Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (11): 3151-3159.doi: 10.13229/j.cnki.jdxbgxb.20220004

Previous Articles Next Articles

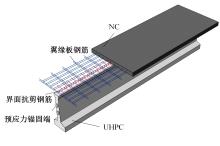

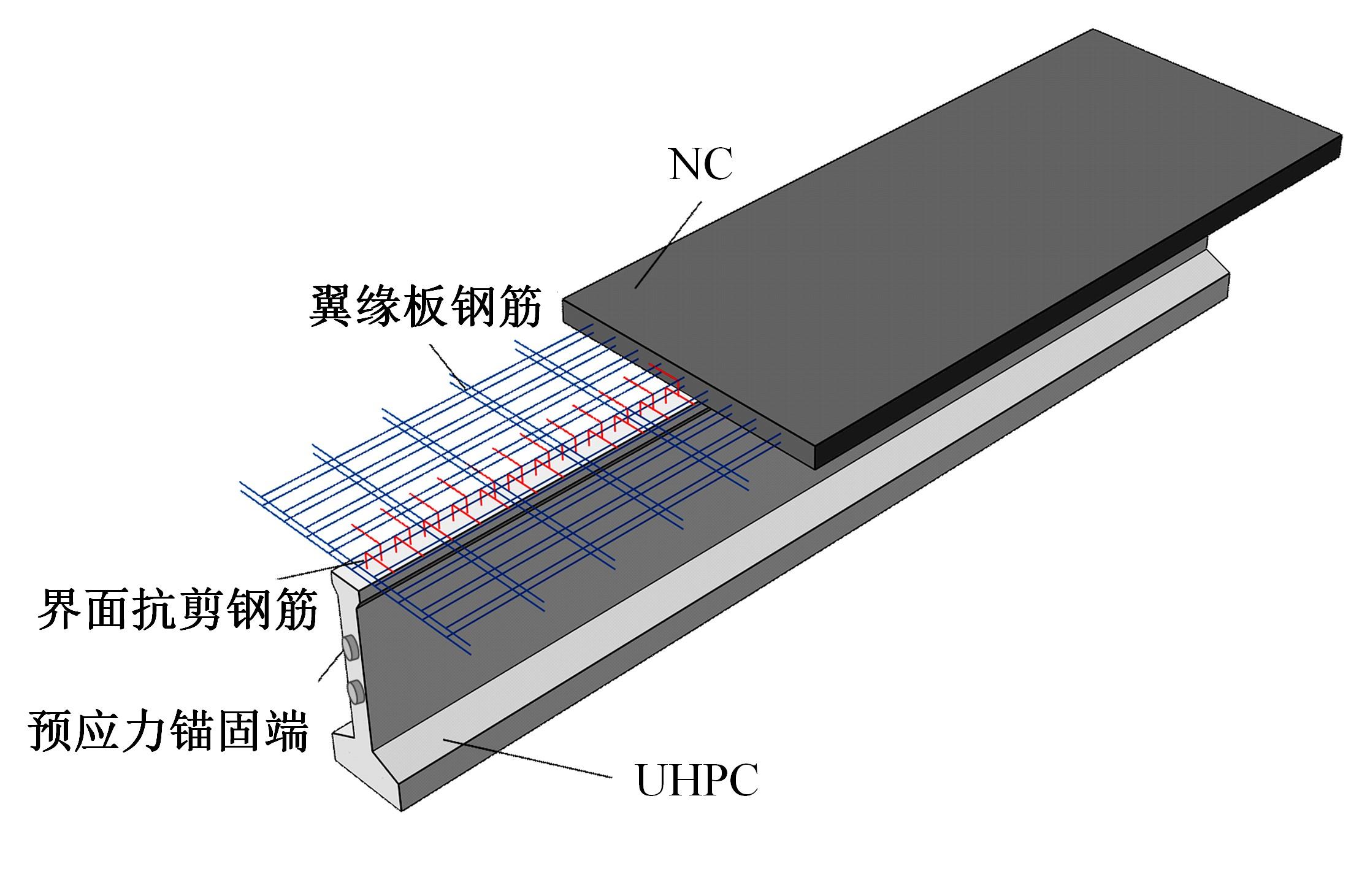

Section optimization design of prestressed UHPC-NC composite beams

Jin-song ZHU1,2( ),Ya-ting QIN1,Zhou-qiang LIU1

),Ya-ting QIN1,Zhou-qiang LIU1

- 1.School of Civil Engineering,Tianjin University,Tianjin 300072,China

2.Key Laboratory of Coast Civil Structure Safety,Ministry of Education,Tianjin University,Tianjin 300072,China

CLC Number:

- TU318.1

| 1 | Al-Osta M A, Isa M N, Baluch M H, et al. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete[J]. Construction and Building Materials, 2017, 134: 279-296. |

| 2 | Valikhani A, Jahromi A J, Mantawy I M, et al. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application[J]. Construction and Building Materials, 2020, 238: 117753. |

| 3 | Shirai K, Yin H, Teo W. Flexural capacity prediction of composite RC members strengthened with UHPC based on existing design models[J]. Structures, 2020, 23: 44-55. |

| 4 | Shafieifar M, Farzad M, Azizinamini A. Experimental and numerical study on mechanical properties of ultra high performance concrete (UHPC)[J]. Construction and Building Materials, 2017, 156: 402-411. |

| 5 | 张哲,邵旭东,李文光,等. 超高性能混凝土轴拉性能试验[J]. 中国公路学报, 2015, 28(8): 50-58. |

| Zhang Zhe, Shao Xu-dong, Li Wen-guang, et al. Experimental study on axial tension performance of ultra-high performance concrete[J]. China Journal of Highway and Transport, 2015, 28(8): 50-58. | |

| 6 | Tayeh B A, Abu Bakar B H, Megat Johari M A, et al. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay[J]. Construction and Building Materials, 2012, 36: 538-548. |

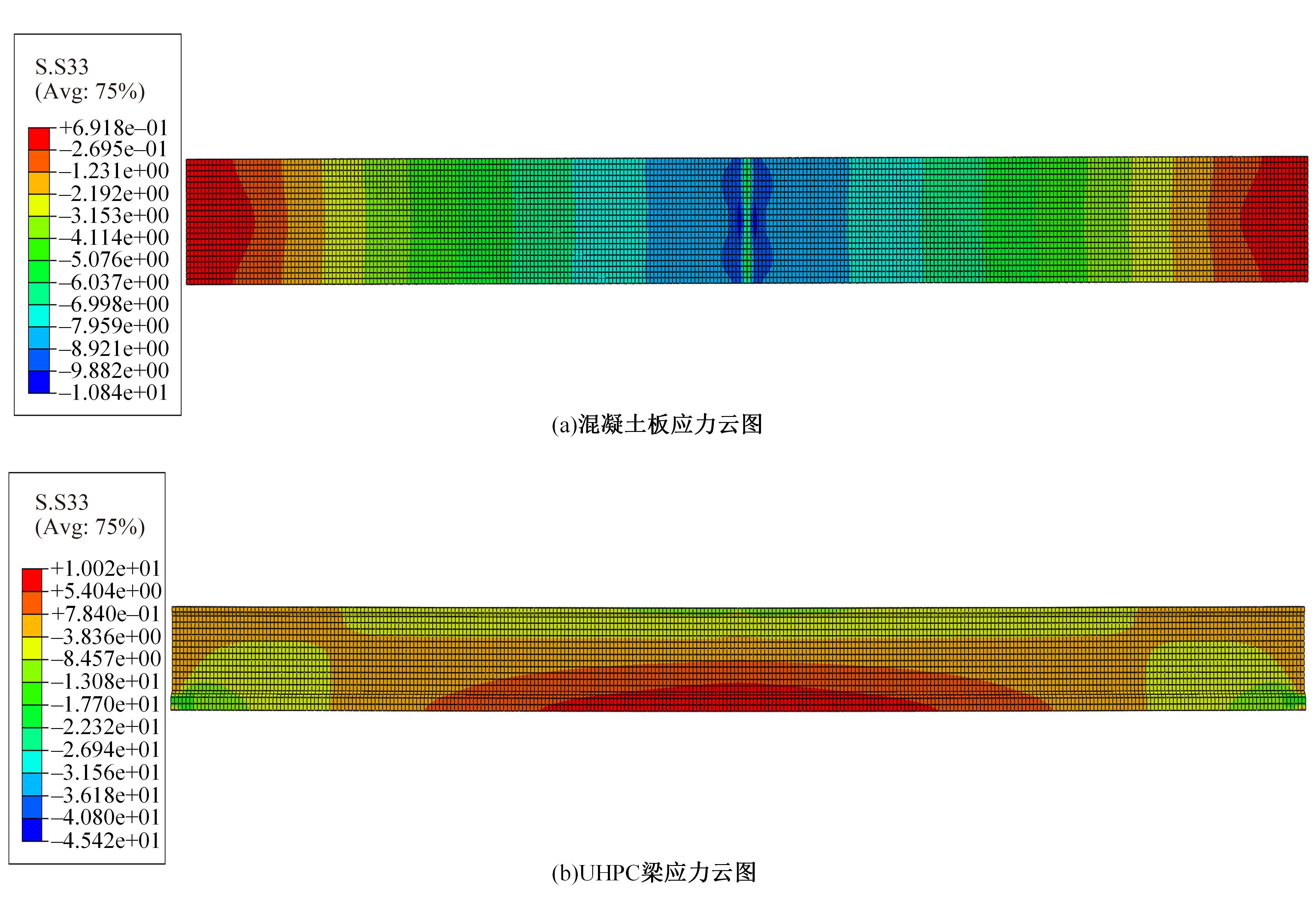

| 7 | 李昭,赵华,朱平,等. UHPC-NC组合结构抗弯性能试验及有限元分析[J]. 公路工程, 2019,44(2): 194-200. |

| Li Zhao, Zhao Hua, Zhu Ping, et al. Test and finite element analysis of flexural performance of UHPC-NC composite structure[J]. Highway Engineering, 2019, 44(2): 194-200. | |

| 8 | 曾蔚,秦阳. 钢筋混凝土梁遗传算法优化设计[J]. 公路交通科技, 2006(8): 81-83. |

| Zeng Wei, Qin Yang. Optimization design of reinforced concrete beam based on genetic algorithm[J]. Journal of Highway and Traffic Science, 2006(8): 81-83. | |

| 9 | Senouci A B, Al-Ansari M S. Cost optimization of composite beams using genetic algorithms[J]. Advances in Engineering Software, 2009, 40(11): 1112-1118. |

| 10 | Pedro R L, Demarche J, Miguel L F F, et al. An efficient approach for the optimization of simply supported steel-concrete composite I-girder bridges[J]. Advances in Engineering Software, 2017, 112: 31-45. |

| 11 | Sudira I G N, Hadi B K, Moelyadi M A, et al. Application of genetic algorithm for the design optimization of geodesic beam structure[J]. Applied Mechanics and Materials, 2016, 842: 266-272. |

| 12 | 邬沛, 李玉顺, 许达, 等. 基于遗传算法的钢-竹组合工字形梁截面优化设计[J]. 建筑结构学报, 2020,41(1): 149-155. |

| Wu Pei, Li Yu-shun, Xu Da, et al. Optimization of section of steel-bamboo composite i-beam based on genetic algorithm[J]. Journal of Building Structures, 2020, 41(1): 149-155. | |

| 13 | de Munck M, de Sutter S, Verbruggen S, et al. Multi-objective weight and cost optimization of hybrid composite-concrete beams[J]. Composite Structures, 2015, 134: 369-377. |

| 14 | Umeonyiagu I E, Nwobi-Okoye C C. Modelling and multi objective optimization of bamboo reinforced concrete beams using ANN and genetic algorithms[J]. European Journal of Wood and Wood Products, 2019, 77(5): 931-947. |

| 15 | 黄冀卓,王湛. 基于遗传算法的抗震钢框架多目标优化设计[J]. 力学学报, 2007(3): 389-397. |

| Huang Ji-zhuo, Wang Zhan. Multi-objective optimization design of seismic steel frame based on genetic algorithm[J]. Chinese Journal of Theoretical and Applied Mechanics, 2007(3): 389-397. | |

| 16 | 王佩艳,赵晨,耿小亮,等. 基于改进自适应遗传算法的层合板铺层顺序优化方法[J]. 科学技术与工程, 2018, 18(6): 336-340. |

| Wang Pei-yan, Zhao Chen, Geng Xiao-liang, et al. Optimization method of laminate layering sequence based on improved adaptive genetic algorithm[J]. Science Technology and Engineering, 2018, 18(6): 336-340. | |

| 17 | Whitworth A H, Tsavdaridis K D. Embodied energy optimization of steel-concrete composite beams using a genetic algorithm[J]. Procedia Manufacturing, 2020, 44: 417-424. |

| 18 | 万世成, 黄侨, 关健, 等. 预应力碳纤维板加固钢-混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报: 工学版, 2019, 49(4): 1114-1123. |

| Wan Shi-cheng, Huang Qiao, Guan Jian, et al. Negative moment zone test of prestressed carbon fiber plate reinforced steel-concrete composite continuous beam[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1114-1123. | |

| 19 | 孙琪凯, 张楠, 刘潇, 等. 基于Timoshenko梁理论的钢-混组合梁动力折减系数[J]. 吉林大学学报: 工学版, 2023, 53(2): 488-495. |

| Sun Qi-kai, Zhang Nan, Liu Xiao, et al. Dynamic reduction coefficient of steel-composite beams based on Timoshenko beam theory[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(2): 488-495. | |

| 20 | 朱劲松, 秦亚婷, 史腾. 预应力UHPC-NC组合梁抗弯承载力计算方法[J]. 中南大学学报, 2022, 53(10): 3989-4000. |

| Zhu Jin-song, Qin Ya-ting, Shi Teng. Calculation method for flexural capacity of prestressed UHPC-NC composite beams[J]. Journal of Central South University(Science and Technology Edition), 2022, 53(10): 3989-4000. | |

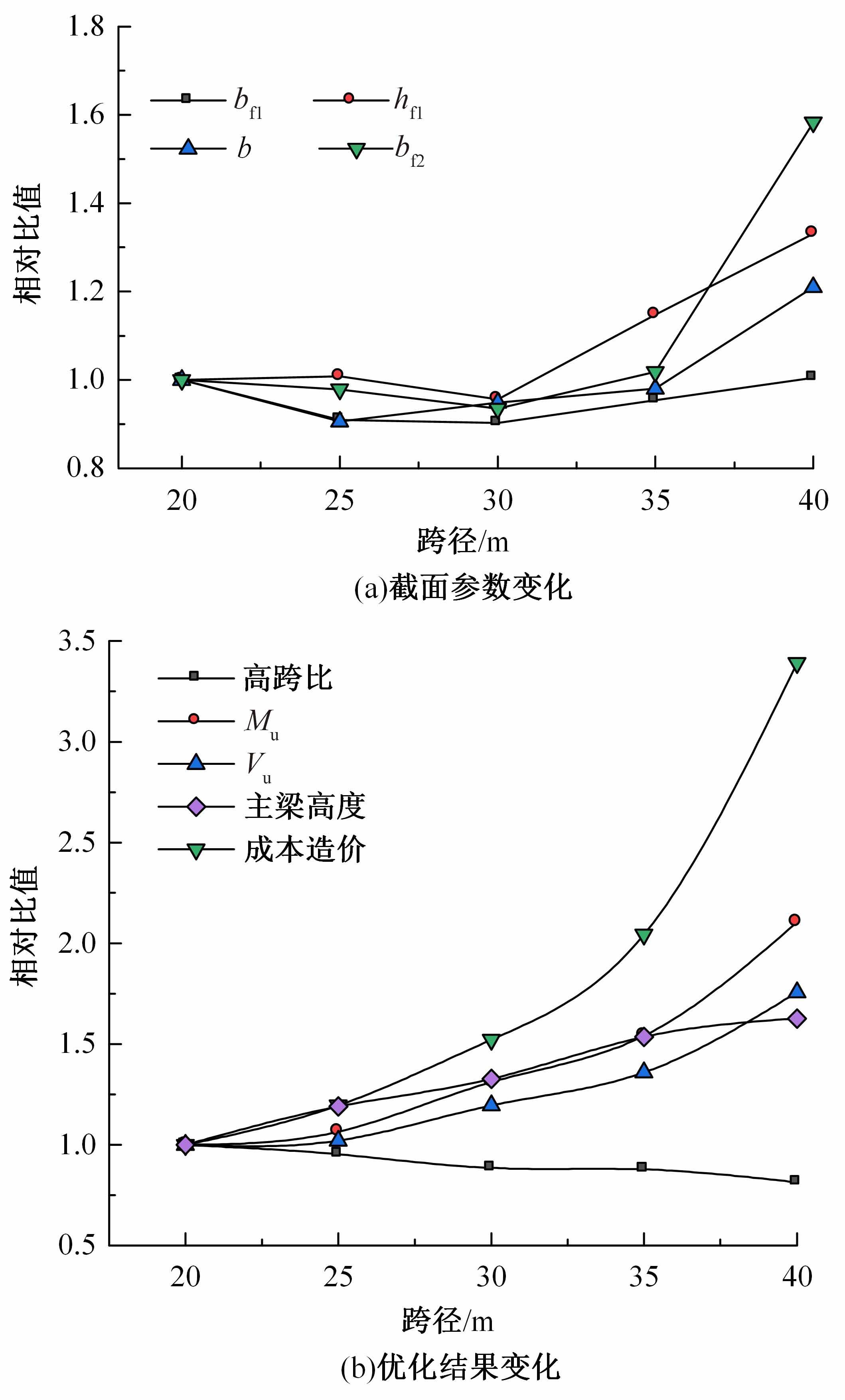

| 21 | 刘大同. 中小跨径桥梁截面优化设计研究[D]. 武汉: 武汉理工大学交通学院, 2005. |

| Liu Da-tong. Study on section optimization design of medium and small span bridges[D]. Wuhan: College of Transportation, Wuhan University of Technology, 2005. |

| [1] | Chang-jiang ZHENG,Huan HU,Mu-qing DU. Design of multimodal express delivery network structure considering hub failure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2304-2311. |

| [2] | Guo-hong TIAN,Peng-jie DAI. Active collision avoidance method of driverless vehicle based on partheno genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2404-2409. |

| [3] | Ying-xin HUI,Jia-wei CHEN. Squeezed branch pile groups optimization method based on improved genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2089-2098. |

| [4] | Jian-qing BU,Zhi-bo GUO,Ji-ren ZHANG,Jing-chuan XUN,Xiao-ming HUANG. Finite element analysis method for mechanical properties of steel⁃concrete composite beam bridges with multiple damages [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1621-1637. |

| [5] | Ya-na MAO,Shi-zhong LIU,Jian XING,Hua YANG,Yu-bo JIAO. Bond⁃slip characterization between ultra⁃high performance glass sand concrete and high⁃strength reinforcement based on acoustic emission parameters [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1686-1694. |

| [6] | Yan-bo LI,Bai-song LIU,Bo-bin YAO,Jun-shuo CHEN,Kai-fa QU,Qi-sheng WU,Jie-ning CAO. Location of electrical changing station of expressway considering stochastic characteristics of road network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1364-1371. |

| [7] | Hong-bo YANG,Wen-ku SHI,Zhi-yong CHEN,Nian-cheng GUO,Yan-yan ZHAO. Multi⁃objective optimization of macro parameters of helical gear based on NSGA⁃Ⅱ [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1007-1018. |

| [8] | Min MA,Da-wei HU,Lan SHU,Zhuang-lin MA. Resilience assessment and recovery strategy on urban rail transit network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 396-404. |

| [9] | Zhi-qiang HAN,Gang XIE,Yong-jun ZHOU,Shi-zhong LIU,Min-jie JIN. Numerical analysis method of vehicle⁃bridge coupling vibration of curved bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 515-522. |

| [10] | Hong-bo YANG,Wen-ku SHI,Zhi-yong CHEN,Nian-cheng GUO,Yan-yan ZHAO. Optimization of tooth surface modification based on a two-stage reduction gear system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1541-1551. |

| [11] | Guo-jun YANG,Qi-wei TIAN,Ming-hang LYU,Yong-feng DU,Guang-wu TANG,Zong-jian HAN,Yi-duo FU. Review of mechanic characteristics of tunnel⁃type anchorage of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1245-1263. |

| [12] | Ying-chao ZHANG,Yun-hang LI,Zi-yu GUO,Guo-hua WANG,Zhe ZHANG,Chang SU. Optimization of the aerodynamic drag reduction of a cab behind engine vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 745-753. |

| [13] | Bin-xiang JIANG,Tong-tong JIANG,Yong-lei WANG. Optimization of consensus algorithm for drug detection block chain based on cultural genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 684-692. |

| [14] | Li-jie ZHANG,Xi-ta A,Xiao TIAN,Wen LI. Multi⁃objective optimization design of accelerated degradation test based on Gamma process [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 361-367. |

| [15] | Zhi-yuan YUANZHOU,Bo-hai JI,Jun-yuan XIA,Tong SUN. Pneumatic impact test on rib⁃to⁃diaphragm fatigue crack of steel box girder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2883-2891. |

|