Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1186-1193.doi: 10.13229/j.cnki.jdxbgxb20180240

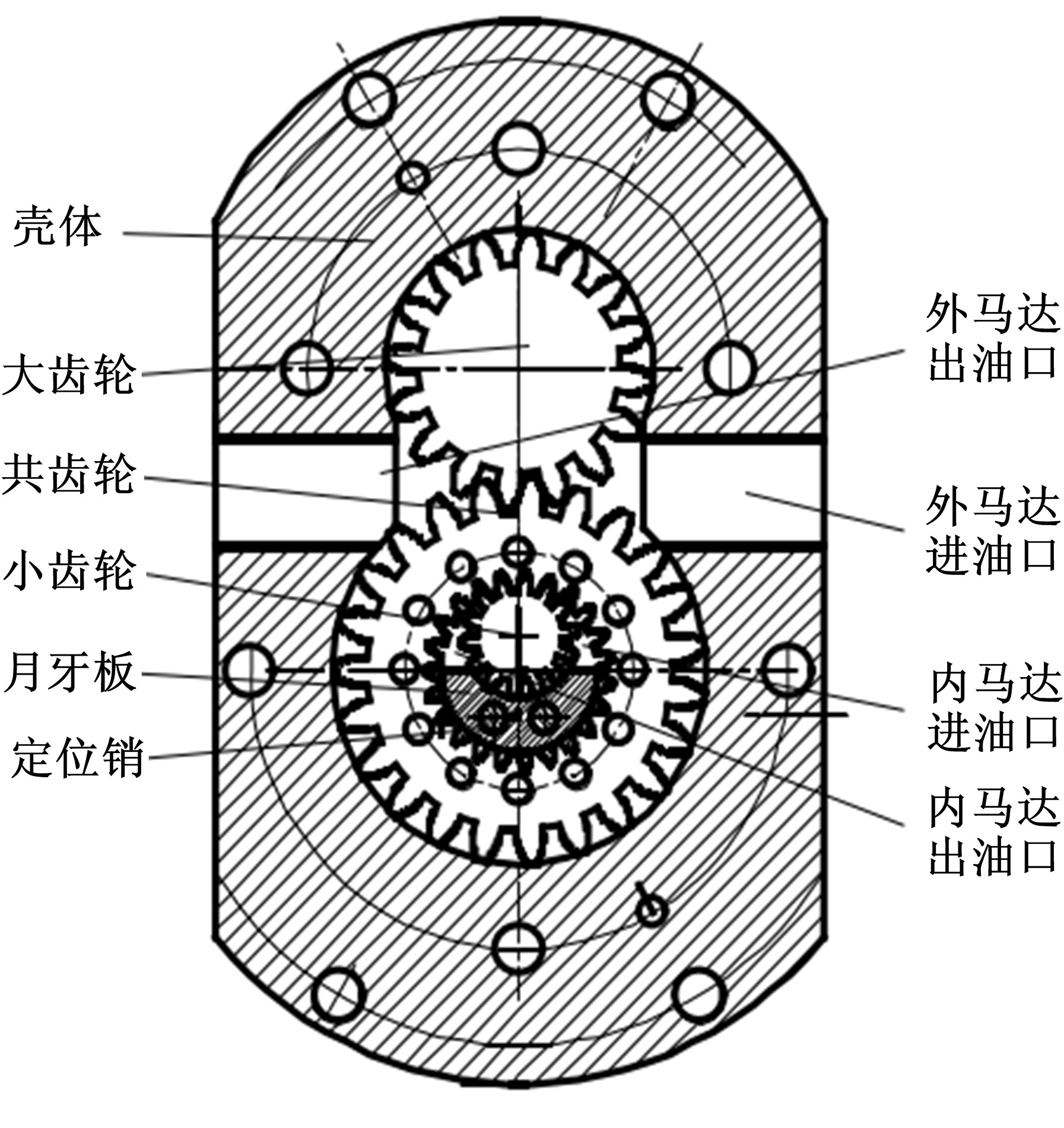

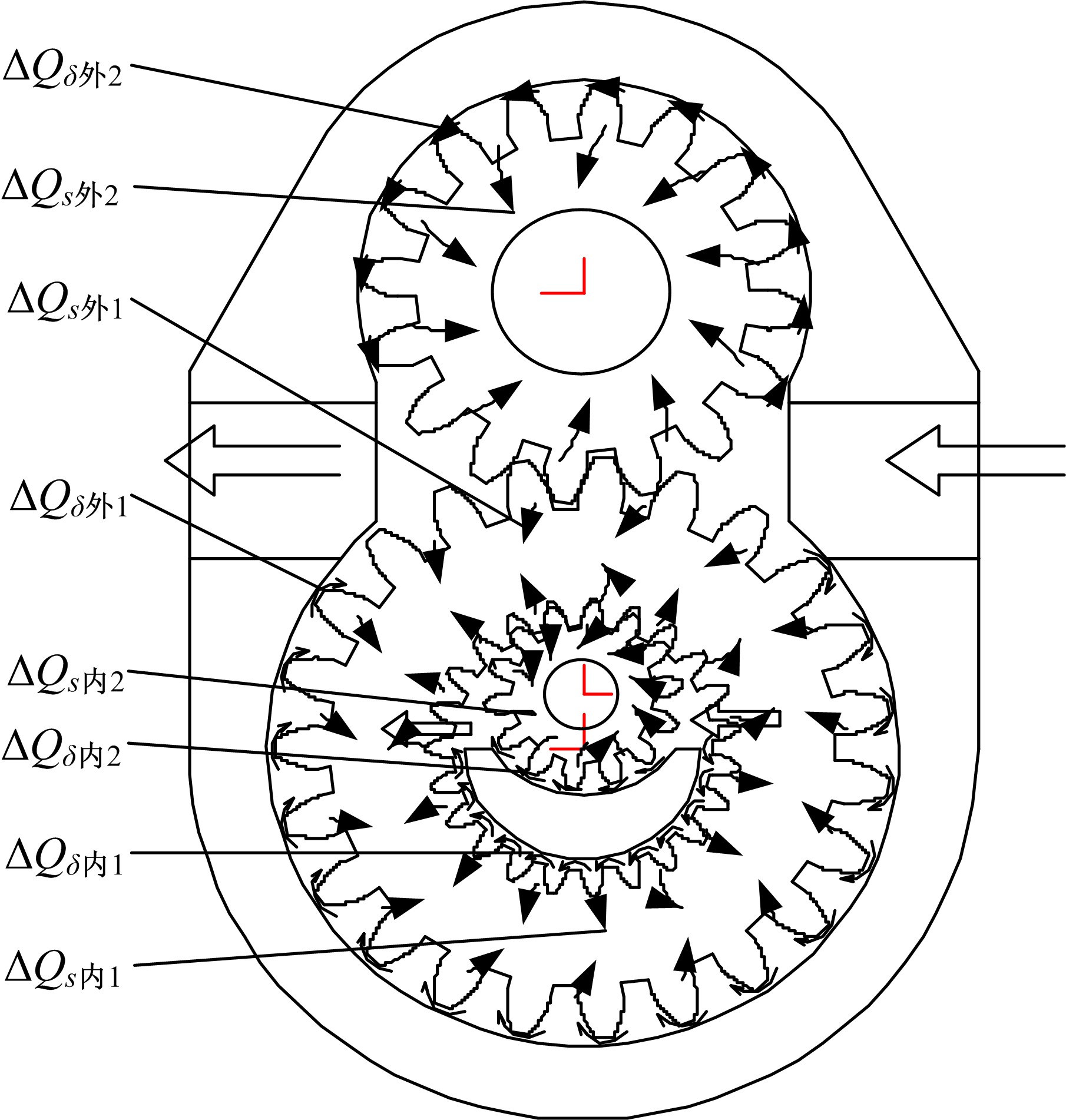

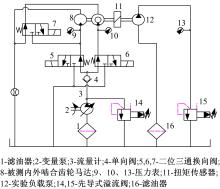

Leakage/volumetric efficiency analysis and experiment of internal and external meshing gear motors

De⁃sheng WEN,Guang⁃dong SUI,Shan⁃heng TIAN,Shao⁃peng WANG,Pei⁃kun FENG,Xiao⁃xue LIU

- College of Mechanical Engineering,Yanshan University,Qinhuangdao 066004,China

CLC Number:

- TH32

| 1 | 李壮云, 葛宜远 . 液压元件与系统[M]. 北京: 机械工业出版社, 1999. |

| 2 | 马强 . 多齿差内啮合摆线泵设计与开发关键技术研究[D]. 大连: 大连理工大学机械工程学院, 2012. |

| Ma Qiang . Research on key technologies for the design and development of a multi⁃tooth difference internal meshing cycloid pump[D]. Dalian: School of Mechanical Engineering, Dalian University of Technology, 2012. | |

| 3 | 吴襄飞 . 多齿轮马达理论及摩擦磨损试验研究[D].淮南: 安徽理工大学机械工程学院, 2011. |

| Wu Xiang⁃fei . Experimental study on the theory of multi⁃gear motor and friction and wear[D]. Huainan: School of Mechanical Engineering, Anhui University of Science and Technology, 2011. | |

| 4 | 叶春浓 . 液压元件与系统的流体力学问题——与液压同行们的交流[J]. 液压气动与密封, 2015, 35(10): 10⁃13. |

| Ye Chun⁃nong . Hydrodynamics problems of hydraulic components and systems⁃communication with hydraulic counterparts[J]. Hydro⁃pneumatic and Sealing, 2015, 35(10): 10⁃13. | |

| 5 | 孔维涛 . 内外啮合齿轮马达的设计与研究[D]. 秦皇岛: 燕山大学机械工程学院, 2013. |

| Kong Wei⁃tao . Design and research of internal and external meshing gear motors[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2013. | |

| 6 | 闻德生, 张凯明, 张三喜, 等 . 内外啮合齿轮马达的理论分析[J]. 北京理工大学学报,2015,35(1): 23⁃26. |

| Wen De⁃sheng , Zhang Kai⁃ming , Zhang San⁃xi , et al . Theoretical analysis of internal and external meshed gear motors[J]. Journal of Beijing Institute of Technology, 2015, 35(1): 23⁃26. | |

| 7 | 闻德生, 高俊, 王志力, 等 .双作用多泵多马达传动中马达输出转矩分析[J].中国机械工程, 2010, 21(23): 2836⁃2838. |

| Wen De⁃sheng , Gao Jun , Wang Zhi⁃li , et al . Analysis of motor output torque in double⁃acting multi⁃pump and multi⁃motor transmission[J]. China Mechanical Engineering, 2010, 21(23): 2836⁃2838. | |

| 8 | 姜继海, 宋锦春, 高常识 . 液压与气压传动[M]. 北京: 高等教育出版社, 2002. |

| 9 | 王鑫 . 基于Fluent的外啮合齿轮泵内部流场的仿真与分析[D]. 兰州: 兰州理工大学能源与动力工程学院, 2013. |

| Wang Xin . Simulation and analysis of internal flow field of external gear pump based on Fluent[D]. Lanzhou: College of Energy and Power Engineering, Lanzhou University of Technology, 2013. | |

| 10 | 赵连春, 宋艳亮, 许贤良 . 三惰轮复合齿轮马达的内部泄漏特性研究[J]. 安徽理工大学学报: 自然科学版, 2005, 25(1): 14⁃17. |

| Zhao Lian⁃chun , Song Yan⁃liang , Xu Xian⁃liang . Research on internal leakage characteristics of three idler gear composite gear motors[J]. Journal of Anhui University of Science and Technology(Natural Science): 2005, 25(1): 14⁃17. |

| [1] | LIU Guo-jun, MA Xiang, YANG Zhi-gang, WANG Cong-hui, WU Yue, WANG Teng-fei. Integrated pulsation micro mixing chip for three-phase flow [J]. 吉林大学学报(工学版), 2018, 48(4): 1063-1071. |

| [2] | LIU Xiang-yong, LI Wan-li. Electro-hydraulic proportional control model of accumulator [J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [3] | LIU Guo-jun, ZHANG Yan-yan, YANG Xu-hao, LI Xin-bo, LIU Jian-fang, YANG Zhi-gang. Application of surface acoustic wave in controlled synthesis of gold nanoparticles [J]. 吉林大学学报(工学版), 2017, 47(4): 1102-1108. |

| [4] | WEN De-sheng, CHEN Fan, ZHEN Xin-shuai, ZHOU Cong, WANG Jing, SHANG Xu-dong. Application of pressure control loop with double-stator pumps and motors [J]. 吉林大学学报(工学版), 2017, 47(2): 504-509. |

| [5] | WEN De-sheng, LIU Qiao-yan, LIU Zhong-xun, GAO Jun-feng, ZHOU Rui-bin. Rotor radial force of double-stator single-acting motor [J]. 吉林大学学报(工学版), 2015, 45(6): 1825-1830. |

| [6] | WEN De-sheng, ZHENG Zhen-quan, WANG Yuan, YANG Jie, ZHANG Kai-ming, ZHANG San-xi. Analysis of rotational speed and torque of differential connection of asymmetric multi-speed hydraulic motor [J]. 吉林大学学报(工学版), 2014, 44(5): 1342-1346. |

| [7] | MA Wen-xing,HU Jing,CHU Ya-xu,WANG Song-lin,WU Yue-shi. Dynamic load strength analysis of over-running clutch of dual turbine torque [J]. 吉林大学学报(工学版), 2014, 44(3): 675-679. |

| [8] | MA Wen-xing, SONG Jian-jun, LIU Chun-bao, HU Jing, CHU Ya-xu. Calculation method of outlet pressure of open-type hydrodynamic retarder [J]. 吉林大学学报(工学版), 2014, 44(01): 86-90. |

| [9] | YUAN Zhe, MA Wen-xing, LU Xiu-quan, HU Jing, YANG Shan-shan. Dynamic braking performance prediction and analysis of hydrodynamic retarder [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 160-164. |

| [10] | YUAN Zhe, MA Wen-xing, LIU Chun-bao, LIU Hao. Temperature field analysis of the open-type hydrodynamic retarder of heavy vehicle [J]. 吉林大学学报(工学版), 2013, 43(05): 1271-1275. |

| [11] | LIU Shu-cheng, WEI Wei, YAN Qing-dong, ZHOU Qia. Simulation method of idling characteristic of hydrodynamic torque converter stator wheel [J]. 吉林大学学报(工学版), 2013, 43(01): 22-27. |

| [12] | YAN Qing-dong, ZOU Bo, WEI Wei. Numerical investigation of brake performance of hydrodynamic tractor-retarder assembly [J]. 吉林大学学报(工学版), 2012, 42(01): 91-97. |

| [13] | LIU Cheng-qiang, JIANG Ji-hai. Flow characteristic of inclined plate and axial plunger type hydraulic transformer [J]. 吉林大学学报(工学版), 2012, 42(01): 85-90. |

| [14] | QI Pan-guo, WANG Hui, HAN Jun-wei. Structured singular value-synthesis based robust control of hydraulic control loading system [J]. 吉林大学学报(工学版), 2011, 41(4): 1004-1009. |

| [15] | LU Xiu-quan,CHU Ya-xu,CAI Wei,MA Wen-xing,SONG Jian-jun. Predicting method for partial-filling performance of hydrodynamic retarder based on one-dimensional flow beam theory [J]. 吉林大学学报(工学版), 2011, 41(4): 988-992. |

|

||