Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (1): 116-124.doi: 10.13229/j.cnki.jdxbgxb.20230295

Previous Articles Next Articles

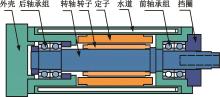

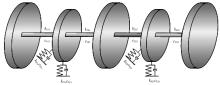

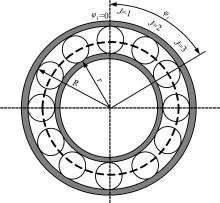

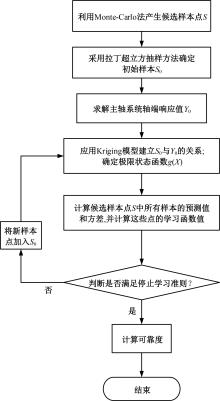

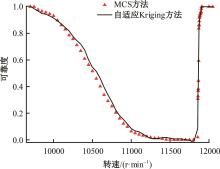

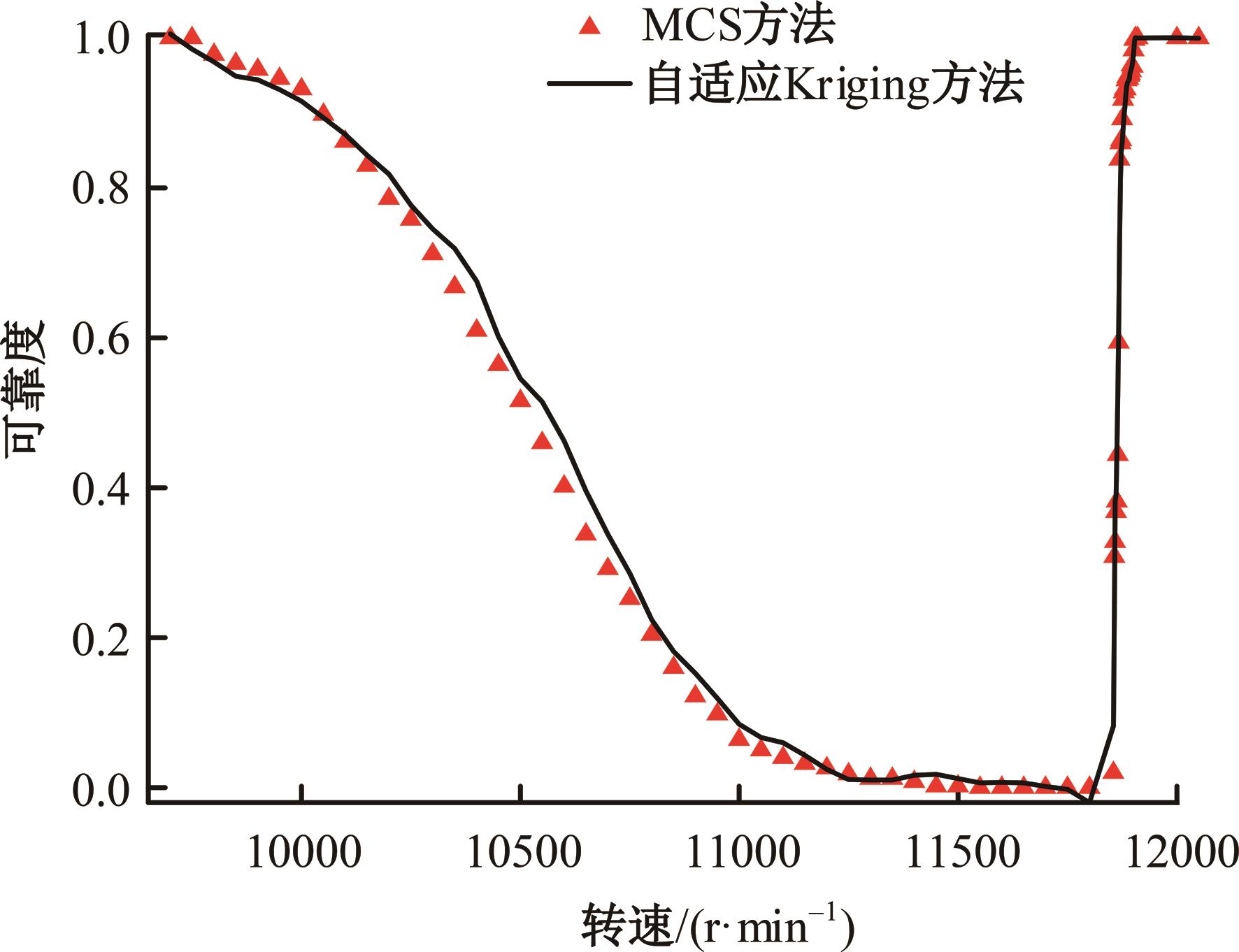

Spindle vibration reliability analysis considering bearing nonlinear restoring force

Xian-zhen HUANG1,2( ),Rui YU1,Hui-zhen LIU1,Ji-wu TANG3

),Rui YU1,Hui-zhen LIU1,Ji-wu TANG3

- 1.School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819,China

2.Key Laboratory of Vibration and Control of Aero-Propulsion Systems Ministry of Education of China,Northeastern University,Shenyang 110819,China

3.Apllied Technology College of Dalian Ocean University,Dalian 116300,China

CLC Number:

- TG659

| 1 | Cao H, Zhang X, Chen X. The concept and progress of intelligent spindles[J]. International Journal of Machine Tools and Manufacture, 2017, 112: 21-52. |

| 2 | 姜彦翠, 季嗣珉, 刘献礼. 基于主轴系统动力学的铣削稳定性建模与分析[J]. 工具技术, 2019, 53(5): 73-76. |

| Jiang Yan-cui, Ji Si-min, Liu Xian-li. Modeling and analysis of milling stability based on spindle System dynamics[J]. Tool Technology, 2019, 53(5): 73-76. | |

| 3 | 陈传海, 姚国祥, 金桐彤,等. 基于响应面与遗传算法的主轴系统动力学建模及参数修正[J]. 吉林大学学报:工学版, 2022, 52(10): 2278-2286. |

| Chen Chuan-hai, Yao Guo-xiang, Jin Tong-tong, et al. Dynamic modeling and parameter correction of spindle system based on response surface and genetic algorithm[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2278-2286. | |

| 4 | Jorgensen B R, Shin Y C. Dynamics of spindle-bearing systems at high speeds including cutting load effects[J].ManuFacturing Science and Engineering, 1998, 120: 387-394. |

| 5 | Xi S, Cao H. Dynamic modeling of machine tool spindle bearing system and model based diagnosis of bearing fault caused by collision[J]. Procedia CIRP, 2018, 77: 614-617. |

| 6 | Lu H, Ding Y, Chang Y. Dynamics modelling and simulating of ultra-precision fly-cutting machine tool[J]. International Journal of Precision Engineering and Manufacturing, 2020, 21: 189-202. |

| 7 | Jiang S, Mao H. Investigation of variable optimum preload for a machine tool spindle[J]. International Journal of Machine Tools and Manufacture, 2010, 50(1): 19-28. |

| 8 | Chen J S. Centrifugal force induced dynamics of a motorized high-speed spindle[J]. International Journal of Advanced Manufacturing Technology, 2006, 30: 10-19. |

| 9 | 金城, 高通, 怀天澍, 等. 数控机床主轴系统可靠性分析[J]. 机械制造, 2021, 59(7): 11-15,24. |

| Jin Cheng, Gao Tong, Huai Tian-shu, et al. Reliability analysis of CNC machine tool spindle system[J]. Machinery, 2021, 59(7): 11-15,24. | |

| 10 | 贺鑫元. 机床主轴的可靠性及可靠性灵敏度分析[J]. 制造技术与机床, 2018(1): 44-46,59. |

| He Xin-yuan. Reliability and reliability sensitivity analysis of machine tool spindles[J]. Manufacturing Technology and Machine Tools, 2018(1): 44-l46,59. | |

| 11 | Miao H, Li C, Wang C, et al. The vibration analysis of the CNC vertical milling machine spindle system considering nonlinear and nonsmooth bearing restoring force[J]. Mechanical Systems and Signal Processing, 2021, 161: 1884-2023. |

| 12 | Sunnersj C S. Varying compliance vibrations of rolling bearings[J]. Journal of Sound and Vibration, 1978, 58: 363-373. |

| 13 | Akturk N, Uneeb M, Gohar R. The effects of number of balls and preload on vibrations associated with ball bearings[J]. Journal of Tribology, 1997, 119: 747-753. |

| 14 | 唐云冰. 航空发动机滚动轴承力学特性研究[D]. 南京: 南京航空航天大学能源与动力学院, 2005. |

| Tang Yun-bing. Research on the mechanical characteristics of aero-engine shaft high-speed ball bearings[D]. Nanjing:College of Energy and Power Engineering, Nanjing University of Aeronautics and Astronautics, 2005. |

| [1] | Shu-kun WANG,Yu-ze FENG,Jing-ran ZHANG,Xin-ming ZHANG,Long ZHENG. Analysis on decontamination performance of lower lip structure of imitation scavenger [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 392-400. |

| [2] | Xian-zhen HUANG,Bin GUO,Zhi-yuan JIANG,Ji-wu TANG. Vibration characteristics and precision reliability analysis of high-speed motorized spindle system [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2432-2440. |

| [3] | Chang-jiang ZHENG,Tong-tong TAO,Zhi-chao CHEN. Cascading failure model based on adjustable redistribution of traffic flow [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2441-2450. |

| [4] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [5] | Yang LIU. Simulation and experiment of elastic roughing for rubber shoe [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2167-2173. |

| [6] | Xue-lian GUO,Wan-shui HAN,Tao WANG,Kai ZHOU,Xiu-shi ZHANG,Shu-ying ZHANG. Assessment method of resistant overturning stability safety factors of curved bridge under customized transport vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2229-2237. |

| [7] | Ying AN,Shuai GAO. Design of automatic mechanical transmission system based on torsional vibration reduction [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1844-1850. |

| [8] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [9] | Lei WANG,Dong-xia LI,Song ZHOU,Li HUI,Zhen-xin SHEN. Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1563-1569. |

| [10] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

| [11] | Chao CHEN,Meng-chu DAI,Le ZHOU,Yun-dong LIANG. Reliability allocation of agricultural machinery based on improved integrated factors method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1493-1500. |

| [12] | Shi-jun WANG,Guan-wei LUO. Periodic motion transition characteristics of a vibro-impact system with multiple impact constraints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 902-916. |

| [13] | Shao-hua WANG,Qi-rui ZHANG,De-hua SHI,Chun-fang YIN,Chun LI. Analysis of nonlinear vibration response characteristics of hybrid transmission system with dual-planetary gear sets [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 890-901. |

| [14] | Xue-ping FAN,Heng ZHOU,Yue-fei LIU. Time⁃variant reliability analysis of bridge members based on Gaussian Copula⁃Bayesian dynamic models [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 485-493. |

| [15] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

|