Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1793-1798.doi: 10.13229/j.cnki.jdxbgxb20170699

Previous Articles Next Articles

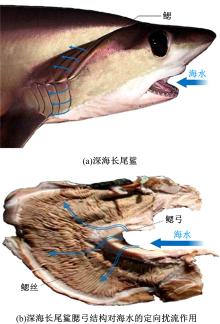

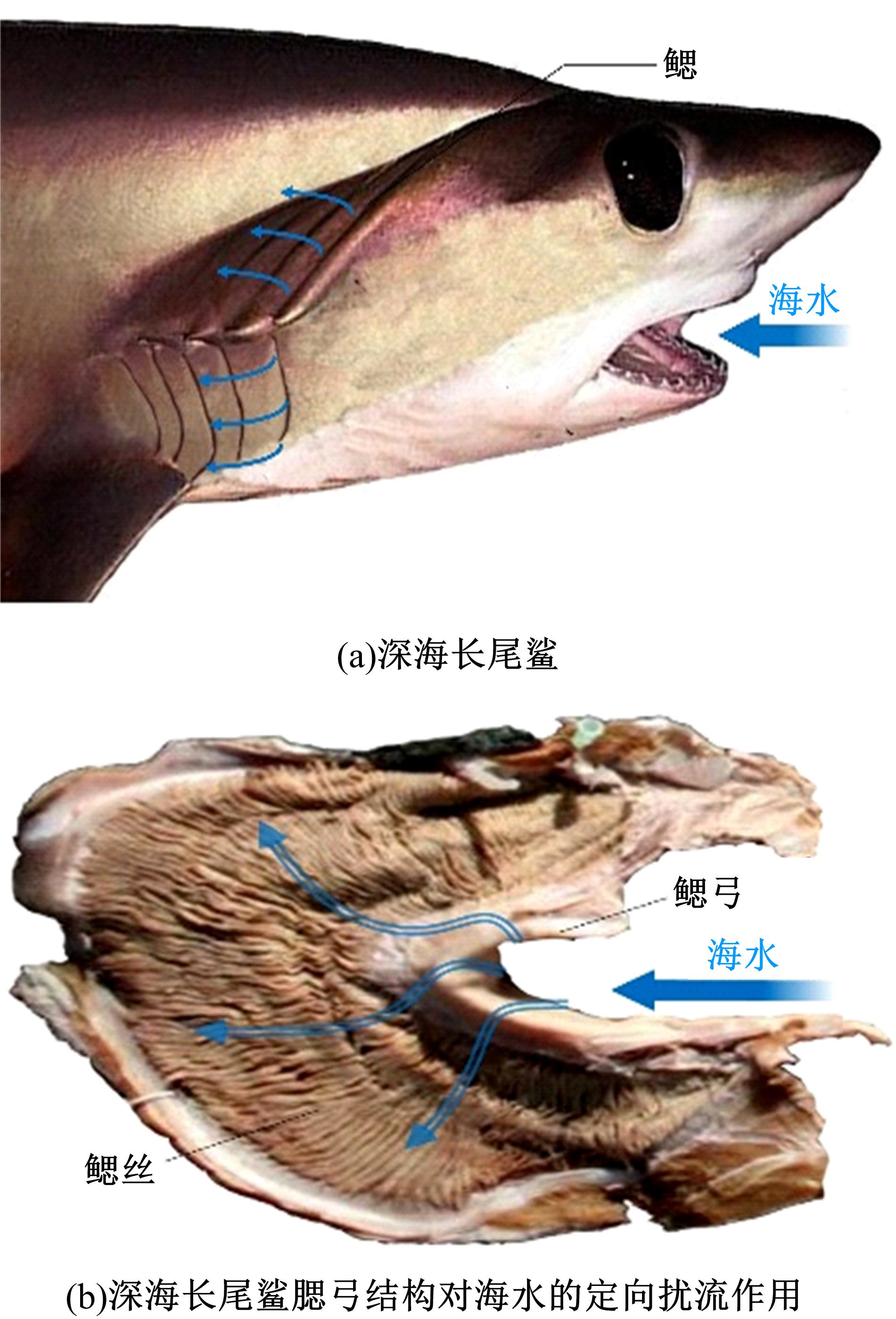

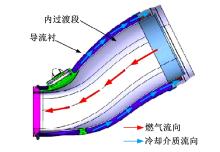

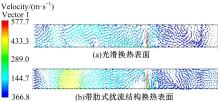

Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece

GUO Hao-tian1( ),XU Tao1,LIANG Xiao1,YU Zheng-lei2(

),XU Tao1,LIANG Xiao1,YU Zheng-lei2( ),LIU Huan1,MA Long1,3

),LIU Huan1,MA Long1,3

- 1. College of Mechanical Science and Engineering, Jilin University, Changchun 130022,China

2. Key of Bionic Engineering,Ministry of Education, Jilin University, Changchun 130022,China

3. College of Aviation Warfare Scervice,Aviation University of Air Force,Changchun 130022,China

CLC Number:

- TB17

| [1] |

蒋洪德, 任静, 李雪英 , 等. 重型燃气轮机现状与发展趋势[J]. 中国电机工程学报, 2014,34(29):5096-5102.

doi: 10.13334/j.0258-8013.pcsee.2014.29.011 |

|

Jiang Hong-de, Ren Jing, Li Xue-ying , et al. Status and development trend of the heavy duty gas turbine[J]. Proceedings of the CSEE, 2014,34(29):5096-5102.

doi: 10.13334/j.0258-8013.pcsee.2014.29.011 |

|

| [2] |

Xue Rui, Hu Chun-bo, Sethi Vishal , et al. Effect of steam addition on gas turbine combustor design and performance[J]. Applied Thermal Engineering, 2016,104:249-257.

doi: 10.1016/j.applthermaleng.2016.05.019 |

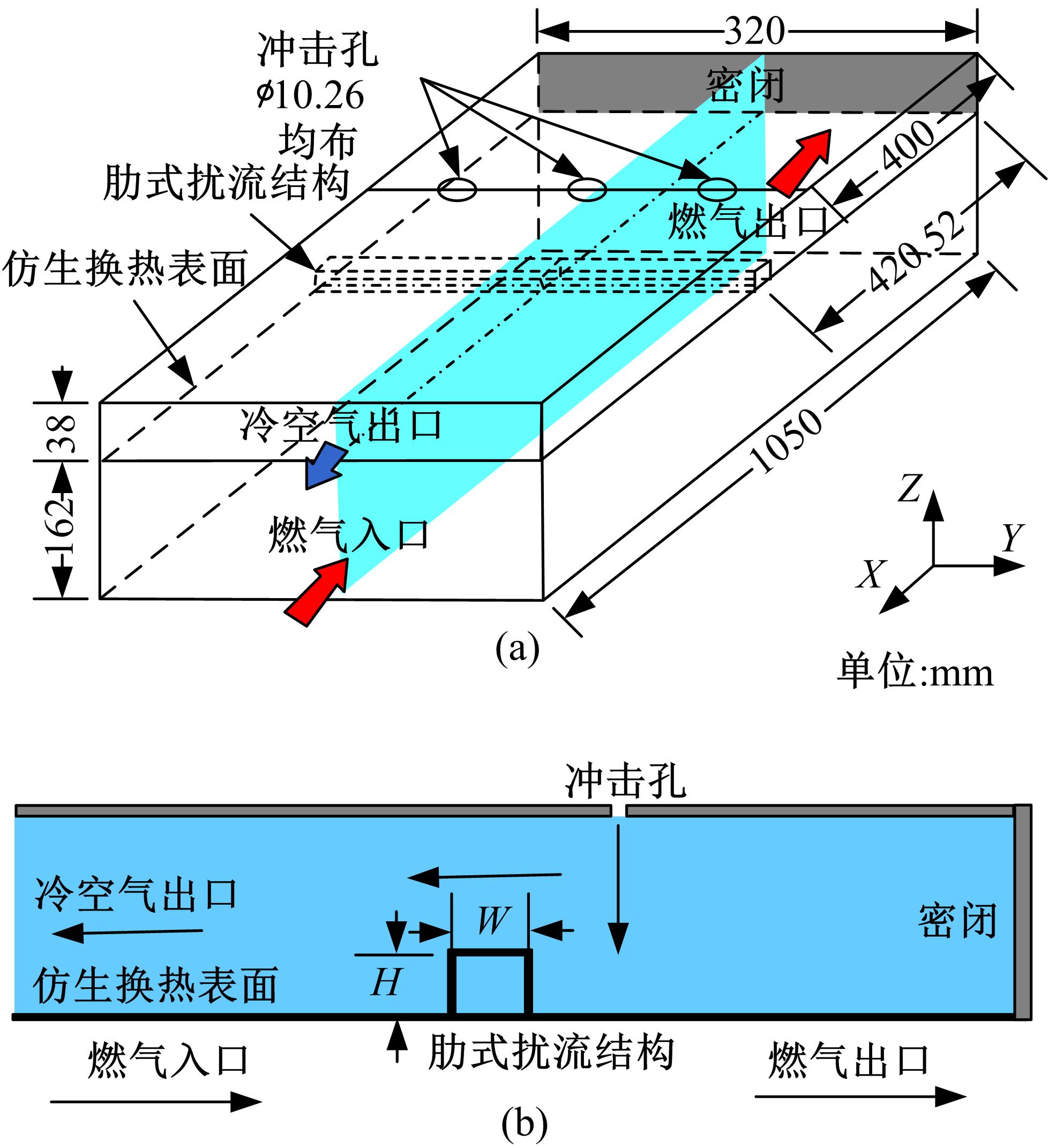

| [3] | 刘光洁, 徐涛, 李俊楼 , 等, 燃气轮机过渡段双腔室模型设计及优化[J]. 吉林大学学报:工学版, 2014,44(5):1360-1365. |

| Liu Guang-jie, Xu Tao, Li Jun-lou , et al. Design and optimization of double chamber model of gas turbine transition piece[J]. Journal of Jilin University(Engineering and Technology Edition), 2014,44(5):1360-1365. | |

| [4] | 徐涛, 于征磊, 张炜 , 等. 燃气轮机燃烧室过渡段冷却结构尺寸优化设计[J]. 吉林大学学报:工学版, 2012,42(4):863-866. |

| Xu Tao, Yu Zheng-lei, Zhang Wei , et al. Size optimization design of cooling structure in transition segment of gas turbine combustor[J]. Journal of Jilin University(Engineering and Technology Edition), 2012,42(4):863-866. | |

| [5] |

Yu Zheng-lei, Xu Tao, Li Jun-lou , et al. Comparison of a series of double chamber model with various hole angles for enhancing cooling effectiveness[J]. International Communications in Heat and Mass Transfer, 2013(44):38-44.

doi: 10.1016/j.icheatmasstransfer.2013.03.002 |

| [6] | Wang L, Wang T . Investigation of the effect of perforated sheath on thermal-flow characteristics over a gas turbine reverse-flow combustor, part 1—experiment[C]// Proceedings of the Asme Turbo Expo: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 2013:GT2013-94474. |

| [7] | Wang L, Wang T . Investigation of the effect of perforated sheath on thermal-flow characteristics over a gas turbine reverse-flow combustor, part 2—computational analysis[C]// Proceedings of the Asme Turbo Expo: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 2013:GT2013-94475. |

| [8] |

Cui J, Fu Y B . A numerical study on pressure drop in microchannel flow with different bionic micro-grooved surfaces[J]. Journal of Bionic Engineering, 2012,9(1):99-109.

doi: 10.1016/S1672-6529(11)60102-9 |

| [9] | 彭毅 . 基于植物叶片结构的仿生均热板研究[D]. 广州:华南理工大学机械与汽车工程学院, 2015. |

| Peng Yi . Study of bionic vapor chamber based on the plant leaf structure[D]. Guangzhou: College of Mechanical and Automotive Engineering, South China Univesity of Technology, 2015. | |

| [10] |

Wootton T P, Sepulveda C A, Wegner N C . Gill morphometrics of the thresher sharks (genus alopias): correlation of gill dimensions with aerobic demand and environmental oxygen[J]. Journal of Morphology, 2015,276(5):589-600.

doi: 10.1002/jmor.20369 pmid: 25703507 |

| [1] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [2] | XI Peng,CONG Qian,WANG Qing-bo,GUO Hua-xi. Wear test and anti-friction mechanism analysis of bionic stripe grinding roll [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1787-1792. |

| [3] | GONG Ya-feng, WANG Bo, WEI Hai-bin, HE Zi-heng, HE Yu-long, SHEN Yang-fan. Surface subsidence law of double-line shield tunnel based on Peck formula [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1411-1417. |

| [4] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [5] | LIANG Xiao-bo, CAI Zhong-yi, GAO Peng-fei. Numerical simulation and experiment of cylindrical forming of sandwich composite panel [J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [6] | QIAN Zhi-hui, ZHOU Liang, REN Lei, REN Lu-quan. Completely passive walking machine with bionic subtalar joint and matatarsal phalangeal joint [J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [7] | LIU Chun-guo, LIU Wei-dong, DENG Yu-shan. Effect of multi-point punch active loading path on the stretch-forming of sheet [J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [8] | FU Wen-zhi, LIU Xiao-dong, WANG Hong-bo, YAN De-jun, LIU Xiao-li, LI Ming-zhe, DONG Yu-qi, ZENG Zhen-hua, LIU Gui-bin. Multi-point forming process of 1561 aluminum alloy surfaces [J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

| [9] | LYU Meng-meng, GU Zheng-wei, XU Hong, LI Xin. Process optimization of hot stamping for anti-collision beam with ultra high strength [J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [10] | WANG Hong-chao, SHAN Xi-zhuang, YANG Zhi-gang. Numerical simulation of the influence of ground effect simulation on vehicle cooling system experiment in climate wind tunnel [J]. 吉林大学学报(工学版), 2017, 47(5): 1373-1378. |

| [11] | WANG Guo-lin, SHEN Fei, ZHOU Hai-chao, YANG Jian. Evaluation of tyre pumping noise and design of low noise structure [J]. 吉林大学学报(工学版), 2017, 47(4): 1024-1031. |

| [12] | PENG Wei, LI Guo-xiang, YAN Wei. Improvement in wall functions for engine radiators [J]. 吉林大学学报(工学版), 2017, 47(3): 804-810. |

| [13] | KOU Shu-qing, SONG Wei-feng, SHI Zhou. Fracture splitting simulation and defect analysis of 36MnVS4 connecting rod [J]. 吉林大学学报(工学版), 2017, 47(3): 861-868. |

| [14] | GU Zheng-wei, LYU Meng-meng, ZHANG Wen-xue, LEI Jiao-jiao, XU Hong. Stamping of front-end three-dimensional skin of China electric multiple units [J]. 吉林大学学报(工学版), 2017, 47(3): 869-875. |

| [15] | ZHANG Peng, KOU Shu-qing, ZHAO Yong, LIN Bao-jun. Ananlsis of three rollers axial knurling process of assembled camshaft [J]. 吉林大学学报(工学版), 2016, 46(6): 1953-1960. |

|