Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (12): 3513-3525.doi: 10.13229/j.cnki.jdxbgxb.20231169

Previous Articles Next Articles

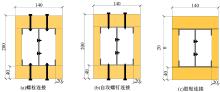

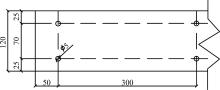

Bending performance of cold-formed thin-walled steel-glulam composite beams

Hai-xu YANG( ),Yue GUO,Hai-biao WANG(

),Yue GUO,Hai-biao WANG( ),Yi HU

),Yi HU

- College of Civil Engineering and Transportation,Northeast Forestry University,Harbin 150040,China

CLC Number:

- TU366.3

| 1 | 龚迎春,娄万里,李明月,等. 我国木结构产业发展展望[J]. 木材工业,2019,33(5):20-24. |

| Gong Ying-chun, Lou Wan-li, Li Ming-yue, et al. Prospects for timber structure industry in China[J]. China Wood Industry, 2019, 33(5):20-24. | |

| 2 | 曹磊,陈伯望. 胶合木梁抗剪性能研究综述[J]. 工程力学,2018,35(6):1-5, 14. |

| Cao Lei, Chen Bo-wang. Research review on shear behavior of glulam[J]. Engineering Mechanics, 2018, 35(6):1-5, 14. | |

| 3 | 谌晓梦. 建筑用木材的使用初探[J]. 中国建材科技,2020,29(1):105-107. |

| Chen Xiao-meng. Brief discussion on use of building timber[J]. China Building Materials Science & Technology, 2020, 29(1):105-107. | |

| 4 | 董福东. 钢-胶合木组合结构的发展与应用前景[J]. 安徽建筑,2019,26(10):202-203. |

| Dong Fu-dong. Development and application prospects of steel-glued wood combination structures[J]. Anhui Architecture, 2019, 26(10):202-203. | |

| 5 | Pan F T, Wang Y, Huang C X, et al. Analysis of flexural performance of steel-timber composite cantilever beam[J]. IOP Conference Series: Materials Science and Engineering, 2020, 964(1):No.012002. |

| 6 | Soriano J, Pellis P B, Mascia T N. Mechanical performance of glued-laminated timber beams symmetrically reinforced with steel bars[J]. Composite Structures, 2016, (150):200-207. |

| 7 | Hassanieh A, Valipour H, Bradford M. Experimental and numerical study of steel-timber composite(STC) beams[J]. Journal of Constructional Steel Research, 2016(122):367-378. |

| 8 | Gomon S S, Petro G, Sviatoslav H, et al. Improving the strength of bending elements of glued wood[J]. Procedia Structural Integrity, 2022 (36):217-222. |

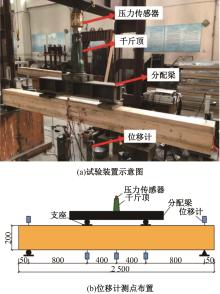

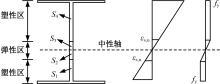

| 9 | 陈爱国,李登辉,方超,等. H形钢-木组合梁受弯性能试验研究[J]. 建筑结构学报,2016,37(S1):261-267. |

| Chen Ai-guo, Li Deng-hui, Fang Chao. Experimental study on flexural behavior of H-shaped steel-wood composite[J]. Journal of Building Structures, 2016, 37(S1):261-267. | |

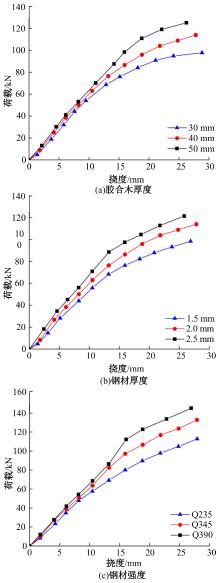

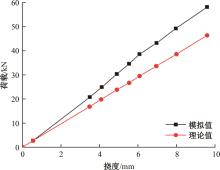

| 10 | 刘德贵,王宇豪,温勇,等. 内置薄壁H形钢-木组合梁受弯性能研究[J]. 建筑结构学报,2022,43(5):149-163. |

| Liu De-gui, Wang Yu-hao, Wen Yong, et al. Study on flexural behavior of built-in thin-walled H-steel timber composite beam[J]. Journal of Building Structures, 2022, 43(5):149-163. | |

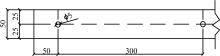

| 11 | 郑志仁. 冷弯薄壁矩形型钢-木组合梁抗弯性能研究[D]. 扬州: 扬州大学建筑科学与工程学院,2023. |

| Zheng Zhi-ren. Study on bending behavior of cold formed thin-wallrectangular section steel-timber composite beam[D]. Yangzhou: College of Architectural Science and Engineering, Yangzhou University, 2023. | |

| 12 | 刘佳桐,雷云,郦维,等. 木-钢组合箱梁抗弯性能试验及有限元对比分析[J]. 中南林业科技大学学报,2023,43(6):178-189. |

| Liu Jia-tong, Lei Yun, Li Wei, et al. Test and fnite element(FE) analysis on the fexural performance of timber-steel composite box girders[J]. Journal of Central South University of Forestry & Technology, 2023, 43(6): 178-189. | |

| 13 | .木结构试验方法标准 [S]. |

| 14 | . 金属材料拉伸试验第1部分:室温试验方法 [S]. |

| 15 | . 钢结构设计标准 [S]. |

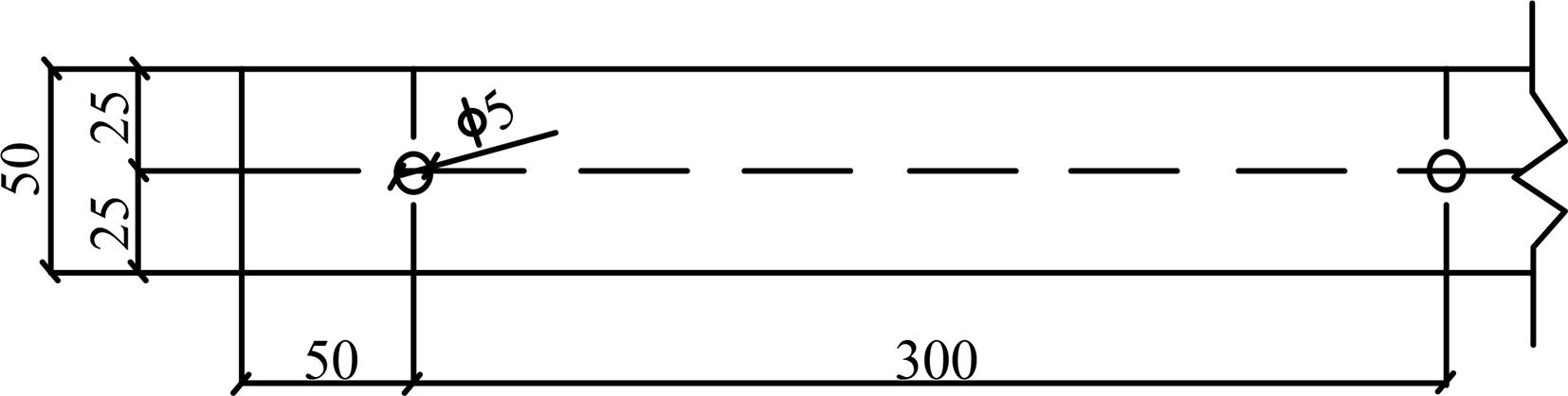

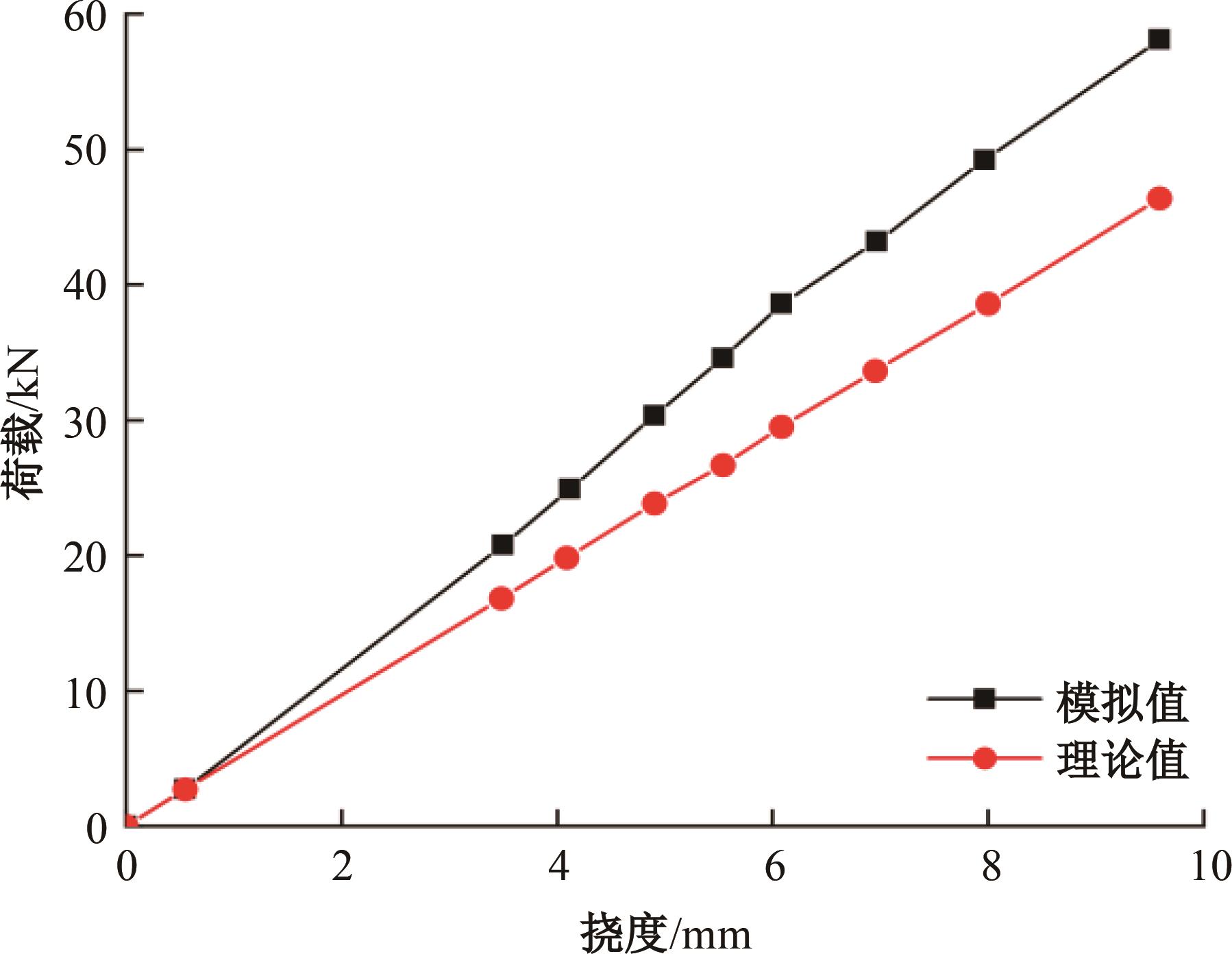

| 16 | 石明. 冷弯薄壁型钢-胶合木组合梁力学性能研究[D]. 哈尔滨: 东北林业大学土木与交通学院,2021. |

| Shi Ming. Research on mechanical propertiesof cold-formed thin-wall steel-glulam composite beams[D]. Harbi: College of Civil Engineering and Transportation, Northeast Forestry University, 2021. | |

| 17 | 建筑结构静力计算手册编写组. 建筑结构静力计算手册[M]. 北京: 中国建筑工业出版社,2000. |

| 18 | . 木结构设计标准 [S]. |

| 19 | 蔡竞. 胶合木材料力学性能研究[D]. 大连: 大连理工大学土木工程学院,2014. |

| Cai Jing. Study on mechanical behavior of glued laminated timber[D]. Dalian: School of Civil Engineering,Dalian University of Technology, 2014. | |

| 20 | 孙泽阳, 刘阳, 杨俊锋, 等. 抢险车对92 m跨度复合材料桁架桥动态响应的影响[J]. 江苏大学学报: 自然科学版, 2024, 45(3): 346-353. |

| Sun Ze-yang, Liu Yang, Yang Jun-feng, et al. Influence of emergency vehicle on dynamic response of 92 m span composite truss bridge[J]. Journal of Jiangsu University(Natural Science Edition), 2024, 45(3): 346-353. | |

| 21 | 胥昕怡, 徐超. 基于原型监测的分离式加筋土桥台工作性能数值分析[J]. 江苏大学学报: 自然科学版, 2024, 45(2): 234-241. |

| Xu Xinyi, Xu Chao. Numerical analysis on working performance of separated reinforced soil abutment based on prototype monitoring[J]. Journal of Jiangsu University (Natural Science Edition), 2024, 45(2): 234-241. |

| [1] | Jin-quan ZHAO,Long ZHOU,Yong-gang DING,Rong-ji ZHU. Experiment on anchoring performance of spiral stirrup-corrugated pipe grout splicing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2484-2494. |

| [2] | Wei-song YANG,An ZHANG,Wei-xiao XU,Hai-sheng LI,Ke DU. Seismic performance of stiffness enhanced metal coupling beam damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2469-2483. |

| [3] | Qi-wu YAN,Zhong-liang ZOU. Hybrid algorithm for seismic energy-dissipated structures based on optimal placement of dampers [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2267-2274. |

| [4] | Feng-guo JIANG,Yu-ming ZHOU,Li-li BAI,Shuang LIANG. Improved krill algorithm and its application in structural optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2256-2266. |

| [5] | Guang-tai ZHANG,Cheng-xiao ZHOU,Shi-tuo LIU. Restoring force model of fiber lithium slag concrete column in saline soil environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1944-1957. |

| [6] | Chun-lei ZHANG,Chang-yu SHAO,Qing-tian SU,Chang-yuan DAI. Experimental on positive bending behaviour of composite bridge decks with steel-fiber-reinforced concrete and longitudinal bulb-flat ribs [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1634-1642. |

| [7] | Yan-song DIAO,Yi-jian REN,Yuan-qiang YANG,Ling-yun ZHAO,Xiu-li LIU,Yun LIU. Experimental on seismic performance of replaceable splicing steel beam-column joints with friction energy dissipation components [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1643-1656. |

| [8] | Xue-ping FAN,Yue-fei LIU. Bridge extreme stress dynamic prediction based on improved Gaussian mixed particle filter new algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1038-1044. |

| [9] | Yi-fan LIU,Zhi-wei MIAO,Chen SHEN,Xiang-dong GENG. Evaluation of mechanical properties of non-uniform corroded rebars based on Monte Carlo method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1007-1015. |

| [10] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Time⁃variant reliability analysis of bridge members based on Gaussian Copula⁃Bayesian dynamic models [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 485-493. |

| [11] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Multi⁃process Bayesian dynamic combinatorial prediction of time⁃variant reliability for bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2332-2338. |

| [12] | Er-gang XIONG,Zhong-wen GONG,Jia-ming LUO,Tuan-jie FAN. Experiment on cracks in reinforced concrete beams based on digital image correlation technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1094-1104. |

| [13] | Xiao-dong WANG,Ning-jing LI,Qiang LI. Experimental on crushing of concrete beams by high⁃voltage pulse discharge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 496-504. |

| [14] | Ya-chuan KUANG,Li-bin CHEN,Chao-ju LI,Yu-hao HE. Analysis of mechanical properties of stud shear connectors [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 538-546. |

| [15] | Li-zhao DAI,Liang ZHOU,Xiao-wen YANG,Lei WANG. Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on connector element [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2886-2896. |

|