Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (2): 574-588.doi: 10.13229/j.cnki.jdxbgxb.20220380

Theory and experiment of high⁃speed seed filling in limited gear⁃shaped side space based on seeds group stress

Bin HU1,2( ),Yi-quan CAI1,Xin LUO1,2,Zi-bin MAO1,Jun-wei LI1,Meng-yu GUO1,2,Jian WANG1

),Yi-quan CAI1,Xin LUO1,2,Zi-bin MAO1,Jun-wei LI1,Meng-yu GUO1,2,Jian WANG1

- 1.College of Mechanical and Electronic Engineering,Shihezi University,Shihezi 832003,China

2.Key Laboratory of Northwest Agricultural and Rural Affairs,Shihezi University,Shihezi 832003,China

CLC Number:

- S223.2

| 1 | 卢合全, 代建龙, 李振怀, 等. 出苗期遇雨对不同播种方式棉花出苗及产量的影响[J]. 中国农业科学, 2018, 51(1): 60-70. |

| Lu He-quan, Dai Jian-long, Li Zhen-huai, et al. Effects of rainfall at emergence on stand establishment and yield of cotton under different seeding patterns[J]. Scientia Agricultura Sinica, 2018, 51(1): 60-70. | |

| 2 | 代建龙, 李振怀, 罗振, 等. 精量播种减免间定苗对棉花产量和产量构成因素的影响[J]. 作物学报, 2014, 40(11): 2040-2045. |

| Dai Jian-long, Li Zhen-huai, Luo Zhen, et al. Effects of precision seeding without thinning process on yield and yield components of cotton[J]. Acta Agronomica sinica, 2014, 40(11): 2040-2045. | |

| 3 | 康施为. 分置式棉花膜上精密播种装置的设计与试验研究[D]. 石河子: 石河子大学机械电气工程学院, 2020. |

| Kang Shi-wei. Design and experimental study of precision seeding device on split cotton membrane[D]. Shihezi: College of Mechanical and electrical Engineering, Shihezi University, 2020. | |

| 4 | 刘艳芬, 林静, 李宝筏, 等. 玉米播种机水平圆盘排种器型孔设计与试验[J]. 农业工程学报, 2017, 33(8): 37-46. |

| Liu Yan-fen, Lin Jing, Li Bao-fa, et al. Design and experiment of horizontal disc seed metering device for maize seeder[J]. Transactions of the CSAE, 2017, 33(8): 37-46. | |

| 5 | 陈玉龙,贾洪雷,王佳旭,等. 大豆高速精密播种机凸勺排种器设计与试验[J]. 农业机械学报,2017,48(8):95-104. |

| Chen Yu-long, Jia Hong-lei, Wang Jia-xu, et al. Design and experiment of scoop metering device for soybean high speed and precision seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(8): 95-104. | |

| 6 | 耿端阳,李玉环,孟鹏祥,等.玉米伸缩指夹式排种器设计与试验[J]. 农业机械学报,2016,47(5):38-45. |

| Geng Duan-yang, Li Yu-huan, Meng Peng-xiang, et al. Design and test on telescopic clip finger type of metering device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 38-45. | |

| 7 | Han D D, Zhang D X, Jing H R, et al. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed metering device[J]. Computers and Electronics in Agriculture, 2018, 150: 426-438. |

| 8 | Lei X L, Liao Y T, Zhang Q S, et al. Numerical simulation of seed motion characteristics of distribution head for rapeseed and wheat[J]. Computers and Electronics in Agriculture, 2018, 150: 98-109. |

| 9 | 高筱钧, 徐杨, 张东兴, 等. 气送式高速玉米精量排种器设计与试验[J]. 农业工程学报, 2019, 23: 9-20. |

| Gao Xiao-jun, Xu Yang, Zhang Dong-xing, et al. Design and experiment of air-assisted high speed precision maize seed metering device[J]. Transactions of the CSAE, 2019, 23: 9-20. | |

| 10 | 侯攀登. 棉花排种器的发展趋势[J]. 时代农机, 2018, 45(6): 76. |

| Hou Pan-deng. Development trend of cotton seed feeder[J]. Times Agricultural Machinery, 2018, 45(6): 76. | |

| 11 | 闫建伟, 魏松, 张富贵. 膜上精量播种装备研究现状及发展趋势[J]. 新疆农机化, 2021(2): 15-19. |

| Yan Jian-wei, Wei Song, Zhang Fu-gui. Present research status and development trend of over-film precision seeding equipment[J]. Xinjiang Agricultural Mechanization, 2021(2): 15-19. | |

| 12 | 戴飞, 赵武云, 张锋伟, 等. 西北雨养区全膜双垄沟播技术与配套机具研究进展分析[J]. 农业机械学报, 2019, 50(5): 1-16. |

| Dai Fei, Zhao Wu-yun, Zhang Feng-wei, et al. Research progress analysis of furrow sowing with whole plastic-film mulching on double ridges technology and machine in northwest rainfed area[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(5): 1-16. | |

| 13 | 王业成,邱立春,张文娇,等. 摩擦型立式圆盘精密排种器的设计与试验[J]. 农业工程学报,2012,28(1):22-26. |

| Wang Ye-cheng, Qiu Li-chun, Zhang Wen-jiao, et al. Design and experiment of friction vertical plate precision seed-metering device[J]. Transactions of the CSAE, 2012, 28(1): 22-26. | |

| 14 | 李俊伟, 罗昕, 魏敏,等. 一种型孔式棉花精量穴播器的设计及运动仿真分析[J]. 新疆农机化, 2014(1): 16-18. |

| Li Jun-wei, Luo Xin, Wei Min, et al. Design and motion simulation analysis of a type of cotton precision hole planter[J]. Xinjiang Agricultural Mechanization, 2014(1): 16-18. | |

| 15 | 李沐桐, 李天宇, 官晓东, 等. 锥盘排种器离心推送结构设计与充种机理分析[J]. 农业机械学报, 2018, 49(3): 77-85. |

| Li Mu-tong, Li Tian-yu, Guan Xiao-dong, et al. Design on push structure of centrifugal cone seed-metering device and its filling mechanism analysis[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 77-85. | |

| 16 | 王金武,唐汉,王金峰,等. 指夹式玉米精量排种器导种投送运移机理分析与试验[J]. 农业机械学报, 2017, 48(1): 29-37. |

| Wang Jin-wu, Tang Han, Wang Jin-feng, et al. Analysis and experiment of guiding and dropping migratory mechanism on pick up finger precision seed metering device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(1): 29-37. | |

| 17 | 王金武, 唐汉, 王奇, 等. 基于EDEM软件的指夹式精量排种器排种性能数值模拟与试验[J]. 农业工程学报, 2015, 31(21): 43-50. |

| Wang Jin-wu, Tang Han, Wang Qi, et al. Numerical simulation and experiment on seeding performance of pickup finger precision seed metering device based on EDEM[J]. Transactions of the CSAE, 2015, 31(21): 43-50. | |

| 18 | 王吉奎, 郭康权, 吕新民. 夹持式穴播轮种子室内种子运动分析[J]. 农业工程学报,2012,28(11):35-39. |

| Wang Ji-kui, Guo Kang-quan, Xin-min Lü. Analysis on seed movement in seed chamber of clamping dibber wheel[J]. Transactions of the CSAE, 2012, 28(11): 35-39. | |

| 19 | 王在满, 罗锡文, 黄世醒, 等. 型孔式水稻排种轮充种过程的高速摄像分析[J].农业机械学报, 2009, 40(12): 56-61. |

| Wang Zai-man, Luo Xi-wen, Huang Shi-xing, et al. Rice seeds feeding process in cell wheel based on high-speed photography technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(12): 56-61. | |

| 20 | 吕金庆, 杨颖, 李紫辉, 等. 舀勺式马铃薯播种机排种器的设计与试验[J]. 农业工程学报, 2016, 32(16): 17-25. |

| Lv Jin-qing, Yang Ying, Li Zi-hui, et al. Design and experiment of cup-belt type potato seed-metering device[J]. Transactions of the CSAE, 2016, 32(16): 17-25. | |

| 21 | 张石平, 陈进, 李耀明. 振动气吸式穴盘精量播种装置种子群“沸腾”运动分析[J]. 农业工程学报, 2008(7): 20-24. |

| Zhang Shi-ping, Chen-jin, Li Yao-ming. Analysis of seeds "boiling" motion on vibrational air-suction tray seeder[J]. Transactions of the CSAE, 2008, 24(7): 20-24. | |

| 22 | 陈玉龙. 基于有序充种方式的滚筒鸭嘴穴播器的设计研究[D]. 石河子:石河子大学机械电气工程学院, 2015. |

| Chen Yu-long. Design and research of the duckbill pattern roller dibbler based on characteristics of ordered system[D]. Shihezi: College of Mechanical and Electrical Engineering, Shihezi University, 2015. | |

| 23 | 都鑫,刘彩玲,姜萌, 等. 自扰动内充型孔轮式玉米精量排种器设计与试验[J]. 农业工程学报,2019,35(13):23-34. |

| Du Xin, Liu Cai-ling, Jiang Meng, et al. Design and experiment of self-disturbance inner-filling cell wheel maize precision seed-metering device[J]. Transactions of the CSAE, 2019, 35(13): 23-34. | |

| 24 | 周勇, 胡梦杰, 夏俊芳, 等. 内充种组合型孔式播量可调棉花精量排种器设计与试验[J]. 农业工程学报,2018,34(18):59-67. |

| Zhou Yong, Hu Meng-jie, Xia Jun-fang, et al. Design and experiment of inside-filling adjustable precision seed-metering device with combined hole for cotton[J]. Transactions of the CSAE, 2018, 34(18): 59-67. | |

| 25 | 刘彩玲, 王超, 宋建农, 等. 振动供种型孔轮式非圆种子精密排种器设计与试验[J]. 农业机械学报, 2018, 49(5): 108-115. |

| Liu Cai-ling, Wang Chao, Song Jian-nong, et al. Design and seed-filling test of cell-type precision seed-metering device with vibration technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(5): 108-115. | |

| 26 | 李玉华,张智龙,李天华,等. 轮勺式大蒜单粒取种装置设计与试验[J]. 农业机械学报,2020,51(3):61-68. |

| Li Yu-hua, Zhang Zhi-long, Li Tian-hua, et al. Design and experiment of wheel-spoon type garlic precision seed-picking device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(3): 61-68. | |

| 27 | 胡斌, 陈玉龙, 李苗苗, 等. 一种并排双腔式滚筒排种器[P]. 新疆: CN103749048A, [2014-04-30]. |

| Hu Bin, Chen Yu-long, Li Miao-miao, et al. A side-by-side double-chamber roller seed feeder: China [P]. | |

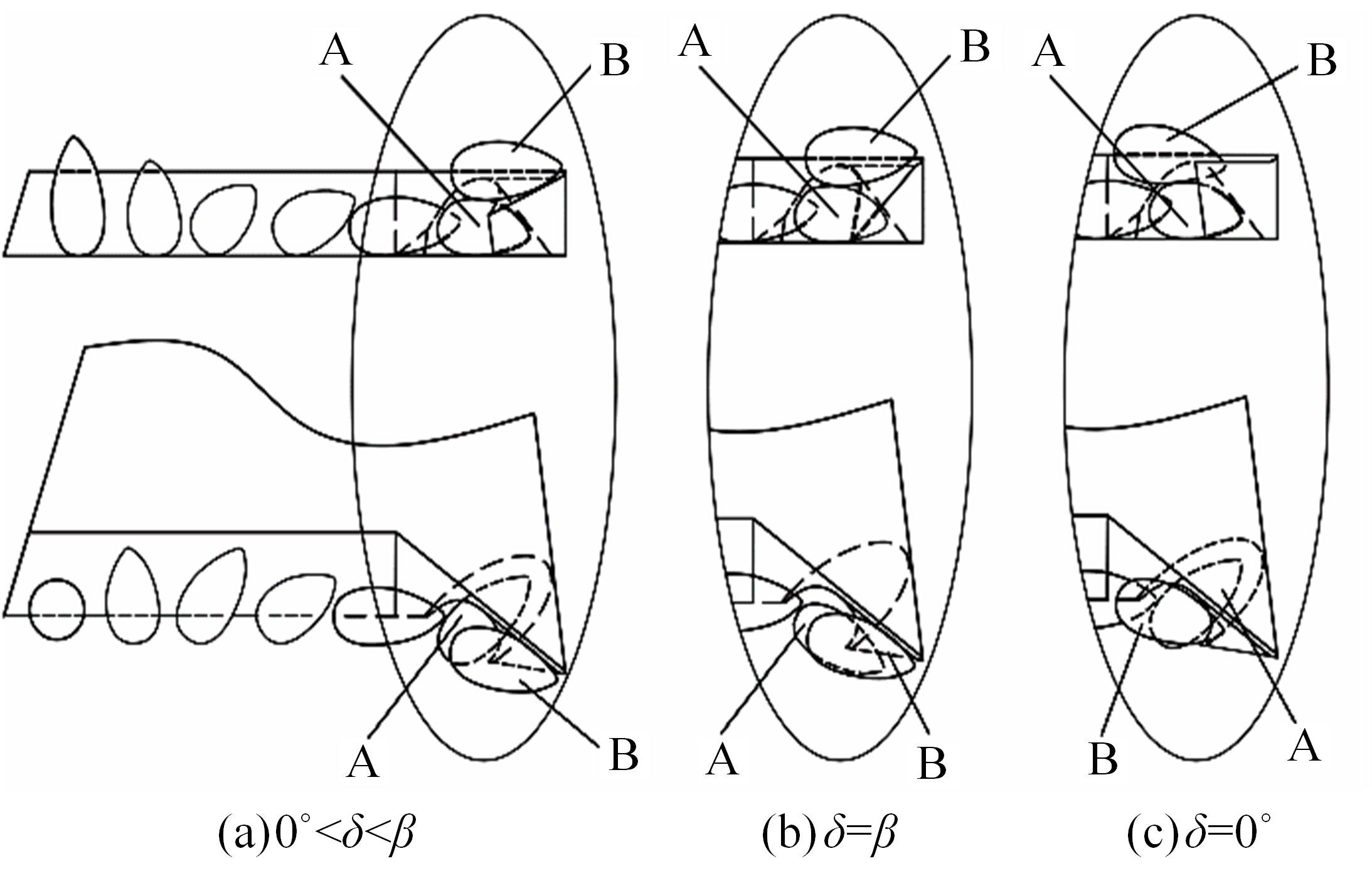

| 28 | 李俊伟, 胡斌, 罗昕, 等. 型孔式棉花精量穴播器滚落清种过程的理论分析与仿真[J]. 中国机械工程, 2011, 22(19): 2344-2348. |

| Li Jun-wei, Hu Bin, Luo Xin, et al. Theoretical analysis and simulation in rolling seed clearing process of hole-type cotton accurate device[J]. China Mechanical Engineering, 2011, 22(19): 2344-2348. | |

| 29 | 李成华, 夏建满, 何波. 倾斜圆盘勺式精密排种器投种过程分析[J]. 农业机械学报, 2005, 36(3): 50-58. |

| Li Cheng-hua, Xia Jian-man, He Bo. Analysis of seed throwing procedure by declined scop metering device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(3): 50-58. | |

| 30 | 丁力, 杨丽, 张东兴, 等. 气吸式排种器卸种机构设计与试验[J]. 农业机械学报, 2020, 51(1): 37-46. |

| Ding Li, Yang Li, Zhang Dong-xing, et al. Design and test of unloading mechanism of air-suction seed metering device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(1): 37-46. | |

| 31 | 中国农业机械化科学研究院.农业机械设计手册[M]. 北京: 中国农业科学技术出版社,2007. |

| 32 | 顿国强, 刘文辉, 毛宁, 等.交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报: 工学版, 2023, 53(1): 285-296. |

| Guo-qiang Dun, Liu Wen-hui, Mao Ning, et al. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 285-296. | |

| 33 | 张青松,余琦,王磊,等. 油菜勺式精量穴播排种器设计与试验[J]. 农业机械学报,2020,51(6):47-54. |

| Zhang Qing-song, Yu Qi, Wang Lei, et al. Design and experiment of a spoon type precision hole seeding and metering device for rape[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 47-54. | |

| 34 | 李娟娟, 张和平, 毕新胜, 等. 转轴型孔式精量排种器充种性能仿真分析与试验[J]. 农业工程学报, 2020, 36(5): 38-49. |

| Li Juan-juan, Zhang He-ping, Bi Xin-sheng, et al. Simulation analysis and test on the filling performance of rotary type-hole precision seed-metering device for cotton[J]. Transactions of the CSAE, 2020, 36(5): 38-49. | |

| 35 | 张波屏. 播种机械设计原理[M]. 北京:机械工业出版社,1982. |

| 36 | 刘彩玲,王亚丽,都鑫,等. 摩擦复充种型孔带式水稻精量排种器充种性能分析与验证[J]. 农业工程学报,2019,35(4):29-36. |

| Liu Cai-ling, Wang Ya-li, Du Xin, et al. Filling performance analysis and verification of cell-belt rice precision seed-metering based on friction and repeated filling principle[J]. Transactions of the CSAE, 2019, 35(4): 29-36. | |

| 37 | 张学军,陈勇,史增录,等. 双仓转盘式棉花竖直圆盘穴播排种器设计与试验[J]. 农业工程学报,2021,37(19):27-36. |

| Zhang Xue-jun, Chen Yong, Shi Zeng-lu, et al. Design and experiment of double-storage turntable cotton vertical disc hole seeding and metering device[J]. Transactions of the CSAE, 2021, 37(19): 27-36. | |

| 38 | 曹成茂, 秦宽, 王安民, 等. 水稻直播机气吹辅助勺轮式排种器设计与试验[J]. 农业机械学报, 2015, 46(1): 66-72. |

| Cao Cheng-mao, Qin Kuan, Wang An-min, et al. Design and experiment on rice hill seeder with air-blowing special hole and scoop-wheel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(1): 66-72. | |

| 39 | 张春艳, 康建明, 彭强吉, 等.棉花气吸滚筒式穴播器二次投种机构设计与试验[J]. 农业机械学报, 2021, 52(6): 106-116. |

| Zhang Chun-yan, Kang Jian-ming, Peng Qiang-ji, et al. Design and test of seed feeding mechanism of air-suction roller dibbler for cotton[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(6): 106-116. | |

| 40 | 倪向东, 徐国杰, 王琦, 等. 气吸滚筒阵列式棉花精密排种器设计与试验[J]. 农业机械学报, 2017, 48(12): 58-67. |

| Ni Xiang-dong, Xu Guo-jie, Wang Qi, et al. Design and experiment of pneumatic cylinder array precision seed-metering device for cotton[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12): 58-67. |

| [1] | Xiao HAN,Xian-zhang LING,Shuang TIAN,Sheng-yi CONG. Analysis and control of mud spillover in high⁃speed railway ballast⁃track subgrade caused by grouting [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 506-515. |

| [2] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [3] | Yang LIU. Calculation method of anti-backward-tilting buffer force of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2785-2794. |

| [4] | Yong-hui SHANG,Lin-rong XU,Zhao-feng CHEN. Consolidation characteristics and influencing factors of rigid pile-raft foundation of high-speed railway [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1588-1597. |

| [5] | Li-heng WANG,Ming ZHUANG,Kai YUAN. Design of high speed motor power conversion system based on intelligent control algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 934-941. |

| [6] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

| [7] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [8] | Wei CHEN,Yu-long LEI,Xing-zhong LI,Yao FU,Jian-long HU,Li-guo HOU. Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1628-1634. |

| [9] | Zhen GUO,Hong-ying YU,Zhong-xin HUA,Di ZHAO. Kinematic analysis and simulation of folding process for rigid origami mechanisms [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 66-76. |

| [10] | Qing⁃ying LAI,Jun LIU,Ruo⁃yu ZHAO,Yong⁃ji LUO,Ling⁃yun MENG,Ya⁃zhi XU. Optimal trajectory planning for middle⁃to⁃high speed maglev based on dynamic programming with mutative spacing [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 749-756. |

| [11] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

| [12] | TIAN Wei-jun, WANG Ji-yue, LI Ming, ZHANG Xing-wang, ZHANG Yong, CONG Qian. Observation of locomotion of water strider towards water strider robot [J]. 吉林大学学报(工学版), 2018, 48(3): 812-820. |

| [13] | HOU Ping-ping, WANG Li-qin, BAI Ying-cun, PENG Qiu-yang, HAO Ting. Effect of grease filling amount on the performance of bearing in high speed motorized spindle [J]. 吉林大学学报(工学版), 2017, 47(2): 518-523. |

| [14] | ZHU Yu-hong, CHEN He-xin. Design of the multimedia terminal circuit and analysis of the signal integrity [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 398-401. |

| [15] | CHU Liang, WANG Yan-bo, QI Fu-wei, ZHANG Yong-sheng. Control method of inlet valves for brake pressure fine regulation [J]. 吉林大学学报(工学版), 2013, 43(03): 564-570. |

|

||