Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (6): 2096-2107.doi: 10.13229/j.cnki.jdxbgxb20200591

Eccentric compression behavior of bamboo⁃plywood and steel⁃tube dual⁃confined dust⁃powder concrete columns

Jing ZHOU1,2( ),Ya-jun LI1,Wei-feng ZHAO1,Zong-jian LUO1,Guo-bin BU3

),Ya-jun LI1,Wei-feng ZHAO1,Zong-jian LUO1,Guo-bin BU3

- 1.College of Civil Engineering and Mechanics,Xiangtan University,Xiangtan 411105,China

2.State Key Laboratory of Subtropical Building Science,South China University of Technology,Guangzhou 510640,China

3.College of Civil Engineering,Hunan University of Technology,Zhuzhou 412007,China

CLC Number:

- TU398.9

| 1 | Dehwah H A F.Mechanical properties of self-compacting concrete incorporating quarry dust powder,silica fume or fly ash[J]. Construction and Building Materials, 2011, 26(1):547-551. |

| 2 | Saghafi B, Nageim H A, Atherton W. Mechanical behavior of a new base material containing high volumes of limestone waste dust, PFA, and APC residues[J]. Journal of Materials in Civil Engineering, 2013, 25(4):450-461. |

| 3 | Kandolkar S, Mandal J. Behavior of reinforced stone dust walls under strip loading[J]. Advances in Civil Engineering Materials, 2015, 4(1):1-30. |

| 4 | Singh S, Nagar R, Agrawal V. A review on properties of sustainable concrete using granite dust as replacement for river sand[J]. Journal of Cleaner Production, 2016, 126(10):74-87. |

| 5 | Febin G K, Abhirami A, Vineetha A K, et al. Strength and durability properties of quarry dust powder incorporated concrete blocks[J]. Construction and Builing Materials, 2019, 228:1-9. |

| 6 | 郑大为, 韩红静, 郝连学. 回收粉尘的掺量对水泥稳定碎石基层的影响研究[J]. 硅酸盐通报, 2017, 36(7):2476-2480, 2491. |

| Zheng Da-wei, Han Hong-jing, Hao Lian-xue. Influence of the amount of recycled dust on cement stabilized crushed stone base[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(7):2476-2480, 2491. | |

| 7 | Xiao Y, Chen G, Feng L. Experimental studies on roof trusses made of glubam[J]. Materials and Structures, 2014, 47(11):1879-1890. |

| 8 | Xu Q F, Chen L Z, Harries K A. et al. Combustion performance of engineered bamboo from cone calorimeter tests[J]. European Journal of Wood and Wood Products, 2017, 75(2):161-173. |

| 9 | Huang D S, Bian Y L, Zhou A P, et al. Experimental study on stress-strain relationships and failure mechanisms of parallel strand bamboo made from Phyllostachys[J].Construction and Building Materials, 2015, 77:130-138. |

| 10 | 马丽, 周凌, 何慧, 等. 竹粉高温蒸煮对竹粉/ABS木塑复合材料性能的影响[J]. 吉林大学学报:工学版, 2011, 41():205-209. |

| Ma Li, Zhou Ling, He Hui, et al. Effect on properties of bamboo/ABS composites by high-temperature cooking of bamboo[J]. Journal of Jilin University(Engineering and Technology Edition), 2011, 41(Sup.2):205-209. | |

| 11 | Yu D, Tan H, Ruan Y. A future bamboo-structure residential building prototype in China:life cycle assessment of energy use and carbon emission[J]. Energy and Buildings, 2011, 43(10):2638-2646. |

| 12 | Sharma B, Gatoo A, Bock M, et al. Engineered bamboo for structural applications[J]. Construction and Building Materials, 2015, 81:66-73. |

| 13 | 李海涛, 张齐生, 吴刚, 等. 竹集成材研究进展[J]. 林业工程学报, 2016, 1(6):10-16. |

| Li Hai-tao, Zhang Qi-sheng, Wu Gang, et al. A review on development of laminated bamboo lumber[J]. Journal of Forestry Engineering, 2016, 1(6):10-16. | |

| 14 | 肖岩, 杨瑞珍, 单波, 等. 结构用胶合竹力学性能试验研究[J]. 建筑结构学报, 2012, 33(11):150-157. |

| Xiao Yan, Yang Rui-zhen, Shan Bo, et al. Experimental research on mechanical properties of glubam[J]. Journal of Building Structures, 2012, 33(11):150-157. | |

| 15 | Sharma B, Gatóo A, Ramage M H. Effect of processing methods on the mechanical properties of engineered bamboo[J]. Construction and Building Materials, 2015, 83:95-101. |

| 16 | 郭楠, 张平阳, 左煜, 等. 竹板增强胶合木梁受弯性能[J]. 吉林大学学报: 工学版, 2017, 47(3):778-788. |

| Guo Nan, Zhang Ping-yang, Zuo Yu, et al. Bending performance of glue-lumber beam reinforced by bamboo plyboard[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(3):778-788. | |

| 17 | Yu W K, Chung K F, Chan S L. Axial buckling of bamboo columns in bamboo scaffolds[J]. Engineering Structures, 2005, 27(1):61-73. |

| 18 | Lugt P, Dobbelsteen A A J F, Janssen J J A. An environmental,economic and practical assessment of bamboo as a building material for supporting structures[J]. Construction and Builing Materials, 2006, 20(9):648-656. |

| 19 | He M J, Li Z,Sun Y L, et al. Experimental investigations on mechanical properties and column buckling behavior of structural bamboo[J]. Structural Design of Tall and Special Buildings, 2015, 24(7):491-503. |

| 20 | Tian L M, Kou Y F, Hao J P. Axial compressive behaviour of sprayed composite mortar-original bamboo composite columns[J]. Construction and Building Materials, 2019, 215:726-736. |

| 21 | Li H, Su J W, Zhang Q, et al. Mechanical performance of laminated bamboo column under axial compression[J]. Composites Part B: Engineering, 2015, 79:374-382. |

| 22 | Li H T, Liu R, Lorenzo R, et al. Eccentric compression properties of laminated bamboo columns with different slenderness ratios[J]. Proceedings of the Institution of Civil Engineers:Structures and Buildings, 2019, 172(5):315-326. |

| 23 | 魏洋, 周梦倩, 袁礼得. 重组竹柱偏心受压力学性能[J]. 复合材料学报,2016,33(2):379-385. |

| Wei Yang, Zhou Meng-qian, Yuan Li-de. Mechanical performance of glulam bamboo columns under eccentric loading[J]. Acta Materiae Compositae Sinica, 2016, 33(2):379-385. | |

| 24 | Xiao Y, Zhou Q, Shan B. Design and construction of modern bamboo bridges [J]. Journal of Bridge Engineering, 2010, 15(5):533-541. |

| 25 | Li H T, Chen G, Zhang Q S, et al. Mechanical properties of laminated bamboo lumber column under radial eccentric compression[J]. Construction and Building Materials, 2016, 121:644-652. |

| 26 | 李冀, 陈思甜, 孟旭. 箍筋增强型胶合竹柱抗压试验[J]. 林业科技开发, 2014, 28(4):113-115. |

| Li Ji, Chen Si-tian, Meng Xu. Compression test of stirrup reinforced glued bamboo columns[J]. China Forestry Science and Technology, 2014, 28(4): 113-115. | |

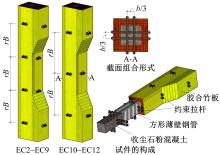

| 27 | 赵卫锋, 张武东, 周靖, 等. 薄壁方型钢管/竹胶板组合空芯柱轴心抗压性能[J]. 农业工程学报, 2014, 30(6):37-45. |

| Zhao Wei-feng, Zhang Wu-dong, Zhou Jing, et al. Axial compression behavior of square thin-walled steel tube/laminated bamboo composite hollow column [J]. Transactions of Chinese Society of Agricultural Engineering, 2014, 30(6):37-45. | |

| 28 | 赵卫锋, 谷伟, 周靖, 等. 带约束拉杆钢管/竹胶板组合空芯短柱的偏心抗压性能[J]. 农业工程学报, 2016, 32(15):75-82. |

| Zhao Wei-feng, Gu Wei, Zhou Jing, et al. Eccentric compression behavior of thin-walled steel-tube/bamboo-plywood assembling short hollow column with binging bars[J]. Transactions of Chinese Society of Agricultural Engineering, 2016, 32(15):75-82. | |

| 29 | Zhao W F, Yang B, Zhou J. Axial compressive creep behaviour of a square steel tube/bamboo plywood composite column with binding bars[J]. Wood Research, 2019, 64(2):223-236. |

| 30 | 解其铁, 张王丽, 蒋天元, 等. 钢-竹组合柱轴心受压性能的试验研究[J]. 工程力学, 2012, 29():221-225. |

| Xie Qi-tie, Zhang Wang-li, Jiang Tian-yuan, et al. Experimental study on performance of steel-bamboo composite column under axial compression[J]. Engineering Mechanics, 2012, 29(Sup.2):221-225. | |

| 31 | . 金属材料室温拉伸试验方法[S]. |

| 32 | . 木结构试验方法标准[S]. |

| 33 | Park R, Priestley M J N, Gill W D.Ductility of square-confined concrete columns[J]. Journal of the Structural Division, 1982,108(4): 929-950. |

| 34 | . 木结构设计标准[S]. |

| [1] | Chang-jun ZHONG,Zhong-bin WANG,Chen-yang LIU. Influencing factors and structural optimization of main cable saddle bearing capacity of suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2068-2078. |

| [2] | Guang-tai ZHANG,Lu-yang ZHANG,Guo-hua XING,Yin-long CAO,Bao YI. Seismic performance of steel⁃polypropylene hybrid fiber reinforced concrete shear wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 946-955. |

| [3] | Liu LIU,Wei-xing FENG. Field measurement and calculation analysis of tunnel shield tunnel construction based on NNBR model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 245-251. |

| [4] | Wei-xiao XU,Yang CHENG,Wei-song YANG,Jia-chang JU,De-hu YU. Quasi-static test of RC frame-seismic wall dual structural system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 268-277. |

| [5] | De-shan SHAN,Xiao ZHANG,Xiao-yu GU,Qiao LI. Analytical method for elongation of stayed-cable with catenary configuration [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 217-224. |

| [6] | Su-duo XUE,Jian LU,Xiong-yan LI,Ren-jie LIU. Influence of grid⁃jumping arrangement on static and dynamic performance of annular crossed cable⁃truss structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1687-1697. |

| [7] | Bo WANG,Yuan-zheng DONG,Li-xin DONG. Calculation of basic wind pressure based on short⁃term wind speed data [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1739-1746. |

| [8] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [9] | Peng-hui WANG,Hong-xia QIAO,Qiong FENG,Hui CAO,Shao-yong WEN. Durability model of magnesium oxychloride-coated reinforced concrete under the two coupling factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 191-201. |

| [10] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [11] | Jun ZHANG,Cheng QIAN,Chun⁃yan GUO,Yu⁃jun QIAN. Dynamic design of building livability based on multi⁃source spatiotemporal data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1169-1173. |

| [12] | Ning⁃hui LIANG,Qing⁃xu MIAO,Xin⁃rong LIU,Ji⁃fei DAI,Zu⁃liang ZHONG. Determination of fracture toughness and softening traction⁃separation law of polypropylene fiber reinforced concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1144-1152. |

| [13] | Lei ZHANG,Bao⁃guo LIU,Zhao⁃fei CHU. Model test of the influence on shield shaft owing to water loss settlement of deep sandstone aquifer layer [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 788-797. |

| [14] | ZHENG Yi-feng, ZHAO Qun, BAO Wei, LI Zhuang, YU Xiao-fei. Wind resistance performance of long-span continuous rigid-frame bridge in cantilever construction stage [J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [15] | NI Ying-sheng, SUN Qi-xin, MA Ye, XU Dong. Calculation of capacity reinforcement about composite box girder with corrugated steel webs based on tensile stress region theory [J]. 吉林大学学报(工学版), 2018, 48(1): 148-158. |

|

||