Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (7): 1561-1573.doi: 10.13229/j.cnki.jdxbgxb20210114

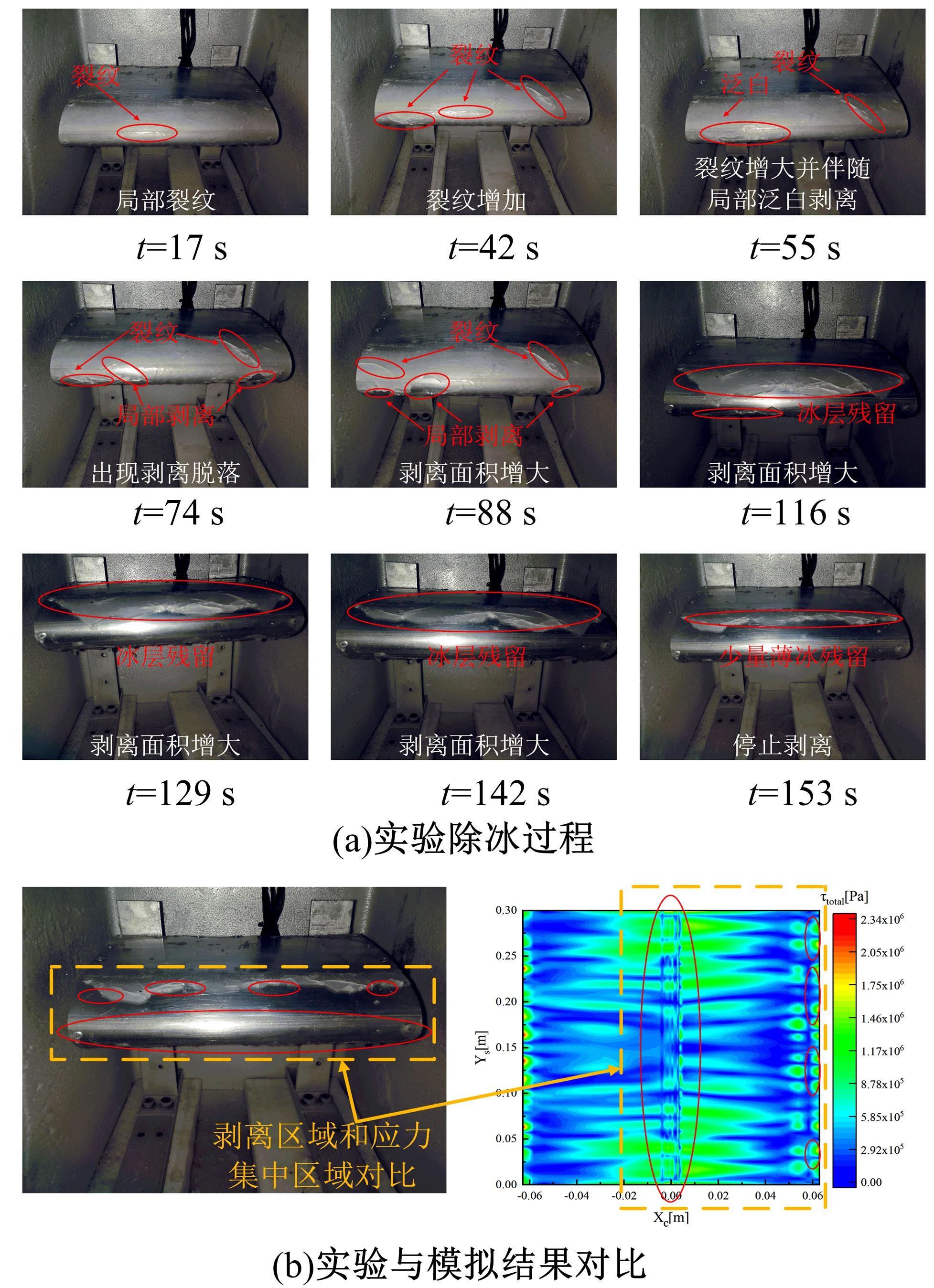

Numerical simulation and experiment on ultrasonic deicing system of airfoil structure

Zhong-hua SHI( ),Quan-wei SONG,Zhen-hang KANG,Qiang XIE,Ji-feng ZHANG(

),Quan-wei SONG,Zhen-hang KANG,Qiang XIE,Ji-feng ZHANG( )

)

- College of Aerospace and Civil Engineering,Harbin Engineering University,Harbin 150001,China

CLC Number:

- V244.1

| 1 | Cao Y, Tan W, Wu Z. Aircraft icing: an ongoing threat to aviation safety[J]. Aerospace Science and Technology, 2018, 75: 353-385. |

| 2 | Pei B, Xu H, Xue Y. Flight-safety space and cause of incident under icing conditions[J]. Journal of Guidance, Control, and Dynamics, 2017, 40(11): 2983-2990. |

| 3 | Pouryoussefi S G, Mirzaei M, Nazemi M-M, et al. Experimental study of ice accretion effects on aerodynamic performance of an NACA 23012 airfoil[J]. Chinese Journal of Aeronautics, 2016, 29(3): 585-595. |

| 4 | Goraj Z. An overview of the deicing and anti-icing technologies with prospects for the future[C]∥The 24th International Congress of the Aeronautical Sciences, Yokohama, Japan, 2004. |

| 5 | Xie T, Dong J, Chen H, et al. Experimental investigation of deicing characteristics using hot air as heat source[J]. Applied Thermal Engineering, 2016, 107: 681-688. |

| 6 | Liu Y, Kolbakir C, Hu H, et al. A comparison study on the thermal effects in DBD plasma actuation and electrical heating for aircraft icing mitigation[J]. International Journal of Heat and Mass Transfer, 2018, 124: 319-330. |

| 7 | Muthumani A, Fay L, Akin M, et al. Correlating lab and field tests for evaluation of deicing and anti-icing chemicals: a review of potential approaches[J]. Cold Regions Science and Technology, 2014, 97: 21-32. |

| 8 | Wang Z. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft[J]. Energy and Buildings, 2017, 140: 42-49. |

| 9 | 白天, 朱春玲, 苗波,等. 平面铝板上的压电振动除冰方法[J]. 航空学报, 2015, 36(5):1564-1573 |

| Bai Tian, Zhu Chun-ling, Miao Bo, et al. Vibration de-icing method with piezoelectric actuators on flat aluminum plate[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(5): 1564-1573. | |

| 10 | Palacios J, Smith E, Rose J, et al. Ultrasonic de-icing of wind-tunnel impact icing[J]. Journal of Aircraft, 2011, 48(3): 1020-1027. |

| 11 | Shi Z, Kang Z, Xie Q, et al. Ultrasonic deicing efficiency prediction and validation for a flat deicing system[J]. Applied Sciences, 2020, 10(19): 6640. |

| 12 | Gao H, Rose J L. Ice detection and classification on an aircraft wing with ultrasonic shear horizontal guided waves[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2009, 56(2): 334-344. |

| 13 | Shi Z, Zhao Y, Ma C, et al. Parametric study of ultrasonic de-icing method on a plate with coating[J]. Coatings, 2020, 10(7): 631. |

| 14 | Palacios J, Zhu Y, Smith E, et al. Ultrasonic shear and lamb wave interface stress for helicopter rotor de-icing purposes[C]∥The 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and 14th AIAA/ASME/AHS Adaptive Structures Conference, Newport, USA, 2006: 2282. |

| 15 | Dassault Systemes Simulia Corp. Abaqus User Manual[M]. Pairs: Dassault Systemes Simulia Corp, 2020. |

| 16 | Borigo C J. A novel actuator phasing method for ultrasonic de-icing of aircraft structures[D]. Philadelphia: The Pennsylvania State University, 2014. |

| 17 | Cook R D. Concepts and Applications of Finite Element Analysis[M]. London: John Wiley & Sons, 2007. |

| 18 | Koivuluoto H, Stenroos C, Ruohomaa R, et al. Research on icing behavior and ice adhesion testing of icephobic surfaces[C]∥Proceedings of the International Workshop on Atmospheric Icing of Structures, Uppsala, Sweden, 2015. |

| 19 | Overmeyer A, Palacios J, Smith E. Actuator bonding optimization and system control of a rotor blade ultrasonic deicing system[C]∥The 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference and 20th AIAA/ASME/AHS Adaptive Structures Conference, Hawaii, USA, 2012: 1476. |

| [1] | Xiao⁃qin ZHOU,Lu YANG,Lei ZHANG,Li⁃jun CHEN. Finite element analysis of hinging octahedron structure withnegative compressibility [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 865-871. |

| [2] | MENG Guang-wei,LI Xiao-lin,LI Feng,ZHOU Li-ming,WANG Hui. Smoothed multiscale finite element method for flow in fractured media [J]. 吉林大学学报(工学版), 2015, 45(2): 481-486. |

| [3] | CAI Bin,MENG Guang-wei, DONG Xin,LI Feng. Reliability analysis for transverse crack in concrete structure based on fuzzy invalidation criterion [J]. 吉林大学学报(工学版), 2011, 41(4): 1029-1033. |

| [4] | PENG Hui-fen, MENG Guang-wei, ZHOU Li-ming, LI Feng. Virtual crack closure technique based on wavelet finite element method [J]. 吉林大学学报(工学版), 2011, 41(05): 1364-1368. |

| [5] | MENG Guang-Wei, ZHOU Li-Ming, LI Feng. Fuzzy elementfree Galerkin method for the plane with crack [J]. 吉林大学学报(工学版), 2010, 40(增刊): 287-0292. |

| [6] | MENG Guang-Wei, CA Bin, LI Feng, DONG Xin. New method for structural reliability analysis by combining curve fitting with Monte Carlo simulation [J]. 吉林大学学报(工学版), 2010, 40(增刊): 293-0296. |

| [7] | MENG Guang-Wei, ZHOU Li-Ming, LI Feng, SHA Li-Rong. Perturbation stochastic local orthogonal elementfree Galerkin method [J]. 吉林大学学报(工学版), 2010, 40(06): 1556-1561. |

| [8] | WU Deng-feng,XU Tao,SUN Rui-heng,YANG Rong,XUAN Wei-qi,Tatsuo Yoshino. Meshless method based on wavelet basis function [J]. 吉林大学学报(工学版), 2010, 40(03): 740-0744. |

| [9] | MA Liang,CHEN Su-huan,MENG Guang-wei . Eigenvalue analysis of structures with large variations of interval parameters [J]. 吉林大学学报(工学版), 2009, 39(01): 98-102. |

| [10] | Li Cheng, Liu Zhi-hua, Zhang Ping . Analysis on stress and displacement of a composite flywheel composed of twolayer rotor with pre-displacement [J]. 吉林大学学报(工学版), 2007, 37(04): 828-832. |

| [11] | Cao Zong-jie,Wang Ming-wei,Quan Ji-cheng,Hu Jin-hai . Electroelastic fracture analysis of piezoelectric materials with cracks [J]. 吉林大学学报(工学版), 2006, 36(增刊2): 157-160. |

| [12] | DONG Jin-kun, LIU Bin, ZHANG Yan-nian, YE Ye. Stability Against Coupled BendingTorsional Galloping Oscillation by Beam Wind in Tall Building 3-Dimensional Structure [J]. 吉林大学学报(工学版), 2005, 35(05): 562-0566. |

|

||