Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (5): 1897-1907.doi: 10.13229/j.cnki.jdxbgxb20200487

Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester

Jia-cheng YUAN1,2( ),Chang WANG1,2,Kun HE1,2,Xing-yu WAN1,2,Qing-xi LIAO1,2(

),Chang WANG1,2,Kun HE1,2,Xing-yu WAN1,2,Qing-xi LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-Lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

CLC Number:

- S225.99

| 1 | 陈旭, 吴崇友, 张敏. 我国油菜联合收割机发展现状及趋势分析[J]. 中国农机化学报, 2018, 39(10): 28-31. |

| Chen Xu, Wu Chong-you, Zhang Min. Development status and trend analysis of rapeseed combine harvester in China[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(10): 28-31. | |

| 2 | 吴崇友, 肖圣元, 金梅. 油菜联合收获与分段收获效果比较[J]. 农业工程学报, 2014, 30(17): 10-16. |

| Wu Chong-you, Xiao Sheng-yuan, Jin Mei. Comparation on rape combine harvesting and two-stage harvesting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(17): 10-16. | |

| 3 | 吴崇友, 王积军, 廖庆喜, 等. 油菜生产现状与问题分析[J]. 中国农机化学报, 2017, 38(1): 124-131. |

| Wu Chong-you, Wang Ji-jun, Liao Qing-xi, et al. Current status and problems of rapeseed production[J]. Journal of Chinese Agricultural Mechanization, 2017, 38(1): 124-131. | |

| 4 | 黄小毛, 宗望远. 油菜联合收获的研究现状及发展趋势[J]. 农业工程, 2012, 2(1): 14-19. |

| Huang Xiao-mao, Zong Wang-yuan. Research status and development trend of rape combine harvest[J]. Agricultural Engineering, 2012, 2(1): 14-19. | |

| 5 | 吴福良. 多功能油菜联合收获机的现状及发展方向[J]. 农业装备与车辆工程, 2007(4): 3-5. |

| Wu Fu-liang. The existing state and developing direction of multifunction rape combine-harveste[J]. Agricultural Equipment&Vehicle Engineering, 2007(4): 3-5. | |

| 6 | 李耀明, 邓玲黎, 丁为民, 等. 小型联合收割机清选装置的技术分析[J]. 农机化研究, 2004(3): 55-56. |

| Li Yao-ming, Deng Ling-li, Ding Wei-min, et al. Analysis and improvement design on the cleaning mechanism of small grain combine[J]. Journal of Agricultural Mechanization Research, 2004(3): 55-56. | |

| 7 | 汤庆, 吴崇友, 王素珍, 等. 谷物清选装置研究现状及发展趋势[J]. 农机化研究, 2013(12): 225-228. |

| Tang Qing, Wu Chong-you, Wang Su-zhen, et al. Research advances and prospects in cleaning device of grain[J]. Journal of Agricultural Mechanization Research, 2013(12): 225-228. | |

| 8 | 李洋, 徐立章, 周蓥, 等. 脱出物喂入量对多风道清选装置内部气流场的影响[J]. 农业工程学报, 2017, 33(12): 48-55. |

| Li Yang, Xu Li-zhang, Zhou Ying, et al. Effect of extractions feed-quantity on airflow field in multi-ducts cleaning device[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(12): 48-55. | |

| 9 | 徐立章, 李洋, 李耀明, 等. 谷物联合收获机清选技术与装置研究进展[J]. 农业机械学报, 2019, 50(10): 1-16. |

| Xu Li-zhang, Li Yang, Li Yao-ming, et al. Research progress on cleaning technology and device of grain combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50 (10): 1-16. | |

| 10 | 程超, 付君, 陈志, 等. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报: 工学版, 2021, 51(2): 761-771. |

| Cheng Chao, Fu Jun, Chen Zhi, et al. Sieve blocking laws and stripping test of corn grain harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 761-771. | |

| 11 | 刘大为, 卢伟, 王修善, 等. 联合收割机旋风分离清选装置研究现状及发展趋势[J]. 农业装备与车辆工程, 2016, 54(5): 8-13. |

| Liu Da-wei, Lu Wei, Wang Xiu-shan, et al. Research status and development trend of cyclone separating cleaning unit of combine harvesters[J]. Agricultural Equipment&Vehicle Engineering, 2016, 54(5): 8-13. | |

| 12 | 刘正怀, 郑一平, 王志明, 等. 微型稻麦联合收获机气流式清选装置研究[J]. 农业机械学报, 2015, 46(7): 102-108. |

| Liu Zheng-huai, Zheng Yi-ping, Wang Zhi-ming, et al. Design on air-flowing cleaning unit of micro rice-wheat combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 102-108. | |

| 13 | 李杰, 闫楚良, 杨方飞. 联合收割机振动筛的动态仿真与参数优化[J]. 吉林大学学报: 工学版, 2006(5): 701-704. |

| Li Jie, Yan Chu-liang, Yang Fang-fei. Dynamic simulation and parameter optimization of the combine harvester vibration sieve[J]. Journal of Jilin University(Engineering and Technology Edition), 2006, 36(5): 701-704. | |

| 14 | 曹成茂, 罗坤, 彭美乐, 等. 山核桃物料风选机理与风选性能试验研究[J]. 农业机械学报, 2019, 50(9): 105-112. |

| Cao Cheng-mao, Luo Kun, Peng Mei-le, et al. Experiment on winnowing mechanism and winnowing performance of hickory material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(9): 105-112. | |

| 15 | 陈立, 廖庆喜, 宗望远, 等. 油菜联合收获机脱出物空气动力学特性测定[J]. 农业机械学报, 2012, 43(): 125-130. |

| Chen Li, Liao Qing-xi, Zong Wang-yuan, et al. Aerodynamic characteristics measurement of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Sup.1): 125-130. | |

| 16 | 廖庆喜, 陈立, 李海同, 等. 油菜联合收获机脱出物清选试验台[J]. 农业机械学报, 2013, 44(10): 80-85, 79. |

| Liao Qing-xi, Chen Li, Li Hai-tong, et al. Cleaning unit test-bed of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(10): 80-85, 79. | |

| 17 | 刘师多, 张利娟, 师清翔, 等. 微型小麦联合收获机旋风分离清选系统研究[J]. 农业机械学报, 2006, 37(6): 45-48. |

| Liu Shi-duo, Zhang Li-juan, Shi Qing-xiang, et al. Experimental research on cyclone separating cleaning system used on micro-combine harvester of wheat[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(6): 45-48. | |

| 18 | 高连兴, 赵学观, 杨德旭, 等. 大豆脱粒机气力清选循环装置研制与性能试验[J]. 农业工程学报, 2012, 28(24): 22-27. |

| Gao Lian-xing, Zhao Xue-guan, Yang De-xu, et al. Development and performance test on pneumatic cleaning-circulatory device of soybean thresher[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(24): 22-27. | |

| 19 | 戴飞, 赵武云, 刘国春, 等. 胡麻脱粒物料分离清选机设计与试验[J]. 农业机械学报, 2019, 50(8): 140-147. |

| Dai Fei, Zhao Wu-yun, Liu Guo-chun, et al. Design and experiment of separating and cleaning machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 140-147. | |

| 20 | 倪长安, 张利娟, 刘师多, 等. 无导向片旋风分离清选系统的试验分析[J]. 农业工程学报, 2008,24(8): 135-138. |

| Ni Chang-an, Zhang Li-juan, Liu Shi-duo, et al. Experimental analysis on cyclone separating cleaning system of no-guide vanes[J]. Transactions of the Chinese Society of Agricultural Engineering, 2008, 24(8): 135-138. | |

| 21 | 敬志臣, 韩正晟, 高爱民, 等. 基于Fluent软件的旋风分离清选系统仿真研究[J]. 机械研究与应用, 2014, 27(6): 25-27, 30. |

| Jing Zhi-chen, Han Zheng-sheng, Gao Ai-min, et al. Simulation study on cyclone separation cleaning system based on Fluent[J]. Mechanical Research & Application, 2014, 27(6): 25-27, 30. | |

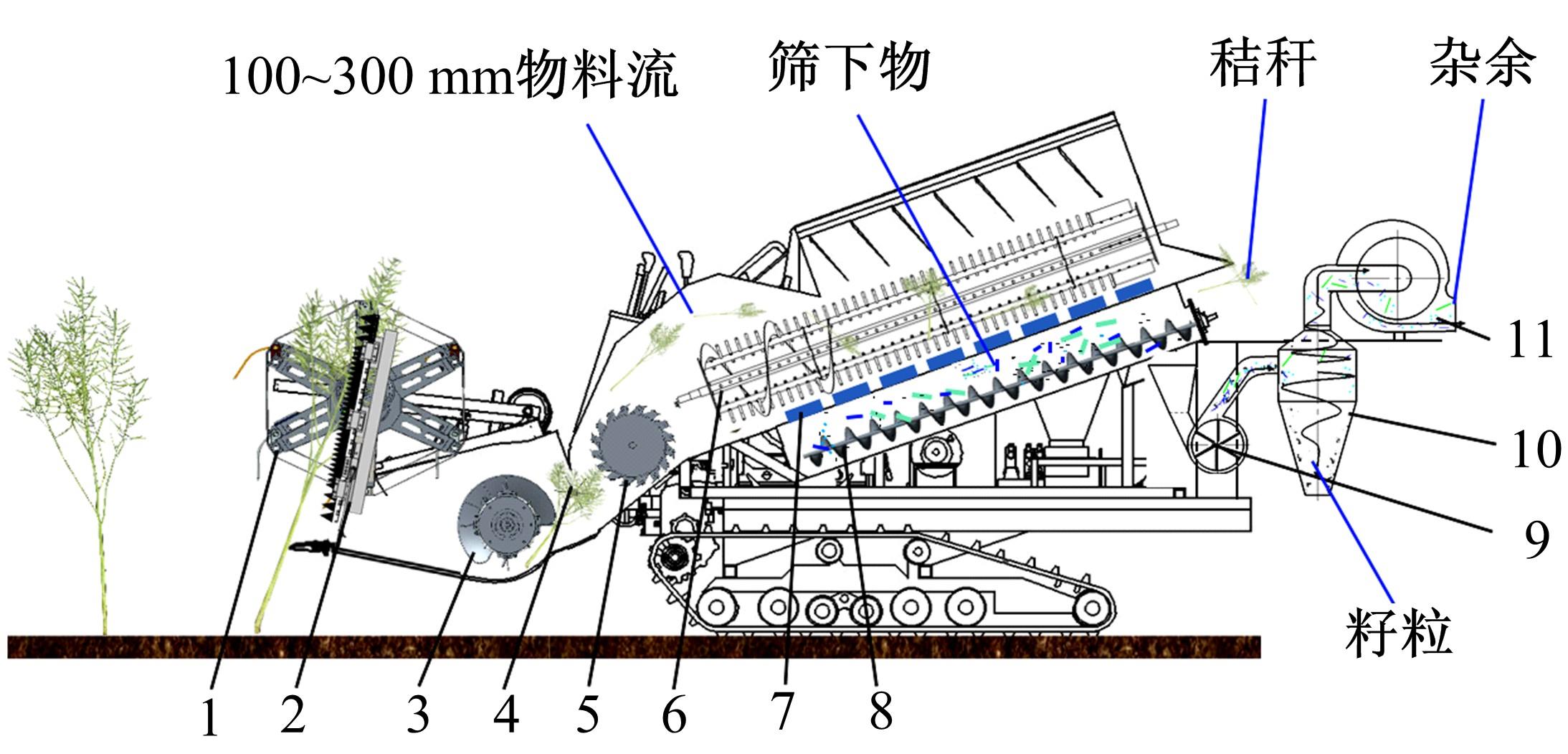

| 22 | 廖庆喜, 万星宇, 李海同, 等. 油菜联合收获机旋风分离清选系统设计与试验[J]. 农业工程学报, 2015, 31(14): 24-31. |

| Liao Qing-xi, Wan Xing-yu, Li Hai-tong, et al. Design and experiment on cyclone separating cleaning system for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(14): 24-31. | |

| 23 | 陈翠英, 王志华, 李青林. 油菜脱出物在气流中的运动分析[J]. 农业机械学报, 2004, 35(5): 90-93. |

| Chen Cui-ying, Wang Zhi-hua, Li Qing-lin. Analysis of aerodynamic properties of rape extractions[J]. Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(5): 90-93. | |

| 24 | 侯华铭, 崔清亮, 郭玉明. 全喂入谷子联合收获机脱出物含水率对其悬浮特性的影响[J]. 农业工程学报, 2018, 34(24): 29-35. |

| Hou Hua-ming, Cui Qing-liang, Guo Yu-ming. Effects of moisture contents of threshed materials from whole-feeding combine for foxtail millet on their suspension characteristics[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(24): 29-35. | |

| 25 | Huang A N, Ito K, Fukasawa T, et al. Effects of particle mass loading on the hydrodynamics and separation efficiency of a cyclone separator[J]. Journal of the Taiwan Institute of Chemical Engineers, 2018, 90: 61-67. |

| 26 | 程超, 付君, 郝付平, 等. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报: 工学版, 2020, 50(1): 351-360. |

| Cheng Chao, Fu Jun, Hao Fu-ping, et al. Effect of motion parameters of cleaning screen on corn cob blocking law[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. | |

| 27 | 廖庆喜, 徐阳, 袁佳诚, 等. 油菜联合收获机切抛组合式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2019, 50(7): 140-150. |

| Liao Qing-xi, Xu Yang, Yuan Jia-cheng, et al. Design and experiment of combined cutting and throwing vertical axial flow detachment device for rape combine harvester[J]. Transactions of the Chinese Society for Agricultura Machinery, 2019, 50(7): 140-150. | |

| 28 | 万星宇, 舒彩霞, 徐阳, 等. 油菜联合收获机分离清选差速圆筒筛设计与试验[J]. 农业工程学报, 2018, 34(14): 27-35. |

| Wan Xing-yu, Shu Cai-xia, Xu Yang, et al. Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(14): 27-35. |

| [1] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [2] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

| [3] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

| [4] | Chao CHENG,Jun FU,Fu-ping HAO,Zhi CHEN,De-yi ZHOU,Lu-quan REN. Effect of motion parameters of cleaning screen on corn cob blocking law [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. |

| [5] | Chao CHENG,Jun FU,Xin⁃long TANG,Zhi CHEN,Lu⁃quan REN. Effects of vibration mode on interface adhesion law of rice threshed mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1228-1235. |

| [6] | FU Jun,QIAN Zhi-hui,YIN Wei,WANG Jia-jia,REN Lu-quan. Experimental study of friction and tensile properties of wheat [J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [7] | QIN Zheng-kun,HE Fei,LIU Chun-ling,MA Chun-sheng. Effect of reactive ion etching process on simulation of polymeric arrayed waveguide grating multiplexers [J]. 吉林大学学报(工学版), 2011, 41(03): 791-794. |

| [8] | Zhao Ji-yin;Zheng Rui-rui;Liu Yu . Power transformer fault diagnosis based on trapezium gray clustering analysis [J]. 吉林大学学报(工学版), 2008, 38(03): 726-0730. |

| [9] |

Li Jie,Yan Chu-liang,Yang Fang-fei .

Dynamic simulation and parameter optimization of the combine harvester vibration sieve [J]. 吉林大学学报(工学版), 2006, 36(05): 701-0704. |

|

||