Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1747-1754.doi: 10.13229/j.cnki.jdxbgxb20170854

Previous Articles Next Articles

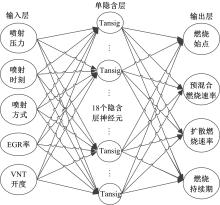

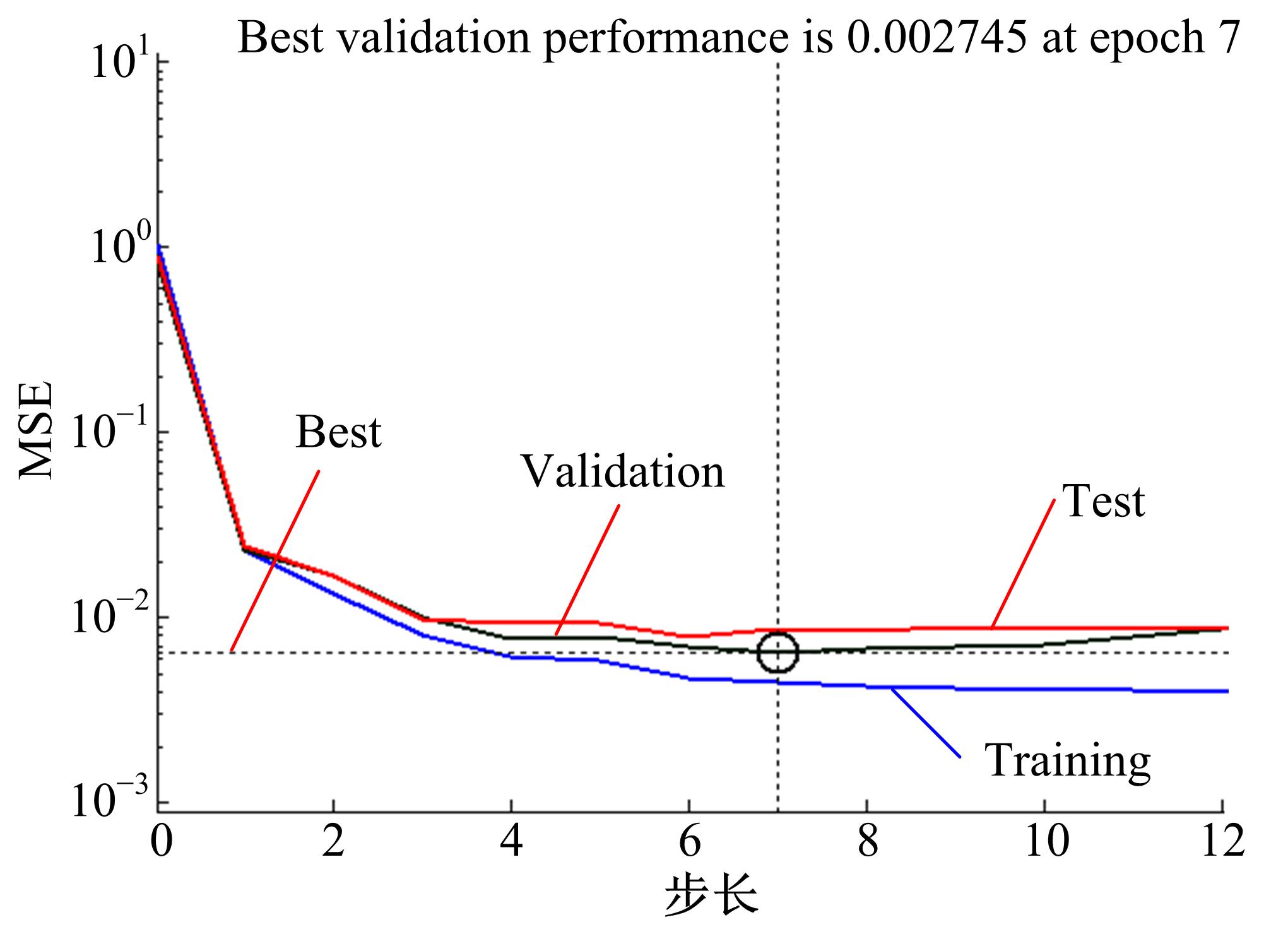

Effect of control parameters on heat release rate with ANN method

JIANG Tao( ),LIN Xue-dong,LI De-gang(

),LIN Xue-dong,LI De-gang( ),YANG Miao,TANG Xue-lin

),YANG Miao,TANG Xue-lin

- State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

CLC Number:

- TK421

| [1] | Heywood J B . Internal Combustion Engine Funda-Mentals[M]. New York: McGraw-Hill, 1988. |

| [2] |

Kim J, Jang J, Lee K , et al. Combustion and emissions characteristics of diesel and soybean biodiesel over wide ranges of intake pressure and oxygen concentration in a compression-ignition engine at a light-load condition[J]. Fuel, 2014,129:11-19.

doi: 10.1016/j.fuel.2014.03.022 |

| [3] |

Li Xin-ling, Xu Zhen, Guan Chun , et al. Impact of exhaust gas recirculation (EGR) on soot reactivity from a diesel engine operating at high load[J]. Applied Thermal Engineering, 2014,68(1/2):100-106.

doi: 10.1016/j.applthermaleng.2014.04.029 |

| [4] |

Wang Ying, Li Dong-chang, Lei Xiong , et al. Combustion and emission characteristics of a DME (dimethyl ether)-diesel dual fuel premixed charge compression ignition engine with EGR (exhaust gas recirculation)[J]. Energy, 2014,72(7):608-617.

doi: 10.1016/j.energy.2014.05.086 |

| [5] |

Asad U, Zheng M . Fast heat release characterization of a diesel engine[J]. International Journal of Thermal Sciences, 2008,47(12):1688-1700.

doi: 10.1016/j.ijthermalsci.2008.01.009 |

| [6] |

Taghavifar H, Mardani A, Mohebbi A , et al. Exhaust emissions prognostication for DI diesel group-hole injectors using a supervised artificial neural network approach[J]. Fuel, 2014,125:81-89.

doi: 10.1016/j.fuel.2014.02.016 |

| [7] |

Taghavifar H, Mardani A, Mohebbi A , et al. Investigating the effect of combustion properties on the accumulated heat release of DI engines at rated EGR levels using the ANN approach[J]. Fuel, 2014,137:1-10.

doi: 10.1016/j.fuel.2014.07.073 |

| [8] |

Rezaei J, Shahbakhti M, Bahri B , et al. Performance prediction of HCCI engines with oxygenated fuels using artificial neural networks[J]. Applied Energy, 2015,138:460-473.

doi: 10.1016/j.apenergy.2014.10.088 |

| [9] |

Taghavifar H, Mardani A, Mohebbi A , et al. On the modeling of convective heat transfer coefficient of hydrogen fueled diesel engine as affected by combustion parameters using a coupled numerical-artificial neural network approach[J]. International Journal of Hydrogen Energy, 2015,40(12):4370-4381.

doi: 10.1016/j.ijhydene.2015.01.140 |

| [10] |

Muralidharan K, Vasudevan D . Applications of artificial neural networks in prediction of performance, emission and combustion characteristics of variable compression ratio engine fuelled with waste cooking oil biodiesel[J]. J Braz Soc Mech Sci Eng, 2014,7(3):1-14.

doi: 10.1007/s40430-014-0213-4 |

| [11] |

Mohammadhassani J, Dadvand A, Khalilarya S , et al. Prediction and reduction of diesel engine emissions using a combined ANN-ACO method[J]. Applied Soft Computing, 2015,34:139-150.

doi: 10.1016/j.asoc.2015.04.059 |

| [12] |

Chen J, Randall R B . Improved automated diagnosis of misfire in internal combustion engines based on simulation models[J]. Mechanical Systems & Signal Processing, 2015,64- 65:58-83.

doi: 10.1016/j.ymssp.2015.02.027 |

| [13] | Dukowicz J K . Quasi-steady droplet change in the presence of convection[R]. Informal Report Los Alamos Scientific Laboratory, LA7997-MS, 1979. |

| [14] | Patankar S V. Numerical Heat and Mass Transfer and Fluid Flow[M]. New York: Hemisphere Publishing Corporation, 1980. |

| [15] |

van der Vorst H A. Bi-CGSTAB: a fast and smoothly converging variant of Bi-CG for the solution of nonsymmetric linear systems[J]. SIAM J Sci Stat Comput, 1992,13:631-644.

doi: 10.1137/0913035 |

| [1] | Peng⁃fei ZANG,Zhe WANG,Yang GAO,Chen⁃le SUN. Investigation of integrated control strategy for stable operation of linear generator/engine system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 798-804. |

| [2] | LI Zhi-jun, WANG Hao, HE Li, CAO Li-juan, ZHANG Yu-chi, ZHAO Xin-shun. Soot distribution features and its influence factors in catalytic diesel particulate filte [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1466-1474. |

| [3] | QIN Jing, XU He, PEI Yi-qiang, ZUO Zi-nong, LU Li-li. Influence of initial temperature and initial pressure on premixed laminar burning characteristics of methane-dissociated methanol flames [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1475-1482. |

| [4] | LIN Xue-dong, JIANG Tao, XU Tao, LI De-gang, GUO Liang. Control strategy of high pressure pump in starting condition of high pressure common rail diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1436-1443. |

| [5] | ZHONG Bing, HONG Wei, JIN Zhao-hui, SU Yan, XIE Fang-xi, ZHANG Fu-wei. Movement characteristics of hydraulic variable valve train with early intake valve closing [J]. 吉林大学学报(工学版), 2018, 48(3): 727-734. |

| [6] | LI Long, ZHANG You-tong, ZUO Zheng-xing. Application of variable-load control in cylinder pressure control of free-piston engine generator [J]. 吉林大学学报(工学版), 2018, 48(2): 473-479. |

| [7] | WEI Hai-qiao, PEI Zi-gang, FENG Deng-quan, PAN Jia-ying, PAN Ming-zhang. Effect of multi-injectionpiezo injector on particulate emission in gasoline direct injection engine [J]. 吉林大学学报(工学版), 2018, 48(1): 166-173. |

| [8] | TIAN Jing, LIU Zhong-chang, LIU Jin-shan, DONG Chun-xiao, ZHONG Ming, DU Wen-chang. Performance optimization of diesel engine based on response surface methodology of multi-boundary combustion conditions [J]. 吉林大学学报(工学版), 2018, 48(1): 159-165. |

| [9] | LI Zhi-jun, HE Li, JIANG Rui, SHEN Bo-xi, KONG Xiang-jin, LIU Shi-yu. Evaluation of influence of ash distribution on diesel particulate filter pressure drop [J]. 吉林大学学报(工学版), 2017, 47(6): 1760-1766. |

| [10] | YU Liu, LIU Zhong-chang, LIU Jiang-wei, DU Hong-fei, XU Yun. Gasoline direct injection engine spray droplet characteristics [J]. 吉林大学学报(工学版), 2017, 47(5): 1482-1488. |

| [11] | LIU Zhong-chang, TENG Peng-kun, TIAN Jing, XU Yun, QI Sheng-lin, YU Kai-bo. Regulation characteristics of bypass valve of two stage turbocharged diesel engine [J]. 吉林大学学报(工学版), 2017, 47(3): 796-803. |

| [12] | SUN Wen-xu, HONG Wei, XIE Fang-xi, SU Yan, JIANG Bei-ping, LI Xiang-yu. Effects of idle speed and throttle opening on engine shutdown characteristics and realization of direct start mode [J]. 吉林大学学报(工学版), 2017, 47(2): 483-489. |

| [13] | LI Zhi-jun, WANG Nan, ZHANG Li-qiang, HUANG Qun-jin, WEI Suo-ku, ZHANG Yan-ke. Numerical simulation for flow and pressure drop characteristics in asymmetrical channels of diesel particulate filter [J]. 吉林大学学报(工学版), 2016, 46(6): 1892-1899. |

| [14] | SUN Wen-xu, HONG Wei, HUANG En-li, XIE Fang-xi, SU Yan, JIANG Bei-ping. Effect of initial piston position on direct-start mode of gasoline engine without starter [J]. 吉林大学学报(工学版), 2016, 46(5): 1471-1477. |

| [15] | LI Xiao-ping, HONG Wei, XIE Fang-xi, LI Xiang-yu, YANG Wen-hai, DAI Zhi-yao. NOx emission reduction of a lean-burn methanol engine by retarding ignition timing, exhaust gas recirculation and leaner air/fuel mixture [J]. 吉林大学学报(工学版), 2016, 46(5): 1478-1483. |

|