Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1258-1265.doi: 10.13229/j.cnki.jdxbgxb20180303

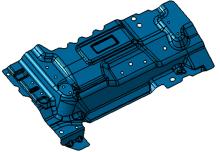

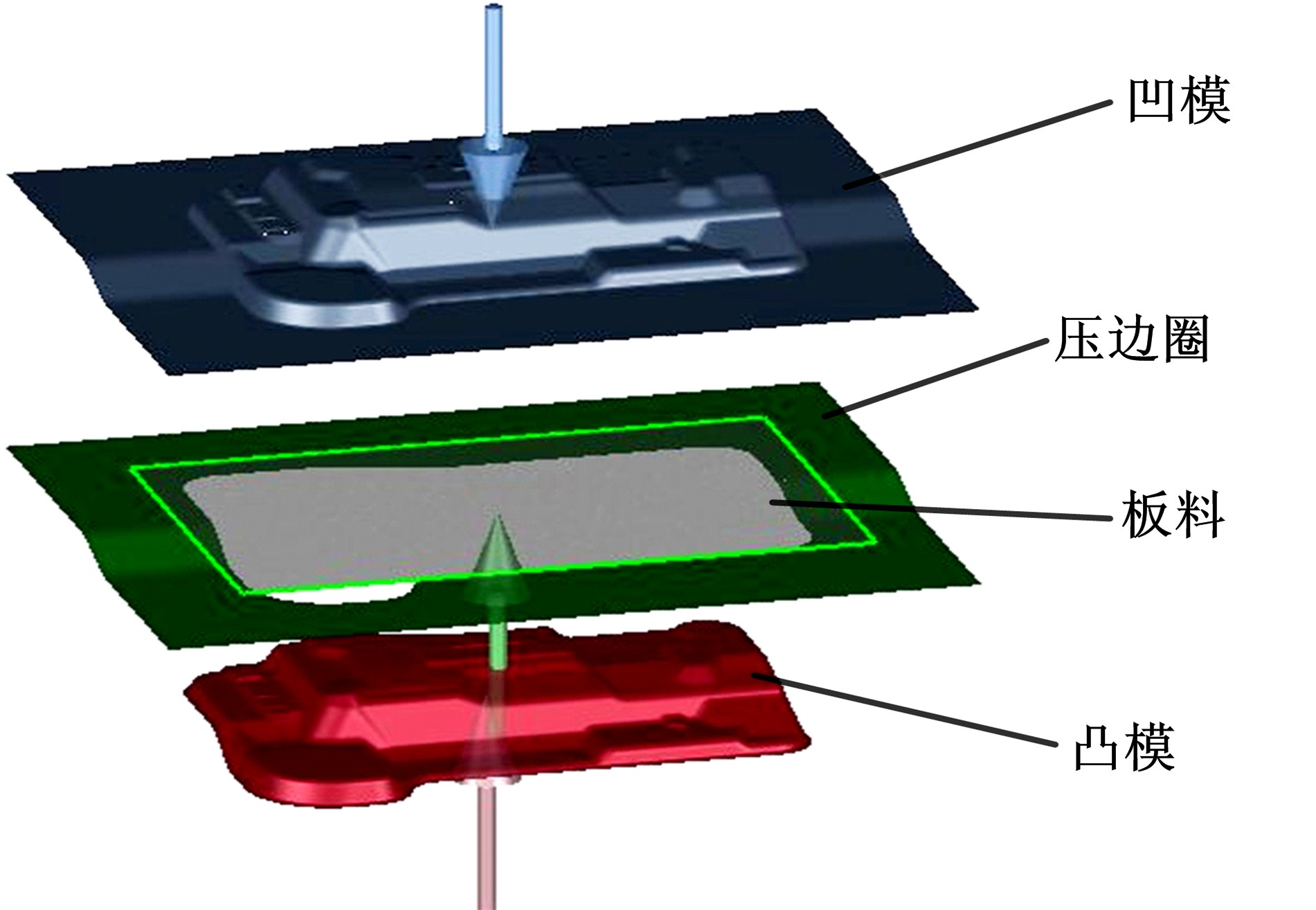

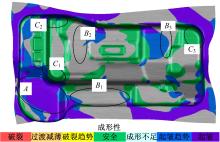

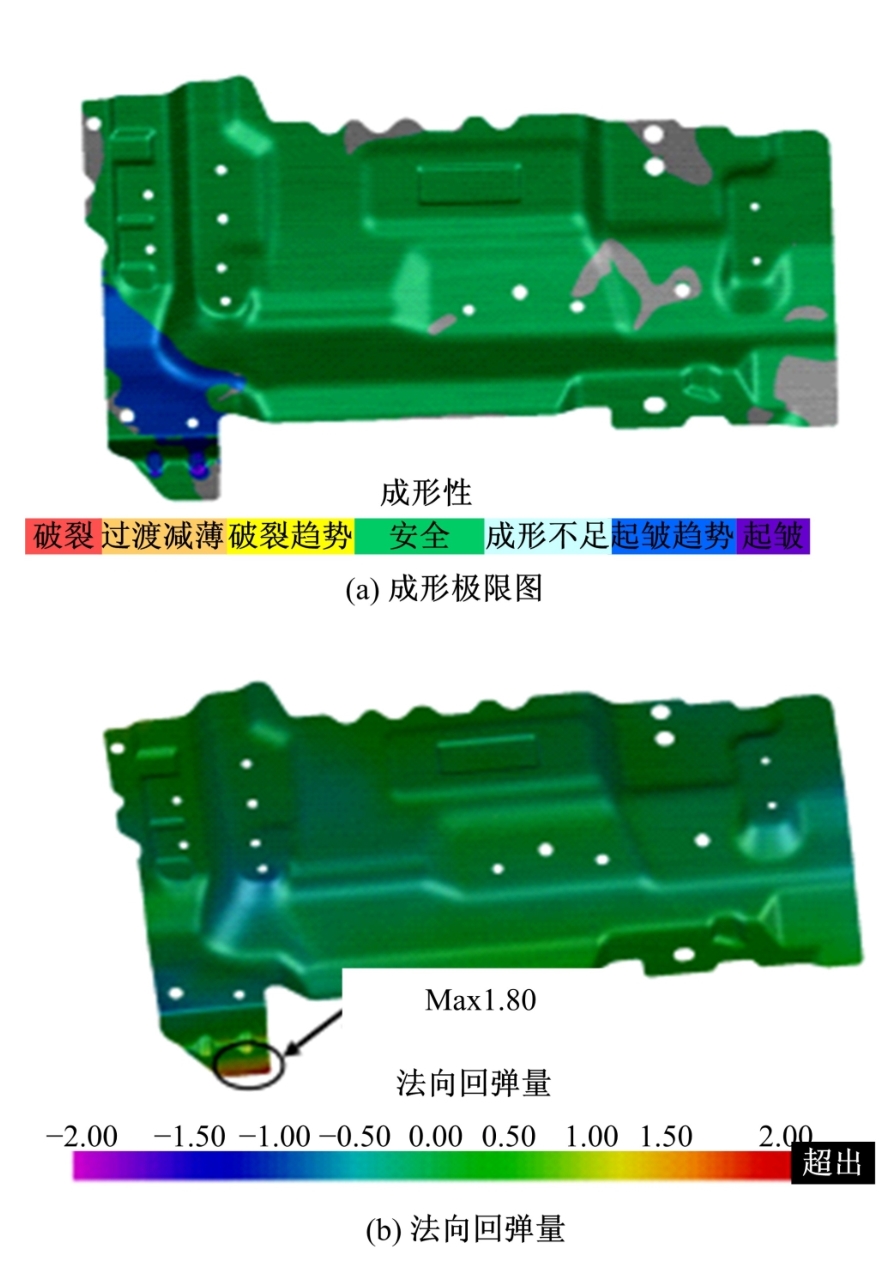

Numerical simulation for handbrake fixed plate forming

Xin LI1( ),Dan WANG1,Jun⁃xu CHEN2,Yan⁃peng SUN1,Zheng⁃wei GU1,Hong XU1

),Dan WANG1,Jun⁃xu CHEN2,Yan⁃peng SUN1,Zheng⁃wei GU1,Hong XU1

- 1. College of Materials Science and Engineering, Jilin University, Changchun 130022, China

2. FAW Jiefang Automobile Company Limited, Qingdao 266000, China

CLC Number:

- TG386

| 1 | 关来德 . 汽车侧围外板A柱拐角起皱的分析及解决方案[J]. 锻压技术,2017,42(4):50⁃54. |

| Guan Lai⁃de . Analysis and solution on corner wrinkling of side panel A column for automobile[J]. Forging and Stamping Technology,2017,42(4):50⁃54. | |

| 2 | 李春光,胡平,郭威 . 汽车覆盖件深拉延有限元仿真过程中的材料塑性与失效模型[J]. 吉林大学学报:工学版,2005,35(3):277⁃281. |

| Li Chun⁃guang , Hu Ping , Guo Wei . Material plasticity and invalidation model in fem simulation of automobile panels deep drawing[J]. Journal of Jilin University(Engineering and Technology Edition),2005,35(3):277⁃281. | |

| 3 | 张海波,黎甜,白贺 . 基于Cimatron E的离心泵蜗壳数控加工技术研究[J]. 东北电力大学学报,2013,33(3):1⁃4. |

| Zhang Hai⁃bo , Li Tian , Bai He . Numerical control processing technology research of centrifugal pump volute based on Cimatron E[J]. Journal of Northeast Dianli University,2013,33(3):1⁃4. | |

| 4 | Kawka M , Olejnik L , Rosochowski A , et al . Simulation of wrinkling in sheet metal forming[J]. Journal of Materials Processing Technology,2001,109(3):283⁃289. |

| 5 | 肖红波,蔡浩华 .汽车前翼子板冲压成形工艺优化[J]. 锻压技术,2016,41(2):35⁃38. |

| Xiao Hong⁃bo , Cai Hao⁃hua . Improvement of stamping process for car front fender[J]. Forging and Stamping Technology,2016,41(2):35⁃38. | |

| 6 | 段向敏 . 汽车覆盖件成形数值模拟及拉延筋优化研[D]. 重庆:西南大学工程技术学院,2014. |

| Duan Xiang⁃min . Numerical simulation and draw bead optimization of automobile panels forming[D]. Chongqing:School of Engineering and Technology,Southwest University,2014. | |

| 7 | Mehta H S , Kobayashi S . Finite element analysis and experimental investigation of Sheet metal stretching[J]. Journal of Manufacturing Science and Engineering,1973,95(3):874⁃880. |

| 8 | De Moor E , Lacroix S , Samek L ,et al . Dilatometric study of the quench and partitioning process[C]∥The 3rd International Conference on Advanced Structural Steels, Gyeongju,Korea, 2006:873⁃879. |

| 9 | 张早明 . CAE在汽车工业中的应用[J]. 汽车科技,2008(5):7⁃11. |

| Zhang Zao⁃ming . Application of CAE in car industry[J].Automobile Science and Technology,2008(5):7⁃11. | |

| 10 | Lam Y C , Brtiion G A , Deng Y M . A computer⁃aided system for optimal moulding design using a simulation⁃based approach[J]. International Journal of Advanced Manufacturing Technology,2003,22: 574⁃586. |

| [1] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [2] | Zhao⁃wei QU,Zhao⁃tian PAN,Yong⁃heng CHEN,Peng⁃fei TAO,Di SUN. Car⁃following model with improving safety distance based on optimal velocity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1092-1099. |

| [3] | Jia⁃xu WANG,Qian⁃qian JIANG,Jun⁃yang LI,Yan⁃feng HAN,Lei ZHANG,Ting TANG. Multi⁃objective optimization design of flexspline profile parameters of double⁃arc harmonic drive [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1194-1202. |

| [4] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [5] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [6] | GONG Ya-feng, WANG Bo, WEI Hai-bin, HE Zi-heng, HE Yu-long, SHEN Yang-fan. Surface subsidence law of double-line shield tunnel based on Peck formula [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1411-1417. |

| [7] | HU Zhi-qing, YAN Ting-xu, LI Hong-jie, LYU Zhen-hua, LIAO Wei, LIU Geng. Effect of cryogenic treatment on punch-shearing performance of aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1524-1530. |

| [8] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [9] | QIU Xiao-ming, WANG Yin-xue, YAO Han-wei, FANG Xue-qing, XING Fei. Multi-objective optimization of resistance spot welding parameters for DP1180/DP590 using grey relational analysis based Taguchi [J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [10] | CHEN Jun-fu, GUAN Zhi-ping, YANG Chang-hai, NIU Xiao-ling, JIANG Zhen-tao, Song Yu-quan. Comparison of strain ranges and mechanical properties of metal rods under tension and torsion tests [J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [11] | LIANG Xiao-bo, CAI Zhong-yi, GAO Peng-fei. Numerical simulation and experiment of cylindrical forming of sandwich composite panel [J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [12] | LIU Zi-wu, LI Jian-feng. Erosion damage and evaluation of remanufacturing cladding layer for impeller metals FV520B [J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [13] | LIU Chun-guo, LIU Wei-dong, DENG Yu-shan. Effect of multi-point punch active loading path on the stretch-forming of sheet [J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [14] | FU Wen-zhi, LIU Xiao-dong, WANG Hong-bo, YAN De-jun, LIU Xiao-li, LI Ming-zhe, DONG Yu-qi, ZENG Zhen-hua, LIU Gui-bin. Multi-point forming process of 1561 aluminum alloy surfaces [J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

| [15] | LYU Meng-meng, GU Zheng-wei, XU Hong, LI Xin. Process optimization of hot stamping for anti-collision beam with ultra high strength [J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

|

||