Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (1): 44-52.doi: 10.13229/j.cnki.jdxbgxb20181239

Previous Articles Next Articles

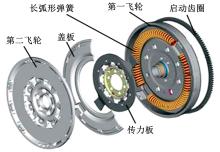

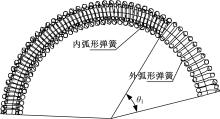

Modeling and tests for torsional characteristics of multi-stage stiffness dual mass flywheel torsional dampers

Wen-ku SHI1( ),Long CHEN1,Gui-hui ZHANG2,Zhi-yong CHEN1(

),Long CHEN1,Gui-hui ZHANG2,Zhi-yong CHEN1( )

)

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. Dahua Machine Manufacturing Co. Ltd. , Changchun 130103, China

CLC Number:

- U461.1

| 1 | Mahl T , Sawodny O . Modelling of an automotive dual mass flywheel[C]∥IFAC Proceedings Volumes, 2010, 43(18): 517-523. |

| 2 | Theodossiades S , Gnanakumarr M , Rahnejat H , et al . Effect of a dual-mass flywheel on the impact-induced noise in vehicular powertrain systems[J]. Institution of Mechanical Engineers Part D Journal of Automobile Engineering, 2006, 220(6): 747-761. |

| 3 | Gupta K , Choudhary A , Bidre R . NVH performance improvement study using a dual mass flywheel(DMF) , inertia ring type tuned torsional vibration damper(TVD) and single mass flywheel(SMF) in a front engine and rear wheel driveline architecture[C]∥SAE Paper, 2017-01-1752. |

| 4 | 宋立权, 周建东, 吴荣华, 等 . 摩擦式双级分段变刚度汽车双质量飞轮设计理论研究及应用[J]. 机械工程学报, 2012, 48(15): 150-157. |

| Song Li-quan , Zhou Jian-dong , Wu Rong-hua , et al . Research and application on design theory of friction dual mass flywheel with double-stage piecewise variable stiffness[J]. Journal of Mechanical Engineering, 2012, 48(15): 150-157. | |

| 5 | 李伟, 史文库, 龙岩, 等 . DMF-CS型扭振减振器刚度匹配设计[J]. 吉林大学学报:工学版, 2009, 39(增刊1):62-67. |

| Li Wei , Shi Wen-ku , Long Yan , et al . Match and design of torsional stiffness of the DMF-CS torsional damper[J] Journal of Jilin University(Engineering and Technology Edition), 2009, 39(Sup.1): 62-67. | |

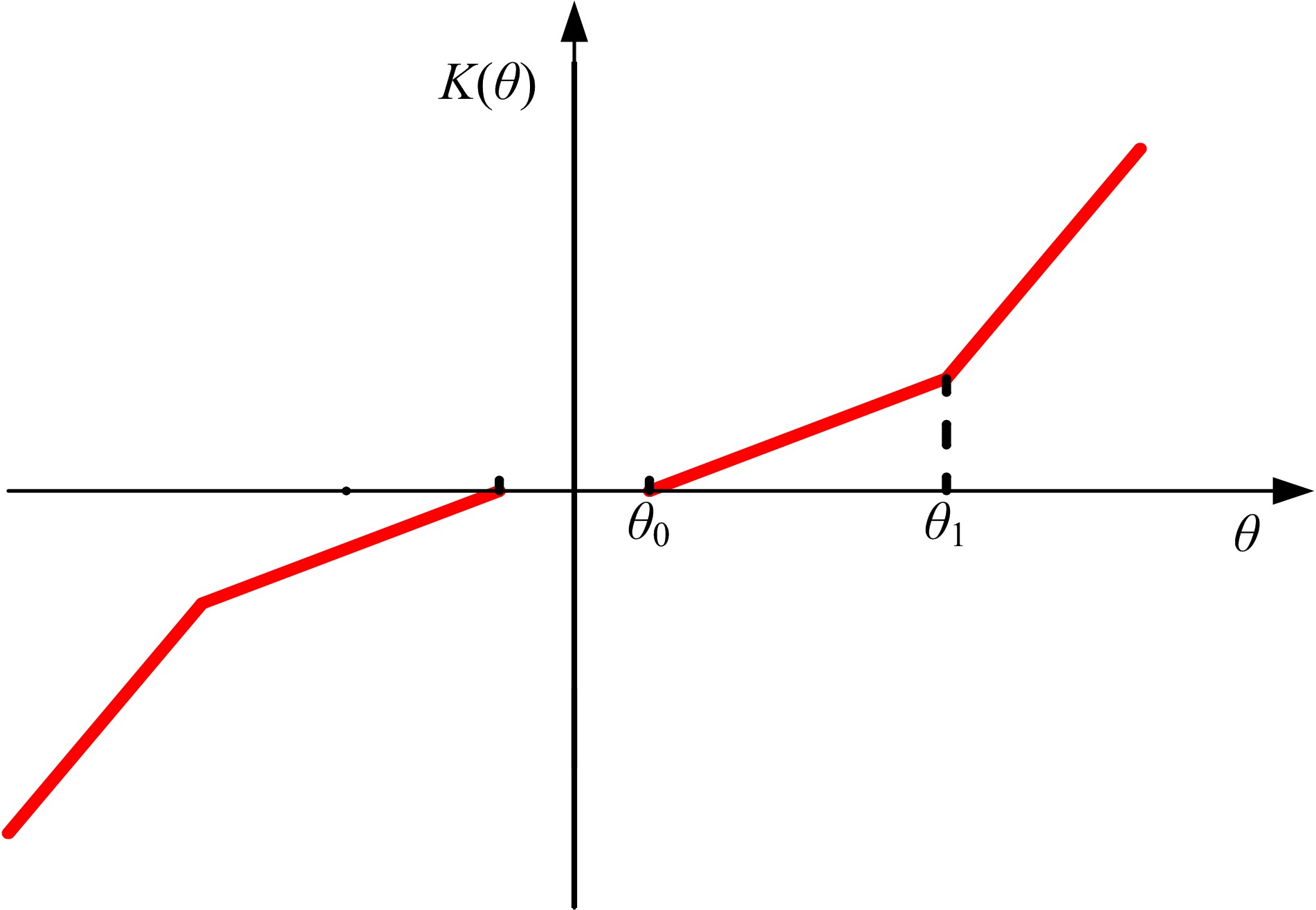

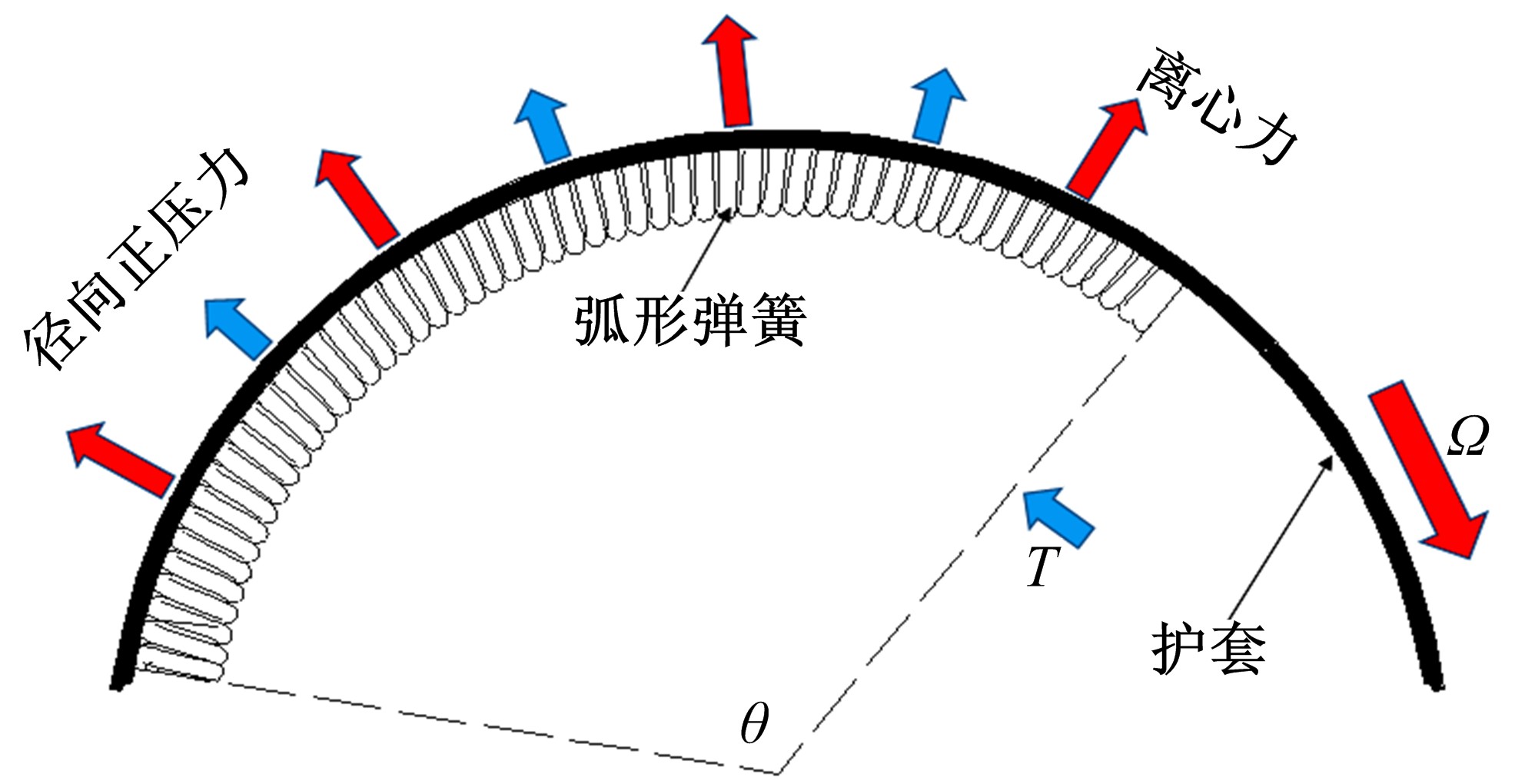

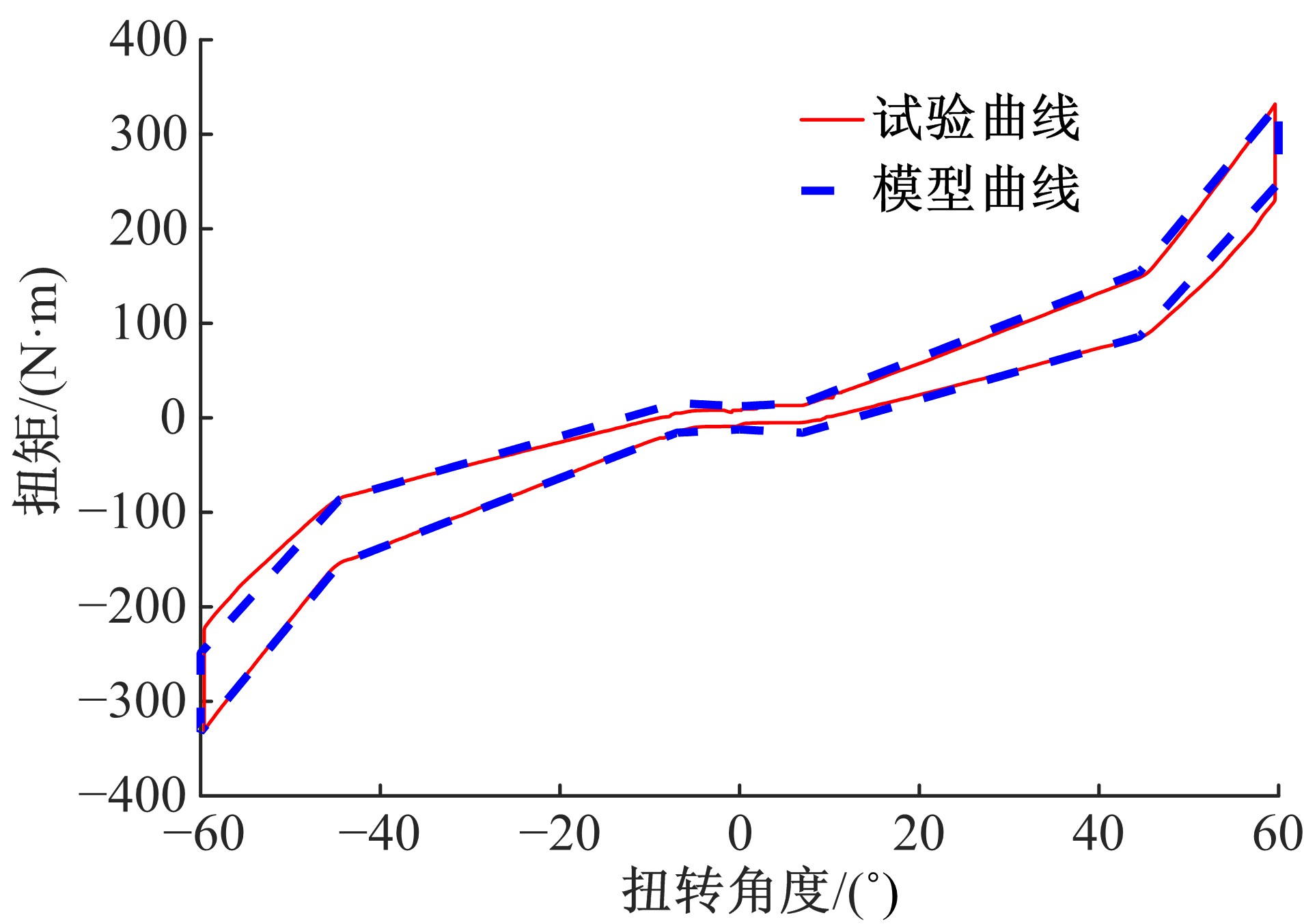

| 6 | 曾荣, 左厅, 江征风, 等 . 周向长弧形弹簧式双质量飞轮迟滞非线性扭转特性模型研究[J]. 中国机械工程, 2015, 26(16): 2148-2153. |

| Zeng Rong , Zuo Ting , Jiang Zheng-feng , et al . Hysteresus torsion characteristic model of circumferential arc spring dual mass flywheel[J] . China Mechanical Engineering, 2015, 26(16): 2148-2153. | |

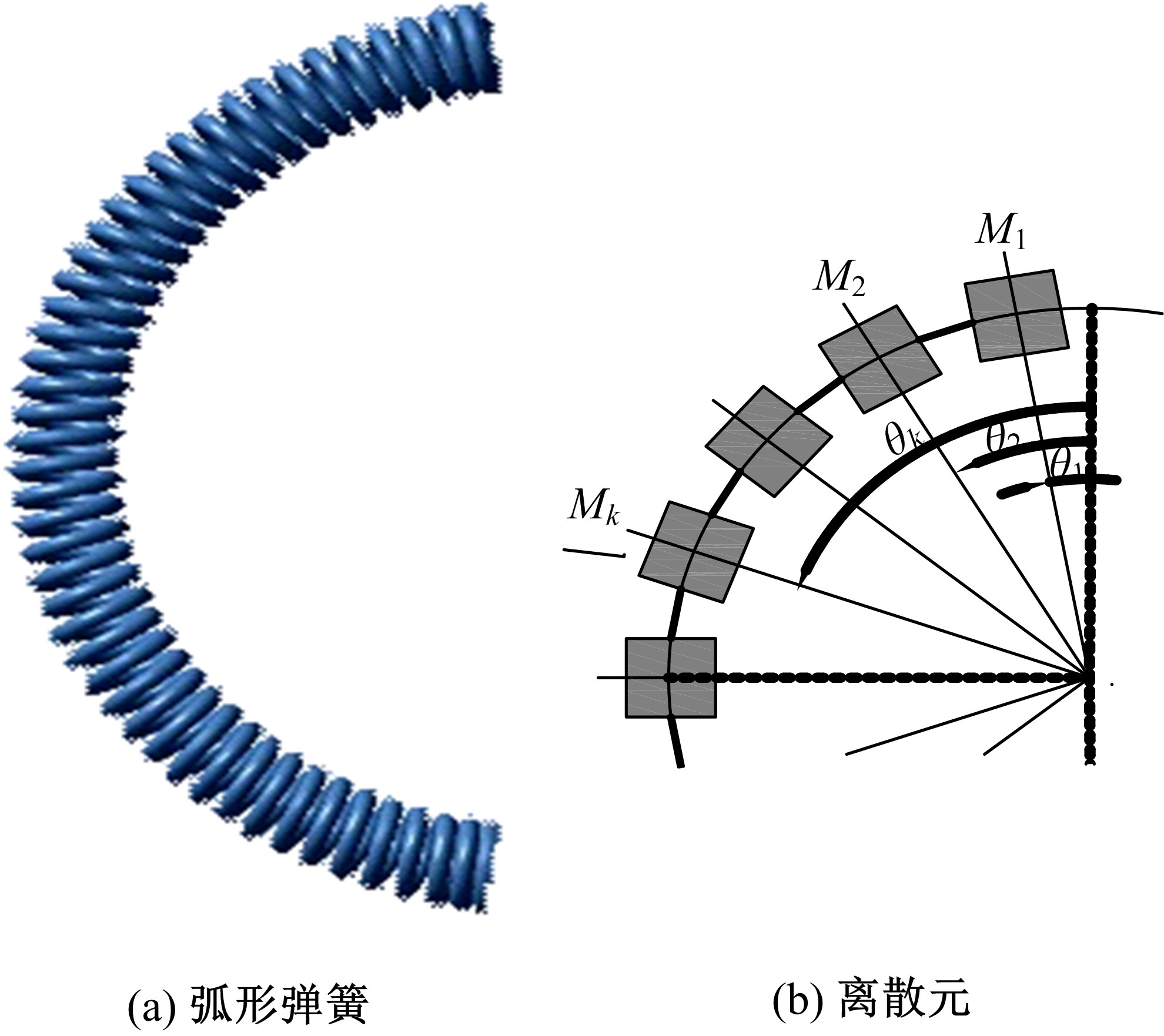

| 7 | Kim T H , Song H L , Hwang S H , et al . Analysis of dual mass flywheel using discrete arcspring model[J]. Key Engineering Materials, 2006, 326-328: 1607-1610. |

| 8 | 宋立权, 周建东, 吴荣华, 等 . 摩擦式双级分段变刚度汽车双质量飞轮设计理论研究及应用[J]. 机械工程学报, 2012, 48(15): 150-157. |

| Song Li-quan , Zhou Jian-dong , Wu Rong-hua , et al . Research and application on design theory of friction dual mass flywheel with double-stage piecewise variable stiffness[J]. Journal of Mechanical Engineering, 2012, 48(15): 150-157. | |

| 9 | 曾礼平, 陈齐平, 袁星星, 等 . 汽车三级分段变刚度双质量飞轮非线性振动研究[J]. 中国机械工程, 2018, 29(20): 2453-2459. |

| Zeng Li-ping , Chen Qi-ping , Yuan Xing-xing , et al . Study on nonlinear vibration of vehicle dual mass flywheel with three-stage piecewise stiffnesses[J]. China Mechanical Engineering, 2018, 29(20): 2453-2459. | |

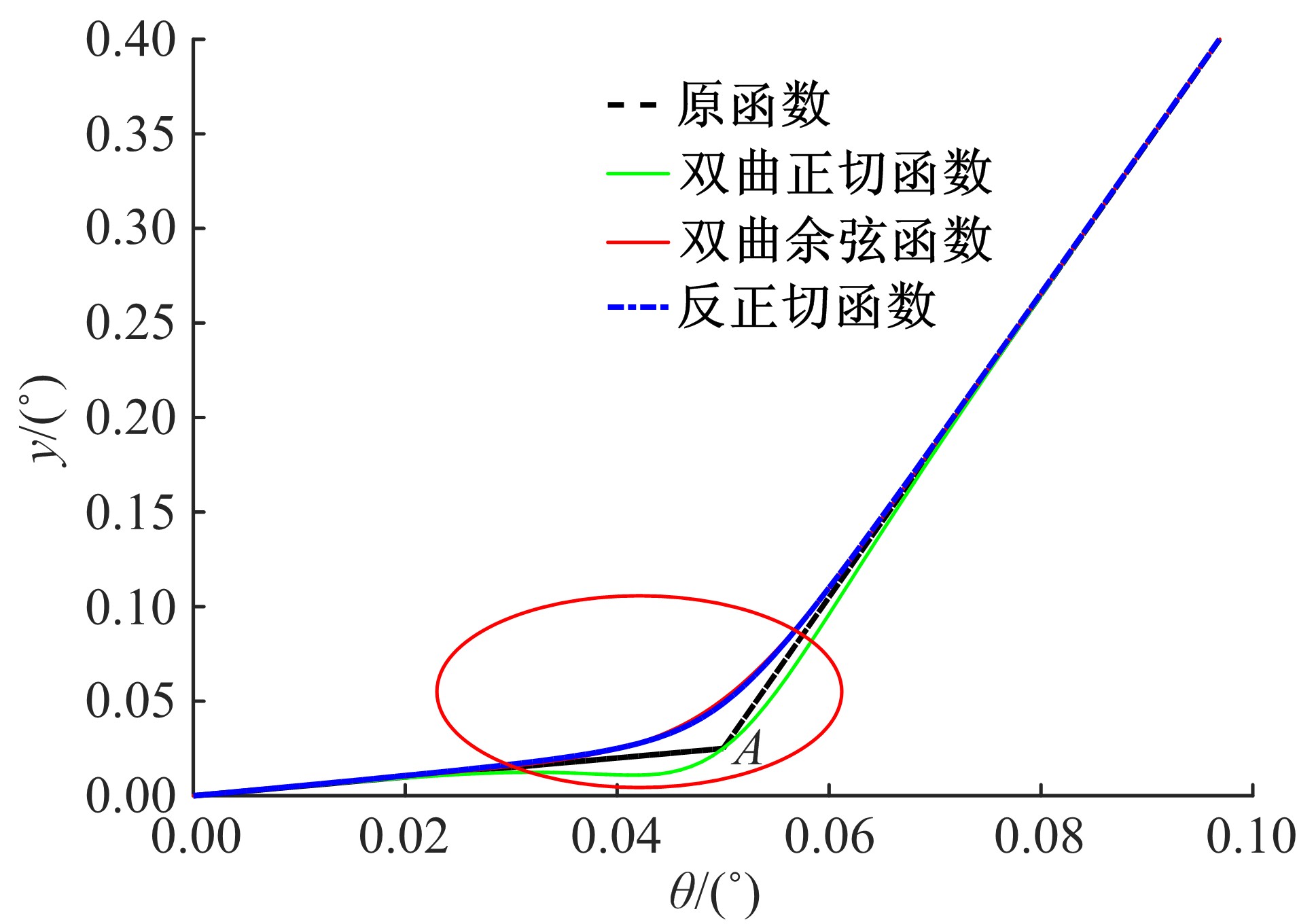

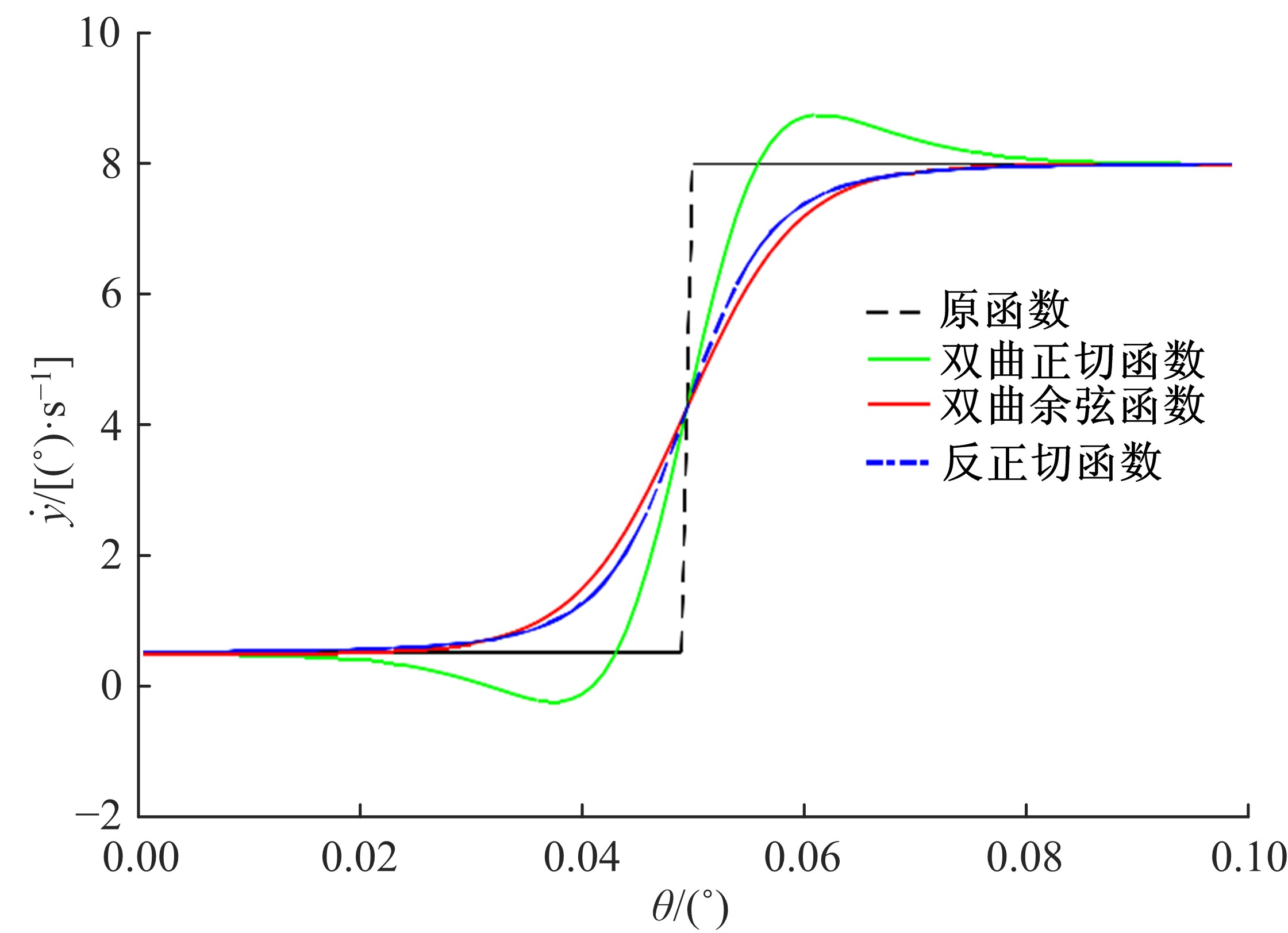

| 10 | Kim T C , Rook T E , Singh R . Effect of smoothening functions on the frequency response of an oscillator with clearance non-linearity[J]. Journal of Sound & Vibration, 2003, 263(3): 665-678. |

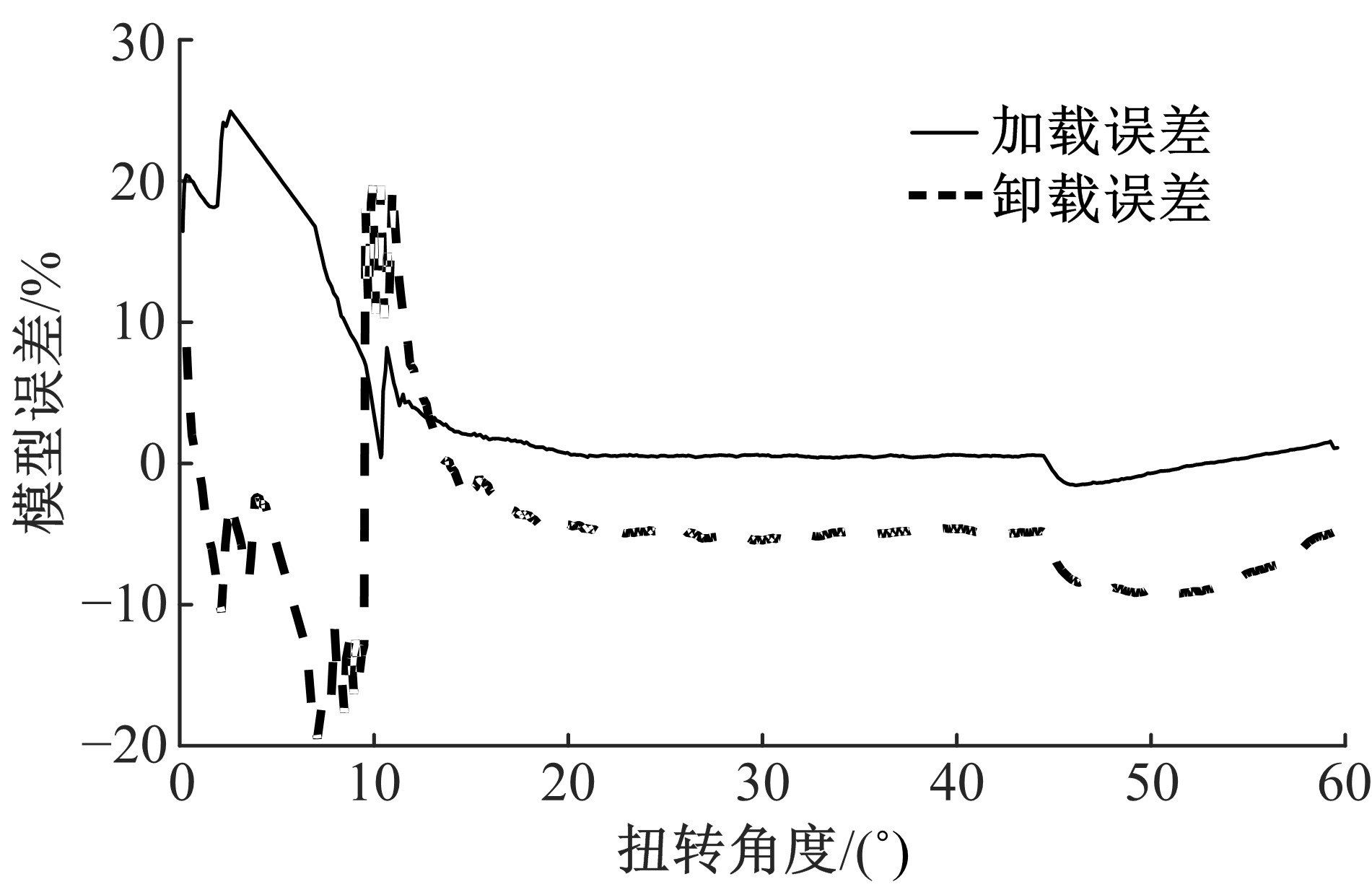

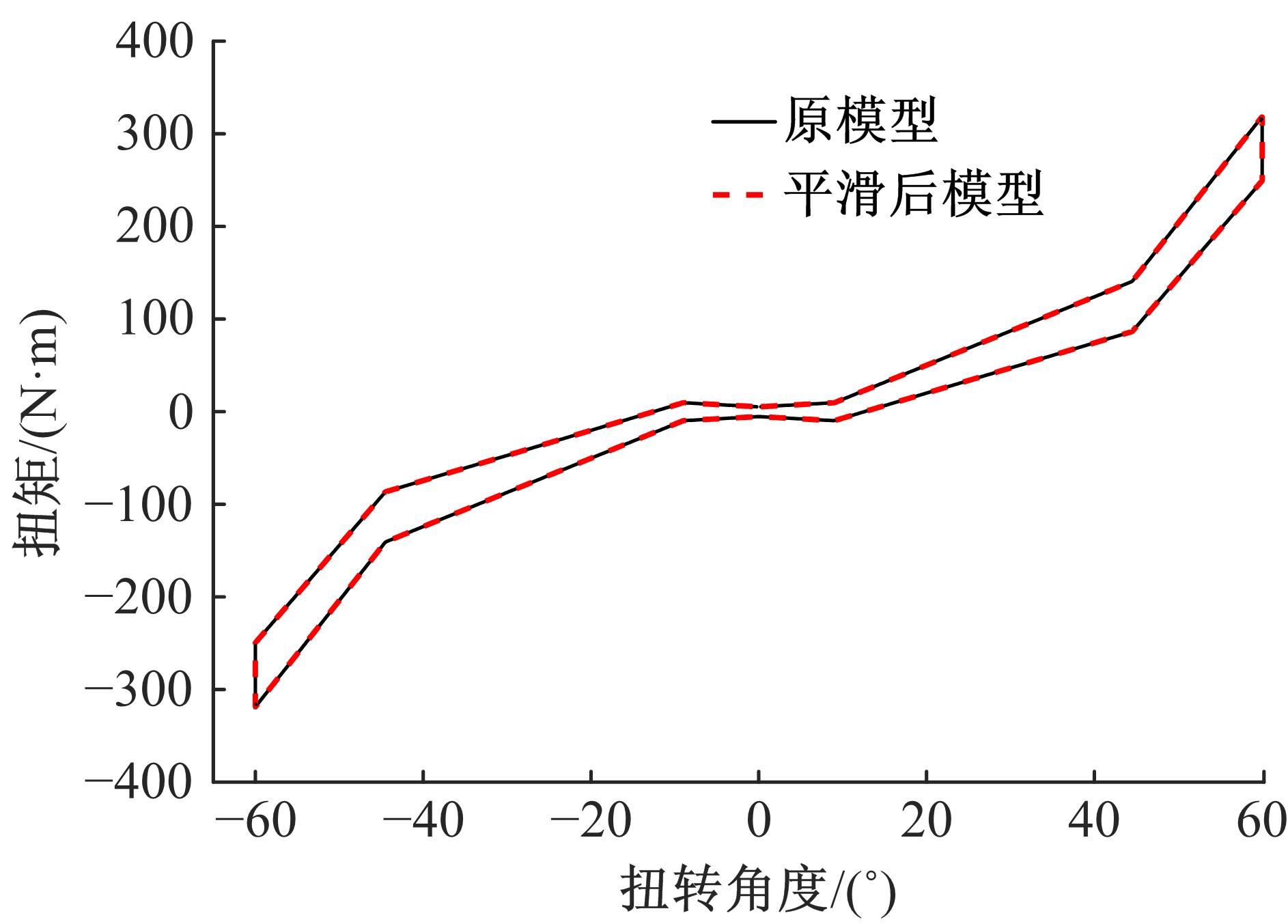

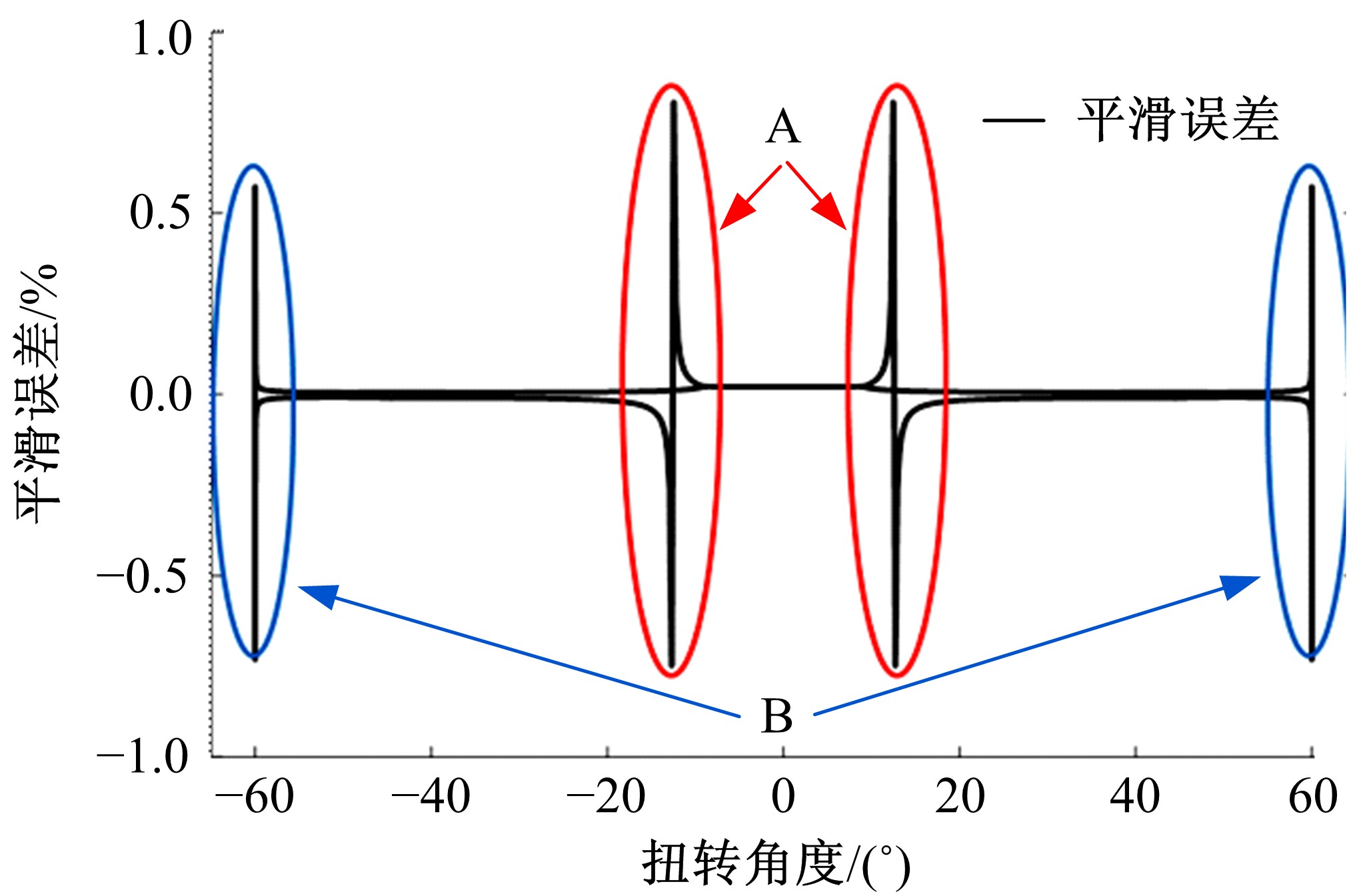

| 11 | 吴虎威, 吴光强, 陈祥, 等 . 考虑迟滞特性的多级刚度扭转减振器建模及试验验证[J]. 振动与冲击, 2017, 36(2): 170-176. |

| Wu Hu-wei , Wu Guang-qiang , Chen Xiang , et al . Numerical and experimental analysis on multi-staged stiffness clutch dampers considering hysteresis characteristics[J]. Journal of Vibration and Shock, 2017, 36(2): 170-176. | |

| 12 | 刘圣田 . 双质量飞轮式扭振减振器对振动的控制分析[J]. 农业机械学报, 2004, 35(3): 16-19. |

| Liu Sheng-tian . Influences of a dual-mass flywheel damper on idling vibration[J] Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(3): 16-19. | |

| 13 | 史文库, 龙岩, 卢玉东 . 多级非线性双质量飞轮参数设计和优化[J]. 振动与冲击, 2009, 28(5): 92-96. |

| Shi Wen-ku , Long Yan , Lu Yu-dong . Study on multistage non-linear dual mass flywheel damper[J]. Journal of Vibration and Shock, 2009, 28(5): 92-96. | |

| 14 | 赵光明, 江征风, 陈雷, 等 . 周向长弧形弹簧双质量飞轮阻尼特性研究及其试验验证[J]. 内燃机工程, 2012, 33(1): 81-86. |

| Zhao Guang-ming , Jiang Zheng-feng , Chen Lei , et al . Research and experiment verification on damping characteristics of circumferential arc spring dual mass flywheel[J]. Chinese Internal Combustion Engine Engineering, 2012, 33(1): 81-86. | |

| 15 | 丁千, 翟红梅 . 机械系统摩擦动力学研究进展[J]. 力学进展, 2013, 43(1): 112-131. |

| Ding Qian , Zhai Hong-mei . The advance in researches of friction dynamics in mechanics system[J]. Advances in Mechanics, 2013, 43(1): 112-131. |

| [1] | Fang-wu MA,Hong-yu LIANG,Ying ZHAO,Meng YANG,Yong-feng PU. Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 29-35. |

| [2] | Kong-hui GUO,Shi-qing HUANG,Hai-dong WU. In⁃plane dynamic tire model for high⁃frequency excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 19-28. |

| [3] | Zhe WANG,Yi XIE,Peng-fei ZANG,Yao WANG. Energy management strategy of fuel cell bus based on Pontryagin′s minimum principle [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 36-43. |

| [4] | Xin CHEN,Xin-jian RUAN,Ming LI,Ning WANG,Jia-ning WANG,Kai-xuan PAN. Application of modified discrete scheme based onlarge eddy simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1756-1763. |

| [5] | Fang-wu MA,Li-wei NI,Liang WU,Jia-hong NIE,Guang-jian XU. Position and attitude closed loop control of wheel⁃leggedall terrain mobile robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1745-1755. |

| [6] | Li-qiang JIN, Duan-yang TIAN, Hao TIAN, Meng-meng LIU. Brake force assistant technology for vehicle electronicstability control system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1764-1776. |

| [7] | Yang WANG,Zhan⁃shuai SONG,Kong⁃hui GUO,Ye ZHUANG. Measurement of inertial parameters of rotating inertia rig [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1795-1801. |

| [8] | Wei-min ZHUANG,Yang LIU,Peng-yue WANG,Hong-da SHI,Ji-shuan XU. Simulation on peeling failure of self⁃piercing riveted joints insteel and aluminum alloy dissimilar sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1826-1835. |

| [9] | Jie LI, Wen-cui GUO, Qi ZHAO, Sheng-feng GU. Road roughness identification based on vehicle responses [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1810-1817. |

| [10] | Bai-chao CHEN,Meng ZOU,Zhao-long DANG,Han HUANG,Yang JIA,Rui-yang SHI,Jian-qiao LI. Experiment on pressure⁃sinkage for mesh wheels of CE⁃3lunar rover on lunar regolith [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1836-1843. |

| [11] | Ren HE,Kun TU. Electromagnetic brake with changed⁃temperature air gap width [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1777-1785. |

| [12] | Qiao-bin LIU,Wen-ku SHI,Zhi-yong CHEN,Lian-meng LUO,Zhi-yong SU,Kai-jun HUANG. Parameter estimation of mixed reliability model based on kernel density optimal grouping and gravity search algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1818-1825. |

| [13] | Xin GUAN,Hao JIN,Chun-guang DUAN,Ping-ping LU. Estimation of lateral slope of vehicle driving road [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1802-1809. |

| [14] | Ting YAN,Lin YANG,Liang CHEN. AMT shift actuator adaptive intelligent control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1441-1450. |

| [15] | Fang-wu MA,Lu HAN,Yang ZHOU,Shi-ying WANG,Yong-feng PU. Multi material optimal design of vehicle product using polylactic acid composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1385-1391. |

|

||