Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (9): 2465-2473.doi: 10.13229/j.cnki.jdxbgxb.20211234

Previous Articles Next Articles

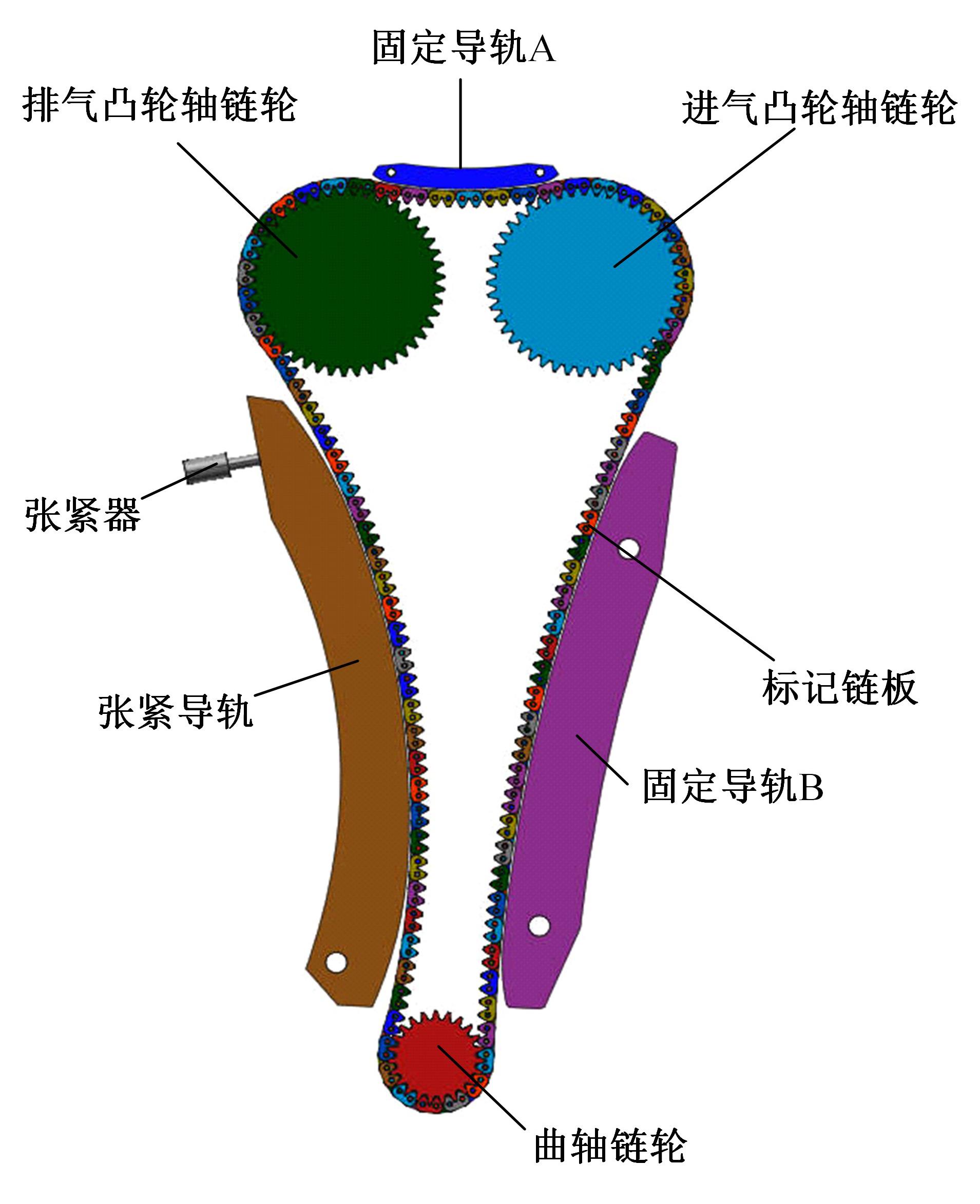

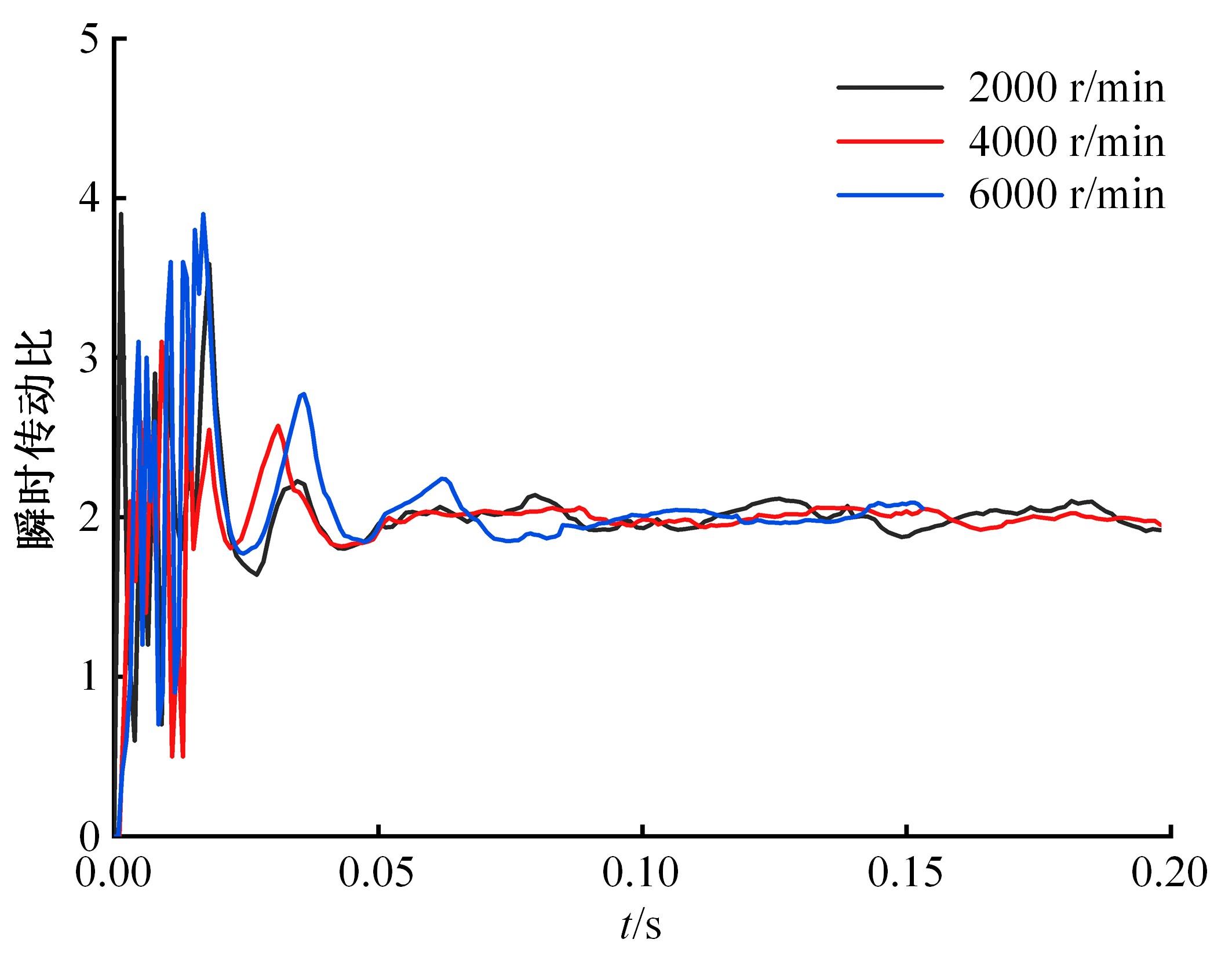

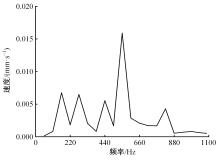

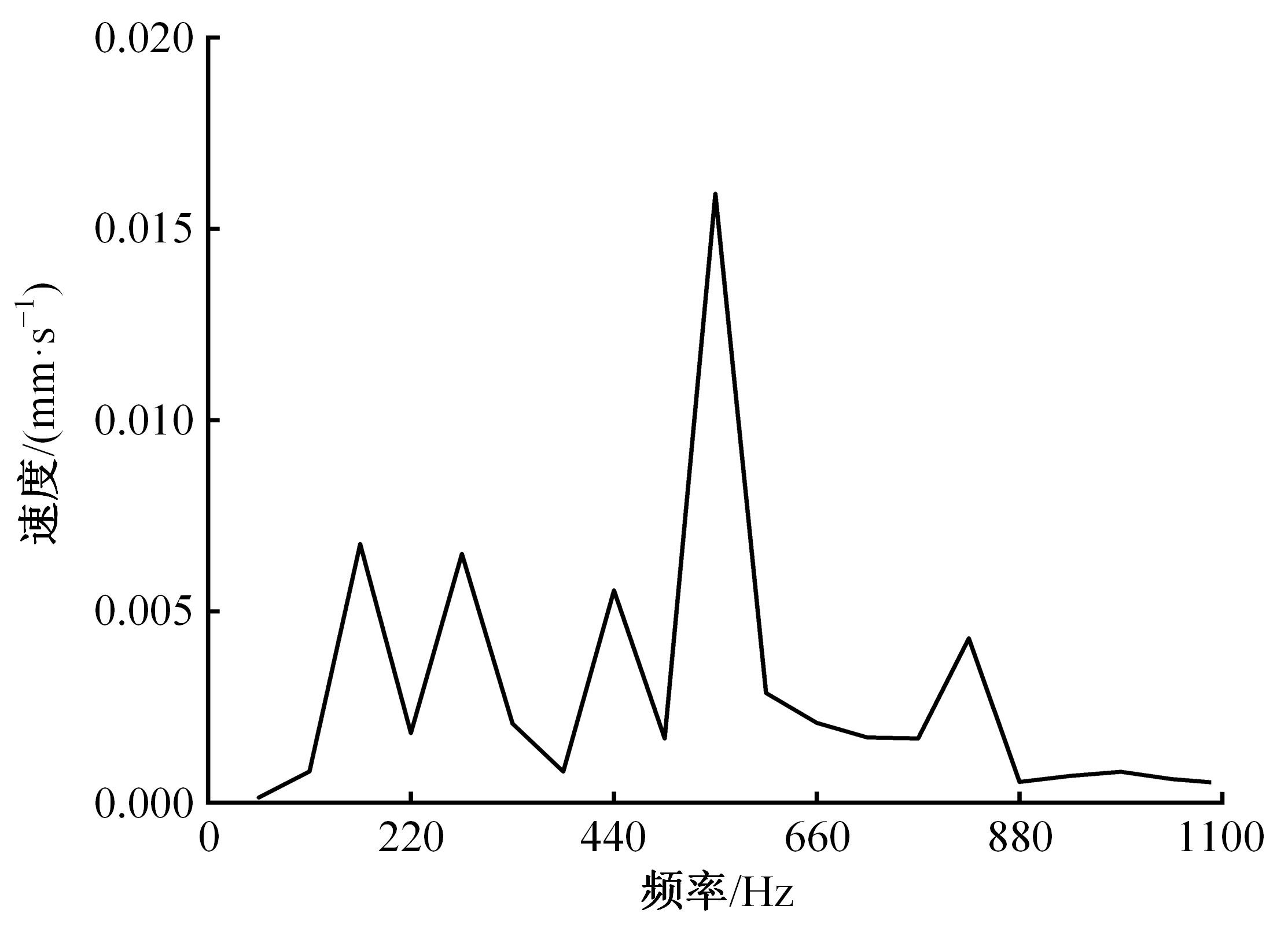

Vibration and noise characteristics base on timing silent chain system of hybrid electric vehicle

Ya-bing CHENG1( ),Ze-yu YANG1,Yan LI2,Li-chi AN1,Ze-hui XU1,Peng-yu CAO1,Lu-xiang CHEN1

),Ze-yu YANG1,Yan LI2,Li-chi AN1,Ze-hui XU1,Peng-yu CAO1,Lu-xiang CHEN1

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.Powertrain Factory,China First Automobile Co. ,Ltd. ,Changchun 130013,China

CLC Number:

- TB534

| 1 | 王长卉. 不同构型混合动力汽车排放及发动机运行工况特性试验研究[D]. 烟台:烟台大学机电汽车工程学院, 2021. |

| Wang Chang-hui. Emissions and engine operation behaviors of hev with different topology[D]. Yantai: School of Electromechanical and Automotive Engineering, Yantai University, 2021. | |

| 2 | 孟繁忠. 齿形链啮合原理[M]. 2版. 北京:机械工业出版社, 2015. |

| 3 | 孟繁忠, 李宝林, 吕翔, 等. 汽车发动机正时链系统设计方法[J].哈尔滨工业大学学报, 2009, 41(5):121-124. |

| Meng Fan-zhong, Li Bao-lin, Lv Xiang, et al. Design method of timing chain system for automotive engine[J]. Journal of Harbin Institute of Technology, 2009, 41(5): 121-124. | |

| 4 | 程亚兵, 王洋, 李磊, 等. 汽车V型发动机用正时链传动系统的设计[J]. 吉林大学学报: 工学版, 2015,45(1): 139-144. |

| Cheng Ya-bing, Wang Yang, Li Lei, et al. Design of V type engine timing chain system[J]. Journal of Jilin University (Engineering and Technology Edition), 2015,45(1):139-144. | |

| 5 | Cheng Y B, Wang X, Liu H, et al. Research on multi-variation coupling effect of heart-shaped dual phase Hy-Vo silent chain system[J]. Advances in Engineering Software, 2017, 107: 1-6. |

| 6 | Cheng Y B, Wang Y, Li L, et al. Design method of dual phase Hy-Vo silent chain transmission system[J]. Strojniški vestnik-Journal of Mechanical Engineering, 2015, 61(4):237-246. |

| 7 | Cheng Y B, Yin S, Wang X, et al. Design and analysis of double-side meshing and dual-phase driving timing silent chain system[J]. Strojniški vestnik-Journal of Mechanical Engineering, 2016, 62(2): 127-136. |

| 8 | 李磊. 发动机正时链系统设计分析及其高速特性试验研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2015. |

| Li Lei. Design and analysis of the engine timing silent chain system and experimental study on high-speed characteristics[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2015. | |

| 9 | Stephenson R, Glennie D, Fawcett J N, et al. A method of measuring the dynamic loads in high-speed timing chains[J]. Journal of Automobile Engineering,2000, 214(2): 217-226. |

| 10 | Cheng Y B, Zhang J Y, Gao W, et al. Study on vibration and noise characteristics of rounded-jointed silent chain system[J]. Institute of Noise Control Engineering, 2018,66(4): 290-297. |

| 11 | Xi J X, Feng Z M, Wang G Q, et al. Vibration and noise source identification methods for a diesel engine[J]. Journal of Mechanical Science and Technology, 2015, 29(1): 181-189. |

| 12 | 董成国.汽车正时齿形链系统设计方法与仿真分析及试验研究[D]. 长春:吉林大学机械与航空航天工程学院,2010. |

| Dong Cheng-guo. Design method, simulation analysis and experimental study of automotive timing silent chain system[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University,2010. | |

| 13 | 刘兴恕. 混合动力电动汽车(HEV)车内振动噪声分析研究[D].天津: 天津职业技术师范大学汽车与交通学院, 2016. |

| Liu Xing-shu. Analysis and research on hybrid electric vehicle (HEV) interior vibration and noise[D]. Tianjin: School of Automobile and Transportation,Tianjin University of Technology and Education, 2016. | |

| 14 | 陈家瑞. 汽车构造[M]. 3版. 北京: 机械工业出版社, 2009. |

| 15 | 熊诗波, 黄长艺. 机械工程测试技术基础[M]. 3版. 北京: 机械工业出版社, 2006. |

| 16 | 张军跃. 基于多元变异的圆销式齿形链系统振动噪声特性研究[D]. 长春:吉林大学机械与航空航天工程学院, 2019. |

| Zhang Jun-yue. Study on vibration and noise characteristics of rounded-jointed silent chain system based on multivariate variation[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University,2019. | |

| 17 | Li B, Fan S, Zhang Y, et al. The modal analysis of roller chain drives[J]. Advanced Materials Research, 2011, 291-294: 1551-1554. |

| 18 | 高旺. 圆销式齿形链的变异设计方法研究[D]. 长春:吉林大学机械与航空航天工程学院, 2019. |

| Gao Wang. Research on variation design method of rounded-jointed silent chain[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University,2019. | |

| 19 | O'Connor W J, Mckeown D J. A new approach to modal analysis of uniform chain systems[J]. Journal of Sound and Vibration, 2008, 311(3-5): 623-632. |

| 20 | Pan M, Shieh T. Design modification for reducing silent chain annoying noise[J]. Journal of Mechanical Design, 2002, 124(4): 822-827. |

| 21 | 李增刚, 詹福良. Virtual.Lab Acoustics 声学仿真计算高级应用实例[M].北京: 国防工业出版社, 2010. |

| 22 | . 汽车加速行驶车外噪声限值及测量方法 [S]. |

| [1] | Jia-yi WANG,Xin-hui LIU,Zhan WANG,Jin-shi CHEN,Ya-fang HAN,Yu-qi WANG. Flow characteristics analysis of constant flow control valve based on AMESim [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2499-2507. |

| [2] | Shao-hua WANG,Kun CHU,De-hua SHI,Chun-fang YIN,Chun LI. Robust compound coordinated control of HEV based on finite⁃time extended state observation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1272-1281. |

| [3] | Yan-li YIN,Xue-jiang HUANG,Xiao-liang PAN,Li-tuan WANG,Sen ZHAN,Xin-xin ZHANG. Hierarchical control of hybrid electric vehicle platooning based on PID and Q⁃Learning algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1481-1489. |

| [4] | Yan YANG,Yu-qing SHI,Xiao-rong ZHANG,Guan-wei LUO. Dynamic stability analysis of a amplitude⁃limited vibration system with multiple rigid constraints [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 364-375. |

| [5] | Yun-feng HU,Bao-lin MA,Jia-mei LIN,Xun GONG,Xue-jun LI. Online optimization method of hybrid electric vehicle's engine optimal operating line [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1679-1686. |

| [6] | Yang LIU. Unloading impact simulation and test of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1292-1300. |

| [7] | Ya-bing CHENG,Lu-xiang CHEN,Ping-yu GE,Ze-yu YANG,Peng-yu CAO. Dynamic simulation analysis and wear failure of dual-phase timing bush chain [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 781-788. |

| [8] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

| [9] | Long ZHANG,Tian-peng XU,Chao-bing WANG,Jian-yu YI,Can-zhuang ZHEN. Gearbox fault diagnosis baed on convolutional gated recurrent network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 368-376. |

| [10] | Yong LUO,Yi SUI,Fu-tao SHEN,Qiang SUN,Yun-xiao DENG,Yong-heng WEI. Start up control strategy of plug in hybrid system based on double clutch transmission [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2765-2777. |

| [11] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [12] | Xiao-chao TIAN,Hai-gang WANG,Hu WANG,Zhi-cong WANG,Jian ZHAO,Zhi-gang YANG,Yue WU. Design and test of broadband power generation device with cantilever piezoelectric vibrator [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1953-1958. |

| [13] | Wei CHEN,Yu-long LEI,Xing-zhong LI,Yao FU,Jian-long HU,Li-guo HOU. Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1628-1634. |

| [14] | Jing HU,Cong LI,Bang-cheng ZHANG,Xiao-li QIAO,Xin-ming ZHANG,Xiao-ping ZHOU. Oil film stiffness and damping of double⁃decker ball bearing in consideration of centrifugal expansion [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1601-1611. |

| [15] | Zong-wei YAO,Xu-dong GAO,Gang LIU,Qiu-shi BI. Research on working performance of vertical screw stirring mill based on numerical simulations [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1642-1650. |

|