Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (10): 2367-2375.doi: 10.13229/j.cnki.jdxbgxb20210320

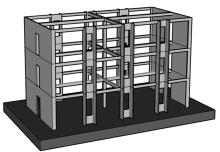

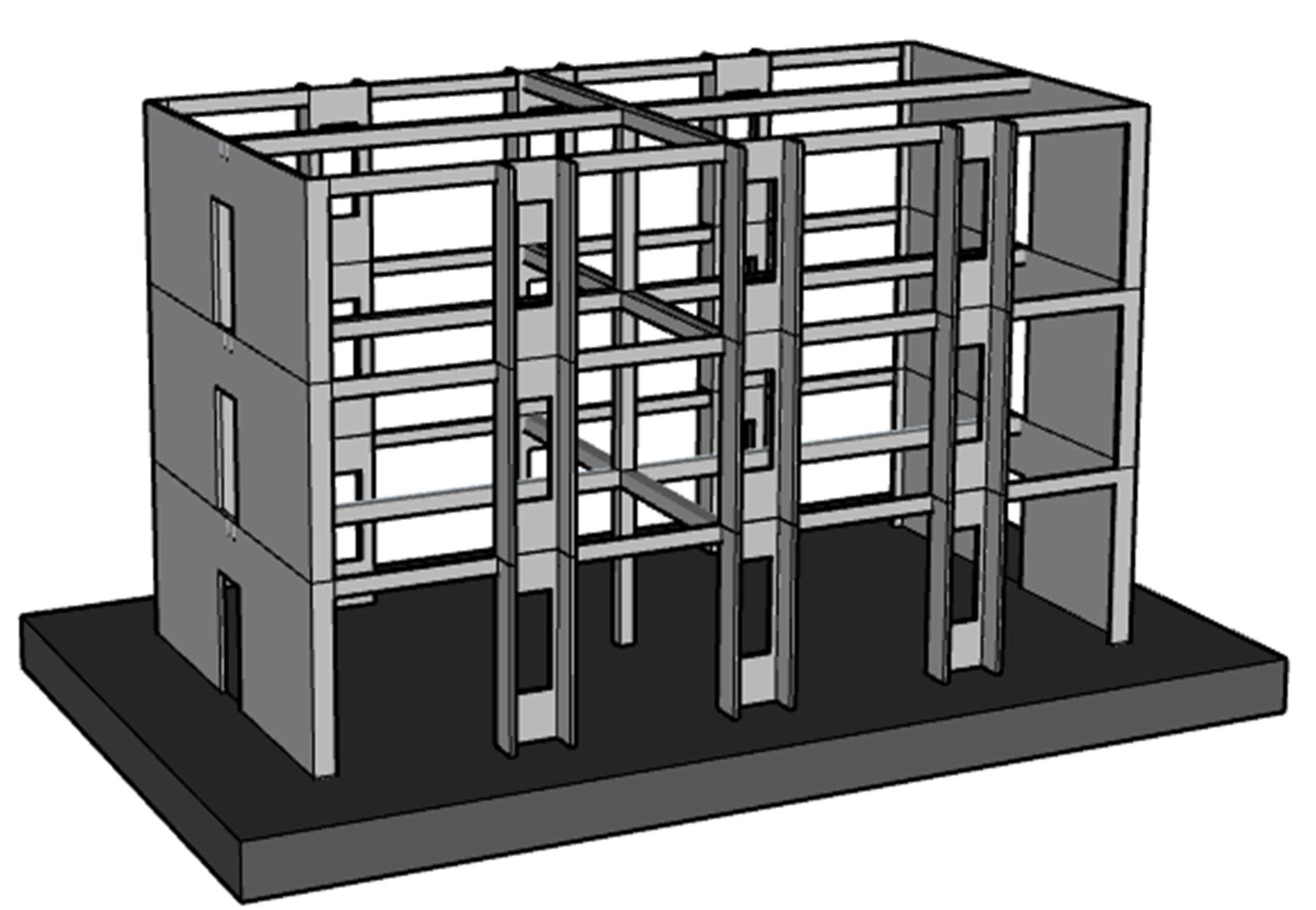

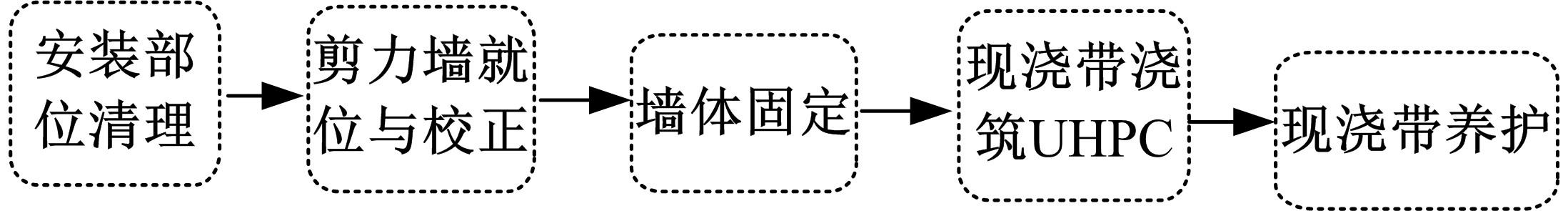

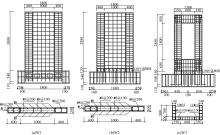

Experiment on seismic behavior of assembled shear wall joints connected by ultra high performance concrete

Yong-zhi GONG1( ),Jin-hua KUANG1,Fu-long KE1,Quan ZHOU2,Xiao-yong LUO1

),Jin-hua KUANG1,Fu-long KE1,Quan ZHOU2,Xiao-yong LUO1

- 1.School of Civil Engineering,Central South University,Changsha 410075,China

2.CSCEC Fifth Engineering Bureau Co. ,Ltd. ,Changsha 410004,China

CLC Number:

- TU375.2

| 1 | 赵唯坚, 郭婉楠, 金峤, 等. 预制装配式剪力墙结构竖向连接形式的发展现状[J]. 工业建筑, 2014, 44(4): 115-121, 59. |

| Zhao Wei-jian, Guo Wan-nan, Jin Qiao, et al. Development status of vertical connection forms of prefabricated shear wall structures[J]. Industrial Architecture, 2014, 44(4): 115-121, 59. | |

| 2 | 李宁波, 钱稼茹, 叶列平, 等. 竖向钢筋套筒挤压连接的预制钢筋混凝土剪力墙抗震性能试验研究[J]. 建筑结构学报, 2016, 37(1): 31-40. |

| Li Ning-bo, Qian Jia-ru, Ye Lie-ping, et al. Experimental study on seismic behavior of precast reinforced concrete shear walls connected by vertical reinforced sleeve compression[J]. Journal of Building Structure, 2016, 37(1): 31-40. | |

| 3 | 王墩, 吕西林, 卢文胜. 带接缝连接梁的预制混凝土剪力墙抗震性能试验研究[J]. 建筑结构学报, 2013, 34(10): 1-11. |

| Wang Dun, Lv Xi-lin, Lu Wen-sheng. Experimental study on seismic behavior of precast concrete shear walls with jointed beams[J]. Journal of Building Structures, 2013, 34(10): 1-11. | |

| 4 | 张海顺. 预制混凝土结构插入式预留孔灌浆钢筋锚固搭接试验研究[D]. 哈尔滨: 哈尔滨工业大学土木工程学院, 2009. |

| Zhang Hai-shun. Experimental study on anchorage lap of grouted reinforcement with inserted pre-hole in precast concrete structure[D]. Harbin: School of Civil Engineering, Harbin Institute of Technology, 2009. | |

| 5 | Gu Qian, Dong Ge, Wang Xiang, et al. Research on pseudo-static cyclic tests of precast concrete shear walls with vertical rebar lapping in grout-filled constrained hole[J]. Engineering Structures, 2019, 189: 396-410. |

| 6 | 钱稼茹, 杨新科, 秦珩, 等. 竖向钢筋采用不同连接方法的预制钢筋混凝土剪力墙抗震性能试验[J]. 建筑结构学报, 2011, 32(6): 51-59. |

| Qian Jia-ru, Yang Xin-ke, Qin Heng, et al. Experimental study on seismic performance of precast reinforced concrete shear walls with different connection methods for vertical reinforcement[J]. Journal of Building Structures, 2011, 32(6): 51-59. | |

| 7 | 钱稼茹, 彭媛媛, 秦珩, 等. 竖向钢筋留洞浆锚间接搭接的预制剪力墙抗震性能试验[J]. 建筑结构, 2011, 41(2): 7-11. |

| Qian Jia-ru, Peng Yuan-yuan, Qin Hang, et al. Experimental study on seismic performance of prefabricated shear wall with mortar anchor indirectly overlapped with vertical reinforcement holes [J]. Building Structure, 2011, 41(2): 7-11. | |

| 8 | 姜洪斌, 陈再现, 张家齐, 等. 预制钢筋混凝土剪力墙结构与拟静力试验研究[J]. 建筑结构学报, 2011, 32(6): 34-40. |

| Jiang Hong-bin, Chen Zai-xian, Zhang Jia-qi, et al. Study on precast reinforced concrete shear wall structure and quasi-static test[J]. Journal of Building Structures, 2011, 32(6): 34-40. | |

| 9 | 姜洪斌, 张海顺, 刘文清, 等. 预制混凝土插入式预留孔灌浆钢筋搭接试验[J]. 哈尔滨工业大学学报, 2011, 43(10): 18-23. |

| Jiang Hong-bin, Zhang Hai-shun, Liu Wen-qing, et al. Lap test of precast concrete grouting reinforcement with inserted reserved holes[J]. Journal of Harbin Institute of Technology, 2011, 43(10): 18-23. | |

| 10 | Wang De-hui, Shi Cai-jun, Wu Ze-mei, et al. A review on ultra high performance concrete: part II.hydration microstructure and pro perties [J]. Construction and Building Materials, 2015, 96: 368-377. |

| 11 | Yoo D Y, Banthia N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: a review [J]. Cement and Concrete Composites,2016, 73(5): 267-280. |

| 12 | Alkaysi M, El-Tawil S. Factors affecting bond development between ultra high performance concrete (UHPC) and steel bar reinforcement [J]. Construction and Building Materials, 2017, 144: 412-422. |

| 13 | Shafieifar M, Farzad M, Azizinamini M. Experimental and numerical study on mechanical properties of ultra high performance concrete (UHPC)[J]. Construction and Building Materials, 2017, 156: 402-411. |

| 14 | Farzad M, Shafieifar M, Azizinamin A. Experimental and numerical study on bond strength between conventional concrete and ultra high-performance concrete (UHPC)[J].Engineering Structures, 2019, 186: 297-305. |

| 15 | Wu Ze-mei, Shi Cai-jun, He Wen, et al. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete [J]. Construction and Building Materials, 2016, 103: 8-14. |

| 16 | 王德辉, 史才军, 吴林妹. 超高性能混凝土在中国的研究和应用[J]. 硅酸盐通报, 2016, 35(1): 141-149. |

| Wang De-hui, Shi Cai-jun, Wu Lin-mei. Research and application of ultra-high performance concrete in China[J]. Silicate Bulletin, 2016, 35(1): 141-149. | |

| 17 | 邵旭东, 邱明红. 基于UHPC材料的高性能装配式桥梁结构研发[J]. 西安建筑科技大学学报: 自然科学版, 2019, 51(2): 160-167. |

| Shao Xu-dong, Qiu Ming-hong. Research and development of high performance fabricated bridge structure based on UHPC material[J]. Journal of Xi 'an University of Architecture and Technology (Natural Science Edition), 2019, 51(2): 160-167. | |

| 18 | Safdar M, Matsumoto T, Kakuma K. Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC)[J]. Composite Structures, 2016, 157: 448-460. |

| 19 | Xu Shen-chun, Wu Cheng-qing, Liu Zhong-xian, et al. Experimental investigation of seismic behavior of ultra-high performance steel fiber reinforced concrete columns[J]. Engineering Structures, 2017, 152: 129-148. |

| 20 | 童小龙, 方志, 罗肖. 活性粉末混凝土剪力墙抗震性能试验研究[J]. 建筑结构学报, 2016, 37(1): 21-30. |

| Tong Xiao-long, Fang Zhi, Luo Xiao. Experimental study on seismic behavior of reactive powder concrete shear walls[J]. Journal of Building Structures, 2016, 37(1): 21-30. | |

| 21 | 郑七振, 刘阳阳, 龙莉波,等. 超高性能混凝土连接的装配式现浇混凝土框架抗震性能[J]. 工业建筑, 2019, 49(10): 85-91. |

| Zheng Qi-zhen, Liu Yang-yang, Long Li-bo, et al. Seismic behavior of fabricated cast-in-place concrete frames connected by ultra-high performance concrete [J]. Industrial Architecture, 2019, 49(10): 85-91. | |

| 22 | 冯军骁, 郑七振, 龙莉波, 等. 超高性能混凝土连接的预制梁受弯性能试验研究[J]. 工业建筑, 2017, 47(8): 59-65. |

| Feng Jun-xiao, Zheng Qi-zhen, Long Li-bo, et al. Experimental study on flexural behavior of precast beams connected by ultra-high performance concrete[J]. Industrial Architecture, 2017, 47(8): 59-65. | |

| 23 | ,混凝土结构设计规范 [S].北京:中国建筑工业出版社,2010. |

| 24 | ,建筑抗震试验规程 [S].北京:中国建筑工业出版社,2015. |

| 25 | 王兴旺. UHPC与普通钢筋混凝土结构界面抗剪性能研究[D].长沙: 湖南大学土木工程学院,2016. |

| Wang Xing-wang. Study on shear behavior of interface between UHPC and ordinary reinforced concrete structure[D]. Changsha: School of Civil Engineering, Hunan University, 2016. |

| [1] | Yun-peng CHU,Xin-hui SUN,Ming LI,Yong YAO,Han-jie HUANG. Wind pressures on a circular hyperbolic⁃paraboloid roof subjected to a simulated downburst [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1826-1833. |

| [2] | Yong YAO,Liu-feng SU,Ming LI,Yun-peng CHU,Han-jie HUANG. Wind load characteristics of double⁃sided spherical shell roof under downburst [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 615-625. |

| [3] | Ya-chuan KUANG,Zhe-xuan SONG,Yin-hu LIU,Xiao-fei MO,Liang-ming FU,Shi-quan LUO. Experiment on mechanical properties of new type assembled double-cabin utility tunnel [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 596-603. |

| [4] | Xue-ping FAN,Guang-hong YANG,Zhi-peng SHANG,Xiao-xiong ZHAO,Qing-kai XIAO,Yue-fei LIU. Dynamic reliability fusion prediction of long-span bridge girder considering structural serviceability [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 144-153. |

| [5] | Fu-shou LIU,Qi WEI,Wen-ting XU,Guo-jin TAN. Damage detection of truss structures based on elastic wave propagation and spectral element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2087-2095. |

| [6] | Jian-bin CHEN,Song-ze ZHOU,Feng-yong FEI,Yong-long CHEN,Guo-ping LING. Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1959-1966. |

| [7] | Xue-ping FAN,Guang-hong YANG,Qing-kai XIAO,Yue-fei LIU. Optimal R-vine copula information fusion for failure probability analysis of long-span bridge girder [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1296-1305. |

| [8] | Guang-tai ZHANG,Lu-yang ZHANG,Guo-hua XING,Yin-long CAO,Bao YI. Seismic performance of steel⁃polypropylene hybrid fiber reinforced concrete shear wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 946-955. |

| [9] | Jiang YU,Zhi-hao ZHAO,Yong-jun QIN. Damage of reinforced concrete shear beams based on acoustic emission and fractal [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 620-630. |

| [10] | Er-gang XIONG,Han XU,Ci TAN,Jing WANG,Ruo-yu DING. Shear strength of reinforced concrete beams based on elastoplastic stress field theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 259-267. |

| [11] | Xue-ping FAN,Guang QU,Yue-fei LIU. Bridge extreme stress prediction based on new data assimilation algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 572-580. |

| [12] | De-lei YANG,Le-wei TONG. Calculation formula of SCF for CHS⁃CFSHS welded T⁃joints with brace under axial tension [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1891-1899. |

| [13] | WANG Deng-feng, ZHANG Shuai, WANG Yong, CHEN Hui. Optimization design of assembled wheel based on performance of fatigue and 13° impact [J]. 吉林大学学报(工学版), 2018, 48(1): 44-56. |

| [14] | ZHANG Peng, KOU Shu-qing, ZHAO Yong, LIN Bao-jun. Ananlsis of three rollers axial knurling process of assembled camshaft [J]. 吉林大学学报(工学版), 2016, 46(6): 1953-1960. |

| [15] | SU Ying-she, YANG Yuan-yuan. Seismic compression performance of the concrete under high temperature [J]. 吉林大学学报(工学版), 2015, 45(5): 1436-1442. |

|

||