Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (1): 231-241.doi: 10.13229/j.cnki.jdxbgxb20210051

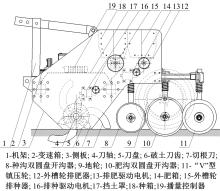

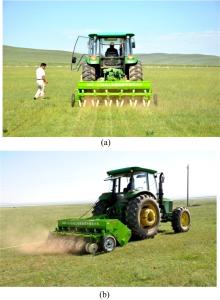

Design and experiment of root-cutter with fertilization and reseeding compound remediation machine for grassland

Fang LIANG1,2,3( ),De-cheng WANG2,4(

),De-cheng WANG2,4( ),Yong YOU2,4,Guang-hui WANG2,4,Yu-bing WANG1,Xiao-ming ZHANG2,Jin-kui FENG2

),Yong YOU2,4,Guang-hui WANG2,4,Yu-bing WANG1,Xiao-ming ZHANG2,Jin-kui FENG2

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.College of Engineering,China Agricultural University,Beijing 100083,China

3.Key Laboratory of Agricultural Equipment in Mid?lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

4.Key Laboratory of Soil?machine?plant System of Chinese Agriculture Ministry,China Agricultural University,Beijing 100083,China

CLC Number:

- S222.3

| 1 | 宝音陶格涛. 不同改良措施下退化羊草草原群落恢复演替规律研究[D]. 呼和浩特: 内蒙古大学生态与环境科学系, 2009. |

| Tao-ge-tao Baoyin. The study on dynamic succession of community in degraded steppe of leymus-chinensis after different improvement measures [D]. Hohhot: Department of Ecological and Environmental Sciences,Inner Mongolia Hohhot Inner Mongolia University, 2009. | |

| 2 | Schnoor T K, Olsson P A. Effects of soil disturbance on plant diversity of calcareous grasslands[J]. Agriculture Ecosystems and Environment, 2010, 139(4): 714-719. |

| 3 | Jerome S, Sebastien G, Frederic B. Evaluation of the most common engineering methods for maritime cliff-top vegetation restoration[J]. Ecological Engineering, 2012,45:45-54. |

| 4 | María C V, Rodolfo A G, Adriana M R, et al. Improvement of saline-sodic grassland soils properties by rotational grazing in argentina[J]. Rangeland Ecology & Management, 2018: 71(6): 807-814. |

| 5 | 何丹. 改良措施对天然草原植被及土壤的影响[D]. 北京: 中国农业科学院,2009. |

| He Dan. Study on effects of improved measures on vegetation and soil of grassland[D]. Beijing: Chinese Academy of Agricultural Sciences, 2009. | |

| 6 | 梁方. 草地切根施肥补播复式改良机械的优化设计与试验研究[D]. 北京:中国农业大学工学院,2015. |

| Liang Fang. Optimization design and experiment study on root-cutter with fertilization and reseeding compound remediation machine for grassland[D]. Beijing: School of Engineering, Agricultural University of China, 2015. | |

| 7 | 贺长彬. 天然草地土壤⁃根系复合体与窄齿类耕作部件作用关系研究[D]. 北京:中国农业大学工学院,2018. |

| He Chang-bin. Interaction relationship research of soil-root composite and narrow tillage tools on natural grassland[D]. Beijing: School of Engineering, Agricultural University of China, 2018. | |

| 8 | You Yong, Wang De-cheng, Liu Ju-de. A device for mechanical remediation of degraded grasslands[J]. Soil and Tillage Research, 2012, 118: 1-10. |

| 9 | 董向前,宋建农,王继承,等.9ST-460型草地振动式间隔松土机改进设计与试验[J].农业机械学报,2011, 42(4): 62-65. |

| Dong Xiang-qian,Song Jian-nong,Wang Ji-cheng,et al. Improved design and experiment of 9ST-460 vibration spacing scarifier for grassland[J]. Transactions of The Chinese Society for Agricultural Machinery, 2011, 42(4): 62-65. | |

| 10 | 武广伟,宋建农,李永磊,等. 草地振动式间隔松土机设计与试验[J]. 农业机械学报,2010, 41(2): 42-46, 41. |

| Wu Guang-wei, Song Jian-nong, Li Yong-lei,et al. Design and experiment on vibration spacing scarifier for meadow[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(2): 42-46, 41. | |

| 11 | 吴佳,张淑敏. 草地点线式破土切根机工作原理及性能测试[J]. 现代农业科学, 2010, 38(5): 218-219. |

| Wu Jia, Zhang Shu-min. Working principie and performance test of dot-line root-cutting machine[J]. Modern Agricultural Science and Technology, 2010, 38(5): 218-219. | |

| 12 | Bueno J, Amiama C, Hernanz J L. No-tillage drilling of Italian ryegrass (Lolium multiflorum L.) : crop residue effects, yields and economic benefits[J]. Soil and Tillage Research, 2007, 95(1/2): 61-68. |

| 13 | Tim Ke S, Pål A O. Effects of soil disturbance on plant diversity of calcareous grasslands[J]. Agriculture, Ecosystems and Environment, 2010,139(4): 714-719. |

| 14 | 杨军,沈卫强,兰秀英,等. 9SB-2.4型草原松土补播机的研制与试验[J]. 农业工程学报,2006, 22(7): 208-210. |

| Yang Jun, Shen Wei-qiang, Lan Xiu-ying, et al. Manufacture and experiment of 9SB-2.4 type no-tillage seeder in prairie[J]. Transactions of the Chinese Society of Agricultural Engineering, 2006, 22(7): 208-210. | |

| 15 | 张永亮,于铁峰,郝凤,等.施肥与混播比例对豆禾混播牧草生产性能的影响[J]. 中国草地学报, 2020, 42(6): 115-124. |

| Zhang Yong-liang,Yu Tie-feng,Hao Feng,et al. Effects of fertilization and mixed sowing ratio on the production performance of grass-alfalfa missed forage[J]. Chinese Journal of Grassland, 2020, 42(6): 115-124. | |

| 16 | 赵明清,陈一昊,任宪涛. 退化羊草草场松耙施肥补播效果研究[J]. 现代农业科技, 2013, 41(2): 273, 276. |

| Zhao Ming-qing, Chen Yi-hao, Ren Xian-tao. Effect of tillage with fertilization and reseeding for degenerated grassland[J]. Modern Agricultural Science and Technology, 2013, 41(2): 273, 276. | |

| 17 | 张淑娟,裘正军,王凤花,等. 农田土壤含水率和坚实度采集仪设计与试验[J]. 农业机械学报, 2010, 41(9): 75-79. |

| Zhang Shu-juan,Qiu Zheng-jun,Wang Feng-hua,et al. Design and test on the field moisture compaction acquisition instrument[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(9): 75-79. | |

| 18 | 王振华.气流分配式牧草播种机关键部件优化与试验[D].北京:中国农业大学工学院,2014. |

| Wang Zhen-hua. Optimizing and experiment of the key parts of the air seeder[D]. Beijing: College of Engineering of China Agricultural University, 2014. | |

| 19 | 杨士昆,苏正范,王德成,等.饲草生产与机械设备[M].北京:中国农业出版社,2009. |

| 20 | Vamerali T, Bertocco M, Sartoe L. Effects of a new wide sweep opener for no-till planter on seed zone properties and root establishment in maize (Zea mays, L.): a comparison with double-disk opener[J]. Soil and Tillage Research, 2006, 89(2): 196-209. |

| 21 | Solhjou A, Fielke J M, Desbiolles J M A, et al. Soil transloc ation by narrow openers with various bent leg geometries[J]. Biosystems Engineering, 2014,127:41-49. |

| 22 | Ryan A, Blaustein, Robert L, et al. Rainfall intensity effects on removal of fecal indicator bacteria from solid dairy manure applied over grass-covered soil[J]. Science of the Total Environment, 2016, 539: 583-591. |

| 23 | Silva M, Franco H C, Paulo S, et al. Liquid fertilizer application to ration cane using a soil punching method[J]. Soil and Tillage Research, 2017, 165: 279-285. |

| 24 | Hengsen F, Buhle L, Wachendorf M. The effect of harvest, mulching and low-dose fertilization of liquid digestive on above ground biomass yield and diversity of lower mountain semi-natural grasslands[J]. Agriculture, Ecosystems & Environment, 2016, 216: 283-292. |

| 25 | Kamger S, Noei-Khodabadi F, Shafaei S M. Design, development and field assessment of a controlled seed metering unit to be used in grain drills for direct seeding of wheat[J]. Information Processing in Agriculture, 2015, 2(3/4): 169-176. |

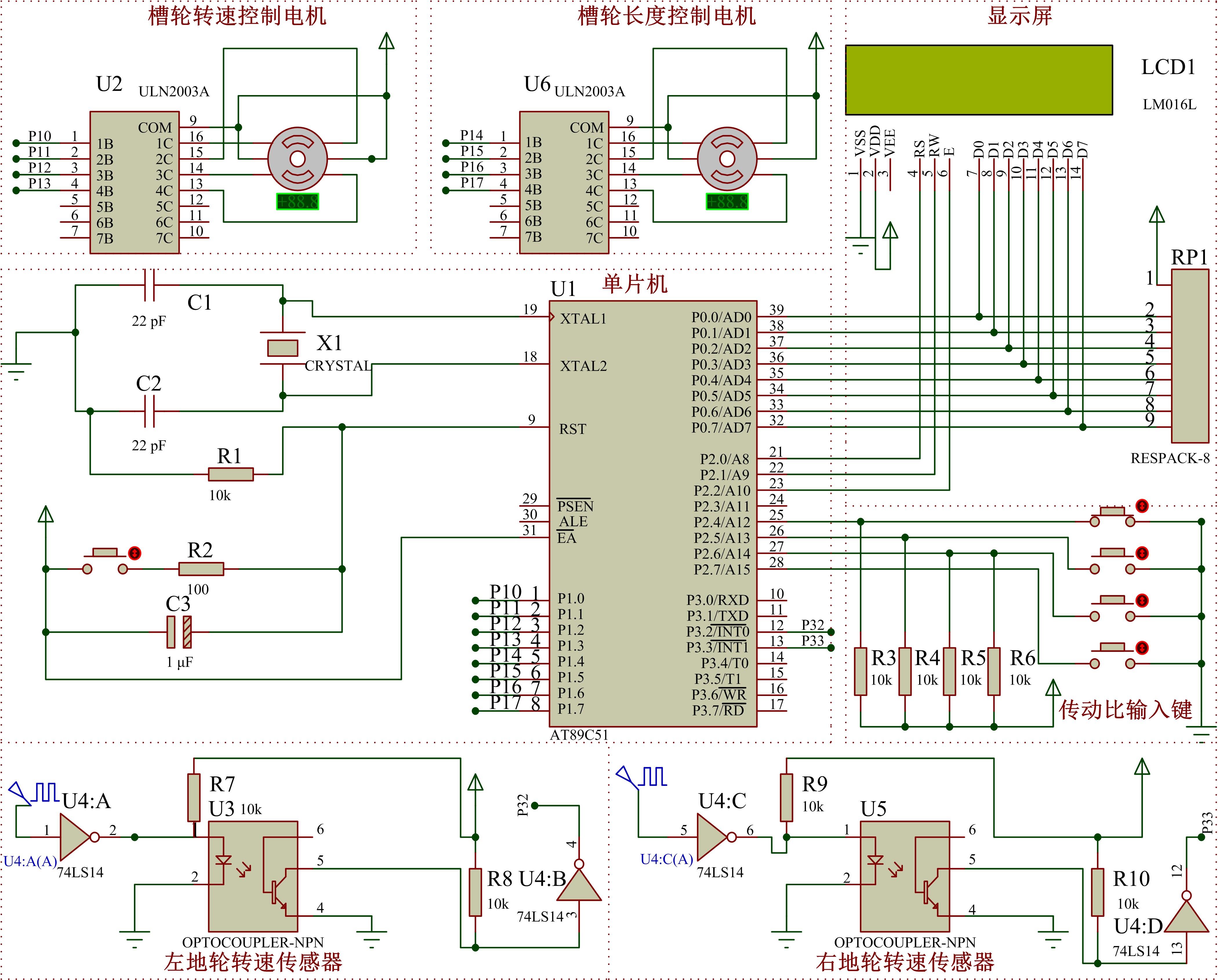

| 26 | 胡恒东. 基于PLC的播量控制装置的研究[D]. 南京:南京农业大学工学院, 2013. |

| Hu Heng-dong. Research on seeding quantity control device based on PLC[D]. Nanjing: School of Engineering, Nanjing Agricultural University, 2013. | |

| 27 | 金亦富, 奚小波, 沈函孝,等. 外槽轮电动排种器设计与播种试验[J]. 中国农机化学报, 2016, 37(10):14-16. |

| Jin Yi-fu, Xi Xiao-bo, Shen Han-xiao, et al. Design and experiment of electric external force feed[J]. Journal of Chinese Agricultural Mechaniztion, 2016, 37(10):14-16. | |

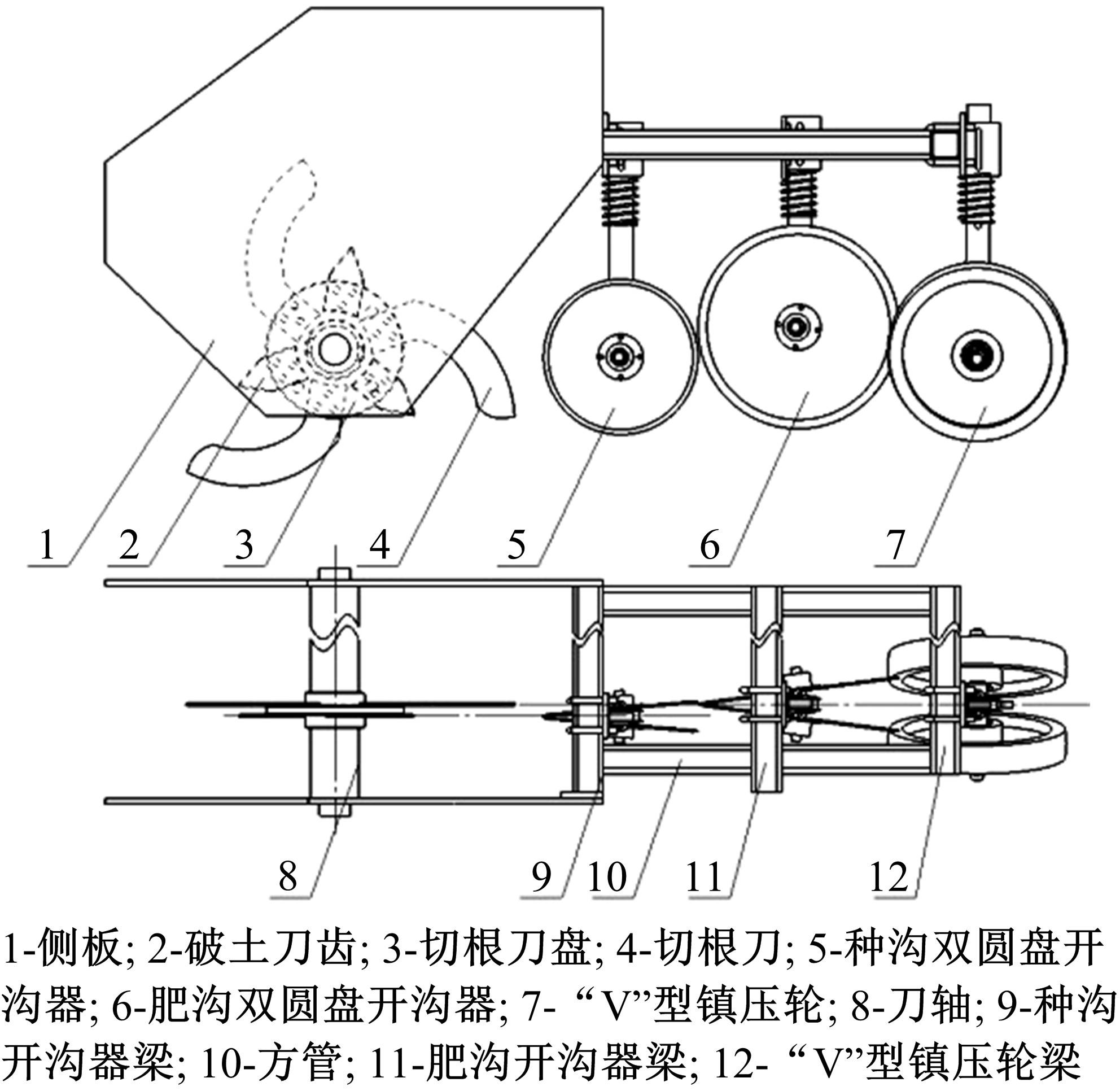

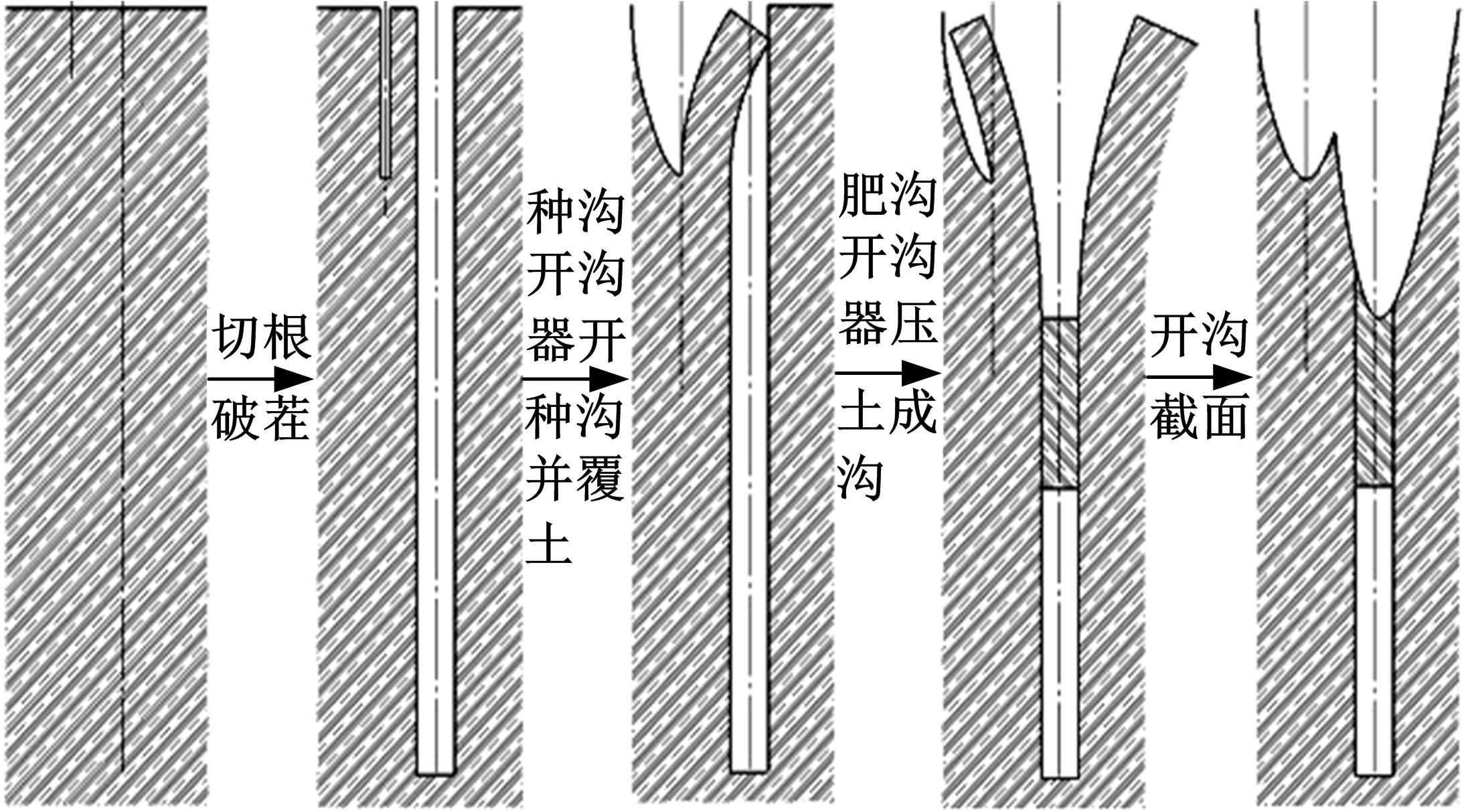

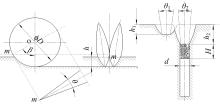

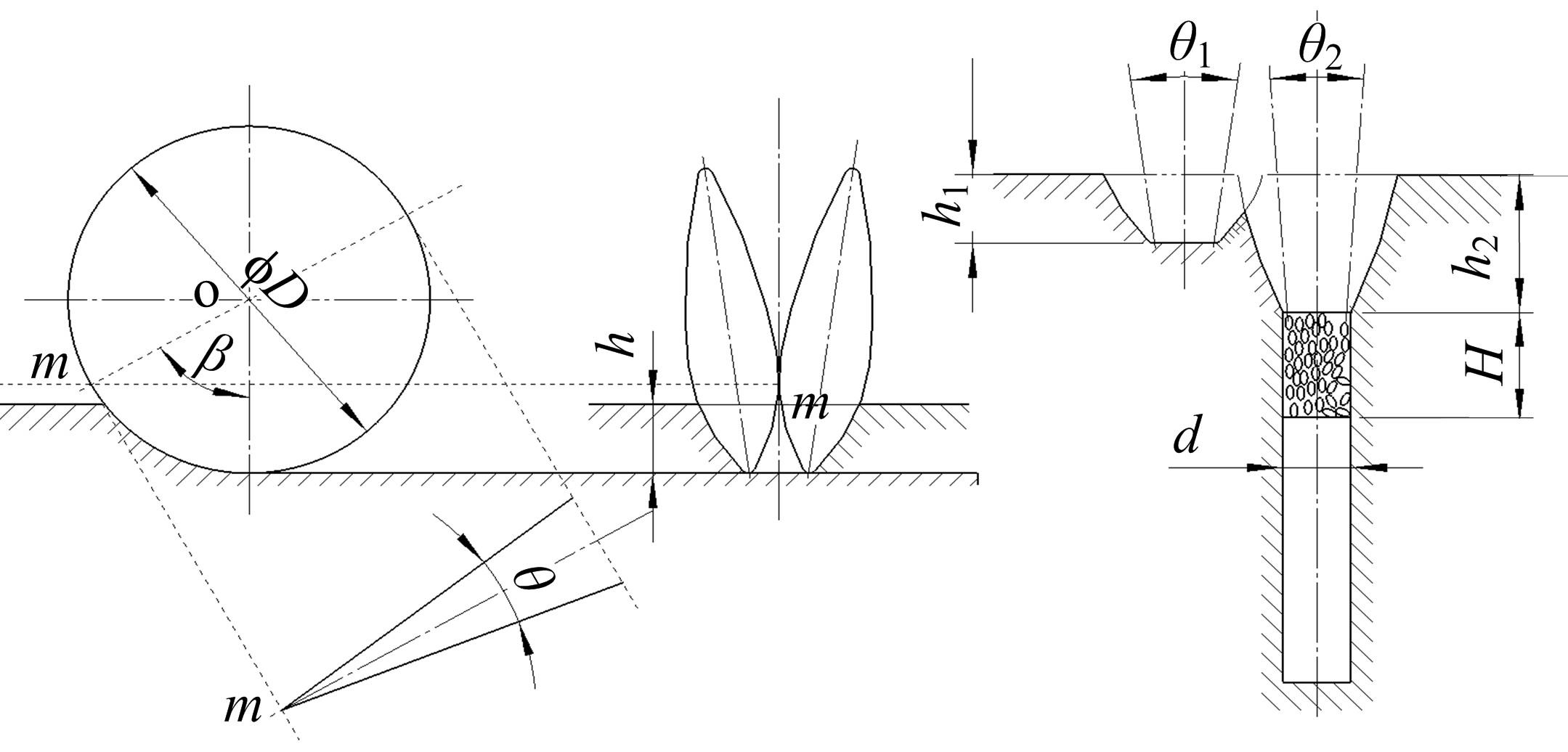

| 28 | 梁方, 王德成, 尤泳, 等. 草地切根施肥补播开沟装置的设计与试验[J]. 华中农业大学学报, 2018, 37(1): 108-114. |

| Liang Fang, Wang De-cheng, You Yong,et al. Design and experiment of furrowing device for Root-cutter with fertilization and reseeding in grassland[J]. Journal of Huazhong Agricultural University, 2018, 37(1): 108-114. | |

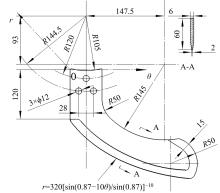

| 29 | 梁方, 尤泳, 王德成, 等.运动参数对草地切根刀具与土壤作用关系的影响[J].吉林大学学报:工学版, 2019, 49(3): 903-911. |

| Liang Fang, You Yong, Wang De-cheng, et al. The effect of dynamic parameters on the relationship between the root cutting blade and the soil in the grassland[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49 (3): 903-911. | |

| 30 | 梁方, 王德成, 尤泳,等. 草地破土切根刀具的刃口曲线设计与优化[J]. 中国农业大学学报, 2016, 21(6): 100-107. |

| Liang Fang, Wang De-cheng, You Yong, et al. The design and optimization of the edge curve of the root-cutting blade in grassland[J]. Journal of China Agricultural University, 2016, 21(6):100-107. | |

| 31 | 中国农业机械化科学研究院. 农业机械设计手册[M].北京:中国农业科学技术出版社,2007. |

| [1] | Xin-yan WANG,Quan JIANG,Feng LYU,Zheng-yang YI. Rollover stability of zero turning radius lawn mower based on parametric model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1908-1918. |

| [2] | Qian CONG,Jin XU,Bo-shuai MA,Xiao-chao ZHANG,Ting-kun CHEN. Design and test of tractor hydraulic suspension system testing device based on virtual simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 754-760. |

| [3] | Chao CHENG,Jun FU,Zhi CHEN,Lu-quan REN. Sieve blocking laws and stripping test of corn grain harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 761-771. |

| [4] | Xue-shen CHEN,Zhu-jian HUANG,Xu MA,Long QI,Gui-jin FANG. Design and test of control system for rice mechanical weeding and seedling-avoiding control [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 386-396. |

| [5] | En-ze LIU,Wen-fu WU. Monochrome fruit growth detection internet architecture based oncomprehensive indicator quality evaluation algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2019-2026. |

| [6] | Jia⁃hao QIN,Zhen LI,Muneshi MITSUOKA,Eiji INOUE,Zheng⁃he SONG,Zhong⁃xiang ZHU. Significance variation of factorial effects on tractor stability employing scale⁃model⁃based experimental approach [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1236-1245. |

| [7] | Fang LIANG,Yong YOU,De‑cheng WANG,Guang‑hui WANG,Chang‑bin HE,Shuai LI. Effect of dynamic parameters on relationship between root‑cutting blade and soil in grassland [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 903-911. |

| [8] | WANG Yang, WANG Xiao-mei, CHEN Ze-ren, YU Jian-qun. Modeling method of maize kernels based on discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [9] | CHEN Dong-hui, LYU Jian-hua, LONG Gang, ZHANG Yu-chen, CHANG Zhi-yong. Static rollover stability of semi-mounted agricultural machinery based on ADAMS [J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [10] | WANG Yang, LYU Feng-yan, XU Tian-yue, YU Jian-qun. Shape and size analysis of soybean kernel and modeling [J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [11] | JIA Hong-lei, ZHENG Jia-xin, YUAN Hong-fang, GUO Ming-zhuo, WANG Wen-jun, YU Lu-lu. Design and experiment of a Double-V-shaped furrow opener of soybean seeder [J]. 吉林大学学报(工学版), 2017, 47(1): 323-331. |

| [12] | YUAN Zhe, XU Dong, LIU Chun-bao, LI Xue-song, LI Shi-chao. Strength analysis of hydraulic retarder blade based on the process of thermal-fluid structure interaction [J]. 吉林大学学报(工学版), 2016, 46(5): 1506-1512. |

| [13] | YUAN Zhe, ZHOU Qian-qian, LIU Chun-bao, MA Wen-xing, XU Zhi-xuan. Blade design and aerodynamics of MW wind turbine based on BEM theory [J]. 吉林大学学报(工学版), 2016, 46(4): 1142-1148. |

| [14] | LIU Yi-qun, DENG Zong-quan, ZHAO Liang, DING Liang, TONG Zhi-zhong, GAO Hai-bo. Performance of walking leg of a hydraulically actuated hexapod robot [J]. 吉林大学学报(工学版), 2015, 45(5): 1512-1518. |

| [15] | TIAN Wei-jun, WANG Ji-yue1, LI Ming1, CHEN Si-yuan, LIU Fang-yuan, CONG Qian. Bionic design of the small blade of horizontal axis wind turbines [J]. 吉林大学学报(工学版), 2015, 45(5): 1495-1501. |

|

||