Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (2): 389-398.doi: 10.13229/j.cnki.jdxbgxb20190172

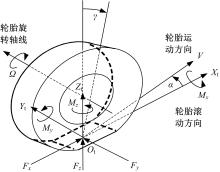

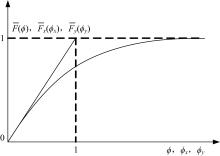

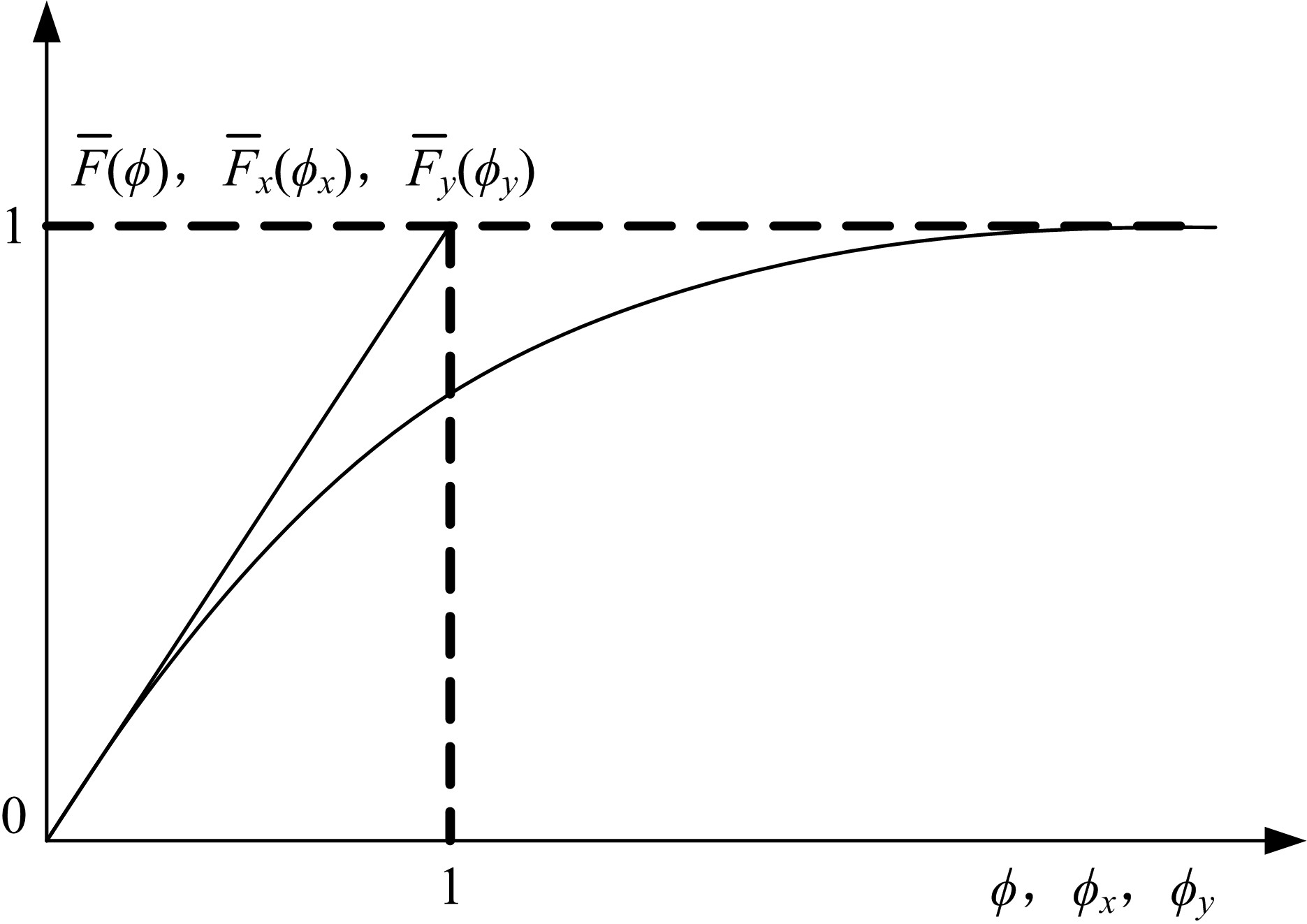

Influence of anisotropic stiffness on tire mechanical properties and vehicle handling characteristics under combined slip situations

Xiao-yu LI1( ),Nan XU1(

),Nan XU1( ),Tao QIU2,Kong-hui GUO1

),Tao QIU2,Kong-hui GUO1

- 1.State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2.KH Automotive Technologies Co. Ltd. , Changchun 130012, China

CLC Number:

- U461.1

| 1 | 郭孔辉. 汽车操纵动力学原理[M]. 南京: 江苏科学技术出版社, 2011: 58- 60. |

| 2 | Rafei M, Ghoreishy M H R, Naderi G. Thermo-mechanical coupled finite element simulation of tire cornering characteristics—effect of complex material models and friction law[J]. Mathematics and Computers in Simulation, 2018, 144: 35- 51. |

| 3 | Calabrese F, Baecker M, Galbally C, et al. A detailed thermo-mechanical tire model for advanced handling applications[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2015, 8( 2): 501- 511. |

| 4 | Bibin S, Pandey A K. A hybrid approach to model the temperature effect in tire forces and moments[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2017, 10( 1): 25- 37. |

| 5 | 马彬, 许洪国, 刘宏飞. 路面分形和橡胶特性对轮胎滑动摩擦因数的影响[J]. 吉林大学学报: 工学版, 2013, 43( 2): 317- 322. |

| Ma Bin, Xu Hong-guo, Liu Hong-fei. Effects of road surface fractal and rubber characteristics on tire sliding friction factor[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43( 2): 317- 322. | |

| 6 | 卢荡, 郭孔辉. 轮胎侧偏力学特性的胎压影响分析及预测[J]. 吉林大学学报: 工学版, 2011, 41( 4): 915- 920. |

| Lu Dang, Guo Kong-hui. Analysis and prediction of tire cornering property for different inflation pressure[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41( 4): 915- 920. | |

| 7 | Höpping K, Augsburg K, Büchner F. Extending the HSRI tyre model for large inflation pressure changes[C]∥ 59th Ilmenau Scientific Colloquium, Technische Universität Ilmenau,Ilmenau, 2017: 11- 15. |

| 8 | Kasprzak E M, Lewis K, Milliken D. Tire asymmetries and pressure variations in the Radt/Milliken nondimensional tire model[C]∥SAE Technical Paper, 2006-01-1968. |

| 9 | Mizuno M, Sakai H, Oyma K, et al. Development of a tyre force model incorporating the influence of the tyre surface temperature[J]. Vehicle System Dynamics, 2005, 43( Sup.1): 395- 402. |

| 10 | Gil G, Park J. Physical handling tire model incorporating temperature and inflation pressure change effect[C]∥SAE Technical Paper, 2018-01-1338. |

| 11 | 许男. 复合工况下轮胎稳态模型研究[D]. 长春: 吉林大学汽车工程学院, 2012. |

| Xu Nan. Study on the steady state tire model under combined conditions[D]. Changchun: College of Automotive Engineering, Jilin University, 2012. | |

| 12 | Reiter M, Wagner J. Automated automotive tire inflation system-effect of tire pressure on vehicle handling[J]. IFAC Proceedings, 2010, 43( 7): 638- 643. |

| 13 | Alexander V. Influence of tyre inflation pressure on fuel consumption, vehicle handling and ride quality-modelling and simulation[D]. Sweden: Chalmers University of Technology, 2013. |

| 14 | Abe M. Vehicle Handling Dynamics[M]. Amsterdam, Netherlands: Elsevier, 2009: 171- 182. |

| [1] | Fang-wu MA,Hong-yu LIANG,Ying ZHAO,Meng YANG,Yong-feng PU. Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 29-35. |

| [2] | Kong-hui GUO,Shi-qing HUANG,Hai-dong WU. In⁃plane dynamic tire model for high⁃frequency excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 19-28. |

| [3] | Zhe WANG,Yi XIE,Peng-fei ZANG,Yao WANG. Energy management strategy of fuel cell bus based on Pontryagin′s minimum principle [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 36-43. |

| [4] | Wen-ku SHI,Long CHEN,Gui-hui ZHANG,Zhi-yong CHEN. Modeling and tests for torsional characteristics of multi-stage stiffness dual mass flywheel torsional dampers [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 44-52. |

| [5] | Xin GUAN,Hao JIN,Chun-guang DUAN,Ping-ping LU. Estimation of lateral slope of vehicle driving road [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1802-1809. |

| [6] | Xin CHEN,Xin-jian RUAN,Ming LI,Ning WANG,Jia-ning WANG,Kai-xuan PAN. Application of modified discrete scheme based onlarge eddy simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1756-1763. |

| [7] | Fang-wu MA,Li-wei NI,Liang WU,Jia-hong NIE,Guang-jian XU. Position and attitude closed loop control of wheel⁃leggedall terrain mobile robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1745-1755. |

| [8] | Li-qiang JIN, Duan-yang TIAN, Hao TIAN, Meng-meng LIU. Brake force assistant technology for vehicle electronicstability control system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1764-1776. |

| [9] | Yang WANG,Zhan⁃shuai SONG,Kong⁃hui GUO,Ye ZHUANG. Measurement of inertial parameters of rotating inertia rig [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1795-1801. |

| [10] | Wei-min ZHUANG,Yang LIU,Peng-yue WANG,Hong-da SHI,Ji-shuan XU. Simulation on peeling failure of self⁃piercing riveted joints insteel and aluminum alloy dissimilar sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1826-1835. |

| [11] | Jie LI, Wen-cui GUO, Qi ZHAO, Sheng-feng GU. Road roughness identification based on vehicle responses [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1810-1817. |

| [12] | Bai-chao CHEN,Meng ZOU,Zhao-long DANG,Han HUANG,Yang JIA,Rui-yang SHI,Jian-qiao LI. Experiment on pressure⁃sinkage for mesh wheels of CE⁃3lunar rover on lunar regolith [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1836-1843. |

| [13] | Ren HE,Kun TU. Electromagnetic brake with changed⁃temperature air gap width [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1777-1785. |

| [14] | Qiao-bin LIU,Wen-ku SHI,Zhi-yong CHEN,Lian-meng LUO,Zhi-yong SU,Kai-jun HUANG. Parameter estimation of mixed reliability model based on kernel density optimal grouping and gravity search algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1818-1825. |

| [15] | Zhen-hai GAO,Tian-jun SUN,Lei HE. Causal reasoning decision⁃making for vehicle longitudinal automatic driving [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1392-1404. |

|

||