| 1 |

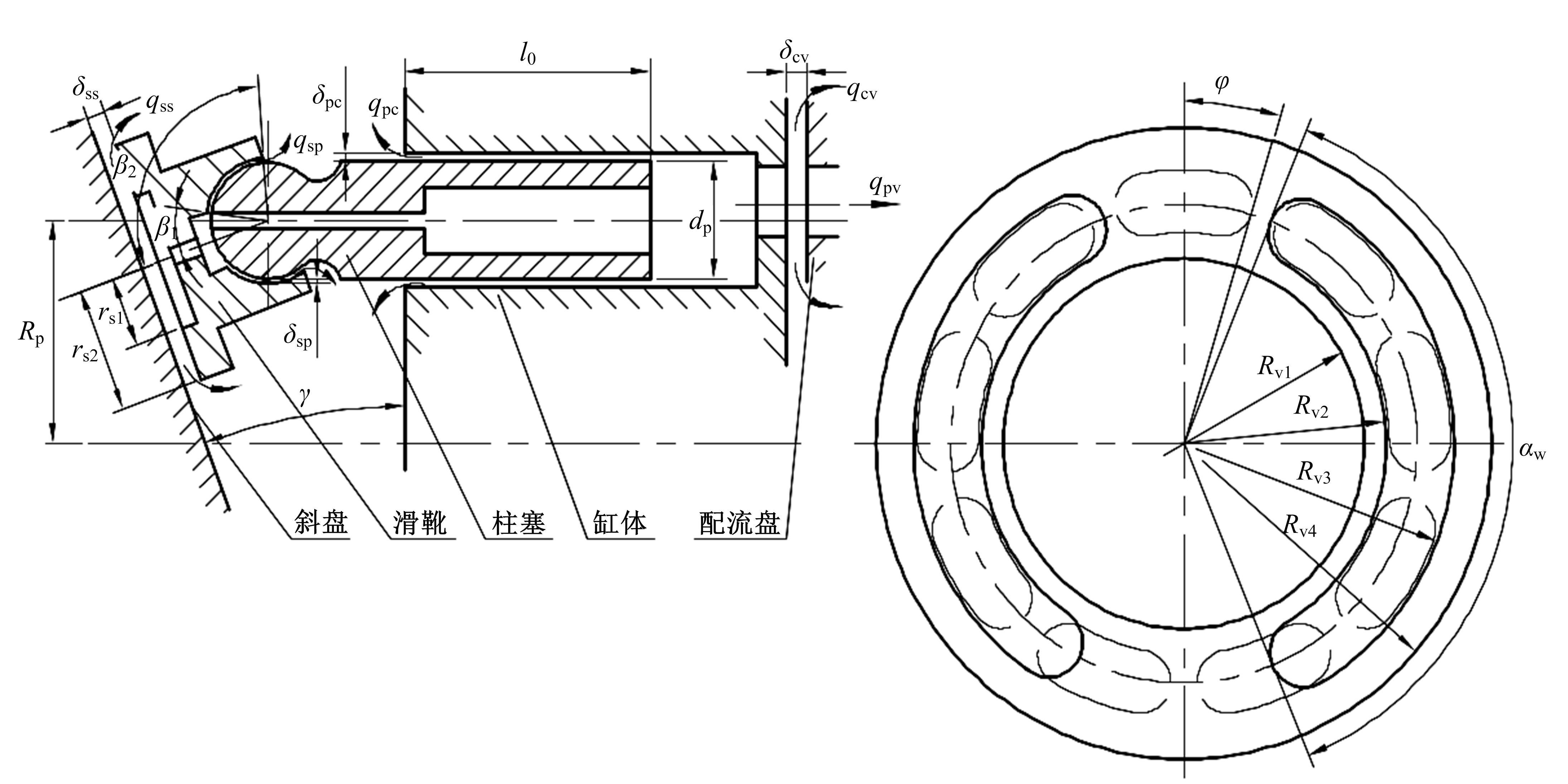

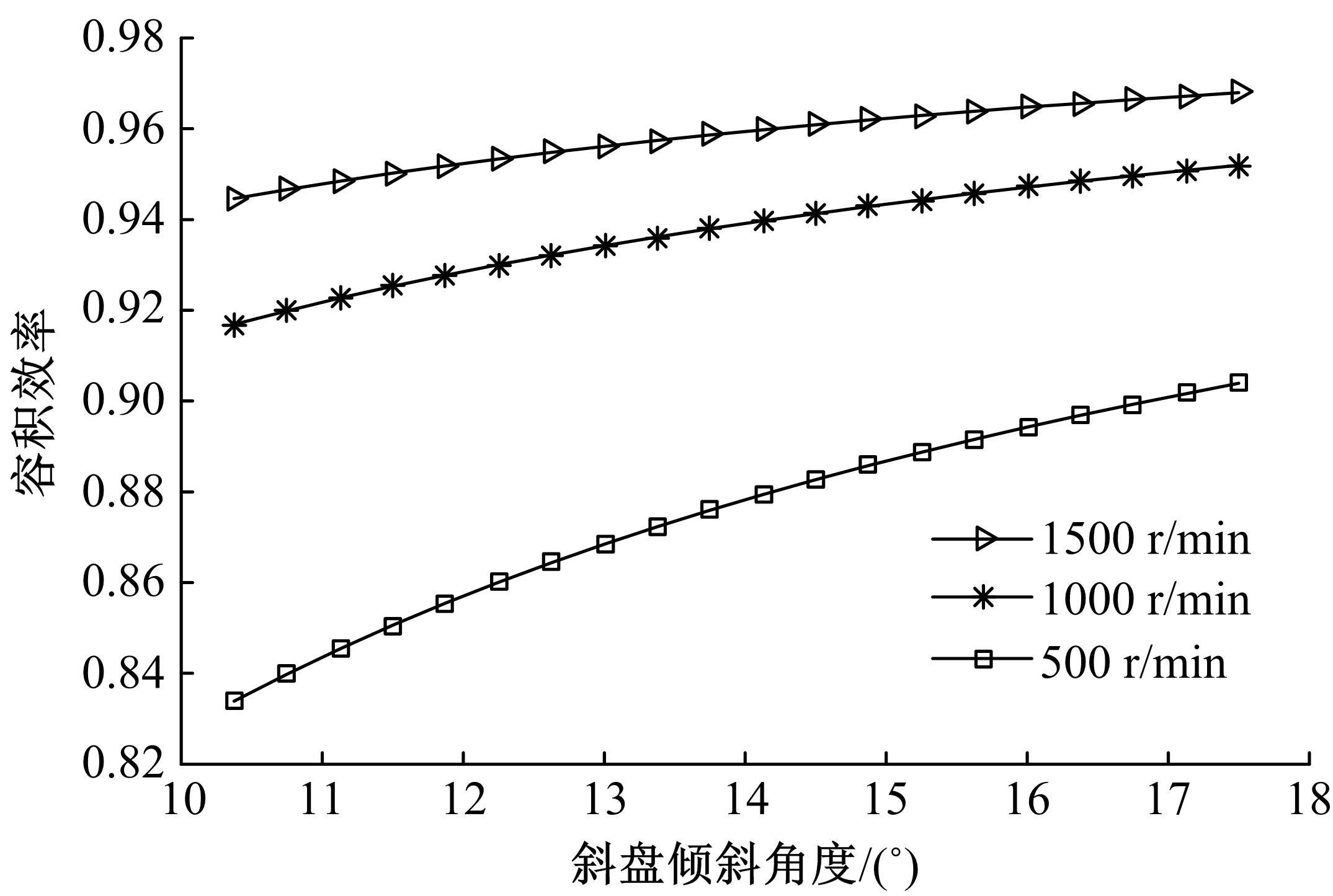

赵存然,刘伟,姜继海,等.斜盘式轴向柱塞泵加速模型[J].吉林大学学报:工学版,2016,46(4):1124-1129.

|

|

Zhao Cun-ran, Liu Wei, Jiang Ji-hai, et al. Accelerated model of swash-plate axial piston pump[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(4):1124-1129.

|

| 2 |

闻德生. 液压元件的创新与发展[M]. 北京:航空工业出版社,2009.

|

| 3 |

姜继海,赵存然,张冠隆,等.航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报:工学版,2021,51(1):147-153.

|

|

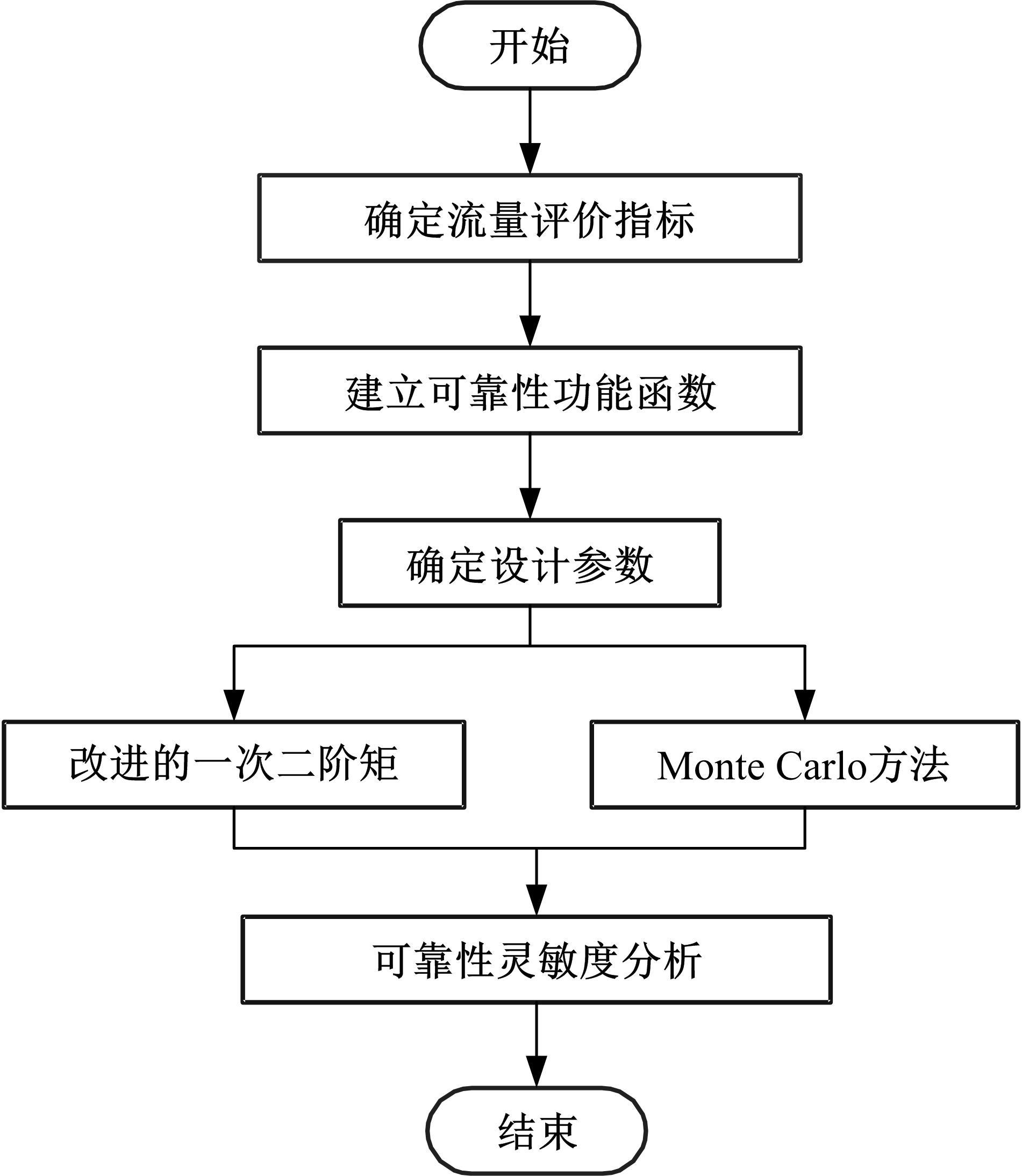

Jiang Ji-hai, Zhao Cun-ran, Zhang Guang-long, et al. Tribological properties of coating materials of tribopairs for aviation kerosene piston pump[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1):147-153.

|

| 4 |

Bergada J M, Kumar S, Davies D L, et al. A complete analysis of axial piston pump leakage and output flow ripples[J]. Applied Mathematical Modelling, 2012, 36(4):1731-1751.

|

| 5 |

Costa G K, Sepehri N. Understanding overall efficiency of hydrostatic pumps and motors[J]. International Journal of Fluid Power, 2018, 19(2):106-116.

|

| 6 |

Wilson W E. Performance criteria for positive displacement pumps and fluid motors[J]. ASME Transactions, 1949, 71(2):115-120.

|

| 7 |

McCandlish D, Dorey R E. The mathematical modelling of hydrostatic pumps and motors[J]. Proceedings of The Institution of Mechanical Engineers, Part B: Management and Engineering Manufacture, 1984, 198(10):165-174.

|

| 8 |

Ortwig H. New method of numerical calculation of losses and efficiencies in hydrostatic power transmissions[C]∥SAE Technical Paper, 2002-01-1418.

|

| 9 |

Jeong H S. A novel performance model given by the physical dimensions of hydraulic axial piston motors: model derivation[J]. Journal of Mechanical Science and Technology, 2007, 21(1):83-97.

|

| 10 |

Bergada J M, Haynes J M, Watton J. Leakage and groove pressure of an axial piston pump slipper with multiple lands[J]. Tribology Transactions, 2008, 51(4):469-482.

|

| 11 |

Gao M D, Huang H H, Li X Y, et al. A novel method to quickly acquire the energy efficiency for piston pumps[J]. Journal of Dynamic Systems Measurement and Control, 2016, 138(10):No.101004.

|

| 12 |

孙毅刚,高建树,李国洪. 液压泵摩擦副可靠性设计基本方法研究[J]. 中国民航学院学报,1999,17(6):5-9.

|

|

Sun Yi-gang, Gao Jian-shu, Li Guo-hong. A reliability analysis and design for the friction pairs of hydraulic pumps[J]. Journal of Civil Aviation University of China, 1999,17(6):5-9.

|

| 13 |

Zhang Tian-xiao, Zhang Yi-min. A new model for reliability design and reliability sensitivity analysis of a hydraulic piston pump[J]. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 2017, 231(1): 11-24.

|

| 14 |

Zhang Tian-xiao, He David. A reliability-based robust design method for the sealing of slipper-swash plate friction pair in hydraulic piston pump[J]. IEEE Transactions on Reliability, 2018, 67(2):459-469.

|

| 15 |

Zhang Tian-xiao. Robust reliability-based optimization with a moment method for hydraulic pump sealing design[J]. Structural and Multidisciplinary Optimization, 2018, 58(5): 1737-1750.

|

| 16 |

Yin F L, Nie S L, Ji H, et al. Non-probabilistic reliability analysis and design optimization for valve-port plate pair of seawater hydraulic pump for underwater apparatus[J]. Ocean Engineering, 2018, 163: 337-347.

|

| 17 |

胡敏. 轴向柱塞泵摩擦副功率损失分析与表面形貌设计研究[D]. 杭州:浙江大学机械工程学院, 2017.

|

|

Hu Min. Study on power losses and design technology for the surface topography of friction pairs of axial piston pump[D]. Hangzhou: School of Mechanical Engineering, Zhejiang University, 2017.

|

| 18 |

吕震宙, 宋述芳, 李璐祎,等.结构/机构可靠性设计基础[M]. 西安:西北工业大学出版社, 2018.

|

| 19 |

. 液压轴向柱塞泵[S].

|