Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (4): 1007-1015.doi: 10.13229/j.cnki.jdxbgxb.20220721

Evaluation of mechanical properties of non-uniform corroded rebars based on Monte Carlo method

Yi-fan LIU( ),Zhi-wei MIAO(

),Zhi-wei MIAO( ),Chen SHEN,Xiang-dong GENG

),Chen SHEN,Xiang-dong GENG

- School of Civil Engineering,Southeast University,Nanjing 211189,China

CLC Number:

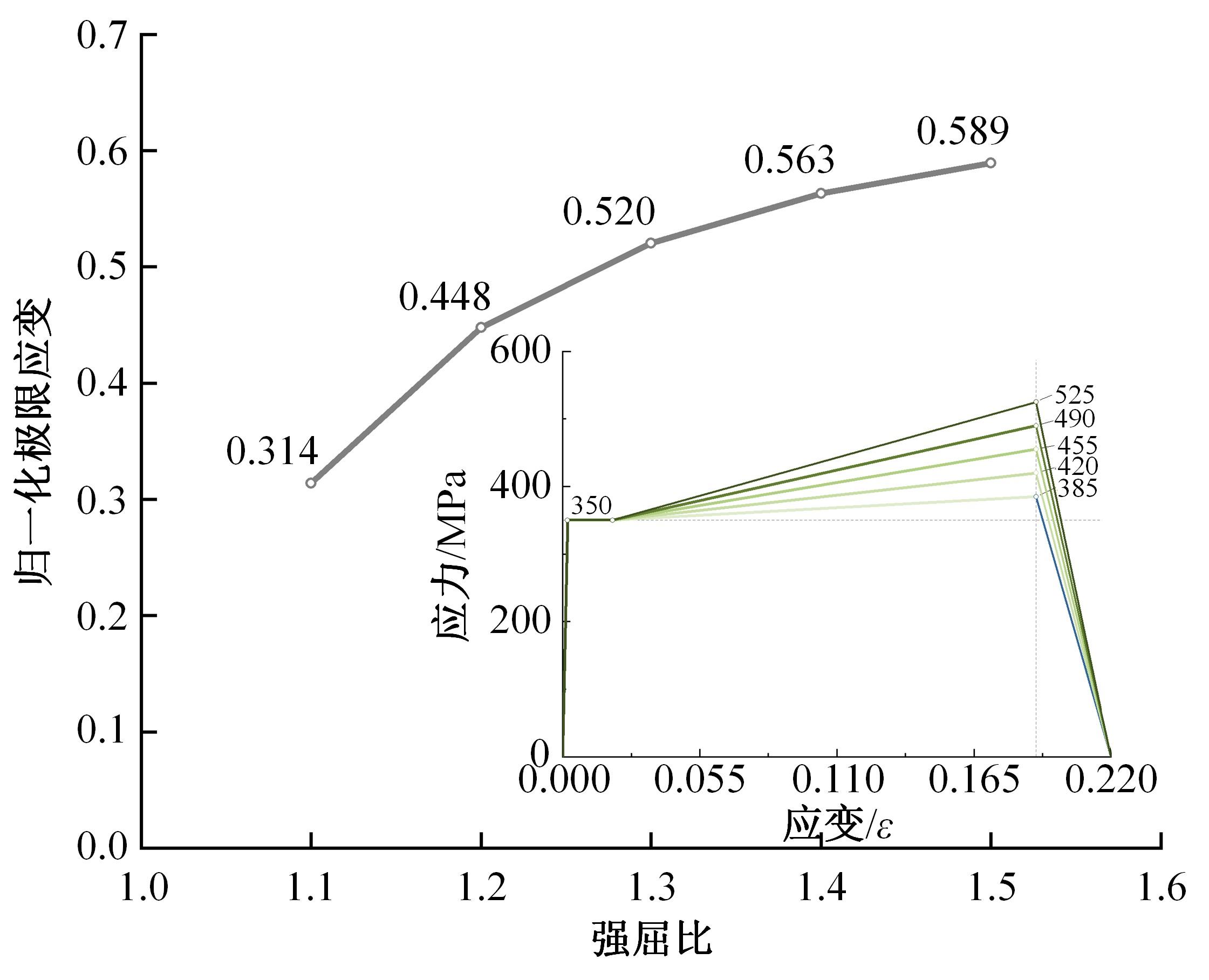

- TU375

| 1 | 李志国, 刘成义, 林陈安攀, 等. 氯盐环境下混凝土中钢筋锈蚀性能试验[J].天津大学学报:自然科学与工程技术版, 2015, 48(3):219-224. |

| Li Zhi-guo, Liu Cheng-yi, An-pan Lin-Chen, et al. Experiment on anti-corrosion property of steel in chloride concrete[J]. Journal of Tianjin University(Science and Technology), 2015, 48(3):219-224. | |

| 2 | 戴理朝,周亮,杨晓文,等.基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报:工学版, 2023,53(10):2886-2896. |

| Dai Li-zhao, Zhou Liang, Yang Xiao-wen, et al. Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on Connector element[J]. Journal of Jilin University(Engineering and Technology Edition), 2023,53(10):2886-2896. | |

| 3 | Kordtabar B, Dehestani M. Effect of corrosion in reinforced concrete frame components on pushover behavior and ductility of frame[J]. Structural Concrete, 2021, 22: 5-23. |

| 4 | Ou Y C, Susanto Y T T, Roh H. Tensile behavior of naturally and artificially corroded steel bars[J]. Construction and Building Materials, 2016, 103: 93-104. |

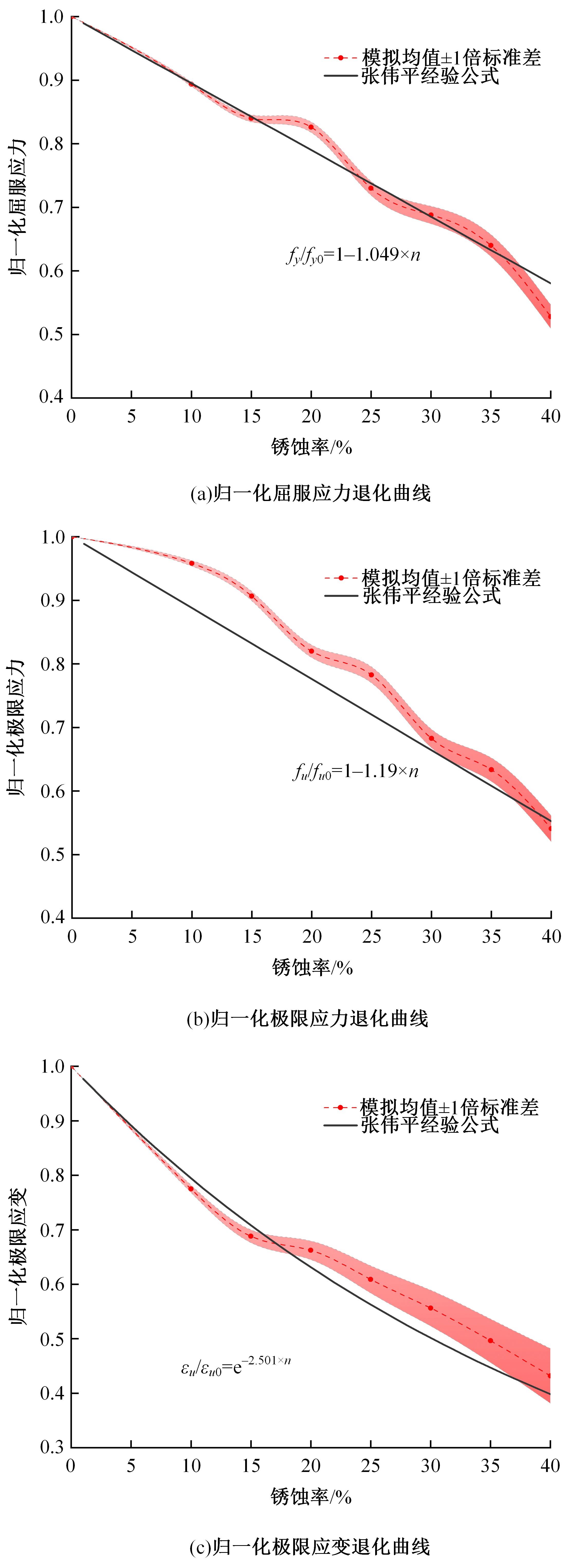

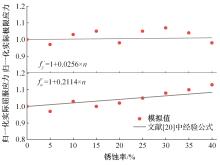

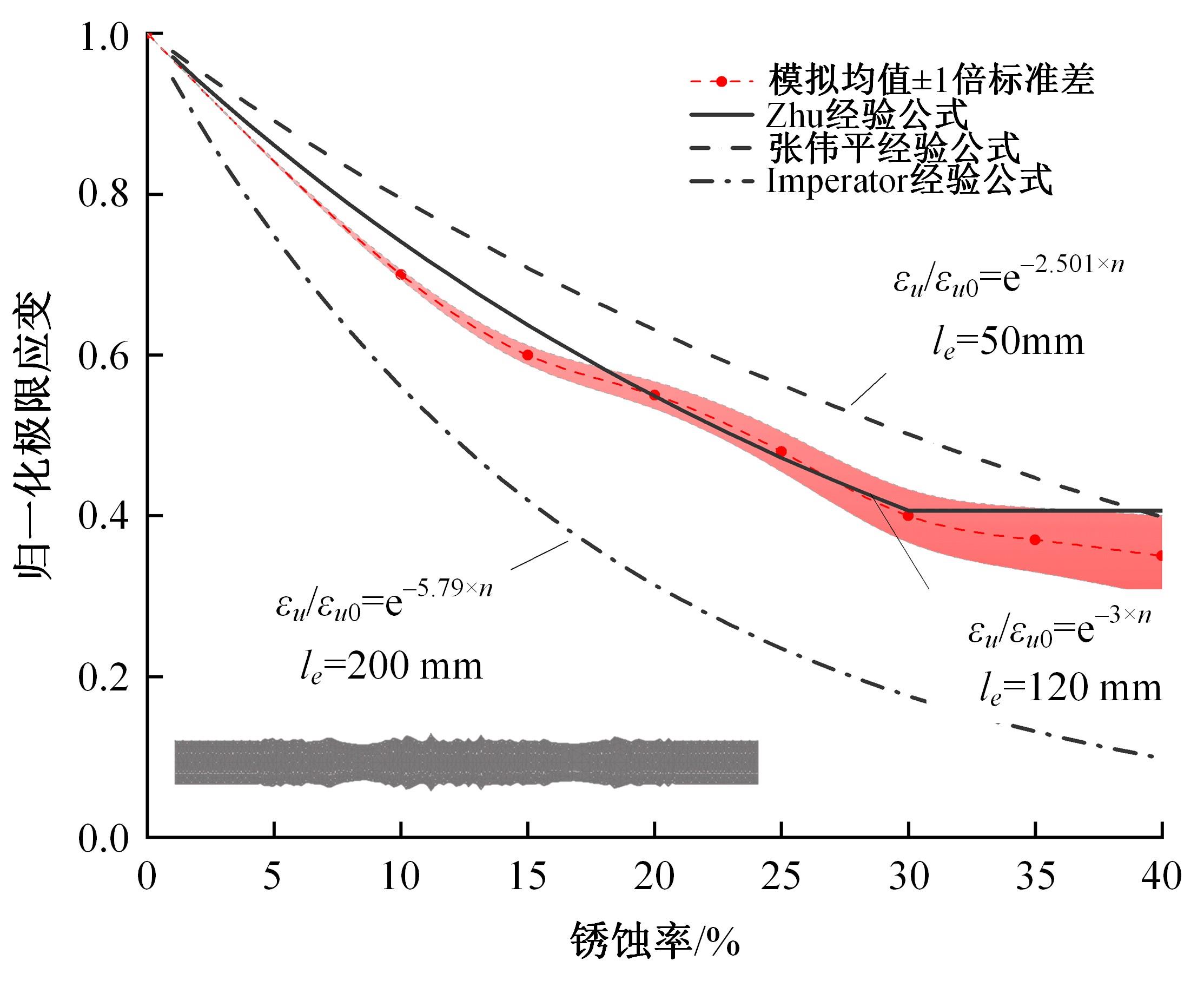

| 5 | 张伟平, 商登峰, 顾祥林. 锈蚀钢筋应力-应变关系研究[J]. 同济大学学报:自然科学版, 2006,34(5): 586-592. |

| Zhang Wei-ping, Shang Deng-feng, Gu Xiang-lin. Stress-strain relationship of corroded steel bars[J]. Journal of Tongji University(Natural Science), 2006,34(5): 586-592. | |

| 6 | Imperatore S, Rinaldi Z, Drago C. Degradation relationships for the mechanical properties of corroded steel rebars[J]. Construction and Building Materials, 2017, 148: 219-230. |

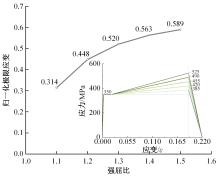

| 7 | Zhu W J, Francois R, Poon C S, et al. Influences of corrosion degree and corrosion morphology on the ductility of steel reinforcement[J]. Construction and Building Materials, 2017, 148: 297-306. |

| 8 | Sun X Y, Kong H T, Wang H L, et al. Evaluation of corrosion characteristics and corrosion effects on the mechanical properties of reinforcing steel bars based on three-dimensional scanning[J]. Corrosion Science, 2018, 142: 284-294. |

| 9 | Fernandez I, Bairán J M, Marí A R. 3D FEM model development from 3D optical measurement technique applied to corroded steel bars[J]. Construction and Building Materials, 2016, 124: 519-532. |

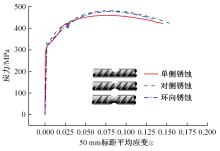

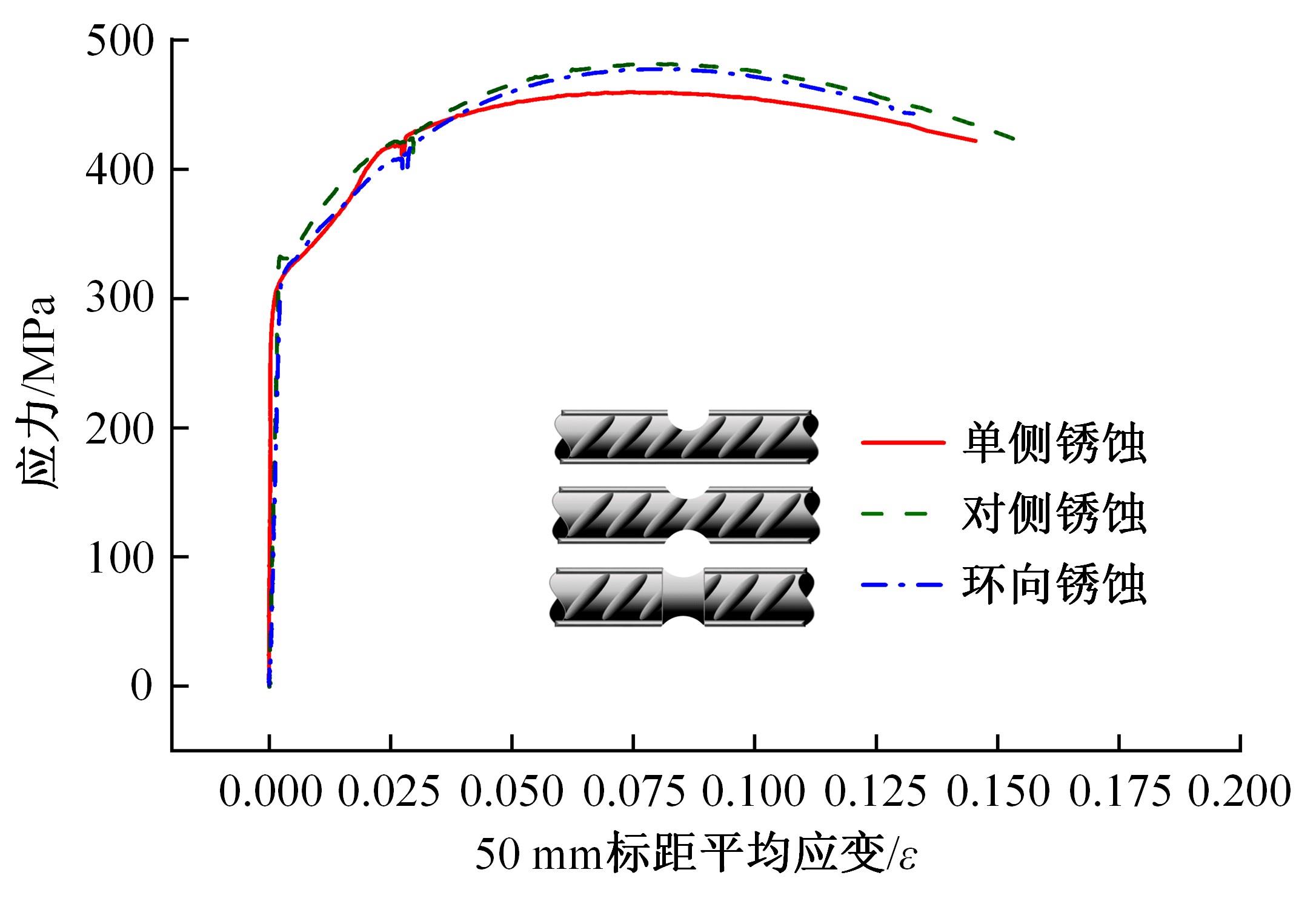

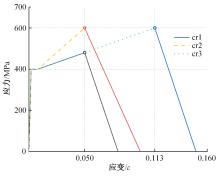

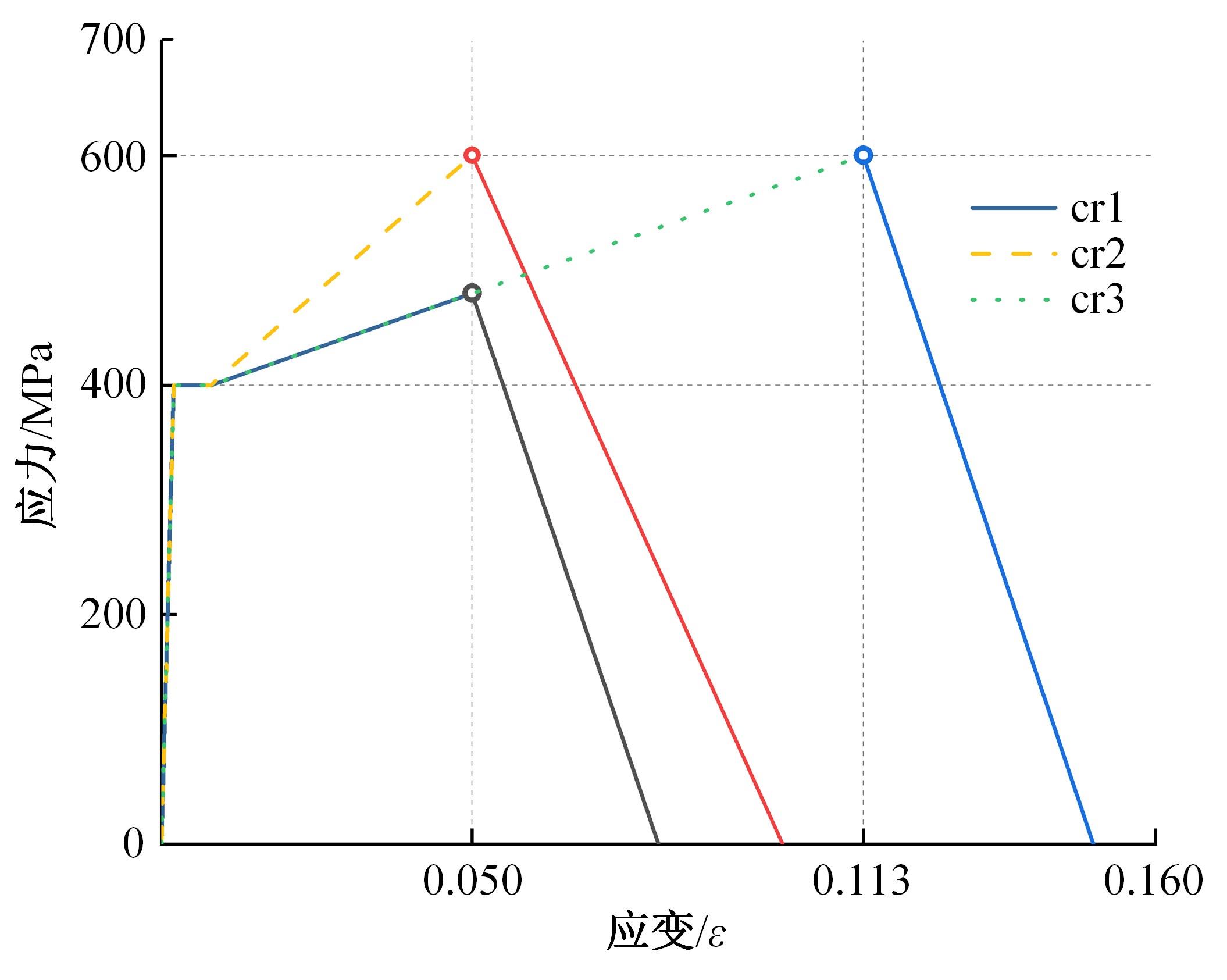

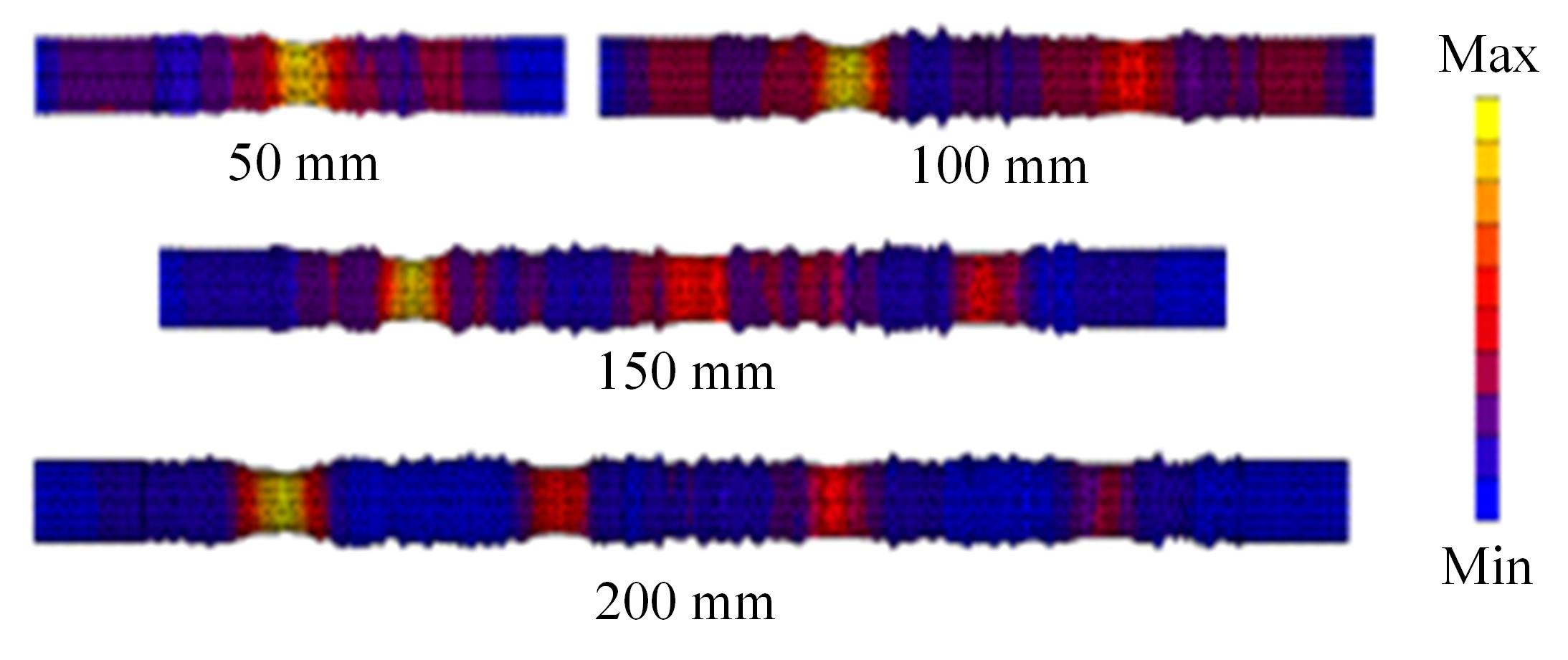

| 10 | 李亚辉, 郑山锁, 董立国, 等. 非均匀锈蚀钢筋拉伸性能试验与模拟[J]. 建筑材料学报, 2022,25(9):991-998. |

| Li Ya-hui, Zheng Shan-suo, Dong Li-guo, et al. Tensile properties test and simulation of non-uniform corroded reinforcement[J]. Journal of Building Materials, 2022,25(9):991-998. | |

| 11 | Cairns J, Plizzari G A, Du Y G, et al. Mechanical properties of corrosion-damaged reinforcement[J]. Aci Materials Journal, 2005, 102: 256-264. |

| 12 | Torres-Acosta A, Martinez-Madrid M. Residual life of corroding reinforced concrete structures in marine environment[J]. Journal of Materials in Civil Engineering, 2003, 15: 344-353. |

| 13 | 张伟平, 李崇凯, 顾祥林, 等.锈蚀钢筋的随机本构关系[J].建筑材料学报, 2014, 17(5): 920-926. |

| Zhang Wei-ping, Li Chong-kai, Gu Xiang-lin, et al. Stochastic model of constitutive relationship for corroded steel bars[J]. Journal of Building Materials, 2014, 17(5): 920-926. | |

| 14 | 金南国, 何家豪, 付传清, 等. 钢筋加速非均匀锈蚀试验方法和锈蚀形态研究[J]. 浙江大学学报:工学版, 2020, 54(3): 483-490. |

| Jin Nan-guo, He Jia-hao, Fu Chuan-qing, et al. Study on experimental method and morphology of accelerated non-uniform corrosion of steel bars[J]. Journal of Zhejiang University(Engineering Science), 2020, 54(3): 483-490. | |

| 15 | Kashani M M, Crewe A J, Alexander N A. Use of a 3D optical measurement technique for stochastic corrosion pattern analysis of reinforcing bars subjected to accelerated corrosion[J]. Corrosion Science, 2013, 73: 208-221. |

| 16 | Hui Y L, Lin Z S, Li R. Experimental study and analysis on the property of corroded rebar[J]. Industrial Construction, 1997, 27(6): 10-13. |

| 17 | 罗小勇, 刘晋宏, 聂经纶. 锈蚀钢筋截面分布特征及轴向拉伸力学性能[J]. 建筑材料学报, 2019, 22(5): 730-736. |

| Luo Xiao-yong, Liu Jin-hong, Nie Jing-lun. Cross-section distribution characteristics and tensile behavior of corroded reinforcing steel bars[J]. Journal of Building Materials, 2019, 22(5): 730-736. | |

| 18 | Francois R, Khan I, Dang V H. Impact of corrosion on mechanical properties of steel embedded in 27-year-old corroded reinforced concrete beams[J]. Materials and Structures, 2013, 46: 899-910. |

| 19 | Li D W, Xiong C, Huang T, et al. A simplified constitutive model for corroded steel bars[J]. Construction and Building Materials, 2018, 186: 11-19. |

| 20 | Gu X L, Guo H Y, Zhou B B, et al. Corrosion non-uniformity of steel bars and reliability of corroded RC beams[J]. Engineering Structures, 2018, 167: 188-202. |

| 21 | Zhang J Z, Huang J, Fu C Q, et al. Characterization of steel reinforcement corrosion in concrete using 3D laser scanning techniques[J]. Construction and Building Materials, 2021, 270: 1-16. |

| 22 | Wang X G, Zhang W P, Gu X L, et al. Determination of residual cross-sectional areas of corroded bars in reinforced concrete structures using easy-to-measure variables[J]. Construction and Building Materials, 2013, 38: 846-853. |

| 23 | 中华人民共和国国家质量监督检验检疫总局. 金属材料拉伸试验第1部分: 室温试验方法 [S]. 北京: 中国标准出版社, 2010. |

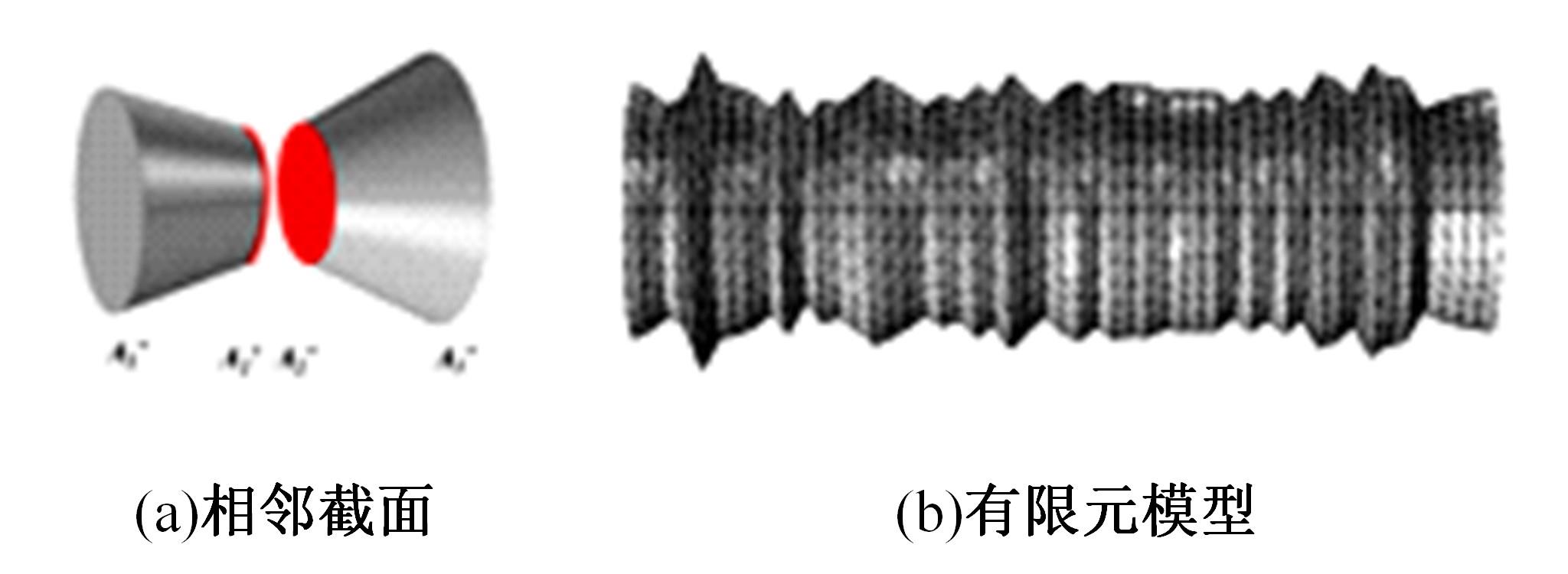

| 24 | Zhao Y X, Xu X Y, Wang Y Z, et al. Characteristics of pitting corrosion in an existing reinforced concrete beam exposed to marine environment[J]. Construction and Building Materials, 2020, 234: 1-12. |

| 25 | Stewart M G. Mechanical behaviour of pitting corrosion of flexural and shear reinforcement and its effect on structural reliability of corroding RC beams[J]. Structural Safety, 2009, 31: 19-30. |

| 26 | 中华人民共和国住房和城乡建设部. 混凝土结构设计规范 [S]. 北京: 中国建筑工业出版社, 2017. |

| [1] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Time⁃variant reliability analysis of bridge members based on Gaussian Copula⁃Bayesian dynamic models [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 485-493. |

| [2] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [3] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Multi⁃process Bayesian dynamic combinatorial prediction of time⁃variant reliability for bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2332-2338. |

| [4] | Jiu-yi LI,Feng-jun ZHOU,Jian-hua LIU,Yun-hou SUN,Jing-zhong ZHU,Ming-kun QIU. Modified IWAN model of helical threaded connector imposed to torsional load [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1305-1314. |

| [5] | Er-gang XIONG,Zhong-wen GONG,Jia-ming LUO,Tuan-jie FAN. Experiment on cracks in reinforced concrete beams based on digital image correlation technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1094-1104. |

| [6] | Ya-chuan KUANG,Li-bin CHEN,Chao-ju LI,Yu-hao HE. Analysis of mechanical properties of stud shear connectors [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 538-546. |

| [7] | Xiao-dong WANG,Ning-jing LI,Qiang LI. Experimental on crushing of concrete beams by high⁃voltage pulse discharge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 496-504. |

| [8] | Li-zhao DAI,Liang ZHOU,Xiao-wen YANG,Lei WANG. Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on connector element [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2886-2896. |

| [9] | Yun-peng CHU,Xin-hui SUN,Ming LI,Yong YAO,Han-jie HUANG. Wind pressures on a circular hyperbolic⁃paraboloid roof subjected to a simulated downburst [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1826-1833. |

| [10] | Yong YAO,Liu-feng SU,Ming LI,Yun-peng CHU,Han-jie HUANG. Wind load characteristics of double⁃sided spherical shell roof under downburst [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 615-625. |

| [11] | Ya-chuan KUANG,Zhe-xuan SONG,Yin-hu LIU,Xiao-fei MO,Liang-ming FU,Shi-quan LUO. Experiment on mechanical properties of new type assembled double-cabin utility tunnel [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 596-603. |

| [12] | Chang-kai WEN,Bin XIE,Zheng-he SONG,Jian-gang HAN,Qian-wen YANG. Design method of tractor durability accelerated structure test [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 703-715. |

| [13] | Yi-hong WANG,Qiao-luo TIAN,Guan-qi LAN,Sheng-fa YAO,Jian-xiong ZHANG,Xi LIU. Experimental research on the mechanical properties of concrete column reinforced with 630 MPa high⁃strength steel under large eccentric loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2626-2635. |

| [14] | Fen YE,Shi-yuan HU. Mechanical properties of ultra⁃thin overlay considering load transfer capacity of old cement pavement joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2636-2643. |

| [15] | Yong-zhi GONG,Jin-hua KUANG,Fu-long KE,Quan ZHOU,Xiao-yong LUO. Experiment on seismic behavior of assembled shear wall joints connected by ultra high performance concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2367-2375. |

|

||