Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (1): 83-95.doi: 10.13229/j.cnki.jdxbgxb20190925

Previous Articles Next Articles

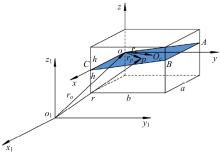

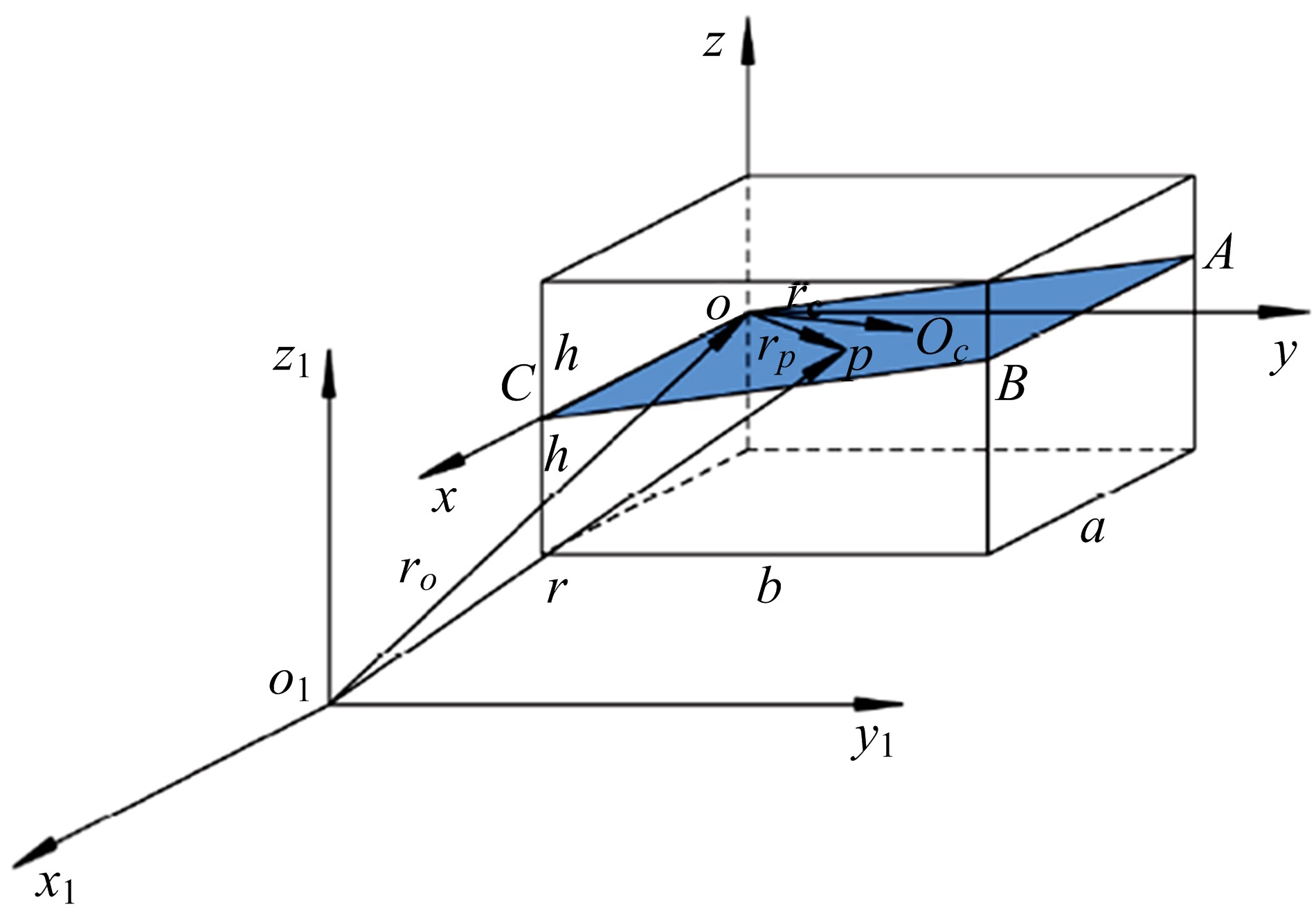

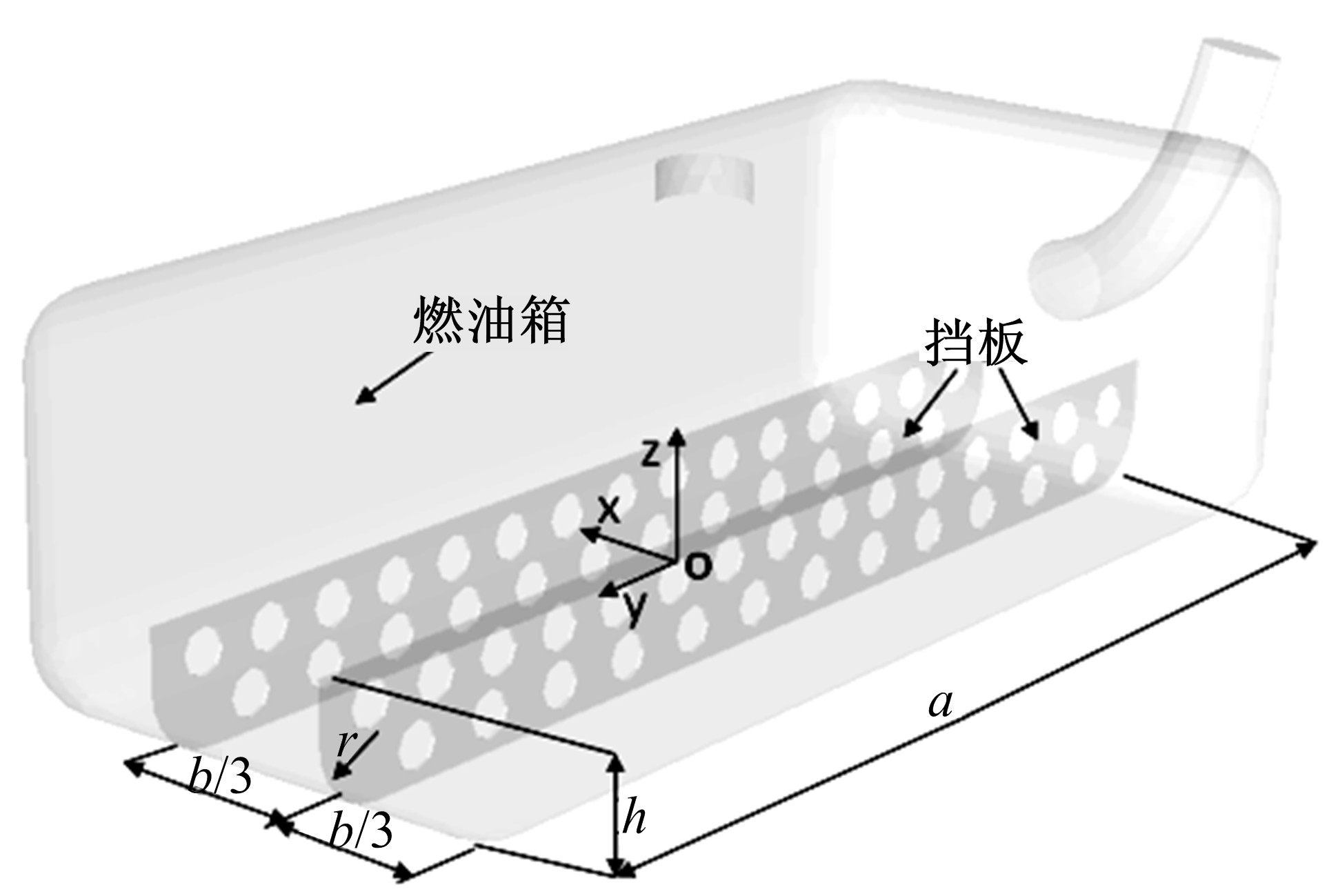

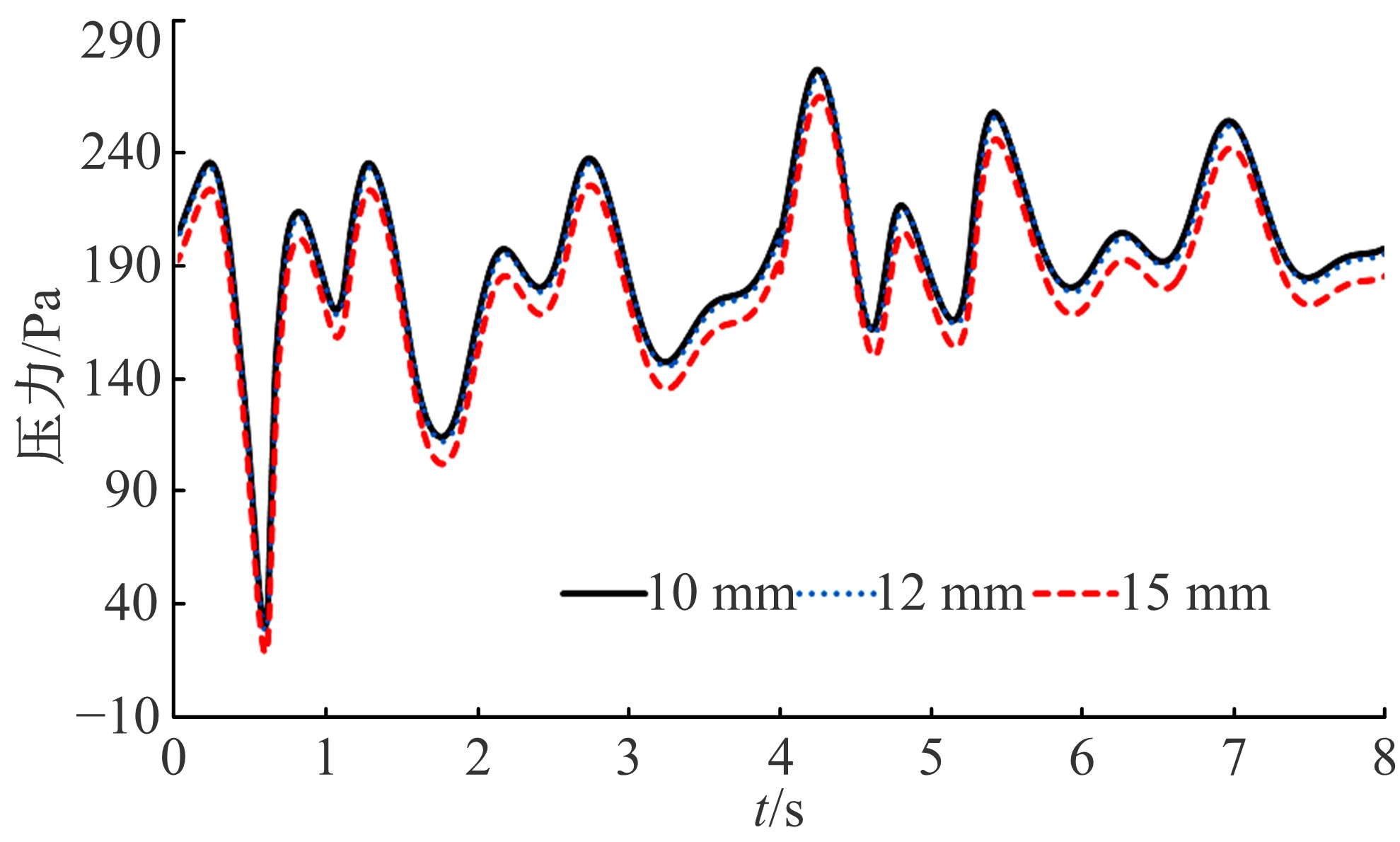

Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures

En-hui ZHANG1,2( ),Ren HE1(

),Ren HE1( ),Wei-dong SU3

),Wei-dong SU3

- 1.School of Automobile and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

2.School of Mechanical Engineering,Inner Mongolia University of Science &Technology,Baotou 014010,China

3.Yapp Automotive Parts Co. Ltd. ,Yangzhou 225000,China

CLC Number:

- U464.136

| 1 | 费翔. 汽车油箱油液晃动噪声分析技术研究[D]. 上海:上海交通大学机械与动力工程学院, 2014. |

| Fei Xiang. Research on analysis technology of oil sloshing noise in automotive fuel tank[D]. Shanghai: School of Mechanical and Power Engineering, Shanghai Jiaotong University, 2014. | |

| 2 | Wiesche S A D. Noise due to sloshing within automotive fuel tanks[J]. Forsch Im Ingenieurwes, 2005, 70: 13-24. |

| 3 | 田哲文, 谢鑫, 戚叶峰, 等. 基于VOF方法小型赛车燃油晃动数值仿真[J]. 汽车科技, 2016, 43(6): 93-97. |

| Tian Zhe-wen, Xie Xin, Qi Ye-feng, et al. Numerical simulation of small racing car fuel sloshing based on VOF method[J]. Automobile Science & Technology, 2016, 43(6): 93-97. | |

| 4 | Hassanvand A, Hashemabadi S H, Bayat M. Evaluation of gasoline evaporation during the tank splash loading by CFD techniques[J]. International Communications in Heat and Mass Transfer, 2010, 37(7): 907-913. |

| 5 | 张恩慧, 何仁. 汽车油箱中油液晃动影响因素的数值分析[J]. 江苏大学学报:自然科学版, 2018, 39(6): 628-633. |

| Zhang En-hui, He Ren. Numerical analysis of influencing factors on sloshing of oil liquid in automobile fuel tank[J]. Journal of Jiangsu University(Natural Science Edition), 2018, 39(6): 628-633. | |

| 6 | He R, Zhang E, Baowei F. Numerical analysis on the sloshing of free oil liquid surface under the variable conditions of vehicle[J]. Advances in Mechanical Engineering, 2019, 11(2): 1-13. |

| 7 | 陈冬娇. 汽车振动对汽油箱内汽油挥发的影响研究[D]. 武汉: 华中农业大学工学院, 2004. |

| Chen Dong-jiao. The study of automotive vibration on gasoline volatilization in oil tank [D]. Wuhan: College of Technology, Huazhong Agricultura University, 2004. | |

| 8 | Akyildiz H, Unal N E. Sloshing in a three dimensional rectangular tank: numerical simulation and experimental validation[J]. Ocean Engineering, 2006, 33(16): 2135-2149. |

| 9 | Arafa M. Finite element analysis of sloshing in rectangular liquid-filled tanks[J]. Journal of Vibration and Control, 2007, 13(7): 883-903. |

| 10 | 周宏. 液体晃动数值模拟及刚-液耦合动力学研究[D]. 北京:清华大学航天航空学院,2008. |

| Zhou Hong. Study on liquid sloshing simulation and rigid-fluid coupling dynamics[D]. Beijing: School of Aeronautics and Astronautics, Tsinghua University, 2008. | |

| 11 | 董彧. 汽车油箱降噪的稳健设计优化[D]. 上海:上海交通大学机械与动力工程学院, 2011. |

| Dong Yu. Robust design optimization for automotive fuel tank slosh noise depression[D]. Shanghai: School of Mechanical and Power Engineering, Shanghai Jiaotong University, 2011. | |

| 12 | 贾善坡, 许成祥, 谭继可. 矩形容器内液体三维晃动特性研究[J]. 水电能源科学, 2012, 30(1): 142-144, 216. |

| Jia Shan-po, Xu Cheng-xiang, Tan Ji-ke. Characteristic analysis of 3D liquid sloshing in rectangular container[J]. Water Resources and Power, 2012, 30(1): 142-144, 216. | |

| 13 | 宋庆华. 基于Abaqus的油箱晃动噪音模拟[J]. 中国高新技术企业, 2013, 257(14): 58-59. |

| Song Qing-hua. The simulation about sloshing noise of fuel tank based on Abaqus[J]. China High Technology Enterprises, 2013, 257(14): 58-59. | |

| 14 | Thomson M M. Theoretical Hydrodynamics[M]. New York: MacMillan, 1965. |

| [1] | Fang-wu MA,Hong-yu LIANG,Qiang WANG,Yong-feng PU. In-plane dynamic crushing of dual-material structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 114-121. |

| [2] | Dao WU,Li-bin ZHANG,Yun-xiang ZHANG,Hong-ying SHAN,Hong-mei SHAN. Visual detection method for vehicle braking time sequence based on slip rate identification [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 206-216. |

| [3] | Lu XIONG,Yan-chao WEI,Le-tian GAO. Inertial measurement unit/wheel speed sensor integrated zero-speed detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 134-138. |

| [4] | Ji-qing CHEN,Qing-sheng LAN,Feng-chong LAN,Zhao-lin LIU. Trajectory tracking control based on tire force prediction and fitting [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1565-1573. |

| [5] | Zhi-gang YANG,Ya-jun FAN,Chao XIA,Shi-jun CHU,Xi-zhuang SHAN. Drag reduction of a square⁃back Ahmed model based on bi⁃stable wake [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1635-1644. |

| [6] | Zhe SHEN,Yi-gang WANG,Zhi-gang YANG,Yin-zhi HE. Drift error correction of unknown sound source in wind tunnel using approximation method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1584-1589. |

| [7] | Zhao LIU,Jiang-lin CHENG,Yu-tian ZHU,Li-hui ZHENG. Vertical vibration modeling and motion correlation analysis of rail vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1600-1607. |

| [8] | Fei GAO,Yang XIAO,Wen-hua ZHANG,Jin-xuan QI,Zi-qiao LI,Xiao-yuan MA. Influence of coupling of elevated temperature and state of charge on mechanical response of Li⁃ion battery cells [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1574-1583. |

| [9] | Jing LI,Qiu-jun SHI,Liang HONG,Peng LIU. Commercial vehicle ESC neural network sliding mode control based on vehicle state estimation [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1545-1555. |

| [10] | Chang-qing DU,Xi-liang CAO,Biao HE,Wei-qun REN. Parameters optimization of dual clutch transmission based on hybrid particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1556-1564. |

| [11] | Yin-ping LI,Tian-xu JIN,Li LIU. Design and dynamic characteristic simulation of pantograph⁃catenary continuous energy system for pure electric LHD [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 454-463. |

| [12] | Chen-guang LAI,Qing-yu WANG,Bo HU,Kai-ping WEN,Yan-yu CHEN. Design and optimization of a car empennage with winglet under effect of static aeroelasticity [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 399-407. |

| [13] | Hui YE,Chang LIU,Kang-kang YAN. Application of fiber reinforced composite in auto⁃body panel [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 417-425. |

| [14] | Xin CHEN,Ning WANG,Chuan-liang SHEN,Xiao FENG,Chang-hai YANG. Effect of rearview mirror modeling on aerodynamic noise of front window [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. |

| [15] | Xiao-yu LI,Nan XU,Tao QIU,Kong-hui GUO. Influence of anisotropic stiffness on tire mechanical properties and vehicle handling characteristics under combined slip situations [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 389-398. |

|

||