Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (1): 392-400.doi: 10.13229/j.cnki.jdxbgxb.20230234

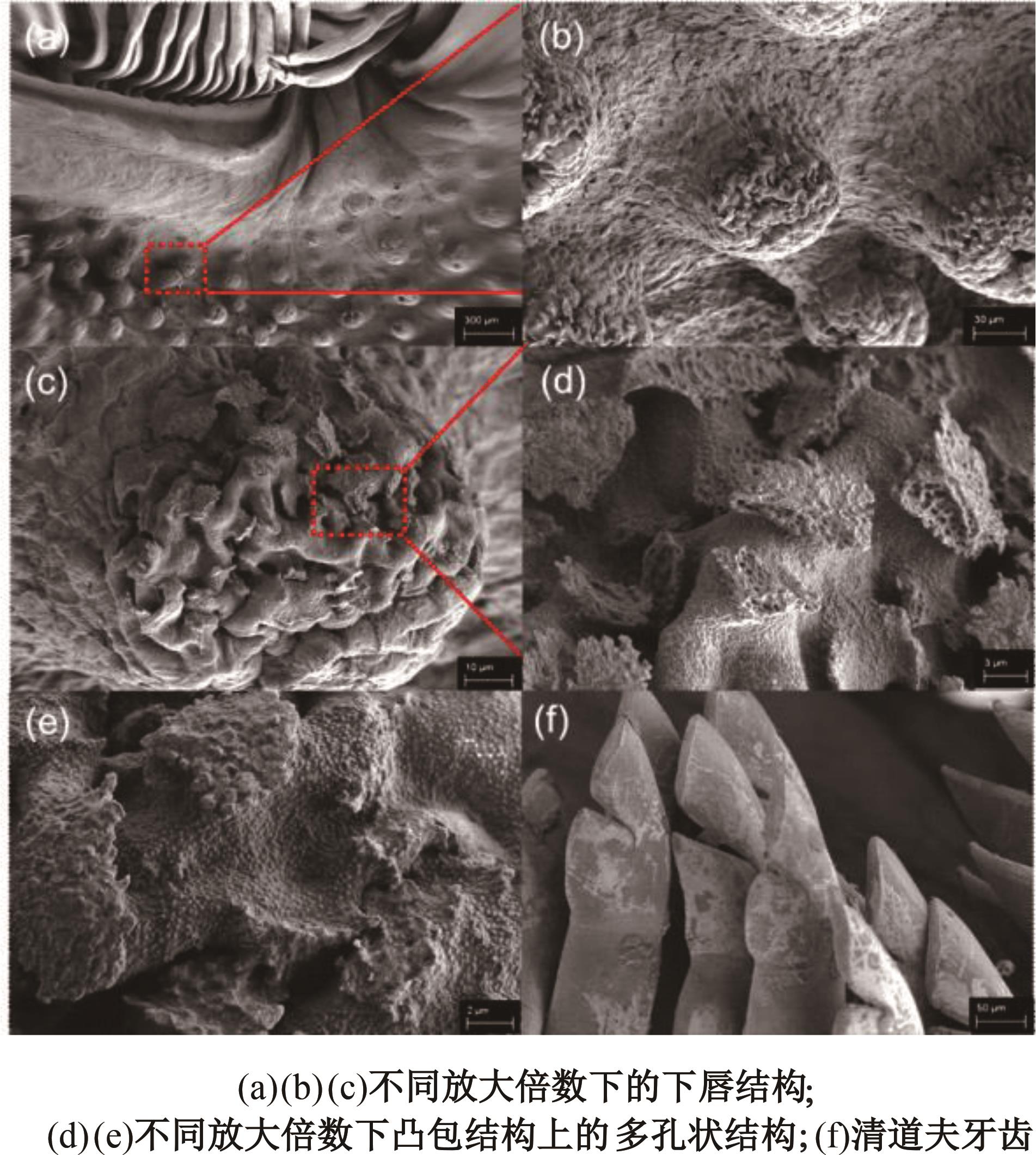

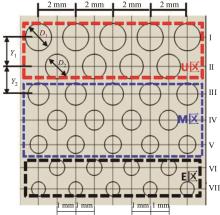

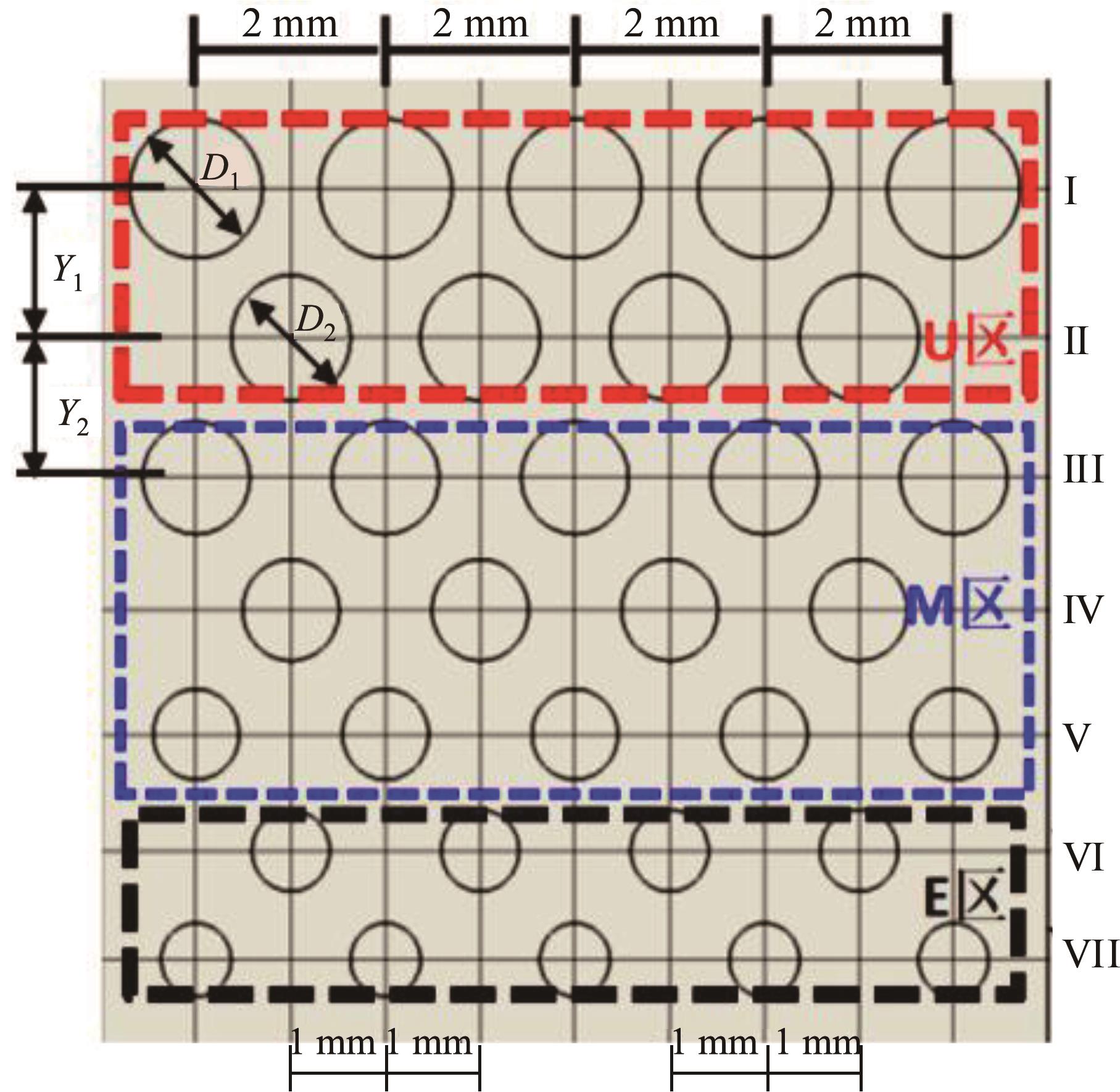

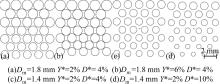

Analysis on decontamination performance of lower lip structure of imitation scavenger

Shu-kun WANG1( ),Yu-ze FENG1,2,Jing-ran ZHANG1,Xin-ming ZHANG1,Long ZHENG2,3(

),Yu-ze FENG1,2,Jing-ran ZHANG1,Xin-ming ZHANG1,Long ZHENG2,3( )

)

- 1.College of Mechanical and Electrical Engineering,Changchun University of Science and Technology,Changchun 130022,China

2.Weihai Institute for Bionics,Jilin University,Weihai 264207,China

3.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

CLC Number:

- TH117.1

| 1 | Schultz M P, Bendick J A, Holm E R, et al. Economic impact of biofouling on a naval surface ship[J]. Biofouling, 2011, 27(1): 87-98. |

| 2 | Townsin R L. The ship hull fouling penalty[J]. Biofouling, 2003, 19(Sup.1): 9-15. |

| 3 | Swain G. Redefining antifouling coatings[J]. Journal of Protective Coatings & Linings, 1999, 16(9): 26-33. |

| 4 | Jin H, Tian L, Bing W, et al. Bioinspired marine antifouling coatings: status, prospects, and future[J]. Progress in Materials Science, 2022, 124:No.100889. |

| 5 | 薛静静. 高附着型有机硅涂层的构建及其生物污损防护性能的研究[D]. 长春:吉林大学化学学院,2022. |

| Xue Jing-jing. Fabrication of mechanically enhanced organic silicone coatings and its anti-biofouling performance[D].Changchun: College of Chemistry,Jilin University,2022. | |

| 6 | Wong T S, Kang S H, Tang S K, et al. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity[J]. Nature, 2011, 477(7365): 443-447. |

| 7 | Tian L, Yin Y, Bing W, et al. Antifouling technology trends in marine environmental protection[J]. Journal of Bionic Engineering, 2021, 18(2): 239-263. |

| 8 | 陈彦臻, 胡以怀. 船体表面附着物清洗技术的研究及应用[J]. 表面技术, 2017, 46(10): 60-71. |

| Chen Yan-zhen, Hu Yi-huai.Research and application of ship hull fouling cleaning technologies[J].2017,46(10):60-71. | |

| 9 | 全玉臣. 船舶清洗市场趋势[J]. 清洗世界, 2007, 143(1): 35-38. |

| Quan Yu-chen.Shiooing cleaning market trend[J].Cleaning World,2007,143(1):35-38. | |

| 10 | 孟庆鑫,王丽慧,王立权,等.水下船体表面清刷机器人方案研究[J]. 船舶工程, 2002 (1): 44-46. |

| Meng Qing-xin, Wang Li-hui, Wang Li-quan,et al.Study of design of underwater robot for brushing hull exterior[J].Ship Engineering,2002 (1):44-46. | |

| 11 | Tribou M, Swain G. Grooming using rotating brushes as a proactive method to control ship hull fouling [J]. Biofouling, 2015, 31(4): 309-319. |

| 12 | Nassiraei A, Sonoda T, Ishii K. Development of ship hull cleaning underwater robot[C]∥Proceedings of the Fifth International Conference on Emerging Trends in Engineering & Technology, Himeji, Japan, 2012: No.2012.74. |

| 13 | 杨兴宇. 船体水下除海生物机器人结构设计及关键技术研究[D]. 天津:河北工业大学机械工程学院, 2019. |

| Yang Xing-yu.Structure design and key technology research of hull underwater clear sea creature robot[D]. Tianjin: College of Mechanical Engineering,Hebei University of Technology,2019. | |

| 14 | Abd-Elhafeez H H, Mokhtar D M. Comparative morphological study of lips and associated structures of two algal grazer fish[J]. Journal of Advanced Microscopy Research, 2014, 9(4): 275-284. |

| 15 | 赵立新, 章宝玲, 刘洋, 等. 基于表面织构技术改善摩擦学性能的研究进展 [J]. 摩擦学学报, 2022, 42(1): 202-224. |

| Zhao Li-xin, Zhang Bao-ling, Liu Yang,et al.State of the art for improving tribological performance based on of surface texturing technology[J].Tribology,2022,42(1):202-224. | |

| 16 | 史航, 王鲁民. 海洋污损生物藤壶的附着机理及防除[J]. 广东农业科学, 2006(6): 72-73, 81. |

| Shi Hang, Wang Lu-min.Adhesion mechanism and prevention of marine biofouling barnacle[J].GuangDong Agricultural Science,2006(6):72-73, 81. |

| [1] | Yang LIU. Simulation and experiment of elastic roughing for rubber shoe [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2167-2173. |

| [2] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [3] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [4] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

| [5] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [6] | Bin HU,Yi-quan CAI,Xin LUO,Zi-bin MAO,Jun-wei LI,Meng-yu GUO,Jian WANG. Theory and experiment of high⁃speed seed filling in limited gear⁃shaped side space based on seeds group stress [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 574-588. |

| [7] | Yang LIU. Calculation method of anti-backward-tilting buffer force of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2785-2794. |

| [8] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

| [9] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [10] | Wei CHEN,Yu-long LEI,Xing-zhong LI,Yao FU,Jian-long HU,Li-guo HOU. Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1628-1634. |

| [11] | Jin TONG,Zi-bo GAO,Chao HUO,Zi-yang WANG,Yun-hai MA,Zhi-yong CHANG. Effect of Cu nanoparticles on friction and wear of ultra⁃high molecular weight polyethylene with composites at low temperature [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 493-500. |

| [12] | Zhen GUO,Hong-ying YU,Zhong-xin HUA,Di ZHAO. Kinematic analysis and simulation of folding process for rigid origami mechanisms [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 66-76. |

| [13] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

| [14] | GUAN Qing-feng, HUANG Wei, LI Huai-fu, GONG Xiao-hua, ZHANG Cong-lin, LYU Peng. Diffusion alloying of Cu-C induced by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [15] | DAI Sheng, ZUO Dun-wen, LI Xiang-feng, CHENG Hu, FANG Zhi-gang, WANG Min, MIAO Hong. Friction and wear behavior of Ni-based WC composite coating on mould steel 2738 prepared by laser cladding [J]. , 2012, 42(04): 924-929. |

|

||