Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1682-1688.doi: 10.13229/j.cnki.jdxbgxb20180842

Temperature decoupling large range fiber Bragg grating strain sensor

Guang YAN1,2( ),Jian-zhong LU1,2,Kai-yu ZHANG1,2,Fan-yong MENG1,2,Lian-qing ZHU1,2(

),Jian-zhong LU1,2,Kai-yu ZHANG1,2,Fan-yong MENG1,2,Lian-qing ZHU1,2( )

)

- 1. Instrument Science and Optoelectronic Engineering, Beijing Information Science and Technology University, Beijing 100192, China

2. Beijing Laboratory of Optical Fiber Sensing and System, Beijing Information Science and Technology University, Beijing 100016, China

CLC Number:

- TP212.9

| 1 | 李飞, 周占廷, 谢帅 . 试验设计在飞机载荷谱飞行实测中的应用[J]. 航空科学技术, 2017, 28(4): 43-46. |

| Li Fei , Zhou Zhan-ting , Xie Shuai . Application for design of experiment in aircraft load spectrum flight measurement[J]. Aeronautical Science and Technology, 2017, 28(4): 43-46. | |

| 2 | 王少杰, 徐赵东, 李舒, 等 . 基于应变监测的连续梁支承差异沉降识别[J]. 吉林大学学报: 工学版, 2016, 46(4): 1090-1096. |

| Wang Shao-jie , Xu Zhao-dong , Li Shu , et al . Differential settlement identification of pier for continuous beam based on strain monitoring[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(4): 1090-1096. | |

| 3 | 闫楚良 . 飞机载荷谱实测技术与编制原理[M]. 北京: 航空工业出版社, 2010. |

| 4 | Ryu C Y , Lee J R , Kim C G , et al . Buckling behavior monitoring of a composite wing box using multiplexed and multi-channeled built-in fiber Bragg grating strain sensors[J]. Ndt & E International, 2008, 41(7): 534-543. |

| 5 | 王义平, 唐剑, 尹国路, 等 . 光纤光栅制作方法及传感应用[J]. 振动, 测试与诊断, 2015, 35(5): 809-819. |

| Wang Yi-ping , Tang Jian , Yin Guo-lu , et al . Fabrication method and sensing application of FBG[J]. Journal of Vibration, Measurement & Diagnosis, 2015, 35(5): 809-819. | |

| 6 | Kim J H , Shrestha P , Park Y , et al . Application of fiber Bragg grating sensors in light aircraft: ground and flight test[C]⫽Ofs2014, International Conference on Optical Fiber Sensors, Santander Spain, 2014: 1-4. |

| 7 | 陈勇, 刘保林, 刘焕淋, 等 . 基于光纤布拉格光栅的载荷定位与检测方法[J]. 机械工程学报, 2016, 52(18): 8-15. |

| Chen Yong , Liu Bao-lin , Liu Huan-lin , et al . Load location and measurement system based on fiber Bragg grating sensor[J]. Journal of Mechanical Engineering, 2016, 52(18): 8-15. | |

| 8 | Davis C , Tejedor S , Grabovac J , et al . High-strain fiber Bragg gratings for structural fatigue testing of military aircraft[J]. Photonic Sensors, 2012, 2(3): 215-224. |

| 9 | 吴晶, 吴晗平, 黄俊斌, 等 . 用于船舶结构监测的大量程光纤布拉格光栅应变传感器[J]. 光学精密工程, 2014, 22(2): 311-317. |

| Wu Jing , Wu Han-ping , Huang Jun-bin , et al . Large range FBG sensor for ship structure health monitoring[J]. Optics and Precision Engineering, 2014, 22(2): 311-317. | |

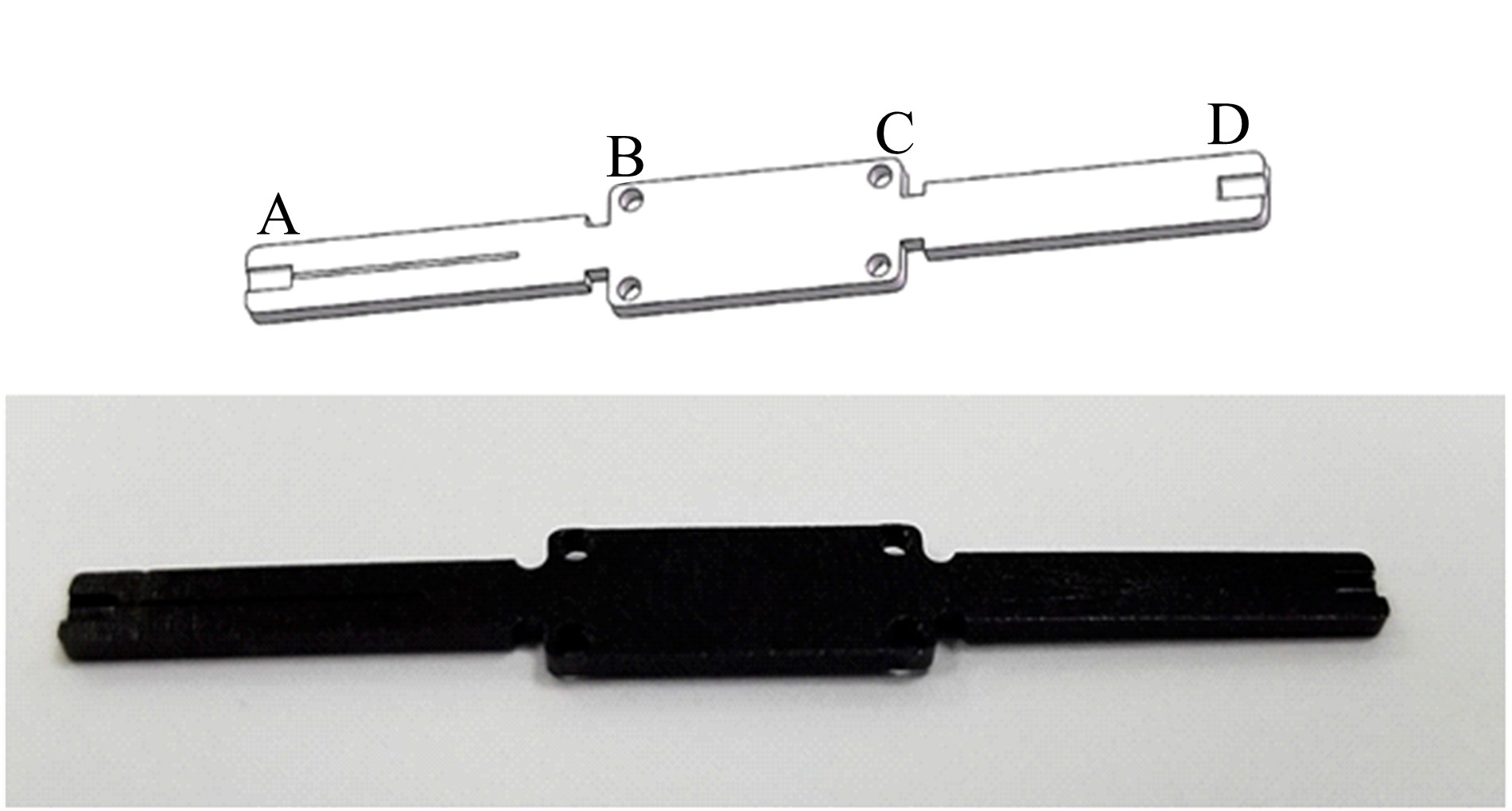

| 10 | 闫光, 庄炜, 刘锋, 等 . 具有增敏效果的光纤光栅应变传感器的预紧封装及传感特性[J]. 吉林大学学报: 工学版, 2016, 46(5): 1739-1745. |

| Yan Guang , Zhuang Wei , Liu Feng , et al . Preload package and characteristics of a sensitizing effect sensor based fiber Bragg grating (FBG)[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(5): 1739-1745. | |

| 11 | 王楚虹 . 基片式光纤光栅应变传感器金属化封装的关键技术[D]. 重庆: 重庆大学光电工程学院, 2017. |

| Wang Chu-hong . Key technology of metallic package for surface-mounted fiber Bragg grating strain sensor[D]. Chongqing: College of Optoelectronic Engineering, Chongqing University, 2017. | |

| 12 | 覃荷瑛, 沈全喜, 钟英杰 . 基于光纤光栅传感器的大应变碳纤维板应力监测研究[J]. 铁道建筑, 2018, 58(4): 53-56. |

| Qin He-ying , Shen Quan-xi , Zhong Ying-jie . Research on stress monitoring of large-strain carbon fiber plate using fiber Bragg grating sensor[J]. Railway Engineering, 2018, 58(4): 53-56. | |

| 13 | 朱星盈, 刘化利, 倪屹, 等 . 新型双环减敏式光纤布拉格光栅应变传感器[J]. 激光与光电子学进展, 2018, 55(3): 174-178. |

| Zhu Xing-ying , Liu Hua-li , Ni Yi , et al . New double-loop desensitization FBG strain sensor[J]. Laser & Optoelectronics Progress, 2018, 55(3): 174-178. | |

| 14 | 王正方, 王静, 隋青美, 等 . 靶式光纤光栅流速传感器在裂隙水模型试验中的应用[J]. 吉林大学学报: 工学版, 2012, 42(6): 1569-1575. |

| Wang Zheng-fang , Wang Jing , Qing-mei Sui , et al . Application of target-type FBG flow velocity sensor in fracture water model test[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42(6): 1569-1575. | |

| 15 | Nicolas M J , Sullivan R W , Richards W L . Large scale applications using FBG sensors: determination of in-flight loads and shape of a composite aircraft wing[J]. Aerospace, 2016, 3(3): 18-32. |

| 16 | 刘寒冰, 时成林, 谭国金 . 考虑剪切滑移效应的叠合梁有限元解[J]. 吉林大学学报: 工学版, 2016, 46(3): 792-797. |

| Liu Han-bing , Shi Cheng-lin , Tan Guo-jin . Finite element solution of composite beam with effect of shear slip[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(3): 792-797. |

| [1] | Jia⁃xu WANG,Qian⁃qian JIANG,Jun⁃yang LI,Yan⁃feng HAN,Lei ZHANG,Ting TANG. Multi⁃objective optimization design of flexspline profile parameters of double⁃arc harmonic drive [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1194-1202. |

| [2] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [3] | WU Jiang, XU Zhuang, LIU Li-jia, JI Yan-ju, LI Su-yi. Peripheral oxygen saturation detecting prototype applied in sleep apnea syndrome [J]. 吉林大学学报(工学版), 2018, 48(2): 640-644. |

| [4] | YANG Cheng, SONG Ping, PENG Wen-jia, JIN Hao-long, PAN Zhi-qiang. Design of armored vehicle integrated test system based on hybrid bus [J]. 吉林大学学报(工学版), 2018, 48(1): 186-198. |

| [5] | YANG Cheng, SONG Ping, PENG Wen-jia, DENG Gao-shou, LIU Xiong-jun. Design of host computer platform for armored vehicle integrated test system [J]. 吉林大学学报(工学版), 2017, 47(6): 1796-1803. |

| [6] | WANG Tian-hao, WANG Zhong-fu, WANG Yu-meng, YANG Kai-yu, GAO Yin-han, MA Xi-lai. Statistic analysis of cable bundle crosstalk based on polynomial chaos expansion [J]. 吉林大学学报(工学版), 2017, 47(5): 1568-1576. |

| [7] | LIU Xiao-wei, LI Hai, WENG Rui, ZHANG Hai-feng, ZHAO Jun. Application of electrostatic torque to improve dynamic characteristics of novel rotational gyroscope [J]. 吉林大学学报(工学版), 2017, 47(3): 850-854. |

| [8] | LIN Jun, ZHAO Yue, JIANG Chuan-dong, WANG Ying-ji. New surface MRS method based on optimized Block inversion [J]. 吉林大学学报(工学版), 2017, 47(2): 530-539. |

| [9] | ZHANG Fei, SHAN Zhong-de, REN Yong-xin, NIE Jun-gang, LIU Feng. Calibration of line array camera for head defect detection system on cylinder cover [J]. 吉林大学学报(工学版), 2017, 47(2): 540-545. |

| [10] | YIN Yao-bao, YUAN Jia-yang, FU Jun-yong. Characteristics of two-stage relief valve with series damping orifice in the front chamber of pilot valve [J]. 吉林大学学报(工学版), 2017, 47(1): 129-136. |

| [11] | YU Sheng-bao, SU Fa, ZHENG Jian-bo, ZHU Zhan-shan. Design of transient electromagnetic receiving system based on LabVIEW [J]. 吉林大学学报(工学版), 2016, 46(5): 1725-1731. |

| [12] | LIN Jun, YANG Yu, HU Xue-yan, WANG Shi-long. Transmitting waveform control technology for transient electromagnetic method based on inductive load [J]. 吉林大学学报(工学版), 2016, 46(5): 1718-1724. |

| [13] | SHEN Mao-dong, CHENG De-fu, AN Zhan-feng, WANG Yi, ZHAO Jing. Optimization of slanting surfaces of five-sided pyramidal full tensor magnetic gradient probe [J]. 吉林大学学报(工学版), 2016, 46(5): 1732-1738. |

| [14] | YAN Guang, ZHUANG Wei, LIU Feng, ZHU Lian-qing. Preload package and characteristics of a sensitizing effect sensor based Fiber Bragg Grating (FBG) [J]. 吉林大学学报(工学版), 2016, 46(5): 1739-1745. |

| [15] | LIN Jun, ZHAO Yue, JIANG Chuan-dong, LI Tong, LIU Xiao-nan. Three-dimensional forward modeling with high precision for underground MRS based on Hammer integration [J]. 吉林大学学报(工学版), 2016, 46(2): 609-615. |

|

||