Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (2): 433-438.doi: 10.13229/j.cnki.jdxbgxb20211146

Fault analysis of machining center based on gray theory

Ying-zhi ZHANG1,2,Sheng-dong HOU1,2,Zhi-qiong WANG1,2( ),Ren-hao DONG1,2,Sheng YANG1,2

),Ren-hao DONG1,2,Sheng YANG1,2

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TG659

| 1 | Du Yan-bin, Liao Lan, Wang Le-su. Failure mode, effects and criticality analysis of remanufactured machine tools in service[J]. International Journal of Precision Engineering and Manufacturing, 2017, 18(3): 425-434. |

| 2 | Nikhil M, Vasu V, Rao P. Failure mode identification and prioritization using FMECA: a study on computer numerical control lathe for predictive maintenance[J]. Journal of Failure Analysis and Prevention, 2019, 19(4): 1153-1157. |

| 3 | 王晓峰, 申桂香, 张英芝, 等. 基于改进危害度和DEMATEL方法的abc轴进给系统的故障排序[J]. 吉林大学学报: 工学版, 2012, 42(1): 122-127. |

| Wang Xiao-feng, Shen Gui-xiang, Zhang Ying-zhi, et al. Priortizing failures of abc-axis feeding systems based on improved criticality and DEMATEL method[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(1): 122-127. | |

| 4 | Gianpaolo B, Alessandro S, Antonio F, et al. AHP-IFM target: an innovative method to define reliability target in an aerospace prototype based on analytic hierarchy process[J]. Quality & Reliability Engineering International, 2017, 33(8): 1731-1751. |

| 5 | 安相华, 于靖博, 蔡卫国. 基于混合多属性决策和关联分析的模糊粗糙FMEA评估方法[J]. 计算机集成制造系统, 2016, 22(11): 2613-2621. |

| An Xiang-hua, Yu Jing-bo, Cai Wei-guo. Fuzzy rough FMEA evaluation method ba sed on hybrid multi-attribute decision and correlation analysis[J]. Computer Integrated Manufacturing Systems, 2016, 22(11): 2613-2621. | |

| 6 | 戴城国, 王晓红, 张新, 等. 基于模糊综合评判的电液伺服阀FMECA[J]. 北京航空航天大学学报, 2011, 37(12): 1575-1578. |

| Dai Cheng-guo, Wang Xiao-hong, Zhang Xin, et al. Fuzzy comprehensive evaluation in FMECA of electro-hydraulic servo valve[J]. Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(12): 1575-1578. | |

| 7 | Hu Chen-liu, Jian Xin-you, You Xiao-yue, et al. A novel approach for failure mode and effects analysis using combination weighting and fuzzy VIKOR method[J]. Applied Soft Computing Journal, 2015, 28: 579-588. |

| 8 | Wang Hao, Zhang Yi-min, Yang Zhou. A risk evaluation method to prioritize failure modes based on failure data and a combination of fuzzy sets theory and grey theory[J]. Engineering Applications of Artificial Intelligence, 2019, 82: 216-225. |

| 9 | 申桂香, 张英芝, 薛玉霞, 等. 基于熵权法的数控机床可靠性综合评价[J]. 吉林大学学报: 工学版, 2009, 39(5): 1208-1211. |

| Shen Gui-xiang, Zhang Ying-zhi, Xue Yu-xia, et al. Comprehensive evaluation of reliability of CNC machine tool based on entropy rights method[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(5): 1208-1211. | |

| 10 | 荣峰. 基于故障率相关的加工中心的可靠性及风险评估[D]. 长春: 吉林大学机械与航空航天工程学院, 2015. |

| Rong Feng. Reliability and risk assessment of machining center based on failure rate correlation[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2015. |

| [1] | Li-ping WANG,Bin ZHU,Jun WU,Zi-han TAO. Fault analysis of circular tool magazine based on Bayesian network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 280-287. |

| [2] | Hai-ji YANG,Jia-long HE,Guo-fa LI,Li-ding WANG,Si-yuan WANG. Application of improved failure mode and effect analysis method in risk analysis of spindle system of machining center [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 345-352. |

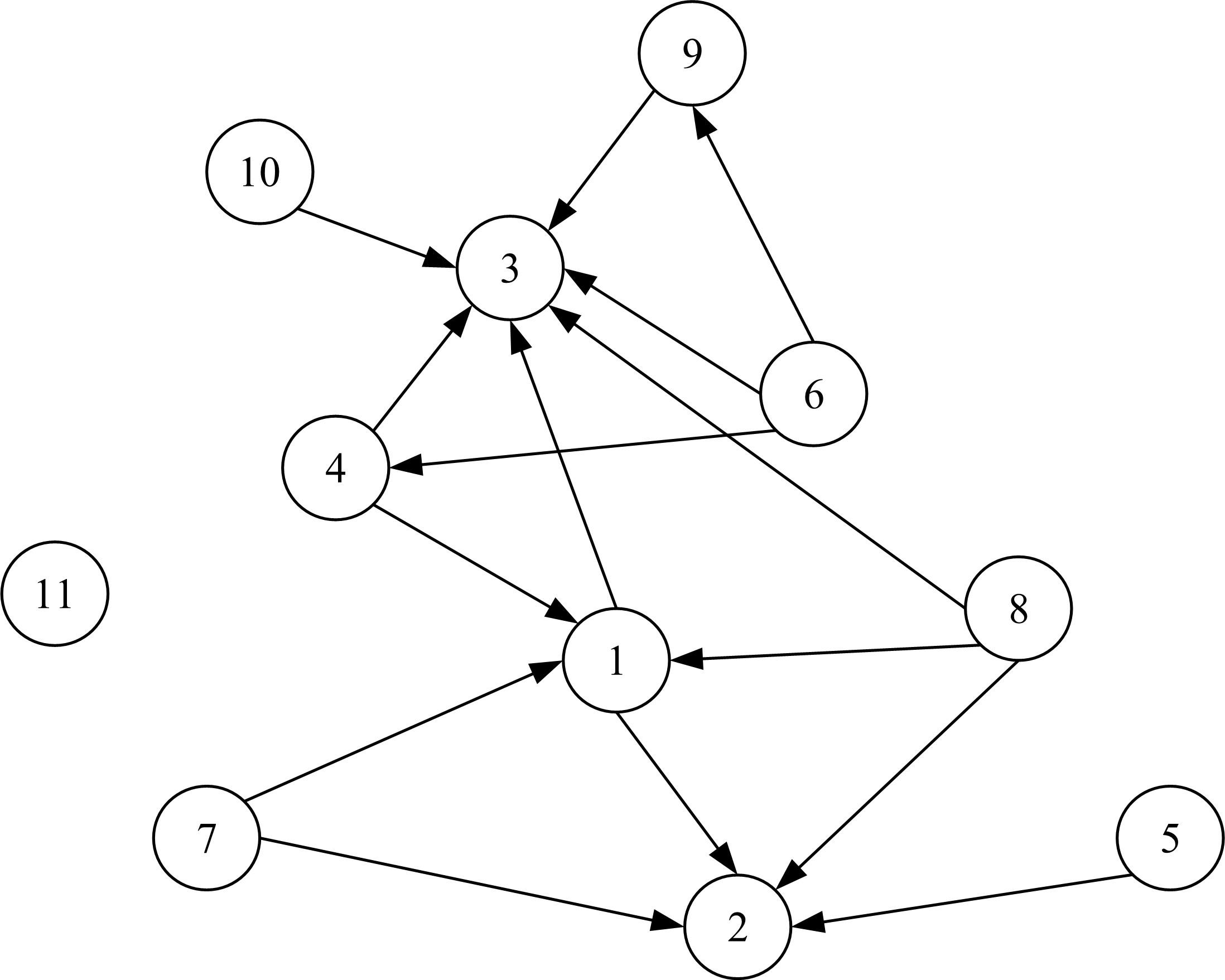

| [3] | Gui-xiang SHEN,Lan LUAN,Ying-zhi ZHANG,Li-ming MU,Shu-bin LIANG. Fault propagation impact assessment of machining center components [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 63-69. |

| [4] | YANG Zhao-jun, YANG Chuan-gui, CHEN Fei, HAO Qing-bo, ZHENG Zhi-tong, WANG Song. Parameter estimation of reliability model of machining center based on particle swarm optimization and support vector regression [J]. 吉林大学学报(工学版), 2015, 45(3): 829-836. |

| [5] | WANG Xiao-feng, SHEN Gui-xiang, ZHANG Ying-zhi, GU Dong-wei, LI Huai-yang, LIU Wei. Prioritizing failures of abc-axis feeding systems based on improved criticality and DEMATEL method [J]. 吉林大学学报(工学版), 2012, 42(01): 122-127. |

| [6] | WANG Xiao-feng, SHEN Gui-xiang, ZHANG Ying-zhi, ZHANG Li-min, WANG Zhi-qiong, LIU Wei. Simulation of reliability and maintainability influence of machining center [J]. 吉林大学学报(工学版), 2011, 41(增刊1): 160-163. |

| [7] | WANG Xiao-feng,SHEN Gui-xiang,ZHANG Ying-zhi,CHEN Bing-kun,LI Huai-yang. Analysis on risk priority number of critical component of machining center based on group decision-making and various assignment ways [J]. 吉林大学学报(工学版), 2011, 41(6): 1630-1635. |

|

||