Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (8): 2181-2186.doi: 10.13229/j.cnki.jdxbgxb.20221360

Previous Articles Next Articles

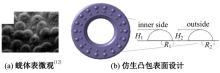

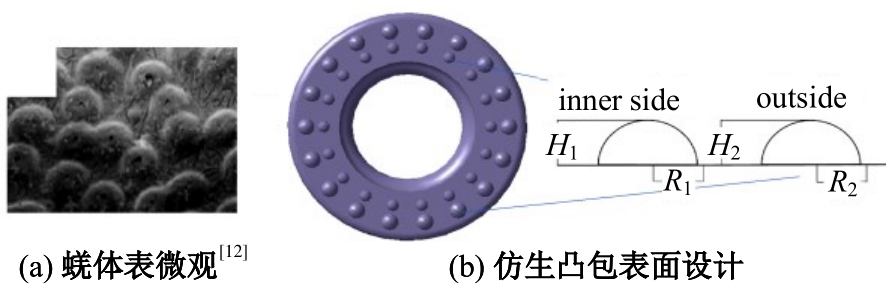

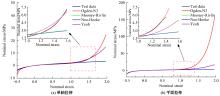

Numerical simulation on friction characteristics of rubber bushing with bionic flexible surfaces

Ce LIANG1( ),Min LI1,Yi LI1,2,Ji-cai LIANG1,2,Qi-gang HAN1(

),Min LI1,Yi LI1,2,Ji-cai LIANG1,2,Qi-gang HAN1( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Chongqing Research Institute,Jilin University,Chongqing 401123,China

CLC Number:

- TG356

| 1 | Kentaro H, Shinichi S. Rubber suspension bushing model identified by general design parameters for initial design phase[J]. SAE International Journal of Vehicle Dynamics, Stability, and NVH, 2018, 2(4): 325-335. |

| 2 | Rivas T, Jonathan T M, Juan C, et al. Analytical design and optimization of an automotive rubber bushing[J]. Shock & Vibration, 2019, 2019: 1-13. |

| 3 | Kemna J, Edelmann J, Ploechl M. Influences on long-term behaviour of elastomer chassis bushings considering their geometric design and rubber compounds[J]. Polymer Testing, 2018, 65: 69-77. |

| 4 | 邓雄志,刘涛,苏泽博. 轿车底盘橡胶衬套半经验设计方法研究[J]. 汽车技术, 2018, 7: 54-58. |

| Deng Xiong-zhi, Liu Tao, Su Ze-bo. Research on half-empirical methodology of car chassis rubber bush[J]. Automobile Technology, 2018, 7: 54-58. | |

| 5 | 张海莉. 控制臂舒适性液压衬套的优化设计[J]. 汽车与新动力, 2022, 5(4): 66-70. |

| Zhang Hai-li. Optimal design of comfortable hydraulic bushing for control arm[J]. Automobile and New Powertrain, 2022, 5(4): 66-70. | |

| 6 | 童华,陈国银,祝效华. 谐壁厚螺杆钻具橡胶衬套线型设计与仿真分析[J]. 系统仿真学报, 2018, 2: 647-653. |

| Tong Hua, Chen Guo-yin, Zhu Xiao-hua. Linear design and simulation analysis for harmonic-distance rubber bushing of PDM[J]. Journal of System Simulation, 2018, 2: 647-653. | |

| 7 | Jia H L, Wang W J, Wang W P, et al. Application of anti-adhesion structure based on earthworm motion characteristics[J]. Soil and Tillage Research, 2018, 178(1): 159-166. |

| 8 | Gu Y Q, Zhao G, Liu H, et al. Characteristics of seal shell body's rubber ring with bionic dimpled surfaces of aerodynamic extinguishing cannon[J]. Journal of Central South University, 2013, 20(11): 3065-3076. |

| 9 | Peifer R, Lungarella M, Iida F. Self-organization, embodiment, and biologically inspired robotics[J]. Science, 2007, 318: 1088-1093. |

| 10 | Wang Z Z, Zhang Z H, Sun Y H, et al. Wear behavior of bionic impregnated diamond bits[J]. Tribology International, 2016, 94: 217-222. |

| 11 | 任露泉,丛茜,陈秉聪, 等. 几何非光滑典型生物体表防粘特性的研究[J]. 农业机械学报, 1992, 2: 29-35. |

| Ren Lu-quan, Cong Qian, Chen Bing-cong, et al. A study on the adhesion reducing character of geometric nonsmooth surface of typical animaL[J]. Transactions of the Chinese Society of Agricultural Machinery, 1992, 2: 29-35. | |

| 12 | 贾贤,任露泉,佟金, 等. 土壤动物体表非光滑对体表润湿性的影响[J]. 农业工程学报, 1995, 11: 1-4. |

| Jia Xian, Ren Lu-quan, Tong Jin, et al. Affectionsofsoilanimal´sunsmoothcuticlesonthewettabilityofthecuticles[J]. Transactions of The Chinese Society of Agricultural Engineering, 1995, 11: 1-4. | |

| 13 | 高晋,宋传学. 橡胶衬套刚度对悬架特性的影响[J]. 吉林大学学报: 工学版, 2010, 40(2): 324-329. |

| Gao Jin, Song Chuan-xue. Influence of rubber bushing stiffness on suspension performance[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(2): 324-329. | |

| 14 | 梁继才,孙磊明,刘天宝,等. 多巴胺改性硅炭黑增强橡胶复合材料性能[J]. 吉林大学学报: 工学版, 2022, 52(5): 1030-1036. |

| Liang Ji-cai, Sun Lei-ming, Liu Tian-bao, et al. Performance of dopamine modified silicon carbon black reinforced rubber composite[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(5): 1030-1036. |

| [1] | Xiao HAN,Xian-zhang LING,Shuang TIAN,Sheng-yi CONG. Analysis and control of mud spillover in high⁃speed railway ballast⁃track subgrade caused by grouting [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 506-515. |

| [2] | Ce LIANG,Fu-lei HUANG,Ji-cai LIANG,Yi LI. Numerical simulation on deformation of protective beam with “日”-shaped section during rotary draw bending [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3397-3403. |

| [3] | Liu ZHANG,Xiao-yi ZHENG,Fan ZHANG,Yu ZHAO,Shu-yang ZHAO. Structural optimization design of large tolerance and multi⁃flexibility lens subassembly [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 478-485. |

| [4] | Yin-ping LI,Tian-xu JIN,Li LIU. Design and dynamic characteristic simulation of pantograph⁃catenary continuous energy system for pure electric LHD [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 454-463. |

| [5] | Wei-min ZHUANG,Hong-da SHI,Dong-xuan XIE,Guan-nan YANG. Thickness distribution of adhesive layer in dissimilar clinch⁃adhesive hybrid joint with steel and aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 100-106. |

| [6] | Dong⁃liang CHEN,Rui ZANG,Peng DUAN,Wei⁃peng ZHAO,Xu⁃tao WENG,Yang SUN,Yi⁃peng TANG. Biomimetic design of multi⁃link fishbone based on crescent′s fishtail propulsion theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1246-1257. |

| [7] | ZHOU Jie, LUO Yan, WANG Xun, WANG Hui, LI Yang, TAO Ya-ping. Multi-objective optimization of stamping forming process of head based on response surface model [J]. 吉林大学学报(工学版), 2016, 46(1): 205-212. |

| [8] | CHENG Qiang, ZHANG Zhen-dong, GUO Hui, XIE Nai-liu. Electro-magnetic-thermal coupling of GDI injector [J]. 吉林大学学报(工学版), 2015, 45(3): 806-813. |

| [9] | LI Guo-fa, HAN Ming-zuo, SHAN Cui-yun, LIU Jia. Finite element simulation and experiment of magneto-rheological torque servo device [J]. 吉林大学学报(工学版), 2013, 43(05): 1284-1289. |

| [10] | GAO Jin, SONG Chuan-Xue. Influence of rubber bushing stiffness on suspension performance [J]. 吉林大学学报(工学版), 2010, 40(02): 324-0329. |

| [11] | Guo Kong-hui;Wang Shuang;Ding Hai-tao;Zhang Jian-wei . Elastic coupling characteristic of unsymmetrical rubber bushings of rear suspension [J]. 吉林大学学报(工学版), 2007, 37(06): 1225-1228. |

| [12] |

Yang Shu-kai, Song Chuan-xue, An Xiao-juan, Cai Zhang-lin .

Analyzing effects of suspension bushing elasticity on vehicle yaw response character with virtual prototype method [J]. 吉林大学学报(工学版), 2007, 37(05): 994-0999. |

|