Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1838-1843.doi: 10.13229/j.cnki.jdxbgxb20170798

Previous Articles Next Articles

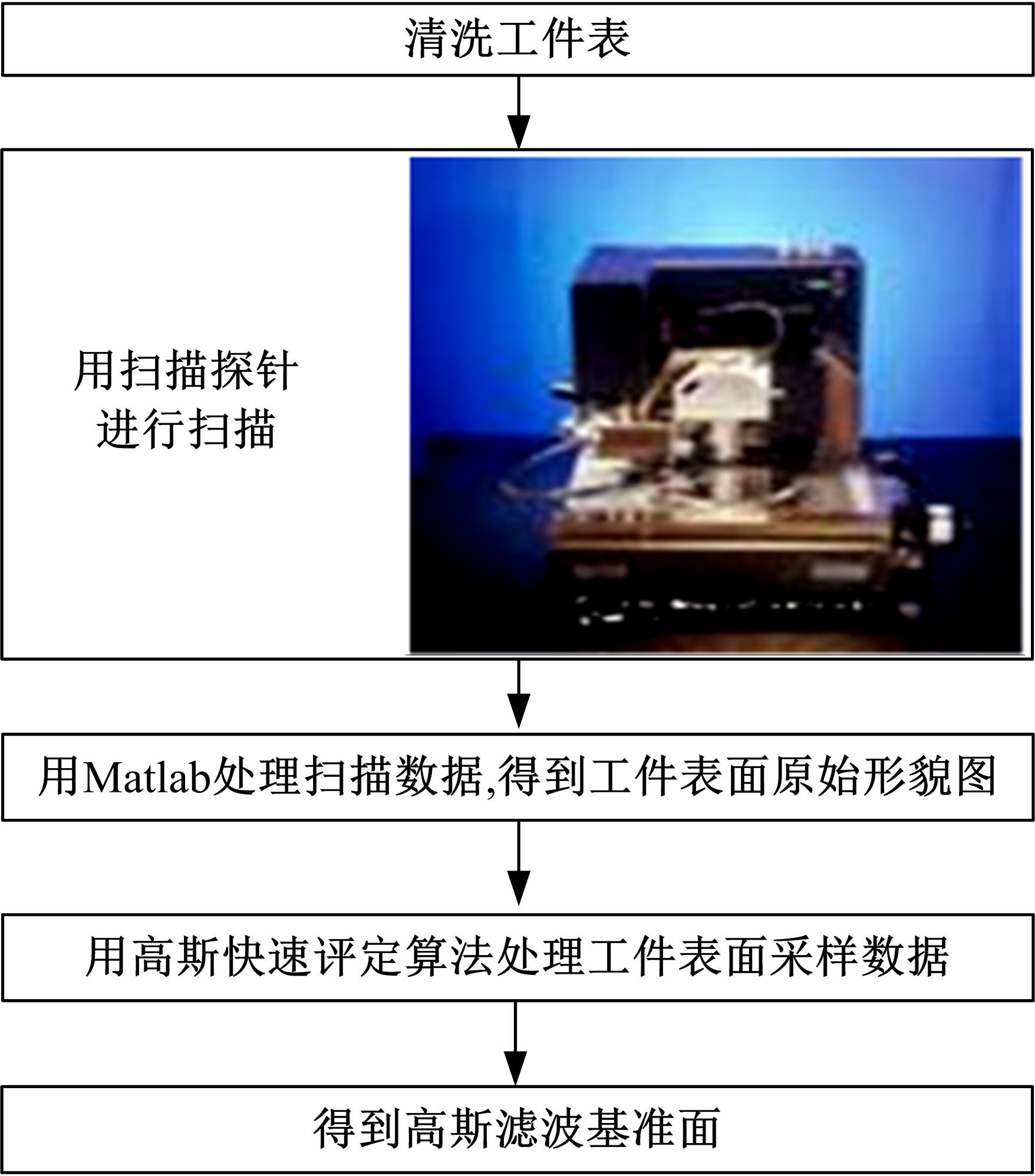

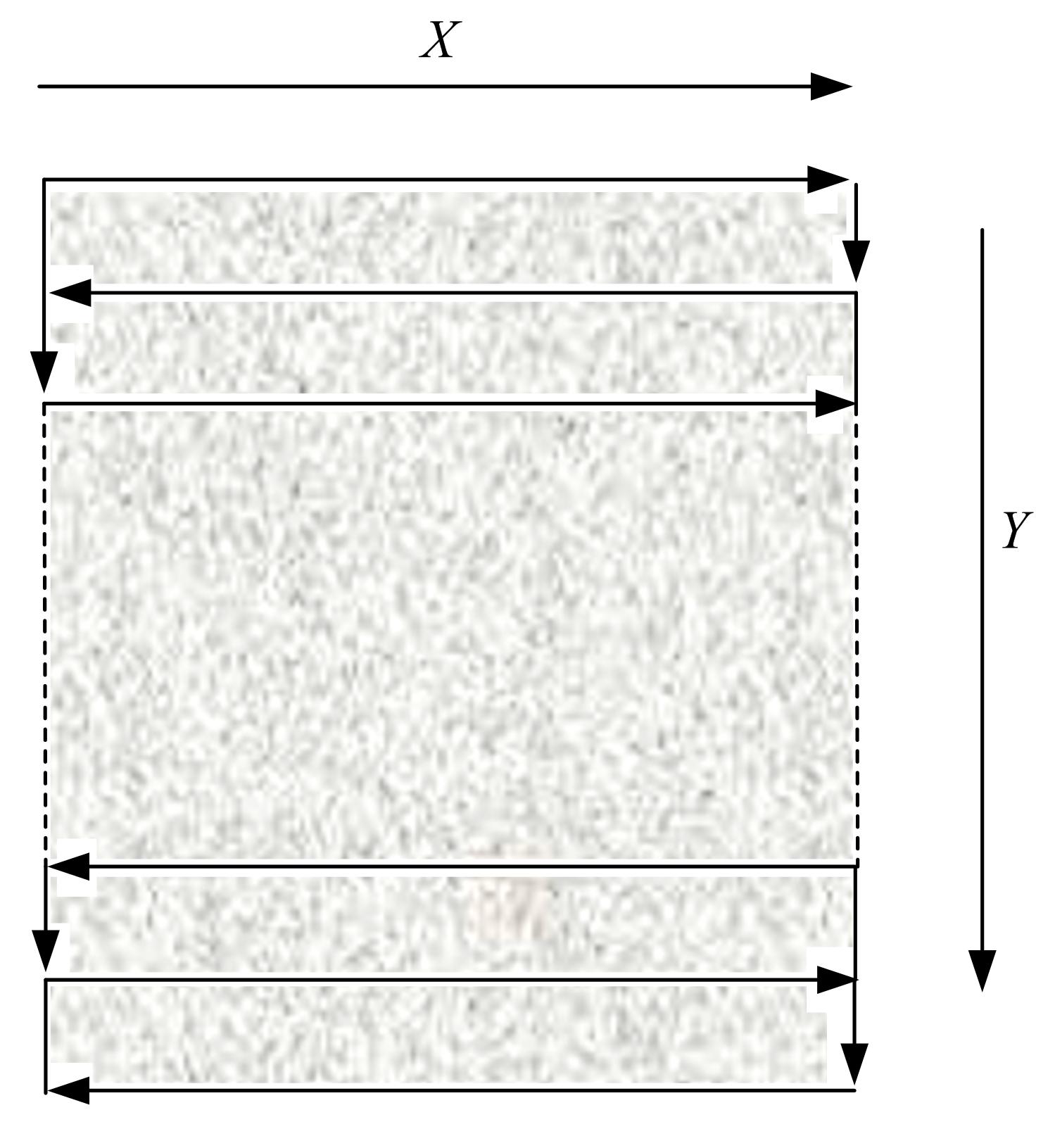

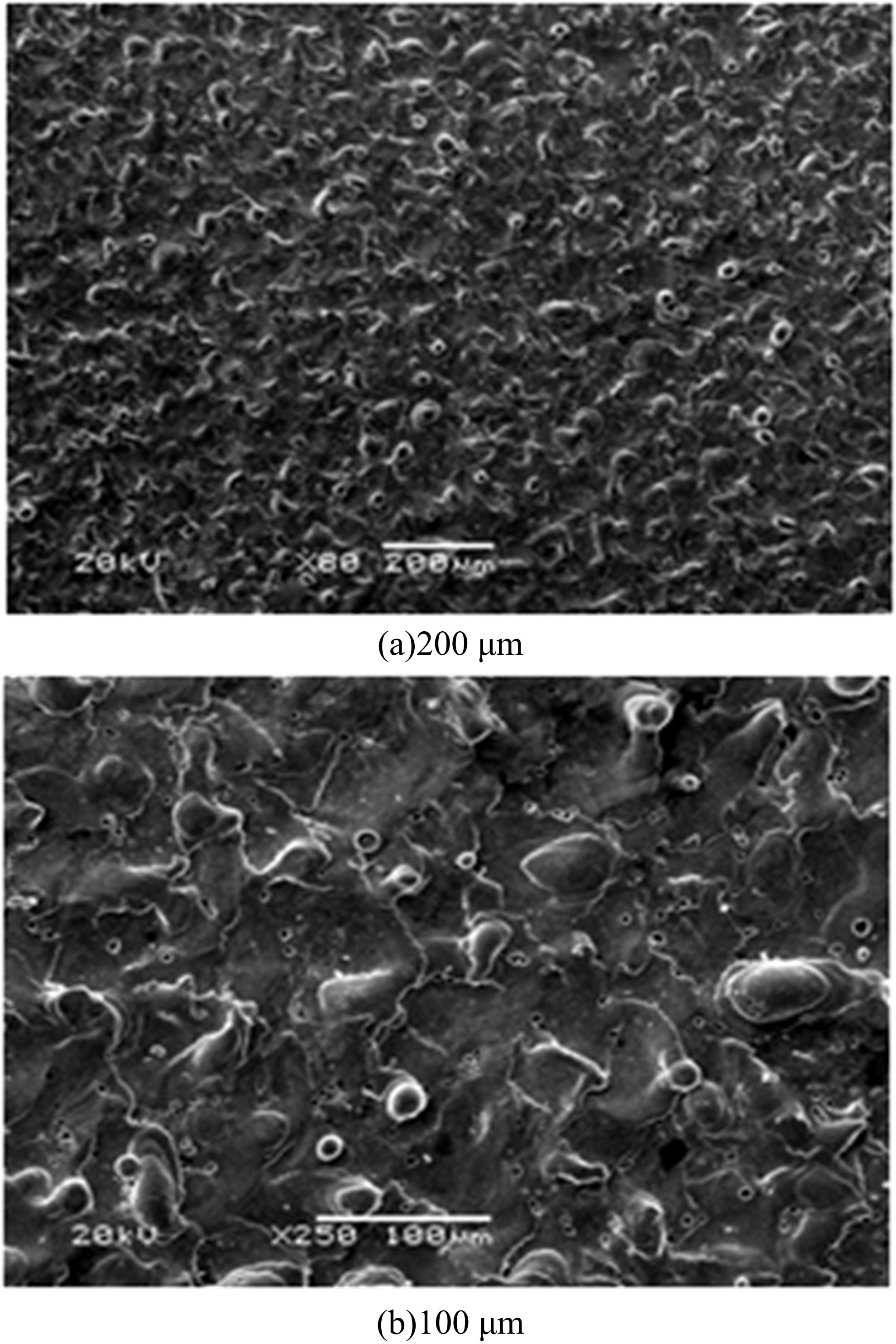

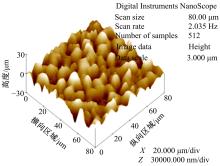

Evaluation of surface roughness of micro electrical discharge machining based-on fast Gauss algorithm

ZHAO Shuang1( ),SHEN Ji-hong2,ZHANG Liu3,ZHAO Han4,CHEN Ke-fan4

),SHEN Ji-hong2,ZHANG Liu3,ZHAO Han4,CHEN Ke-fan4

- 1. College of Automation, Harbin Engineering University, Harbin 150001,China

2. College of Science, Harbin Engineering University, Harbin 150001, China

3. College of Instrumentation & Electrical Engineering, Jilin University, Changchun 130061, China;

4. College of Aerospace and Civil Engineering, Harbin Engineering University, Harbin 150001,China

CLC Number:

- TP274

| [1] |

郭黎滨, 张彬, 崔海 , 等. 微细电火花线切割表面三维粗糙度的结构性参数[J]. 吉林大学学报:工学版, 2015,45(3):851-856.

doi: 10.13229/j.cnki.jdxbgxb201503024 |

|

Guo Li-bin, Zhang Bin, Cui Hai , et al. Structural parameters of 3D roughness for micro wire electrical discharge machining surface[J]. Journal of Jilin University(Engineering and Technology Edition), 2015,45(3):851-856.

doi: 10.13229/j.cnki.jdxbgxb201503024 |

|

| [2] | ISO—11562. Geometrical product specifications(GPS)-surface texture: profile method-metrological characteristics of phase correct filters[S]. |

| [3] | 陈志杰 . 微细电火花加工表面粗糙度评定研究[D]. 哈尔滨:哈尔滨工程大学自动化学院, 2011. |

| Chen Zhi-jie . Research on surface roughness evaluation of micro-EDM[D]. Harbin: College of Automation, Harbin Engineering University, 2011. | |

| [4] |

Raja J, Radhakrishnan V . Filtering of surface profiles using fast fourier transform[J]. International journal of machine tool design & research, 1979,19(3):133-141.

doi: 10.1016/0020-7357(79)90003-9 |

| [5] |

Krystek M . A fast Gauss filtering algorithm for roughness measurements[J]. Precision Engineering, 1996,19(2/3):198-200.

doi: 10.1016/S0141-6359(96)00025-6 |

| [6] | 强锡富, 袁怡宝 . 建立表面粗糙度评定中线的快速算法[J]. 仪器仪表学报, 1994,15(4):353-358. |

| Qiang Xi-fu, Yuan Yi-bao . A fast algorithm founding mean line in surface roughness assessment[J]. Chinese Journal of Scientific Instrument, 1994,15(4):353-358. | |

| [7] | 申丁 . 工程表面表征中基于高斯滤波的并行快速算法研究[D]. 福州:福州大学机械工程及自动化学院, 2014. |

| Shen Ding . The research of the parallel fast algorithm based on gaussian filtering in the characterization of engineering surfaces[D]. Fuzhou: School of Mechanical Engineering and Automation, Fuzhou University, 2014. | |

| [8] | 曾文涵, 高咏生, 谢铁邦 , 等. 三维表面粗糙度高斯滤波快速算法[J]. 计量学报, 2003,24(1):10-13. |

| Zeng Wen-han, Gao Yong-sheng, Xie Tie-bang , et al. A fast gauss filtering algorithm for 3D surface roughness[J]. Acta Metrologica Sinica, 2003,24(1):10-13. | |

| [9] |

许景波, 袁怡宝, 崔晓萌 , 等. 表面测量中高斯滤波中线的有理逼近实现[J]. 吉林大学学报:工学版, 2014,44(5):1347-1352.

doi: 10.7964/jdxbgxb201405020 |

|

Xu Jing-bo, Yuan Yi-bao, Cui Xiao-meng , et al. Rational approximation implementation approach to determine gaussian filtering mean line in surface roughness measurement[J]. Journal of Jilin University (Engineering and Technology Edition), 2014,44(5):1347-1352.

doi: 10.7964/jdxbgxb201405020 |

|

| [10] |

Gagnepain J J, Roques C C . Fractal approach to two dimensional and three dimensional surface roughness[J]. Wear, 1986,109(1-4):119-126.

doi: 10.1016/0043-1648(86)90257-7 |

| [11] | Chen Zhi-jie, Shen Ji-hong, Guo Li-bin. A wavelet method based on goodness of fit test for roughness of micro-EDM [C]//Proceedings of the 2010 IEEE International Conference on Information and Automation, Harbin, China, 2010: 2026-2030. |

| [12] |

Krystek M . A fast gauss filtering algorithm for roughness measurements[J]. Precision Engineering, 1996,19(2):198-200.

doi: 10.1016/S0141-6359(96)00025-6 |

| [13] | 陈桂明, 张明照, 戚红雨 . 应用Matlab语言处理数字信号与数字图像[M]. 北京: 科学出版社, 2000: 124-131. |

| [1] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [2] | LIU Zi-wu, LI Jian-feng. Erosion damage and evaluation of remanufacturing cladding layer for impeller metals FV520B [J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [3] | ZHAO Jia-xin,MA Biao,LI He-yan,ZHU Li,HAN Ming,ZHU Li-an. Thermoelastic stability of wet clutches during engaging process [J]. 吉林大学学报(工学版), 2015, 45(1): 22-28. |

| [4] | MA Yao, DONG Xiao-long, LI Ze-jun, SHEN Lin, ZHAO Hong-wei. Finite element simulation of the effect of different initial contact on nano-indentation [J]. 吉林大学学报(工学版), 2014, 44(5): 1366-1370. |

| [5] | XU Jing-bo,YUAN Yi-bao, CUI Xiao-meng, GUO Xin, WANG Sheng. Rational approximation implementation approach to determine Gaussian filtering mean line in surface roughness measurement [J]. 吉林大学学报(工学版), 2014, 44(5): 1347-1352. |

| [6] | ZHANG Kuo, TAN Qing-chang, WANG Shun, WANG Cong-hui, Bian Li-juan. Friction coefficient in rough soft contact lubrication [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 86-90. |

| [7] | ZHANG Kuo, TAN Qing-chang, WANG Shun, WANG Cong-hui, WANG Chun-yan. Effect of surface roughness amplitude on point contact mixed lubrication condition [J]. 吉林大学学报(工学版), 2012, 42(02): 377-381. |

| [8] | WANG Xiao-lan, WANG Rong-ben. Analysis of lunar rover vibration characteristics based on rigid-flexible coupled model [J]. 吉林大学学报(工学版), 2012, 42(02): 279-284. |

| [9] | ZHANG Lei,HE Xin-sheng,ZHANG Ying,YANG He-ran. Development of new type ER fluid-assisted polishing tool and its polishing experiment [J]. 吉林大学学报(工学版), 2010, 40(04): 1009-1014. |

| [10] | WANG Ruo-ping,LI Cheng-bin,ZHANG Bu-yang, WANG Guo-lin. Application of fractal model in road surface roughness reconstruction [J]. 吉林大学学报(工学版), 2010, 40(04): 991-0994. |

| [11] | WANG Jiazhong, WANG Longshan, LI Guofa1, DING Ning . Surface Roughness Prediction and Control of Cylinder Traverse Grinding Based on Fuzzy Logic [J]. 吉林大学学报(工学版), 2005, 35(04): 386-390. |

|