Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1272-1279.doi: 10.13229/j.cnki.jdxbgxb20180146

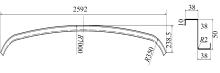

Trajectory design and FE simulation for profile stretch bending based on incremental control method

Xue⁃guang ZHANG1,2( ),Ming⁃meng JIA3,Chun⁃guo LIU2,Guang⁃zhong HE1

),Ming⁃meng JIA3,Chun⁃guo LIU2,Guang⁃zhong HE1

- 1. Engineering Planning and Development Department, CRRC Changchun Railway Vehicles Co. , Ltd. , Changchun 130051, China

2. Rolling Forming Research Institute, Jilin University, Changchun 130022, China

3. College of Automotive Engineering, Jilin Communication Polytechnic, Changchun 130012, China

CLC Number:

- TG386

| 1 | 薛克仲 . 城市轨道车辆车体材料选择[J]. 城市轨道交通研究, 2003, 6(1): 14⁃19. |

| Xue Ke⁃zhong . Selection of car body materials for urban railway vechiles[J]. Urban Mass Transit, 2003, 6(1): 14⁃19. | |

| 2 | 王胜满 . 用于地铁车辆的不锈钢型材拉弯成形缺陷[J]. 吉林大学学报: 工学版, 2013, 43(6): 1546⁃1550. |

| Wang Sheng-man . Stretch bend forming defects of stainless steel profile of metro vechile[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(6): 1546⁃1550. | |

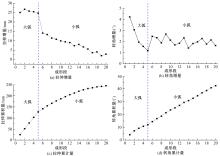

| 3 | 谷诤巍, 吕萌萌, 李欣, 等 . 数控拉弯工艺中型材变形量的影响因素[J]. 吉林大学学报:工学版, 2016, 46(4): 1190⁃1196. |

| Gu Zheng⁃wei , Meng⁃meng Lyu , Li Xin , et al . Influence factors of profile deformation in NC stretch bending[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(4): 1190⁃1196. | |

| 4 | 梁继才,李义,高嵩,等 .型材多点柔性拉弯成形回弹预测[J].吉林大学学报:工学版,2017,47(1):185⁃190. |

| Liang Ji⁃cai , Li Yi , Gao Song , et al . Springback prediction for multi⁃point 3D stretch bending profile[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 185⁃190. | |

| 5 | Yu C L , Li X Q . Theoretical analysis on springback of L⁃section extrusion in rotary stretch bending process[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(12): 2705⁃2710. |

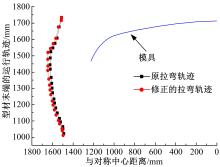

| 6 | 王永军, 黄云华, 王俊彪, 等 . 数控转台拉弯机切点跟踪轨迹生成算法[J]. 机械工程学报, 2005, 41(10): 123⁃127. |

| Wang Yong⁃jun , Huang Yun⁃hua , Wang Jun⁃biao , et al . Algorithm of generating the tracking locus of the tangent point for NC rotary stretch-bending former[J]. Chinese Journal of Mechanical Engineering, 2005, 41(10): 123⁃127. | |

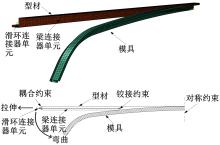

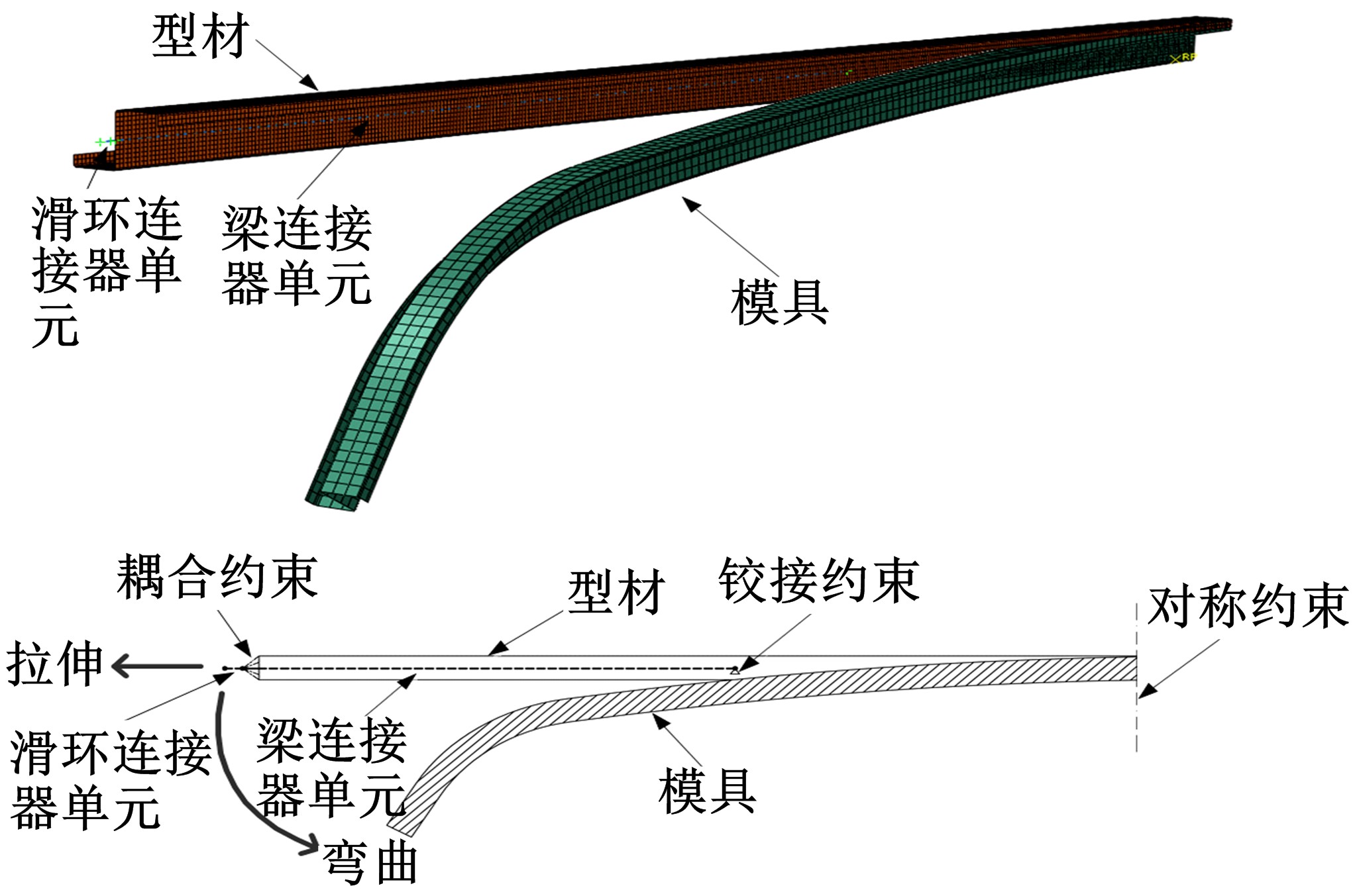

| 7 | 刘志军, 金朝海, 李东升, 等 . 基于 PSBPD 的 T 型材拉弯夹钳加载轨迹设计及有限元模拟[J]. 塑性工程学报, 2012, 19(6): 109⁃113. |

| Liu Zhi⁃jun , Jin Chao⁃hai , Li Dong⁃sheng , et al . PSBPD⁃based jaw trajectory design and numerical simulation for T⁃section profile during stretch⁃bending[J]. Journal of Plasticity Engineering, 2012, 19(6): 109⁃113. | |

| 8 | Reinhard L . Coupling of bending and stretching deformation in vehicle members[J]. Advances in Colloid and Interface Science, 2014, 208(1):14⁃24. |

| 9 | 李小强, 周贤宾, 金朝海, 等 . 基于有限元模拟的三维型材拉弯轨迹设计[J]. 航空学报, 2009, 30(3): 544⁃550. |

| Li Xiao⁃qiang , Zhou Xian⁃bin , Jin Chao⁃hai , et al . Design of stretch bending trajectory based on finite element simulation for three⁃dimensional profile parts[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(3): 544⁃550. | |

| 10 | 李小强, 周贤宾, 金朝海, 等 . 型材拉弯数值模拟夹钳边界条件的一种等效模型[J]. 塑性工程学报, 2009, 16(1): 64⁃69. |

| Li Xiao⁃qiang , Zhou Xian⁃bin , Jin Chao⁃hai , et al . An equivalent model of jaws boundary condition in numerical simulation of stretch bending for extrusions[J].Journal of Plasticity Engineering, 2009, 16(1): 64⁃69. | |

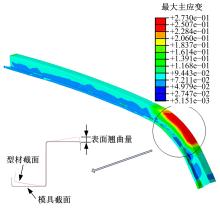

| 11 | 张学广, 刘纯国, 张石磊, 等 . 轴向非对称中空型材拉弯过渡区长度优化[J]. 哈尔滨工业大学学报, 2015, 47(10):85⁃87. |

| Zhang Xue⁃guang , Liu Chun⁃guo , Zhang Shi⁃lei , et al . Optimization of transition zone length in stretch bending of axially asymmetric hollow profiles[J]. Journal of Harbin Institute of Technology, 2015, 47(10): 85⁃87. | |

| 12 | 周苗苗, 王红建, 贺尔铭, 等 . 复杂截面型材3D拉弯数值模拟建模技术研究[J]. 机械科学与技术, 2012, 31(6): 888⁃892. |

| Zhou Miao⁃miao , Wang Hong⁃jian , He Er-ming , et al . Investion of numerical modeling techniques of 3D stretch bending for complex cross section[J]. Mechanical Science and Technology for Aerospace Engineering, 2012, 31(6): 888⁃892. | |

| 13 | 谷诤巍, 张文学, 吕萌萌, 等 . 宽翼边 U 型截面不锈钢型材拉弯成形缺陷控制[J]. 吉林大学学报: 工学版, 2017, 47(4): 1165⁃1170. |

| Gu Zheng⁃wei , Zhang Wen⁃xue , Meng⁃meng Lyu , et al . Stretch bending defect control of U-section stainless steel profile with wide flange[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(4): 1165⁃1170. | |

| 14 | Sushanta G , Kashi N S . An experimental study on stress concentration around a hole under combined bending and stretching stress field[J]. Procedia Technology, 2016, 23(1): 20⁃27. |

| 15 | 梁继业,邓钢,方斌 . L型截面铝型材拉弯成形截面畸变缺陷控制研究[J]. 锻压技术, 2016, 41(12): 42⁃45. |

| Liang Ji⁃ye , Deng Gang , Fang Bin . Section distortion control for L⁃section aluminium profile part in the strecth-bending process[J]. Foring and Stamping Tchnology, 2016, 41(12): 42⁃45. | |

| 16 | 刘天娇,王永军,夏晓娇,等 . 型材拉弯数值模拟轨迹建模方法[J]. 锻压技术, 2014, 39(7): 132⁃137. |

| Liu Tian⁃jiao , Wang Yong⁃jun , Xia Xiao⁃jiao , et al . Trajectory modeling of extrusion stretch bending simulation[J]. Forging and Stamping Technology, 2014, 39(7): 132⁃137. |

| [1] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [2] | Zhao⁃wei QU,Zhao⁃tian PAN,Yong⁃heng CHEN,Peng⁃fei TAO,Di SUN. Car⁃following model with improving safety distance based on optimal velocity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1092-1099. |

| [3] | Xin LI,Dan WANG,Jun⁃xu CHEN,Yan⁃peng SUN,Zheng⁃wei GU,Hong XU. Numerical simulation for handbrake fixed plate forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1258-1265. |

| [4] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [5] | GONG Ya-feng, WANG Bo, WEI Hai-bin, HE Zi-heng, HE Yu-long, SHEN Yang-fan. Surface subsidence law of double-line shield tunnel based on Peck formula [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1411-1417. |

| [6] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [7] | LIANG Xiao-bo, CAI Zhong-yi, GAO Peng-fei. Numerical simulation and experiment of cylindrical forming of sandwich composite panel [J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

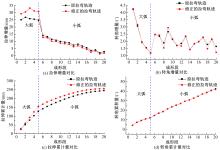

| [8] | LIU Chun-guo, LIU Wei-dong, DENG Yu-shan. Effect of multi-point punch active loading path on the stretch-forming of sheet [J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [9] | FU Wen-zhi, LIU Xiao-dong, WANG Hong-bo, YAN De-jun, LIU Xiao-li, LI Ming-zhe, DONG Yu-qi, ZENG Zhen-hua, LIU Gui-bin. Multi-point forming process of 1561 aluminum alloy surfaces [J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

| [10] | LYU Meng-meng, GU Zheng-wei, XU Hong, LI Xin. Process optimization of hot stamping for anti-collision beam with ultra high strength [J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [11] | WANG Hui, ZHOU Jie, XIONG Yu, TAO Ya-ping, XIANG Rong. Springback compensation for stamping part with complex surface based on reverse engineering [J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [12] | WANG Chun-sheng, ZOU Li, YANG Xin-hua. Analysis of fatigue life factors of aluminum alloy welded joints based on neighborhood rough set theory [J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [13] | WANG Hong-chao, SHAN Xi-zhuang, YANG Zhi-gang. Numerical simulation of the influence of ground effect simulation on vehicle cooling system experiment in climate wind tunnel [J]. 吉林大学学报(工学版), 2017, 47(5): 1373-1378. |

| [14] | WANG Guo-lin, SHEN Fei, ZHOU Hai-chao, YANG Jian. Evaluation of tyre pumping noise and design of low noise structure [J]. 吉林大学学报(工学版), 2017, 47(4): 1024-1031. |

| [15] | GU Zheng-wei, ZHANG Wen-xue, LYU Meng-meng, WANG Wei, XU Hong, LI Xin. Stretch bending defect control of U-section stainless steel profile with wide flange [J]. 吉林大学学报(工学版), 2017, 47(4): 1165-1170. |

|

||