Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2484-2494.doi: 10.13229/j.cnki.jdxbgxb.20221478

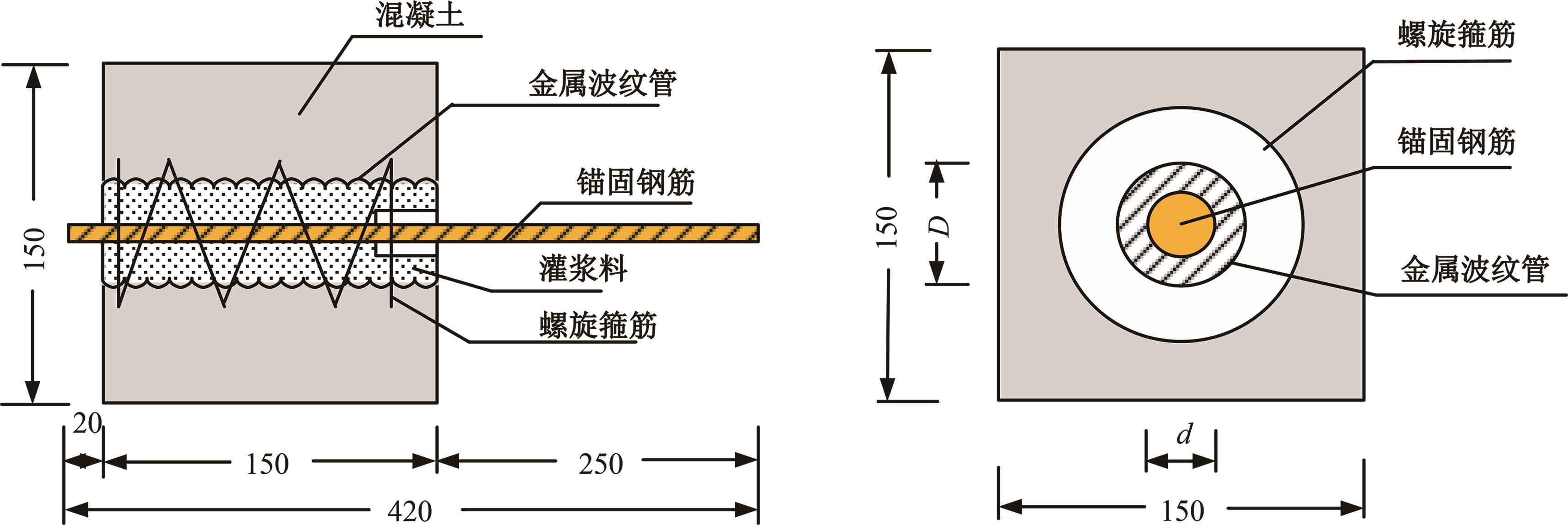

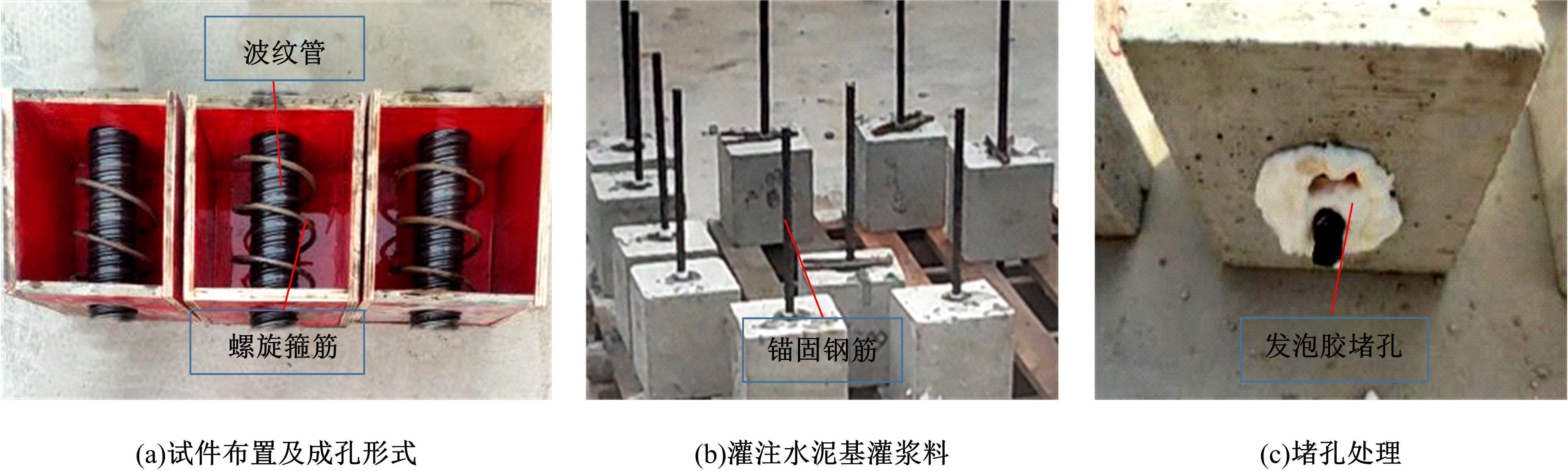

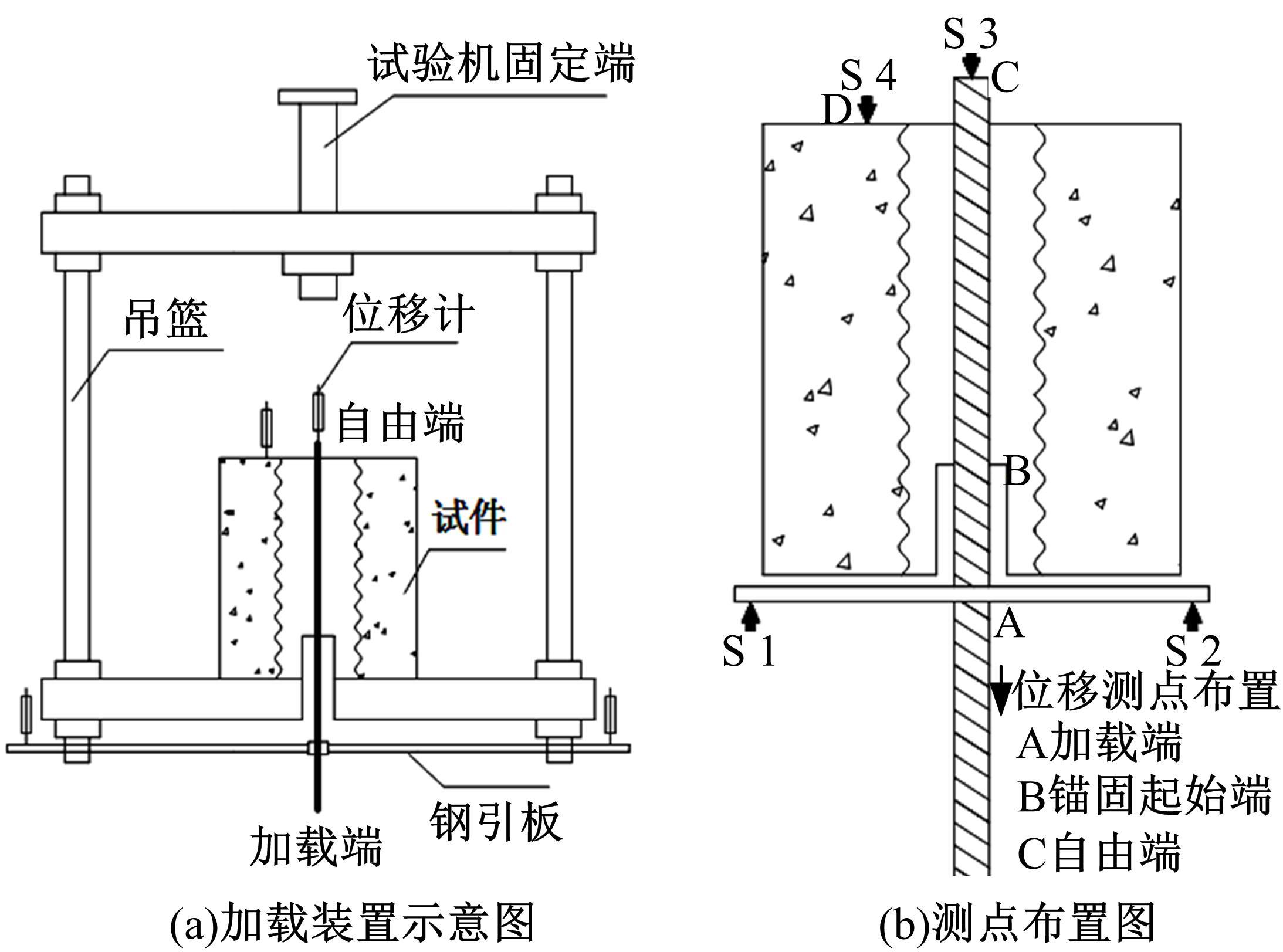

Experiment on anchoring performance of spiral stirrup-corrugated pipe grout splicing

Jin-quan ZHAO1,2( ),Long ZHOU1,Yong-gang DING1,2(

),Long ZHOU1,Yong-gang DING1,2( ),Rong-ji ZHU3

),Rong-ji ZHU3

- 1.College of Civil Engineering,Henan University of Technology,Zhengzhou 450001,China

2.Henan Key Laboratory of Grain Storage Facility and Safety,Zhengzhou 450001,China

3.Design Institute,Zhejiang Southeast Space Frame Co. ,Ltd. ,Hangzhou 311209,China

CLC Number:

- TU375

| 1 | 郭家旭, 胡少伟, 齐浩, 等. 考虑灌浆料龄期的钢筋-金属波纹管浆锚连接锚固性能试验研究[J]. 土木与环境工程学报, 2024, 46(2):108-116. |

| Guo Jia-xu, Hu Shao-wei, Qi Hao, et al. Experimental study on anchorage property of rebar-metallic bellows slurry anchor connection considering grout age[J]. Journal of Civil and Environmental Engineering, 2024, 46(2):108-116. | |

| 2 | 毛小勇, 高奕昕. 约束浆锚搭接连接高温性能试验研究[J]. 建筑结构学报, 2020, 41(7): 117-123. |

| Mao Xiao-yong, Gao Yi-xin. Experimental research on connection performance of restraint grouting-anchoring over lap-joint of steel bar subjected to high temperature[J]. Journal of Building Structures, 2020, 41(7): 117-123. | |

| 3 | 李宪军, 邓美林, 何廷树. 装配式建筑套筒灌浆连接系统膨胀约束关键技术研究[J]. 建筑结构, 2021, 51(9): 43-48. |

| Li Xian-jun, Deng Mei-lin, He Ting-shu. Research on the key technology of restrained expansion of the sleeve grouting connection system in prefabricated building[J]. Building Structure, 2021, 51(9): 43-48. | |

| 4 | Chen J, Chen X L, Ding F X, et al. Mechanical performance of overlap connections with grout-filled anchor reinforcements in embedded metal corrugated pipe[J]. Archives of Civil and Mechanical Engineering, 2020, 20(4): No.128. |

| 5 | Hosseini S J A, Rahman A B A. Efects of spiral confnement to the bond behavior of deformed reinforcement bars subjected to axial tension[J]. Engineering Structures, 2016(112): 1-13. |

| 6 | 陈云钢, 刘家彬, 郭正兴, 等. 预制混凝土结构波纹管浆锚钢筋锚固性能试验研究[J]. 建筑技术, 2014, 45(1): 65-67. |

| Chen Yun-gang, Liu Jia-bin, Guo Zheng-xing, et al. Experimental study on grouting connection in bellows for steel bar anchorage of precast concrete strucure[J]. Architecture Technology, 2014, 45(1): 65-67. | |

| 7 | 余琼, 许雪静, 尤高帅. 带肋钢筋与灌浆料黏结性能试验[J]. 哈尔滨工业大学学报, 2017, 49(12): 91-101. |

| Yu Qiong, Xu Xue-jing, You Gao-shuai. Experimental study on bond behavior for ribbed steel bars and grout[J]. Journal of Harbin Institute of Technology, 2017, 49(12): 91-101. | |

| 8 | 王浩, 柳家为, 石棚, 等. 钢筋-金属波纹管灌浆连接的锚固性能试验研究[J]. 东南大学学报, 2020, 50(2): 215-221. |

| Wang Hao, Liu Jia-wei, Shi Peng, et al. Experimental study on anchorage performance ofrebar-corrugated metal duct for grout splicing[J]. Journal of Southeeast University, 2020, 50(2): 215-221. | |

| 9 | 陈俊, 肖岩, 尹齐. 预埋波纹套管的钢筋-高强浇筑料黏结锚固性能试验研究[J]. 建筑结构学报, 2015, 36(7): 140-147. |

| Chen Jun, Xiao Yan, Yin Qi. Bonding strength of rebar anchorage in embedded corrugated sleeve with high strength grout[J]. Journal of Building Structures, 2015, 36(7): 140-147. | |

| 10 | Chen J, Zhao C H, Ding F X, et al. Mechanical performance of the grouted lapped double reinforcements anchored in embedded corrugated sleeves[J]. Structures, 2020, 28: 1354-1365. |

| 11 | 姜洪斌, 张海顺, 刘文清, 等. 预制混凝土结构插入式预留孔灌浆钢筋锚固性能[J]. 哈尔滨工业大学学报, 2011, 43(4): 28-31, 36. |

| Jiang Hong-bin, Zhang Hai-shun, Liu Wen-qing, et al. Experimental study on plug-in filling hole for steel bar anchorage of the PC structure[J]. Journal of Harbin Institute of Technology, 2011, 43(4): 28-31, 36. | |

| 12 | Zheng Y F, Zhu Z F, Guo Z X, et al. Behavior and splice length of deformed bars lapping in spirally confined grout-filled corrugated duct[J]. Advances in Materials Science and Engineering, 2019, 2019: 1-11. |

| 13 | Ma C F, Jiang H B, Wang Z Y. Experimental investigation of precast RC interior beam-column-slab joints with grouted spiral-confined lap connection[J]. Engineering Structures, 2019, 196: No. 109317. |

| 14 | Hosseini S J A, Rahman A B A, Osman M H,et al. Bond behavior of spirally confined splice of deformed bars in grout[J]. Construction and Building Materials, 2015, 80: 180-194. |

| 15 | 葛继平, 夏樟华, 江恒. 灌浆波纹管装配式桥墩双向拟静力试验[J].中国公路学报, 2018, 31(12): 221-230, 266. |

| Ge Ji-ping, Xia Zhang-hua, Jiang Heng. Biaxial quasi-static eperiment of precast segmengtal bridge piers with grouting corrugated pipe connection[J]. China Journal of Highway and Transport, 2018, 31(12): 221-230, 266. | |

| 16 | 陈昕, 刘明, 姚大鹏, 等. 考虑波纹管组合钢筋浆锚搭接长度的装配式剪力墙拟静力试验[J]. 大连理工大学学报, 2016, 56(6): 616-623. |

| Chen Xin, Liu Ming, Yao Da-peng, et al. Quasi-static experiments on lap length of precast shear walls assembled with reinforcement grouting anchor connection and corrugated pipes[J]. Journal of Dalian University of Technology, 2016, 56(6): 616-623. | |

| 17 | 陈昕, 李家旭, 杨永生, 等. 预埋波纹管单排钢筋浆锚连接的预制剪力墙抗震性能研究[J]. 沈阳建筑大学学报, 2021, 37(5): 814-822. |

| Chen Xin, Li Jia-xu, Yang Yong-sheng, et al. Research on seismic performance of precast shear wall connected by embedded corrugated pipe and single row of steel bars[J]. Journal of Shenyang Jianzhu University, 2021, 37(5): 814-822. | |

| 18 | .普通混凝土力学性能试验方法标准 [S]. |

| 19 | .水泥基灌浆材料应用技术规范 [S]. |

| 20 | 余琼, 孙佳秋, 袁炜航. 带肋钢筋与套筒约束灌浆料黏结性能试验[J]. 哈尔滨工业大学学报, 2018, 50(12): 98-106. |

| Yu Qiong, Sun Jia-qiu, Yuan Wei-hang. Experimental study on bond behavior between ribbed steel bars and sleeve constrained grouting matrrial[J]. Journal of Harbin Institute of Technology, 2018, 50(12): 98-106. | |

| 21 | 徐有邻, 沈文都, 汪洪. 钢筋砼粘结锚固性能的试验研究[J]. 建筑结构学报, 1994(3): 26-37. |

| Xu You-lin, Shen Wen-du, Wang Hong. An experimental study of bond-anchorage properties of bars in concrete[J]. Journal of Building Structures, 1994(3): 26-37. | |

| 22 | . 混凝土结构设计规范 [S]. |

| 23 | ACI318—14. Building code requirements for structural concrete [S]. |

| 24 | 山显彬. 变形钢筋与自密实混凝土之间粘结锚固性能试验研究[D]. 哈尔滨: 哈尔滨工业大学土木工程学院, 2008. |

| Shan Xian-bin. Experimental research on bonding prop-erties between deformed bars and self-compacting concrete[D]. Harbin: School of Civil Engineering, Harbin Institute of Technology, 2008. |

| [1] | Wei-song YANG,An ZHANG,Wei-xiao XU,Hai-sheng LI,Ke DU. Seismic performance of stiffness enhanced metal coupling beam damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2469-2483. |

| [2] | Qi-wu YAN,Zhong-liang ZOU. Hybrid algorithm for seismic energy-dissipated structures based on optimal placement of dampers [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2267-2274. |

| [3] | Feng-guo JIANG,Yu-ming ZHOU,Li-li BAI,Shuang LIANG. Improved krill algorithm and its application in structural optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2256-2266. |

| [4] | Guang-tai ZHANG,Cheng-xiao ZHOU,Shi-tuo LIU. Restoring force model of fiber lithium slag concrete column in saline soil environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1944-1957. |

| [5] | Yan-song DIAO,Yi-jian REN,Yuan-qiang YANG,Ling-yun ZHAO,Xiu-li LIU,Yun LIU. Experimental on seismic performance of replaceable splicing steel beam-column joints with friction energy dissipation components [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1643-1656. |

| [6] | Xue-ping FAN,Yue-fei LIU. Bridge extreme stress dynamic prediction based on improved Gaussian mixed particle filter new algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1038-1044. |

| [7] | Yi-fan LIU,Zhi-wei MIAO,Chen SHEN,Xiang-dong GENG. Evaluation of mechanical properties of non-uniform corroded rebars based on Monte Carlo method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1007-1015. |

| [8] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Time⁃variant reliability analysis of bridge members based on Gaussian Copula⁃Bayesian dynamic models [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 485-493. |

| [9] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Multi⁃process Bayesian dynamic combinatorial prediction of time⁃variant reliability for bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2332-2338. |

| [10] | Er-gang XIONG,Zhong-wen GONG,Jia-ming LUO,Tuan-jie FAN. Experiment on cracks in reinforced concrete beams based on digital image correlation technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1094-1104. |

| [11] | Xiao-dong WANG,Ning-jing LI,Qiang LI. Experimental on crushing of concrete beams by high⁃voltage pulse discharge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 496-504. |

| [12] | Ya-chuan KUANG,Li-bin CHEN,Chao-ju LI,Yu-hao HE. Analysis of mechanical properties of stud shear connectors [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 538-546. |

| [13] | Li-zhao DAI,Liang ZHOU,Xiao-wen YANG,Lei WANG. Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on connector element [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2886-2896. |

| [14] | Yun-peng CHU,Xin-hui SUN,Ming LI,Yong YAO,Han-jie HUANG. Wind pressures on a circular hyperbolic⁃paraboloid roof subjected to a simulated downburst [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1826-1833. |

| [15] | Yong YAO,Liu-feng SU,Ming LI,Yun-peng CHU,Han-jie HUANG. Wind load characteristics of double⁃sided spherical shell roof under downburst [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 615-625. |

|

||