Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1194-1202.doi: 10.13229/j.cnki.jdxbgxb20180336

Multi⁃objective optimization design of flexspline profile parameters of double⁃arc harmonic drive

Jia⁃xu WANG1,2( ),Qian⁃qian JIANG1,Jun⁃yang LI1,Yan⁃feng HAN1,Lei ZHANG1,Ting TANG1

),Qian⁃qian JIANG1,Jun⁃yang LI1,Yan⁃feng HAN1,Lei ZHANG1,Ting TANG1

- 1. State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing 400044, China

2. School of Aeronautics and Astronautics, Sichuan University, Chengdu 610065, China

CLC Number:

- TH132.43

| 1 | Preumont P , Szewczyk R . Key Factors Influencing the Accuracy of Harmonic Gears for Space Applications[C] ∥Szewczyk R , Zieliński C , Kaliczyńska M . Automation 2018. Berlin: Springer, 2018: 483⁃489. |

| 2 | Timofeev G A . Drives with harmonic gears for servo systems[J]. Russian Engineering Research, 2016, 36(3): 187⁃193. |

| 3 | 董惠敏 . 基于柔轮变形函数的谐波齿轮传动运动几何学及其啮合性能研究[D]. 大连: 大连理工大学机械工程学院, 2008. |

| Dong Hui⁃min . Study of kinematics and meshing characteristic of harmonic drive based on the deformation function of the flexspline[D]. Dalian: School of Mechanical Engineering, Dalian University of Technology, 2008. | |

| 4 | 刘邓辉, 邢静忠, 陈晓霞 . 渐开线谐波齿轮的空间齿廓设计及啮合特性分析[J]. 机械设计, 2016, 33(3): 24⁃29. |

| Liu Deng⁃hui , Xing Jing⁃zhong , Chen Xiao⁃xia . Spatial tooth profile design and engagement analysis of harmonic gear with involute profile[J]. Journal of Machine Design, 2016, 33(3): 24⁃29. | |

| 5 | Ishikawa S , Takizawa N . Wave gear drive having negative deflection meshing tooth profile[P]. US Patent: 7735396, 2010⁃06⁃15. |

| 6 | Ishikaua S . Wave gear device having three⁃dimensionally contactable shifted tooth profile[P]. US Patent: 8776638, 2014⁃07⁃15. |

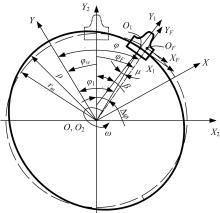

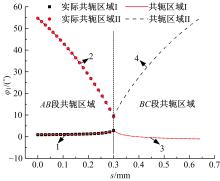

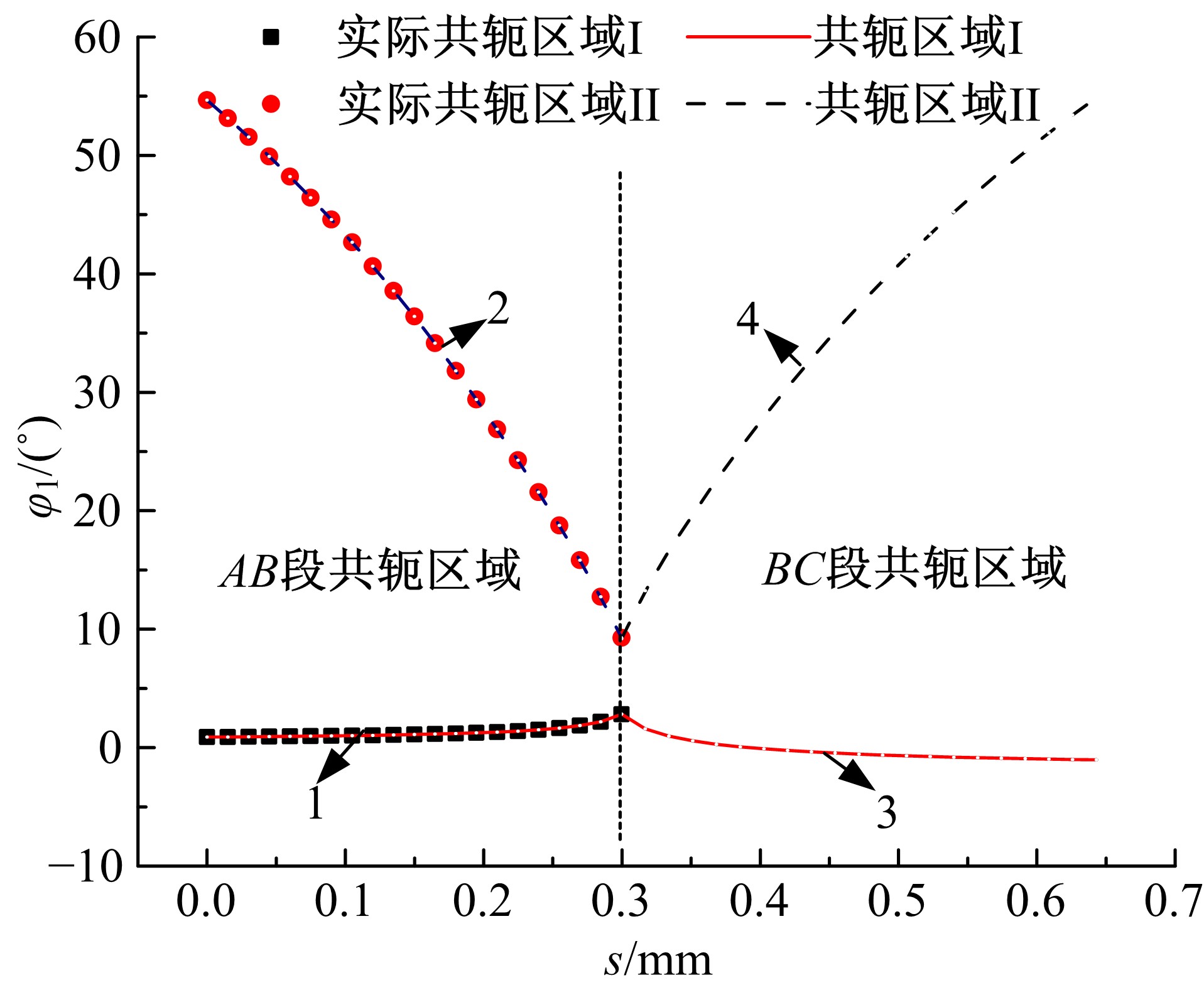

| 7 | 王家序, 周祥祥, 李俊阳, 等 . 不同共轭原理的双圆弧齿廓谐波齿轮传动分析[J]. 四川大学学报: 工程科学版, 2015, 47(5): 160⁃166. |

| Wang Jia⁃xu , Zhou Xiang⁃xiang , Li Jun⁃yang , et al . Double⁃circular⁃arc tooth profile of harmonic drive analysis based on different conjugate principle[J]. Journal of Sichuan University(Engineering Science Edition), 2015, 47(5): 160⁃166. | |

| 8 | 王家序, 周祥祥, 李俊阳,等 . 公切线式双圆弧齿廓谐波齿轮传动设计[J]. 湖南大学学报: 自然科学版, 2016, 43(2): 56⁃63. |

| Wang Jia⁃xu , Zhou Xiang⁃xiang , Li Jun⁃yang , et al . Design of double⁃circular⁃arc and common tangent tooth profile of harmonic drive[J]. Journal of Hunan University (Natural Sciences), 2016, 43(2):56⁃63. | |

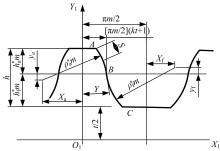

| 9 | Chen Xiao⁃xia , Liu Yu⁃sheng , Xing Jing⁃zhong , et al . The parametric design of double⁃circular⁃arc tooth profile and its influence on the functional backlash of harmonic drive[J]. Mechanism and Machine Theory, 2014, 73(2): 1⁃24. |

| 10 | Chen Xiao⁃xia , Lin Shu⁃zhong , Xing Jing⁃zhong , et al . Simulation on gear backlash and interference check of harmonic drive with circular⁃arc teeth profile[J]. Computer Integrated Manufacturing Systems, 2011, 17(3): 643⁃648. |

| 11 | Xin Hong⁃bing . Design for basic rack of harmonic drive with double⁃circular⁃arc tooth profile[J]. China Mechanical Engineering, 2011, 22(6): 656⁃662. |

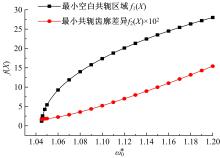

| 12 | 杨勇, 王家序, 周青华, 等 . 双圆弧谐波齿轮传动柔轮齿廓参数的优化设计[J]. 四川大学学报: 工程科学版, 2016, 48(1):186⁃193. |

| Yang Yong , Wang Jia⁃xu , Zhou Qing⁃hua , et al . Optimization design for flexspline tooth profile parameters of double⁃circular⁃arc harmonic drives[J]. Journal of Sichuan University(Engineering Science Edition), 2016, 48(1): 186⁃193. | |

| 13 | 翟永 . 谐波齿轮传动双圆弧齿形设计与分析[D]. 大连:大连海事大学轮机工程学院, 2015. |

| Zhai Yong . Double⁃arc tooth profile design and analysis of harmonic drive[D]. Dalian: School of Marine Engineering, Dalian Maritime University, 2015. |

| [1] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [2] | WU Jiang, XU Zhuang, LIU Li-jia, JI Yan-ju, LI Su-yi. Peripheral oxygen saturation detecting prototype applied in sleep apnea syndrome [J]. 吉林大学学报(工学版), 2018, 48(2): 640-644. |

| [3] | YANG Cheng, SONG Ping, PENG Wen-jia, JIN Hao-long, PAN Zhi-qiang. Design of armored vehicle integrated test system based on hybrid bus [J]. 吉林大学学报(工学版), 2018, 48(1): 186-198. |

| [4] | YANG Cheng, SONG Ping, PENG Wen-jia, DENG Gao-shou, LIU Xiong-jun. Design of host computer platform for armored vehicle integrated test system [J]. 吉林大学学报(工学版), 2017, 47(6): 1796-1803. |

| [5] | BAI De-en, QUAN Qi-quan, LI He, CHEN Ya-wen, DENG Zong-quan. Starting torque test system for harmonic drive based on servo laoding [J]. 吉林大学学报(工学版), 2017, 47(6): 1804-1810. |

| [6] | WANG Tian-hao, WANG Zhong-fu, WANG Yu-meng, YANG Kai-yu, GAO Yin-han, MA Xi-lai. Statistic analysis of cable bundle crosstalk based on polynomial chaos expansion [J]. 吉林大学学报(工学版), 2017, 47(5): 1568-1576. |

| [7] | WANG Jia-xu, YUAN Pan, TAN Chun-lin, HE Yong-qiang, LI Jun-yang, XIAO Ke. Spatial tooth profile design of harmonic drive by rack approximation method [J]. 吉林大学学报(工学版), 2017, 47(4): 1121-1129. |

| [8] | LIU Xiao-wei, LI Hai, WENG Rui, ZHANG Hai-feng, ZHAO Jun. Application of electrostatic torque to improve dynamic characteristics of novel rotational gyroscope [J]. 吉林大学学报(工学版), 2017, 47(3): 850-854. |

| [9] | LIN Jun, ZHAO Yue, JIANG Chuan-dong, WANG Ying-ji. New surface MRS method based on optimized Block inversion [J]. 吉林大学学报(工学版), 2017, 47(2): 530-539. |

| [10] | ZHANG Fei, SHAN Zhong-de, REN Yong-xin, NIE Jun-gang, LIU Feng. Calibration of line array camera for head defect detection system on cylinder cover [J]. 吉林大学学报(工学版), 2017, 47(2): 540-545. |

| [11] | YIN Yao-bao, YUAN Jia-yang, FU Jun-yong. Characteristics of two-stage relief valve with series damping orifice in the front chamber of pilot valve [J]. 吉林大学学报(工学版), 2017, 47(1): 129-136. |

| [12] | LIN Jun, YANG Yu, HU Xue-yan, WANG Shi-long. Transmitting waveform control technology for transient electromagnetic method based on inductive load [J]. 吉林大学学报(工学版), 2016, 46(5): 1718-1724. |

| [13] | YU Sheng-bao, SU Fa, ZHENG Jian-bo, ZHU Zhan-shan. Design of transient electromagnetic receiving system based on LabVIEW [J]. 吉林大学学报(工学版), 2016, 46(5): 1725-1731. |

| [14] | SHEN Mao-dong, CHENG De-fu, AN Zhan-feng, WANG Yi, ZHAO Jing. Optimization of slanting surfaces of five-sided pyramidal full tensor magnetic gradient probe [J]. 吉林大学学报(工学版), 2016, 46(5): 1732-1738. |

| [15] | LIN Jun, ZHAO Yue, JIANG Chuan-dong, LI Tong, LIU Xiao-nan. Three-dimensional forward modeling with high precision for underground MRS based on Hammer integration [J]. 吉林大学学报(工学版), 2016, 46(2): 609-615. |

|

||