA进行结构的屈曲模拟[J]. 化工装备与技术, 2004, 25(3): 27-31. |

| Tang Zhu-cai. The finite element program ANSYS/LS-DYNA was used to simulate the buckling of the structure[J]. Chemical Equipment and Technology, 2004, 25(3): 27-31. | |

| 10 | 周潭飞. 盘扣式钢管模板支撑架稳定承载力研究[D]. 西安: 西安建筑科技大学建筑与土木工程学院, 2019. |

| Zhou Tan-fei. Study on stability bearing capacity of disc-fastened steel tube formwork supporting frame [D]. Xi'an: School of Architecture and civil Engineering, Xi'an University of Architecture and Technology, 2019. | |

| 11 | , 建筑施工承插型盘扣式钢管支架安全技术规程 [S]. |

| 12 | 刘成清. ANSYS/LS-DYNA工程结构抗震、抗撞击与抗连续倒塌分析[M]. 北京:中国建筑工业出版社, 2014. |

| 13 | 陈桂香,郭泽群,胡德平,等. 承插型盘扣式钢管支架盘扣节点扭矩-转角模型适用性研究[J]. 西安建筑科技大学学报:自然科学版, 2020, 52(2): 192-199. |

| Chen Gui-xiang, Guo Ze-qun, Hu De-ping, et al. Study on applicability of torque-rotation model of disk-pin joint node of disk lock steel tubular scaffold [J]. Journal of Xi'an University of Architecture and Technology. (Natural Science Edition), 2020, 52(2): 192-199. | |

| 14 | 李晓旭. 盘扣式支架单根立杆竖向承载性能的研究与应用[D]. 合肥: 安徽建筑大学土木工程学院, 2020. |

| Li Xiao-xu. Research and application of vertical bearing capacity of single upright of disc button bracket [D]. Hefei: College of Civil Engineering, Anhui Jianzhu University, 2020. | |

| 15 | 胡晓斌. 单层平面钢框架连续倒塌动力效应分析[J]. 工程力学, 2008, 25(6): 38-43. |

| Hu Xiao-bin. Dynamic effect analysis during progressive collapse of a single-story steel plane frame[J]. Engineering Mechanics, 2008, 25(6): 38-43. | |

| 16 | 江晓峰. 建筑结构连续性倒塌及其控制设计的研究现状[J]. 土木工程学报, 2008, 41(6): 1-8. |

| Jiang Xiao-feng. A review on the progressive collapse and control design of building structures[J]. China Civil Engineering Journal, 2008, 41(6): 1-8. | |

| 17 | 蔡建国. 大跨空间结构连续倒塌分析若干问题探讨[J]. 工程力学, 2012, 29(3): 143-149. |

| Cai Jian-guo. Discussion on the progressive collapse analysis of long-span space structures[J]. Engineering Mechanics, 2012, 29(3): 143-149. | |

| 18 | 张月强. 大跨度钢结构抗连续倒塌动力分析关键问题研究[J]. 建筑结构学报, 2014, 35(4): 49-56. |

| Zhang Yue-qiang. Study on key issues of dynamic analysis for anti-progressive collapse of large span steel structure[J]. Journal of Building Structures, 2014, 35(4): 49-56. | |

| 19 | 李海锋,郭小农,罗永峰,等. 索支撑柔性摩天轮结构抗倒塌性能分析[J]. 吉林大学学报:工学版, 2015, 45(2): 406-413. |

| Li Hai-feng, Guo Xiao-nong, Luo Yong-feng, et al. Collapse resistance behavior of Ferris wheel with stay cables[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(2): 406-413. |

| [1] | Zhen-yong DI,Xin-hui YANG. Characteristic distribution of inter story deformation of building structure after earthquake [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1377-1384. |

| [2] | Zhi-qiang HAN,Gang XIE,Ya-juan ZHUO,Zuo-long LUO,Hua-teng LI. Vibration response of continuous girder bridge based on wheel⁃deck coherent excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 436-444. |

| [3] | Guo-hui CHEN,Ye-yin XU,Ying-hou JIAO. Meshing stiffness calculation and vibration analysis of helical gear considering deflection [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1902-1910. |

| [4] | Qing-xia ZHANG,Ji-lin HOU,Xin-hao AN,Xiao-yang HU,Zhong-dong DUAN. Road roughness identification method based on vehicle impulse response [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1765-1772. |

| [5] | Zi-yu LIU,Shi-tong CHEN,Mo-mo ZHI,Xiao-ming HUANG,Zhe-xin CHEN. Ultimate bearing capacity of temporary⁃permanent conversion rush⁃repair steel pier for emergency use [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1601-1611. |

| [6] | Zhi-qiang HAN,Gang XIE,Yong-jun ZHOU,Shi-zhong LIU,Min-jie JIN. Numerical analysis method of vehicle⁃bridge coupling vibration of curved bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 515-522. |

| [7] | Yi MA,Jian ZHANG,Mei-xiang YOU,Rong GONG,Te-li HE,Wei FANG. Optimization of dynamic control strategy of fuel cell air supply system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2175-2181. |

| [8] | Jun CHEN,Shao-xian WANG,Hui XU,Duan-quan MO,Jing-si HUO,Xu-hua DENG. Experiment on mechanical properties of detachable prefabricated composite beams subjected to negative bending moment [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 604-614. |

| [9] | Chang-jun ZHONG,Zhong-bin WANG,Chen-yang LIU. Influencing factors and structural optimization of main cable saddle bearing capacity of suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2068-2078. |

| [10] | Jing ZHOU,Ya-jun LI,Wei-feng ZHAO,Zong-jian LUO,Guo-bin BU. Eccentric compression behavior of bamboo⁃plywood and steel⁃tube dual⁃confined dust⁃powder concrete columns [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2096-2107. |

| [11] | Ya-feng GONG,Jia-xiang SONG,Guo-jin TAN,Hai-peng BI,Yang LIU,Cheng-xin SHAN. Multi⁃vehicle bridge weigh⁃in⁃motion algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 583-596. |

| [12] | ZHANG Yun-long, LIU Zhan-ying, WU Chun-li, WANG Jing. Static and dynamic responses of steel-concrete composite beams [J]. 吉林大学学报(工学版), 2017, 47(3): 789-795. |

| [13] | LI Jing, YANG Xiong, MIAO Hui, SHI Zheng-tang. Dynamic characteristics of electronic hydraulic brake system based on bench test [J]. 吉林大学学报(工学版), 2016, 46(1): 15-20. |

| [14] | HOU Zhong-ming, WANG Yuan-qing, XIA He, ZHANG Tian-shen. Simply-supported steel-concrete composite beams under moving load [J]. 吉林大学学报(工学版), 2015, 45(5): 1420-1427. |

| [15] | CHENG Qiang, ZHANG Zhen-dong, GUO Hui, XIE Nai-liu. Electro-magnetic-thermal coupling of GDI injector [J]. 吉林大学学报(工学版), 2015, 45(3): 806-813. |

|

||