Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2568-2580.doi: 10.13229/j.cnki.jdxbgxb.20221403

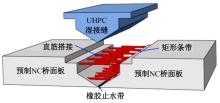

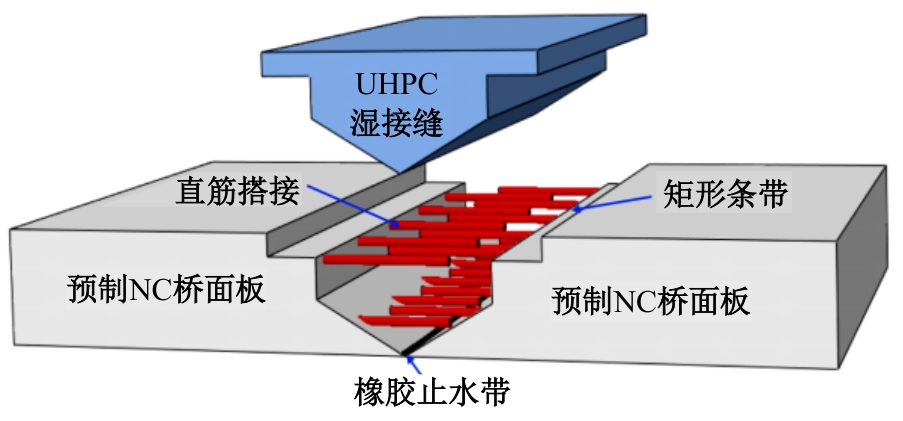

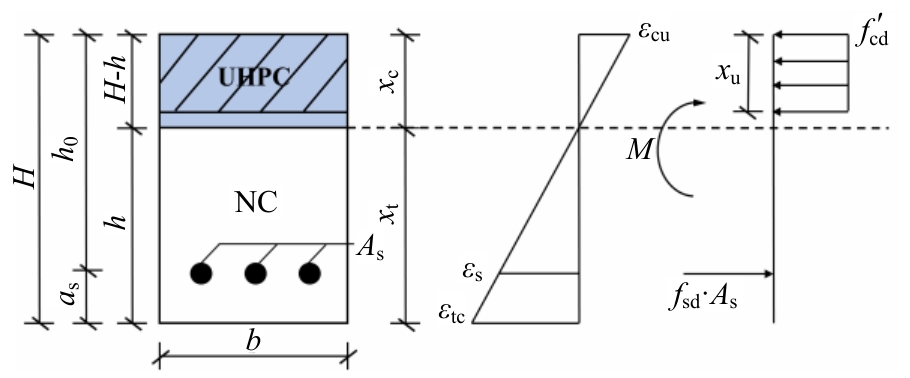

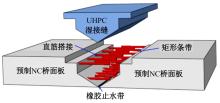

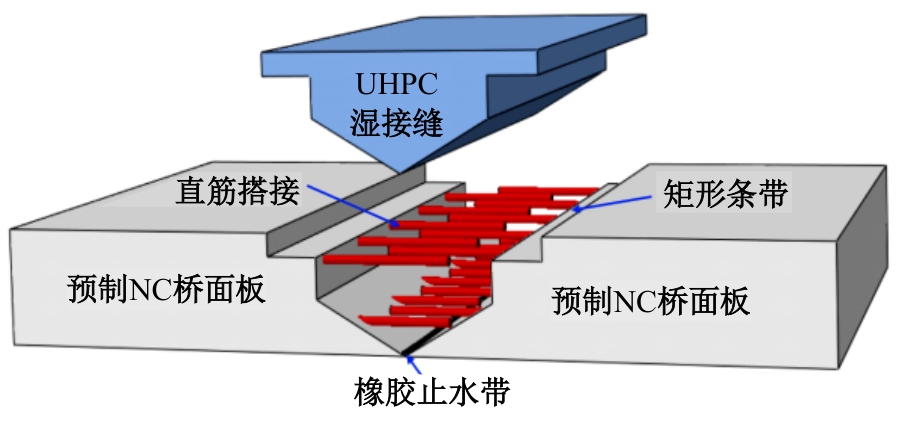

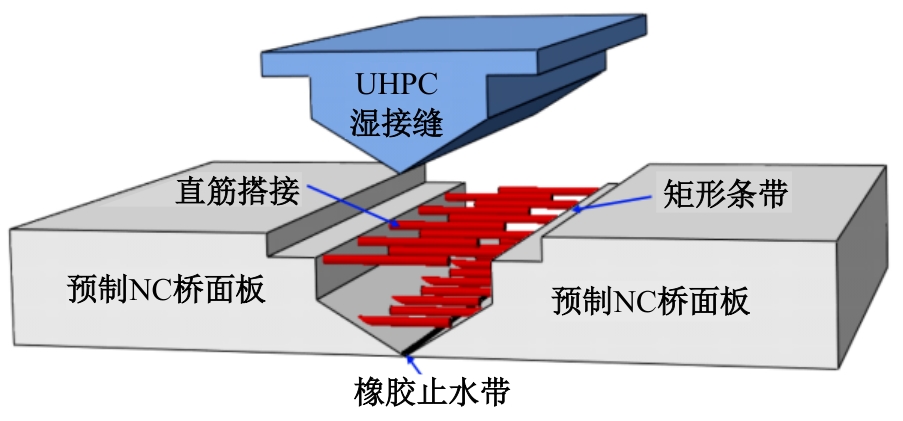

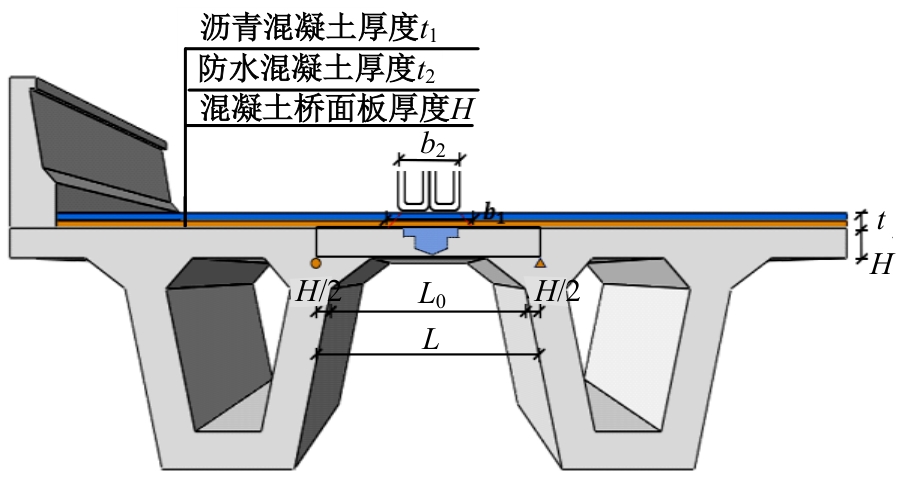

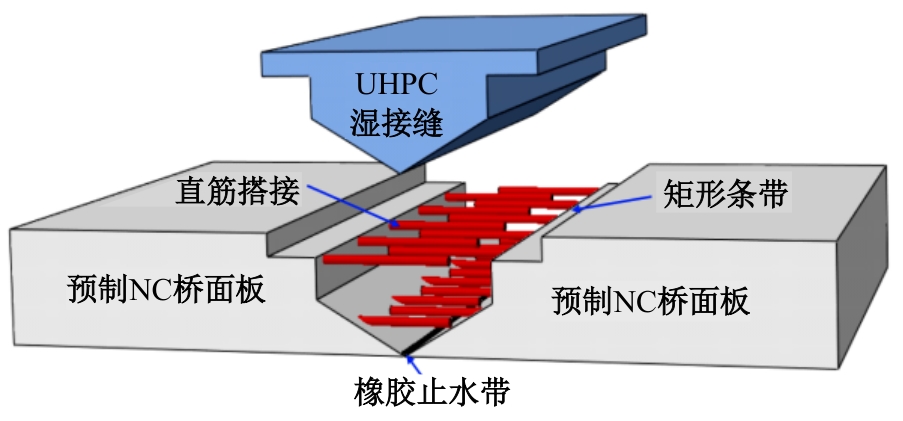

Flexural behavior of ultra-high performance concrete joint without formwork in prefabricated small box girder bridges

Jin-song ZHU1,2( ),Xin-yao TONG1,Xiao-xu LIU1

),Xin-yao TONG1,Xiao-xu LIU1

- 1.School of Civil Engineering,Tianjin University,Tianjin 300072,China

2.Key Laboratory of Coast Civil Structure Safety,Ministry of Education,Tianjin University,Tianjin 300072,China

CLC Number:

- U445.57

| 1 | 李健.小箱梁结构在高等级公路中的应用发展及运营病害综述[J].公路交通科技,2015,11(4):9-12. |

| Li Jian. Summary of application development and operating diseases of small box girder structure in high grade highway[J].Highway Traffic Technology,2015,11(4):9-12 . | |

| 2 | 宫亚峰,王博,谭国金,等.吉林省两种典型装配式箱涵受力特性对比分析[J].吉林大学学报:工学版,2019,49(6):1865-1870. |

| Gong Ya-feng, Wang Bo, Tan Guo-jin,et al. Comparative analysis of the force characteristics of two typical prefabricated box culverts in Jilin Province[J]. Journal of Jilin University (Engineering and Technology Edition),2019,49(6):1865-1870. | |

| 3 | 崔凤坤,赵鹍鹏,董尧一,等.接缝失效对装配式小箱梁车辆荷载效应及结构可靠度影响研究[J].建筑技术,2018,49(S1):10-12. |

| Cui Feng-kun, Zhao Kun-peng, Dong Yao-yi,et al. Effect of joint failure on load effect and structural reliability of assembled small box girder vehicles [J]. Architectural Technology,2018,49(S1):10-12. | |

| 4 | 吴清.预制小箱梁常见裂缝分类和防治[J].城市道桥与防洪,2011 (6):200-203, 323. |

| Wu Qing. Classification and prevention of common cracks in precast box girder[J]. City roads and Bridges and flood control,2011 (6):200-203, 323. | |

| 5 | 龚永智,况锦华,柯福隆,等.UHPC连接的装配式剪力墙节点抗震性能试验[J].吉林大学学报:工学版,2022,52(10):2367-2375. |

| Gong Yong-zhi, Kuang Jin-hua, Ke Fu-long,et al. Seismic performance test of prefabricated shear wall joints connected by UHPC[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(10):2367-2375. | |

| 6 | Graybeal B A. Ultra-high-performance concrete connections for precast concrete bridge decks[J]. Pci Journal, 2014, 59(4): 48-62. |

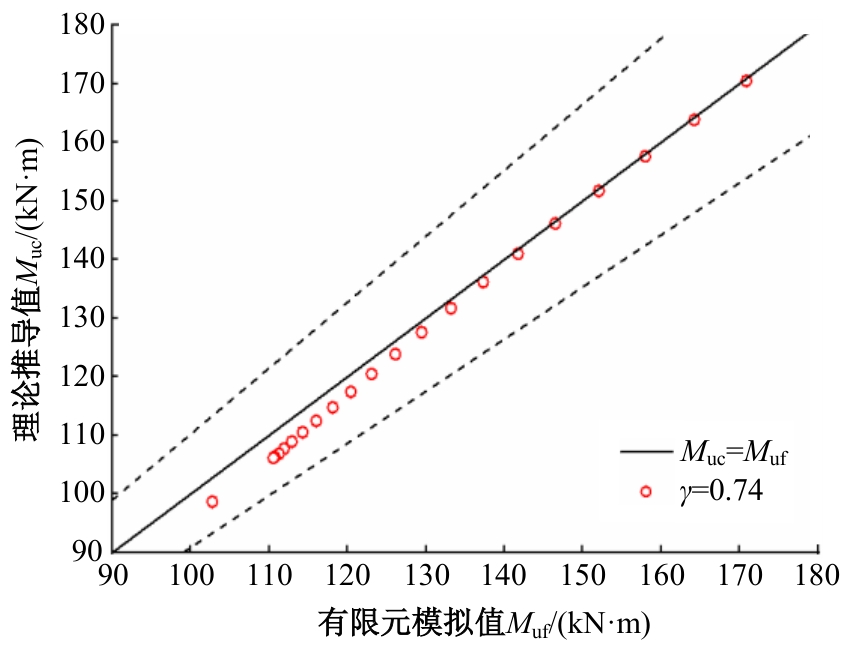

| 7 | 袁嘉梁,贾依楠,晏班夫. 矩形UHPC湿接缝受弯性能研究[J].公路工程,2020,45(5):129-134. |

| Yuan Jia-liang, Jia Yi-nan, Yan Ban-fu. Study on flexural performance of vertical UHPC wet joints[J]. Highway Engineering,2020,45(5):129-134. | |

| 8 | Peng K K, Yan B F. Experimental study of the flexural behaviour of ultra-high-performance concrete beam with wet joint[J]. Magazine of Concrete Research, 2022,74(1/2):70-80. |

| 9 | 张阳,陈贝.预制NC板现浇UHPC接缝的抗弯性能有限元分析研究[J].公路工程, 2018, 43(6): 1-5. |

| Zhang Yang, Chen Bei. Finite element analysis research on flexural performance of prefabricated NC panels with UHPC joints[J]. Highway Engineering,2018,43(6):1-5 . | |

| 10 | 胡志坚,尹炳森,俞文生.预制拼装桥面板UHPC湿接缝抗弯性能分析[J]. 中山大学学报: 自然科学版,2021, 60(6): 29-35. |

| Hu Zhi-jian, Yin Bing-sen, Yu Wen-sheng. Analysis of flexural behavior of prefabricated deck slab with UHPC joints[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni,2021, 60(6): 29-35 . | |

| 11 | 张菊辉,黄帅,管仲国.预制小箱梁纵向U筋交错搭接接缝静载试验[J].中国公路学报, 2018, 31(12):115-123. |

| Zhang Ju-hui, Huang Shuai, Guan Zhong-guo. Static loading test of longitudinal joint details using staggered U-bars in precast multibox girder bridges [J]. China Journal of Highway and Transport, 2018, 31(12): 115-123. | |

| 12 | 龙佩恒, 杜小节, 韩扬, 等. 预制拼装板UHPC湿接缝抗弯性能分析[J]. 建筑结构, 2021, 51(): 1209-1215. |

| Long Pei-heng, Du Xiao-jie, Han Yang,et al. Analysis on flexural performance of prefabricated assembly panels with UHPC wet joints[J]. Building Structure,2021,51(Sup.2):1209-1215 . | |

| 13 | T/CCES 27—2021. 超高性能混凝土梁式桥技术规程 [S]. |

| 14 | . 混凝土结构设计规范 [S]. |

| 15 | Al-Osta M A, Isa M N, Baluch M H,et al. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete[J]. Construction and Building Materials,2017, 134: 279-296. |

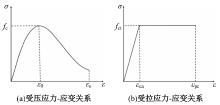

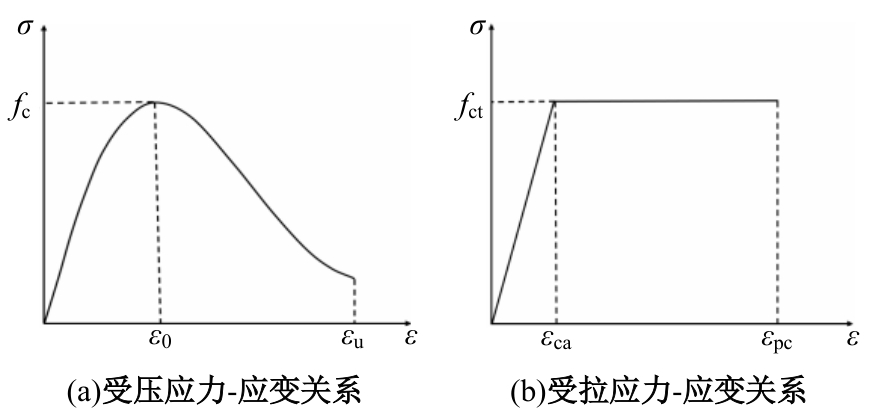

| 16 | 郭晓宇, 亢景付, 朱劲松. 超高性能混凝土单轴受压本构关系[J]. 东南大学学报: 自然科学版, 2017, 47(2): 369-376. |

| Guo Xiao-yu, Kang Jing-fu, Zhu Jin-song. Constitutive relationship of ultrahigh performance concrete under uni-axial compression[J]. Journal of Southeast University (Natural Science Edition), 2017, 47(2): 369-376. | |

| 17 | 张哲, 邵旭东, 李文光, 等.超高性能混凝土轴拉性能试验[J].中国公路学报, 2015, 28(8): 50-58. |

| Zhang Zhe, Shao Xu-dong, Li Wen-guang, et al. Experimental study on axial tension performance of ultra-high performance concrete[J].China Journal of Highway and Transport, 2015, 28(8): 50-58. | |

| 18 | 许建明, 陈勇, 刘骁繁, 等.UHPC-NC叠层梁界面黏结性能的试验研究与数值模拟[J]. 建筑科学与工程学报, 2021, 38(4): 44-56. |

| Xu Jian-ming, Chen Yong, Liu Xiao-fan, et al. Experimental study and numerical simulation of interface bonding properties of UHPC-NC laminated beams [J]. Journal of Building Science and Engineering, 2021, 384: 44-56. | |

| 19 | 马熙伦, 陈宝春, 杨艳, 等.R-UHPC梁的抗剪承载力计算方法[J].交通运输工程学报, 2017, 17(5): 16-26. |

| Ma Xi-lun, Chen Bao-chun, Yang Yan, et al. Calculation method of shear bearing capacity of R-UHPC beam[J].Journal of Traffic and Transportation Engineering, 2017, 17 (5): 16-26. | |

| 20 | . 公路钢筋混凝土及预应力混凝土桥涵设计规范 [S]. |

| 21 | . 公路桥涵设计通用规范 [S]. |

| 22 | FHWA-HRT-14-090. Bond behavior of reinforcing steel in ultra-high performance concrete [S]. |

| 23 | . 公路装配式混凝土桥梁设计规范 [S]. |

| [1] | Yan-ling ZHANG, JIAYun-fei,Xiao-yuan JIA,Wang ZHENG,Yun-sheng LI. Proposed formulae for transverse distribution factor of internal forces of prefabricated small box-girder bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1688-1700. |

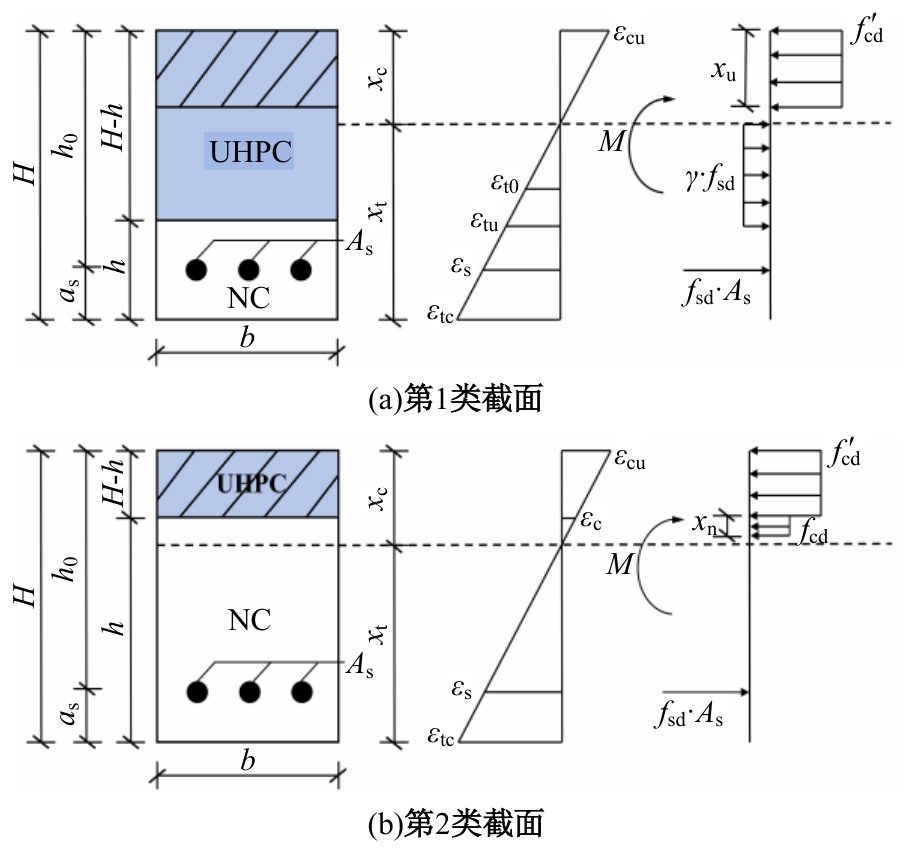

| [2] | Jin-song ZHU,Ya-ting QIN,Zhou-qiang LIU. Section optimization design of prestressed UHPC-NC composite beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3151-3159. |

| [3] | Yong-zhi GONG,Jin-hua KUANG,Fu-long KE,Quan ZHOU,Xiao-yong LUO. Experiment on seismic behavior of assembled shear wall joints connected by ultra high performance concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2367-2375. |

| [4] | Wang Jian, Ge An-lin,Lei Yu-long,Tian Hua . Three-dimensional design for hydraulic torque converter blades and its performance analysis [J]. 吉林大学学报(工学版), 2007, 37(01): 43-47. |

|

||