Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1563-1569.doi: 10.13229/j.cnki.jdxbgxb.20220958

Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints

Lei WANG1,2( ),Dong-xia LI2,Song ZHOU2,3,Li HUI3,Zhen-xin SHEN2

),Dong-xia LI2,Song ZHOU2,3,Li HUI3,Zhen-xin SHEN2

- 1.College of Mechanical Engineering,Suzhou University of Science and Technology,Suzhou 215009,China

2.School of Mechatronics Engineering,Shenyang Aerospace University,Shenyang 110136,China

3.Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University,Shenyang 110136,China

CLC Number:

- TG405

| 1 | 张鹏,陈明和,谢兰生. 热处理2024-O铝合金在自然时效下的拉伸性能及断口形貌演变[J]. 稀有金属材料与工程, 2020, 49(3): 819-824. |

| Zhang Peng, Chen Ming-he, Xie Lan-sheng. Effect of natural aging time on tensile properties and fracture of heat-treated AA2024-O Al-alloy[J]. Rare Metal Materials and Engineering, 2020, 49(3): 819-824. | |

| 2 | Lin Y, Cui X, Chen K, et al. Forming limit and mechanical properties of 2024-O aluminum alloy under electromagnetic forming[J]. Metals and Materials International, 2022,28(10): 2472-2482. |

| 3 | Wang Z W, Zheng R X, Ma C L, et al. Fabrication and mechanical properties of 2024 aluminum alloy reinforced by FeNiCrCoAl3 high entropy particles[J]. Journal of Harbin Institute of Technology, 2013, 20(5): 119-122. |

| 4 | 王淼,李天景,黄婷婷,等. 6061铝合金FSW接头组织与耐蚀性能的研究[J]. 热加工工艺, 2024(15): 31-34. |

| Wang Miao, Li Tian-jing, Huang Ting-ting, et al. Study on microstructure and corrosion resistance of 6061 aluminium alloy friction stir welded joint[J]. Hot Working Technology, 2024(15): 31-34. | |

| 5 | Arora K S. Microstructure evolution during friction stir welding of aluminum alloy AA2219[J]. Journal of Materials Science & Technology, 2010, 26(8): 747-753. |

| 6 | Yokoyama T, Nakai K, Sukedai E, et al. Tensile properties and constitutive modeling of friction stir welded AA6061-T6butt joints[J]. Journal of Solid Mechanics & Materials Engineering, 2011, 5(12): 780-792. |

| 7 | 王希靖,李树伟,牛勇,等. A7075搅拌摩擦焊疲劳裂纹扩展速率试验分析[J].焊接学报, 2008(9): 5-7, 113. |

| Wang Xi-jing, Li Shu-wei, Niu Yong, et al. Experimental analysis of fatigue crack growth rate in friction stir welding A7075[J]. Transactions of the China Welding Institution, 2008(9): 5-7, 113. | |

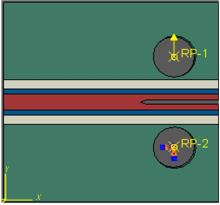

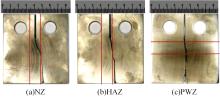

| 8 | Huang B H, Wang L, Hui L, et al. Analysis of multi-zone fatigue crack growth behavior of friction stir welded 5083 aluminum alloy[J]. Journal of Materials Engineering and Performance, 2022, 31(1):53-63. |

| 9 | Sivaraj P, Kanagarajan D, Balasubramanian V. Fatigue crack growth behaviour of friction stir welded AA7075-T651 aluminium alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2014,24(8):2459-2467. |

| 10 | Muzvidziwa Milton, Okazaki Masakazu, Suzuki Kenji, et al. Role of microstructure on the fatigue crack propagation behavior of a friction stir welded Ti-6Al⁃4V[J]. Materials Science & Engineering A, 2016, 652:59-68. |

| 11 | 王磊,付强,周松,等. 2A12-O铝合金搅拌摩擦焊缝裂纹扩展行为研究[J].热加工工艺, 2022(15): 14-17. |

| Wang Lei, Fu Qiang, Zhou Song, et al. Study on crack propagation behavior of 2A12-O aluminum alloy friction stir weld[J]. Hot Working Technology, 2022(15): 14-17. | |

| 12 | 黄伟辰, 龙江. 基于FRANC3D的飞机蒙皮谱载疲劳裂纹扩展分析[J]. 西安航空学院学报,2020,38(1):32-38. |

| Huang Wei-chen, Long Jiang. Fatigue crack propagation analysis of aircraft skin under spectrum load based on FRANC 3D[J]. Journal of Xi'an Aeronautical University, 2020,38(1):32-38. | |

| 13 | 王磊,张璐,赵新华,等. 力学失配2A12铝合金搅拌摩擦焊接头拉伸性能分析[J].科学技术与工程,2020,20(16):6419-6423. |

| Wang Lei, Zhang Lu, Zhao Xin-hua, et al. Analysis of tensile properties of mechanical mismatched friction stir weld of 2A12 aluminum alloy[J]. Science Technology and Engineering,2020,20(16) : 6419-6423. |

| [1] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [2] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

| [3] | Shi-jun WANG,Guan-wei LUO. Periodic motion transition characteristics of a vibro-impact system with multiple impact constraints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 902-916. |

| [4] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [5] | Bin HU,Yi-quan CAI,Xin LUO,Zi-bin MAO,Jun-wei LI,Meng-yu GUO,Jian WANG. Theory and experiment of high⁃speed seed filling in limited gear⁃shaped side space based on seeds group stress [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 574-588. |

| [6] | Jia-yi WANG,Xin-hui LIU,Zhan WANG,Jin-shi CHEN,Ya-fang HAN,Yu-qi WANG. Flow characteristics analysis of constant flow control valve based on AMESim [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2499-2507. |

| [7] | Ya-bing CHENG,Ze-yu YANG,Yan LI,Li-chi AN,Ze-hui XU,Peng-yu CAO,Lu-xiang CHEN. Vibration and noise characteristics base on timing silent chain system of hybrid electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2465-2473. |

| [8] | Fu-yuan SHEN,Wei LI,Dong-nian JIANG. Life prediction and self⁃maintenance method of quadrotor unmanned aerial vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 841-852. |

| [9] | Yan YANG,Yu-qing SHI,Xiao-rong ZHANG,Guan-wei LUO. Dynamic stability analysis of a amplitude⁃limited vibration system with multiple rigid constraints [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 364-375. |

| [10] | Jian-feng SONG,Xin-lei HUANG,Shuai YI,Zhen-xi YANG,Yong-gang DONG,Shu-lin LI. Temperature field and stress-strain distribution of tread during train braking [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2773-2784. |

| [11] | Yang LIU. Calculation method of anti-backward-tilting buffer force of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2785-2794. |

| [12] | Xiao-hong LU,Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN. Research progress of temperature field in friction stir welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 1-17. |

| [13] | Yang LIU. Unloading impact simulation and test of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1292-1300. |

| [14] | Ya-bing CHENG,Lu-xiang CHEN,Ping-yu GE,Ze-yu YANG,Peng-yu CAO. Dynamic simulation analysis and wear failure of dual-phase timing bush chain [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 781-788. |

| [15] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

|

||