Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (7): 1887-1893.doi: 10.13229/j.cnki.jdxbgxb.20221323

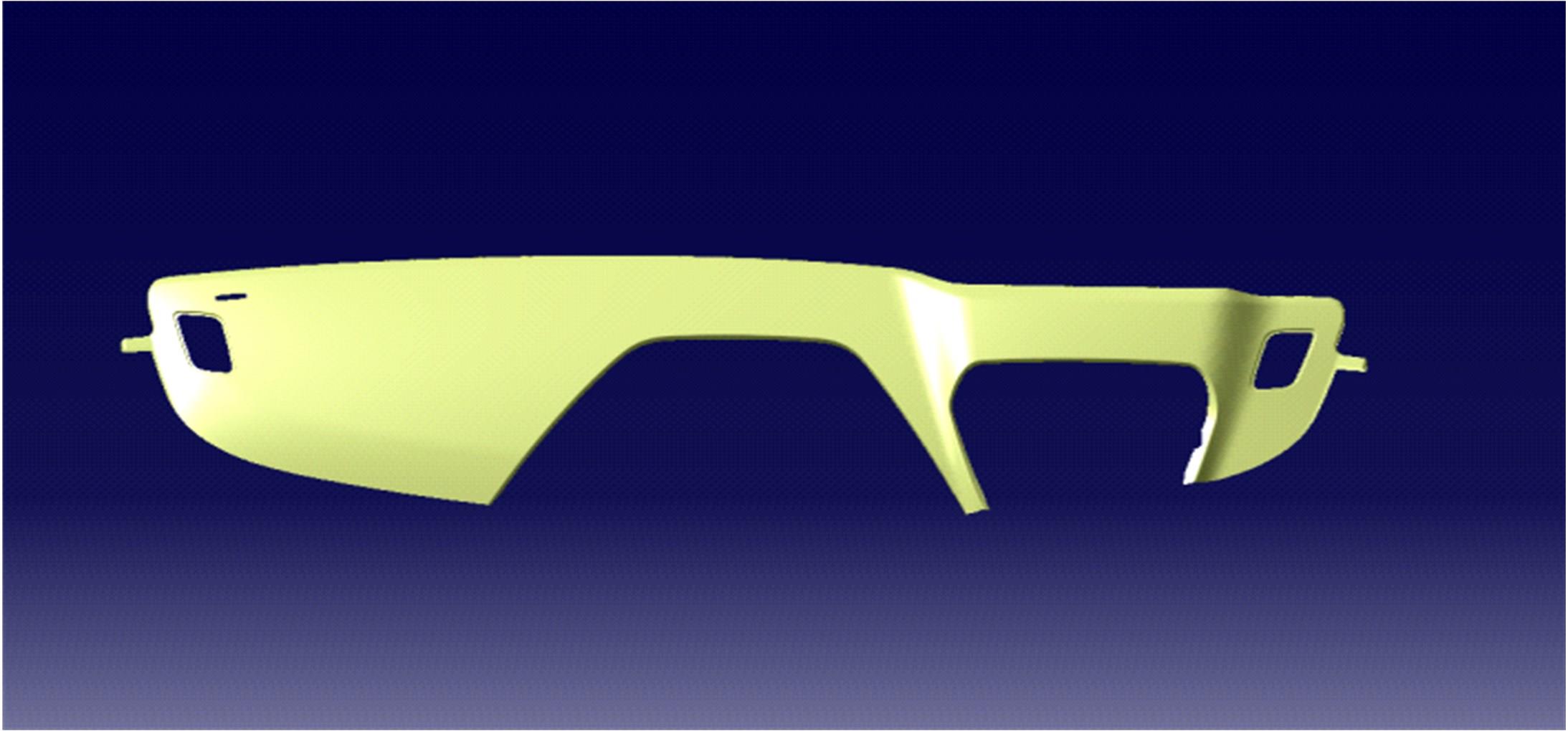

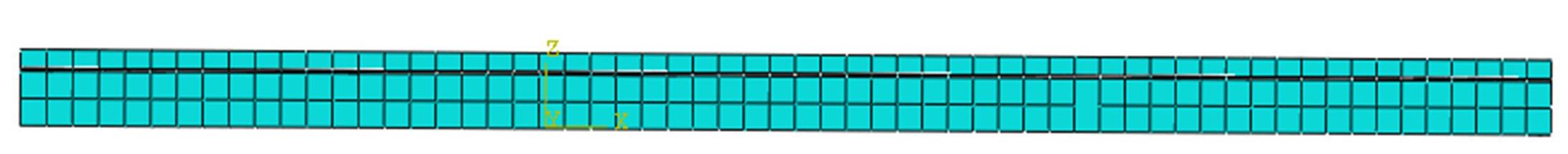

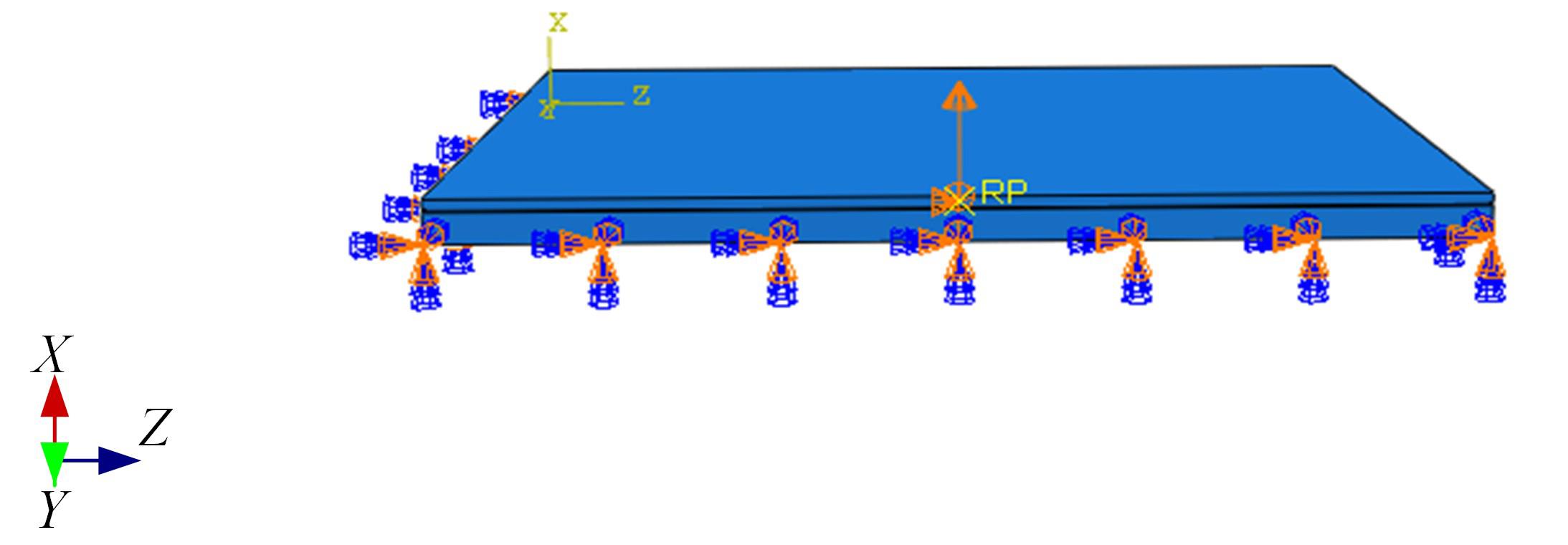

Simulation on influence of temperature field on composite glued structure of car interior

Yi LI1( ),Ya-sai BAI1,Ji-cai LIANG1,2,Wei-guo YAO1,Ce LIANG1(

),Ya-sai BAI1,Ji-cai LIANG1,2,Wei-guo YAO1,Ce LIANG1( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Roll Forging Institute,Jilin University,Changchun 130022,China

CLC Number:

- TG356

| 1 | 蒋志军, 张志刚, 吕崇建,等. 汽车内饰包覆零件设计与工艺研究[J]. 汽车实用技术, 2018,44(7):131-134. |

| Jiang Zhi-jun, Zhang Zhi-gang, Chong-jian Lyu. Research on the design and process of automotive interior coating parts[J]. Automobile Applied Technology,2018,44(7):131-134. | |

| 2 | Hu P, Han X, Li W D, et al. Research on the static strength performance of adhesive single lap joints subjected to extreme temperature environment for automotive industry[J]. International Journal of Adhesion & Adhesives, 2013, 41:119-126. |

| 3 | Sayman O, Arikan V, Dogan A, et al. Failure analysis of adhesively bonded composite joints under transverse impact and different temperatures[J]. Composites Part B: Engineering, 2013, 54(11):409-414. |

| 4 | Vaidya U K, Gautam A, Hosur M, et al. Experimental-numerical studies of transverse impact response of adhesively bonded lap joints in composite structures[J]. International Journal of Adhesion & Adhesives, 2006, 26(3):184-198. |

| 5 | Huang W, Sun L, Li L, et al. Investigations on low-energy impact and post-impact fatigue of adhesively bonded single-lap joints using composites substrates[J]. The Journal of Adhesion, 2019:1-29. |

| 6 | Oz De Mir O, Oztoprak N. An investigation into the effects of fabric reinforcements in the bonding surface on failure response and transverse impact behavior of adhesively bonded dissimilar joints[J]. Composites Part B: Engineering, 2017, 126(10):72-80. |

| 7 | Machado J, Marques E, Lucas F M, et al. The journal of adhesion adhesives and adhesive joints under impact loadings: an overview[J] .The Journal of Adhesion,2018,94(5/7):421-452 . |

| 8 | Soykok I F, Sayman O, Ozen M, et al. Failure analysis of mechanically fastened glass fiber/epoxy composite joints under thermal effects[J]. Composites Part B: Engineering, 2013, 45(1):192-199. |

| 9 | Kemiklioglu U, Sayman O, Batar T.Strength comparison of ductile and brittle adhesives under single and repeated impacts[J]. Applied Adhesion Science, 2015, 3(1):1-9. |

| 10 | Kumagai S, Shindo Y. Experimental and analytical evaluation of the notched tensile fracture of CFRP-woven laminates at low temperatures[J]. Journal of Composite Materials, 2004, 38(13):1151-1164. |

| 11 | Shindo Y, Takahashi S, Takeda T, et al. Mixed-mode interlaminar fracture and damage characterization in woven fabric-reinforced glass/epoxy composite laminates at cryogenic temperatures using the finite element and improved test methods[J]. Engineering Fracture Mechanics, 2008, 75(18):5101-5112. |

| 12 | Tserpes K I, Labeas G, Papanikos P, et al. Strength prediction of bolted joints in graphite/epoxy composite laminates[J]. Composites Part B: Engineering, 2002, 33(7):521-529. |

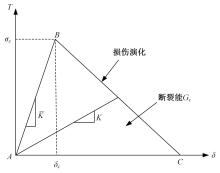

| 13 | Mi Y, Crisfield M A, Davies G A O, et al. Progressive delamination using interface elements[J]. Journal of Composite Matrerials, 1998, 32(14):1246-1272. |

| 14 | 徐庚. 基于率相关粘接界面模型的夹芯复合材料结构极限强度研究[D]. 武汉:武汉理工大学交通与物流工程学院, 2018. |

| Xu Geng. Study of ultimate strength of sandwich composite structures based on rate dependence adhesive interface model[D]. Wuhan: School of Transportation and Logistics Engineering, Wuhan University of Technology, 2018. | |

| 15 | Benzeggagh M L, Kenane M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J]. Composites Science and Technology, 1996, 56(4):439-449. |

| 16 | 欧阳林辉. 温度环境对复合材料力学性能影响研究[D]. 西安: 西北工业大学力学与土木建筑学院, 2016. |

| Ouyang Lin-hui. Effect analysis of temperature environment on composite structure mechanical properites[D]. Xi´an: School of Mechanics, Civil Engineering and Architecture, Northwestern Polytechnical University,2016. | |

| 17 | 田宇. SiCp/AlSi3复合材料热残余应力有限元分析[D]. 长春: 吉林大学物理学院, 2009. |

| Tian Yu. Finite element analysis of SiCp/AlSi3 composite thermal residual stress[D]. Chanchun: College of Physics, Jilin University, 2009. |

| [1] | Yi LI,Chen-yang LYU,Ji-cai LIANG,Ce LIANG. Section deformation analysis of irregular Y-shaped aluminum profile of multi-point stretch-bending process [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 105-113. |

| [2] | Ce LIANG,Fu-lei HUANG,Ji-cai LIANG,Yi LI. Numerical simulation on deformation of protective beam with “日”-shaped section during rotary draw bending [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3397-3403. |

| [3] | Wen-ming JIN,Tian LIANG,Ce LIANG,Yi LI,Jun-tao LI,Ji-cai LIANG. Influence of process parameters on cross-sectional deformation of rotary draw bending forming of automobile protective beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1182-1189. |

| [4] | Ji-cai LIANG,Yan-fei LIAO,Fei TENG,Ce LIANG,Yi LI. Rectangular section profile thinning rate of three-dimensional multi-point stretch bending process [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 163-171. |

| [5] | LIANG Ji-cai, LI Yi, GAO Song, TENG Fei. Springback prediction for multi-point 3D stretch bending profile [J]. 吉林大学学报(工学版), 2017, 47(1): 185-190. |

| [6] | LI Yi, LIANG Ji-cai, TENG Fei, LIANG Ce, YU Jia-qi. Multi-phase iterative compensation method of die shape optimization for multi-point stretch bending profile [J]. 吉林大学学报(工学版), 2016, 46(6): 1961-1966. |

| [7] | XU Zhi-xing, JIANG Xi-cheng, TANG Ke-hong, WEI Fu-yu. Research & Application of a New Water-Sealed Copper Line Annealing Furnace [J]. 吉林大学学报(工学版), 2000, (3): 39-42. |

|

||