Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (11): 3125-3134.doi: 10.13229/j.cnki.jdxbgxb.20221648

Effect of length-to-diameter ratio on DPF pressure drop intersection point and internal flow field

Ming-liang WEI1,2( ),Zhi-dan LI1,2,Bo TIAN3,Qing LI3,Fu-wu YAN3,Yu WANG3

),Zhi-dan LI1,2,Bo TIAN3,Qing LI3,Fu-wu YAN3,Yu WANG3

- 1.State Key Laboratory of Intelligent Agricultural Power Equipment,Luoyang 471039,China

2.Luoyang Tractor Research Institute Co. ,Ltd. ,Luoyang 471039,China

3.School of Automotive Engineering,Wuhan University of Technology,Wuhan 430070,China

CLC Number:

- TK421+.5

| 1 | Dash S K, Ling F P, Barik D. Combined adjustment of injection timing and compression ratio for an agricultural diesel engine fuelled with nahar methyl ester[J]. International Journal of Ambient Energy, 2022, 43(1): 1482-1494. |

| 2 | Waluś K J, Wargula L, Krawiec P, et al. Legal regulations of restrictions of air pollution made by non-road mobile machinery—the case study for Europe: a review[J]. Environmental Science and Pollution Research, 2018, 25(4): 3243-3259. |

| 3 | Huan X C, Gang L, Ying Y, et al. Review and outlook of China non-road diesel mobile machinery emission standards[J]. Johns Matthey Technol Rev, 2020, 64: 76-83. |

| 4 | 王忠, 李游, 张美娟, 等. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报: 工学版, 2021, 51(1): 39-48. |

| Wang Zhong, Li You, Zhang Mei-juan, et al. Kinetic analysis of particle collision process in diesel engine exhaust stage[J]. Journal of Jilin University (Engineering and Techndogy Edition), 2021, 51(1): 39-48. | |

| 5 | Li J, Lu C, Tan D. Investigation on gas-soot flow distribution characteristic of soot capture process in the wall-flow diesel particulate filter[J]. International Journal of Aerospace Engineering, 2021: 6638517. |

| 6 | Mychal T, Atsushi K, Ryuji K, et al. Development of improved SCR on DPF design for future tighter regulations and reduced system packaging[C]∥ SAE Paper, Michigan, USA, 2018: 2018010344. |

| 7 | George S, Achim H. Next generation cordierite thin wall DPF for improved pressure drop and lifetime pressure drop solution[C]∥ SAE Paper, Michigan, USA, 2016: 2016010940. |

| 8 | Ogyu K, Oya T, Ohno K, et al. Improving of the filtration and regeneration performance by the SiC-DPF with the layer coating of PM oxidation catalyst[C]∥ SAE Paper, Michigan, USA, 2008: 2008010621. |

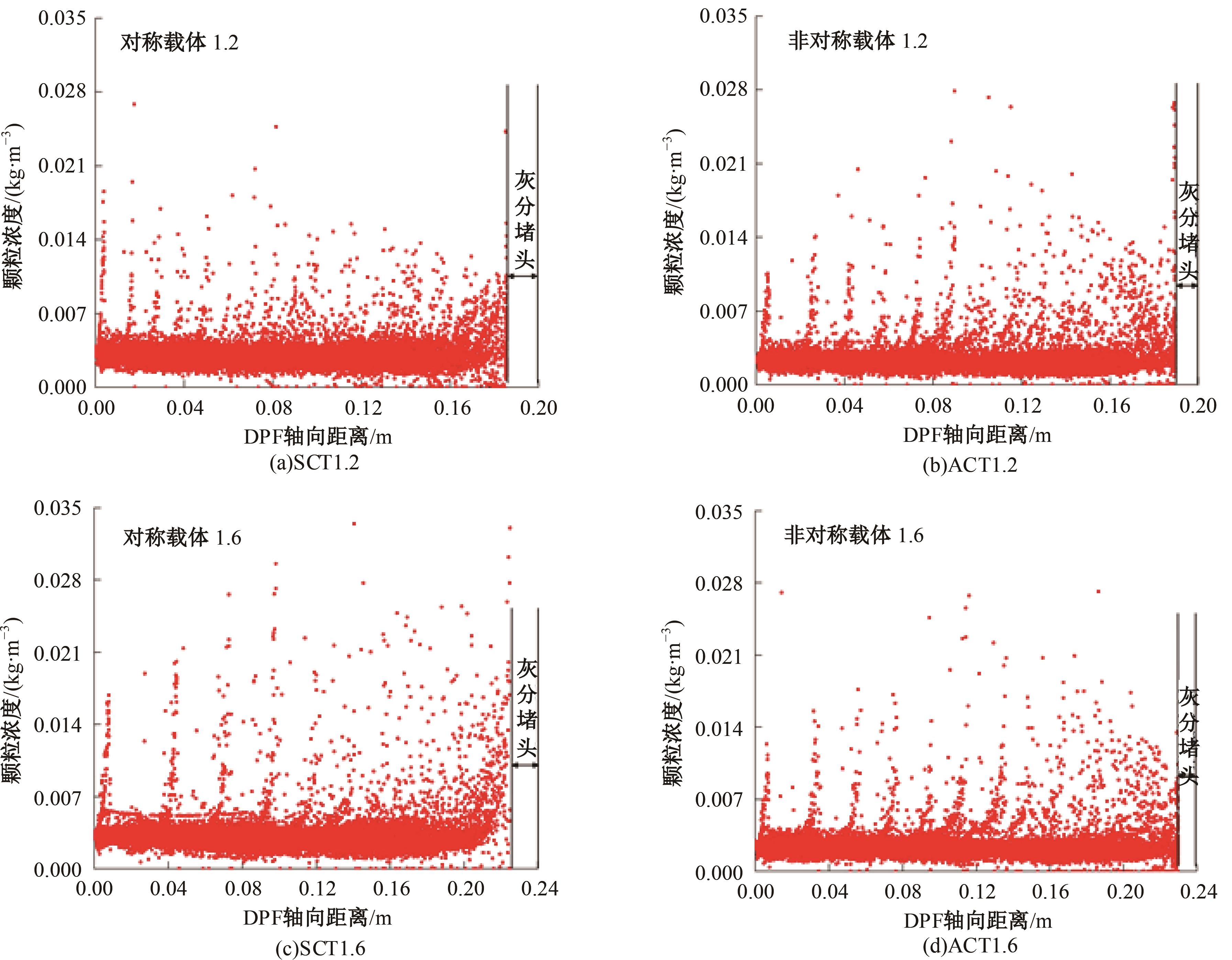

| 9 | Wang Y, Wong V, Sappok A,et al. The sensitivity of DPF performance to the spatial distribution of ash inside DPF inlet channels[C]∥ SAE Paper, Michigan,USA, 2013: 2013010158. |

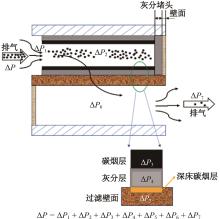

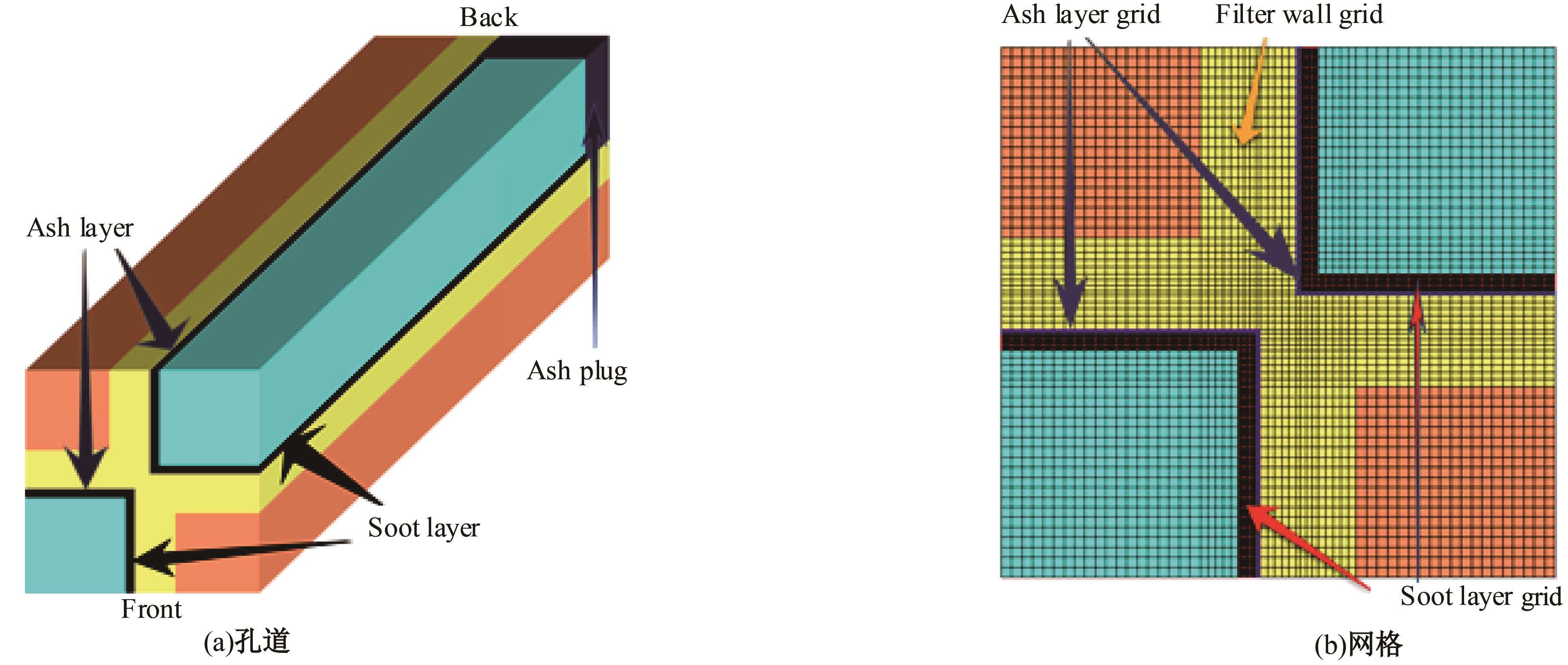

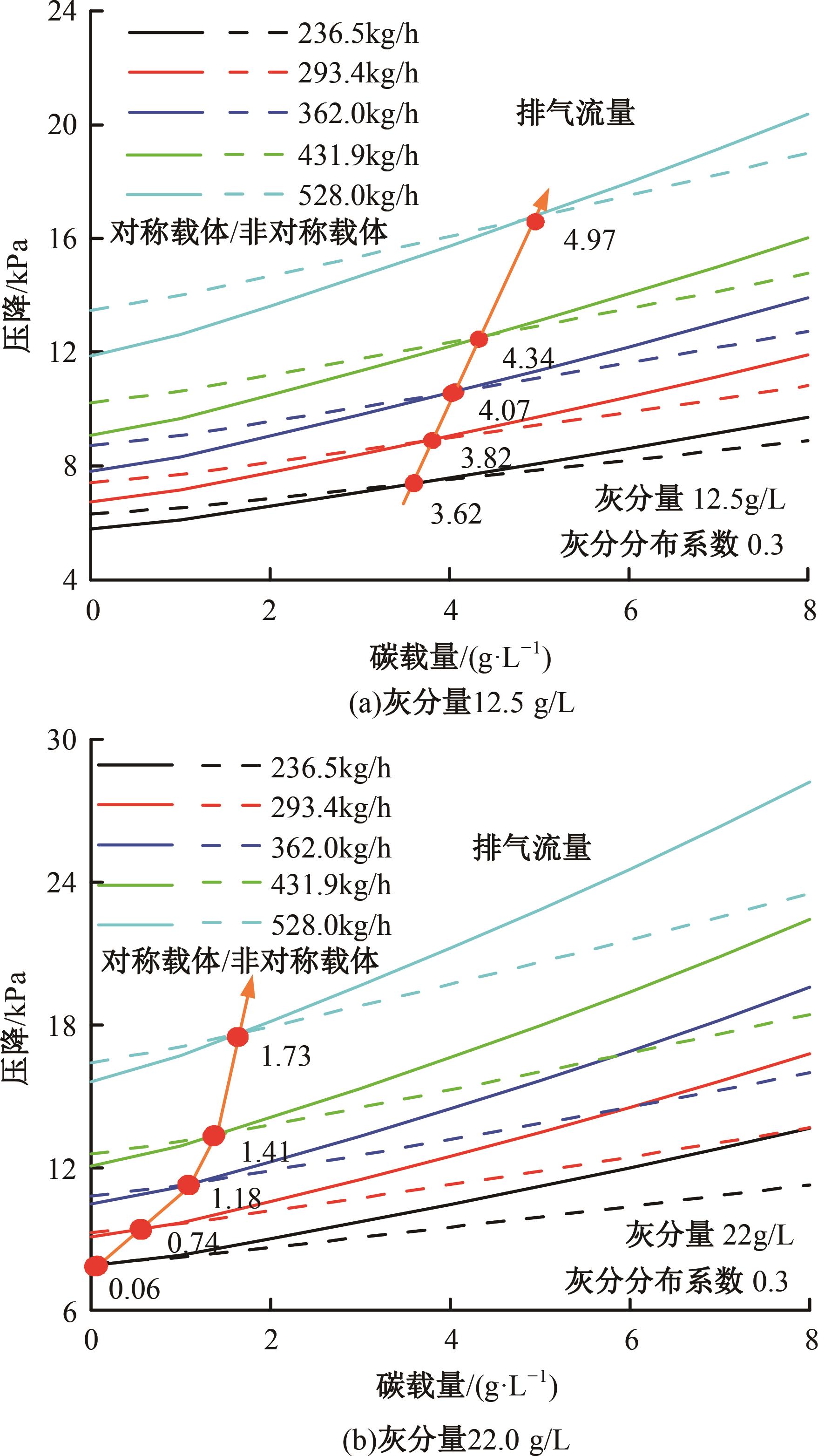

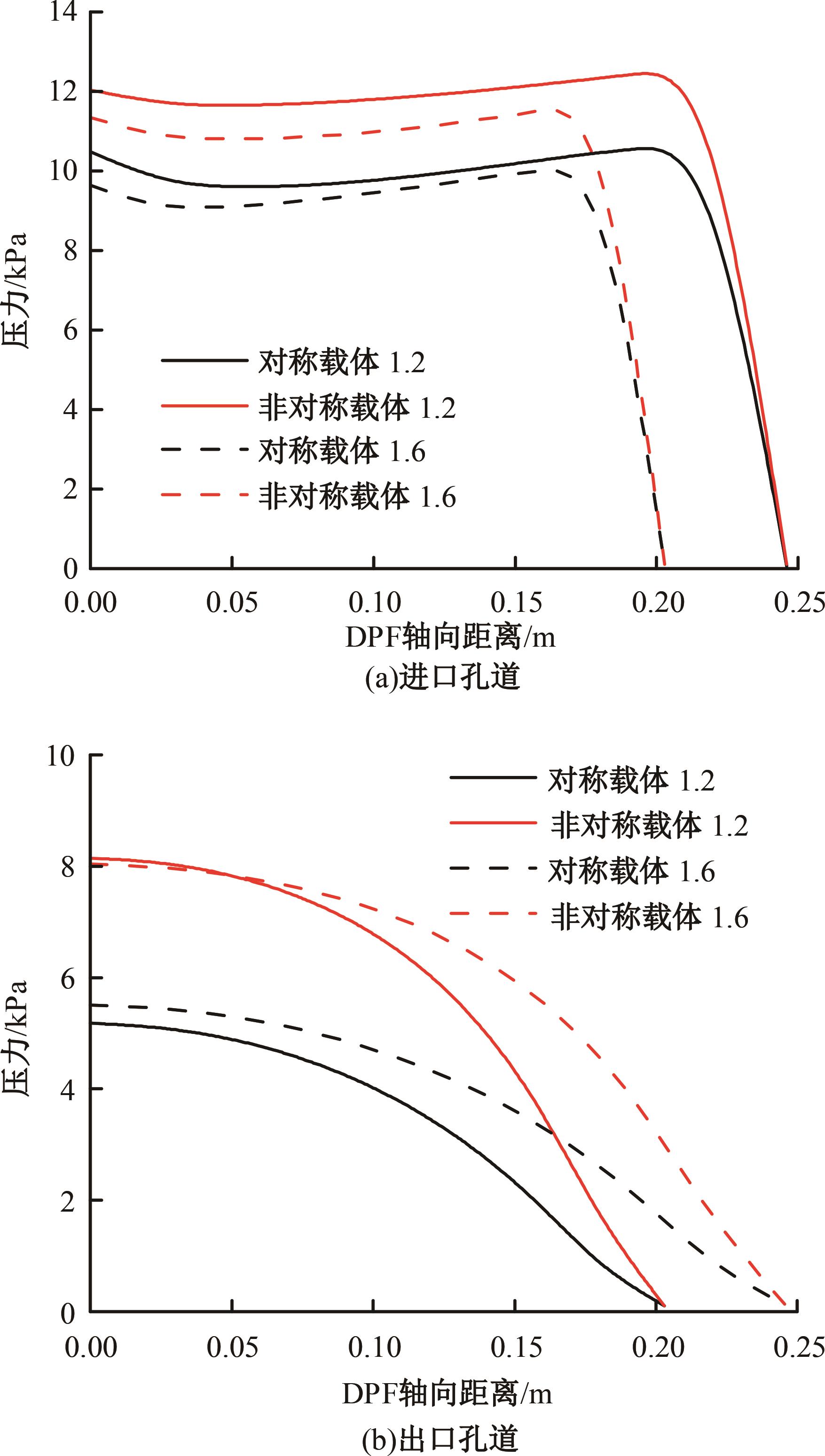

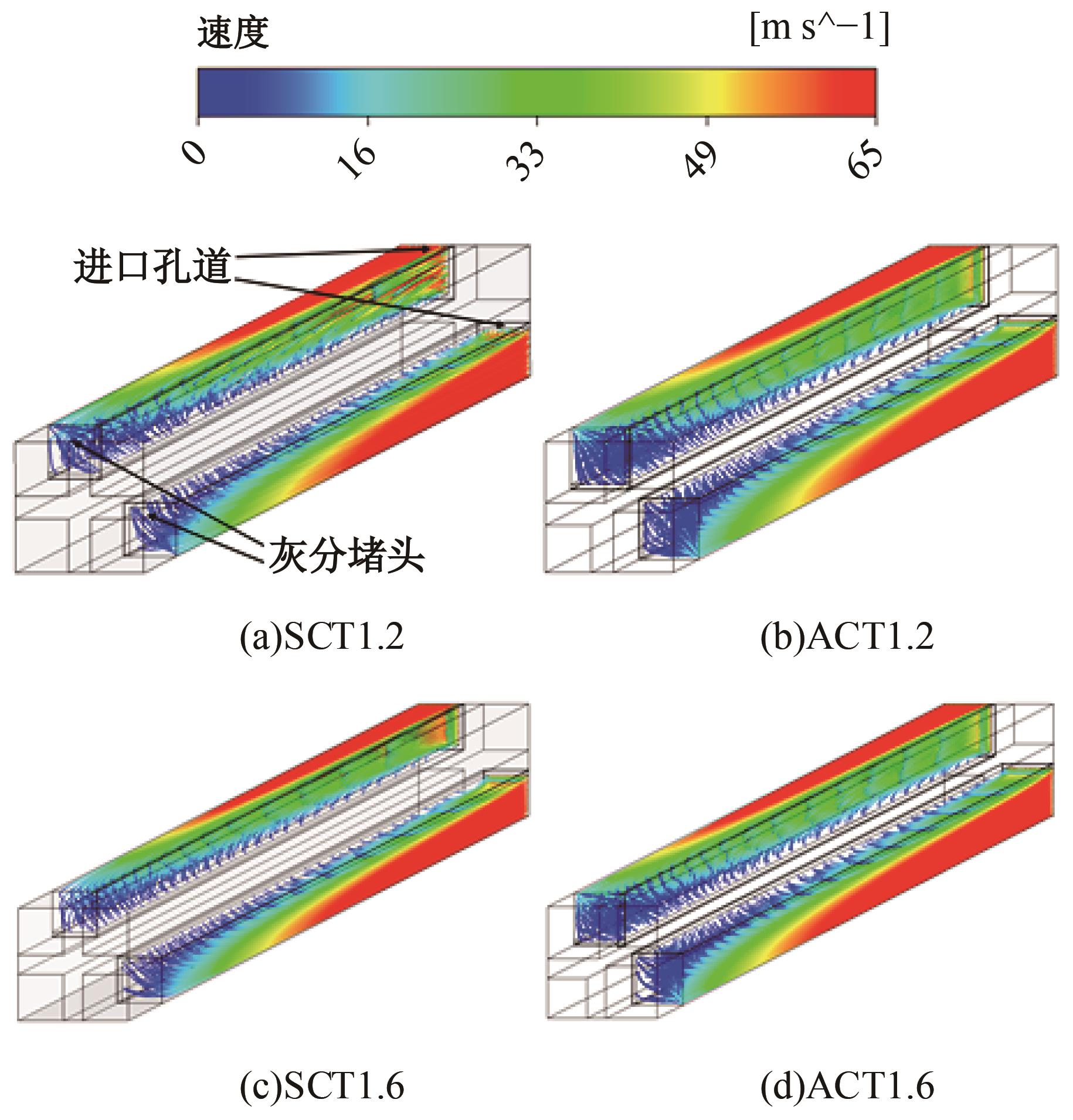

| 10 | 陈贵升, 李青, 吕誉, 等. 灰分及载体结构对DPF内部流场及压降特性的影响[J]. 汽车工程, 2020, 42(10): 1346-1353. |

| Chen Gui-sheng, Li Qing, Yu Lyu, et al. Effects of ash and carrier structure on the internal flow field and pressure drop characteristics of DPF[J]. Automotive Engineering, 2020, 42(10): 1346-1353. | |

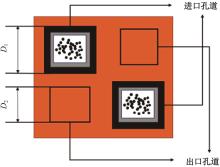

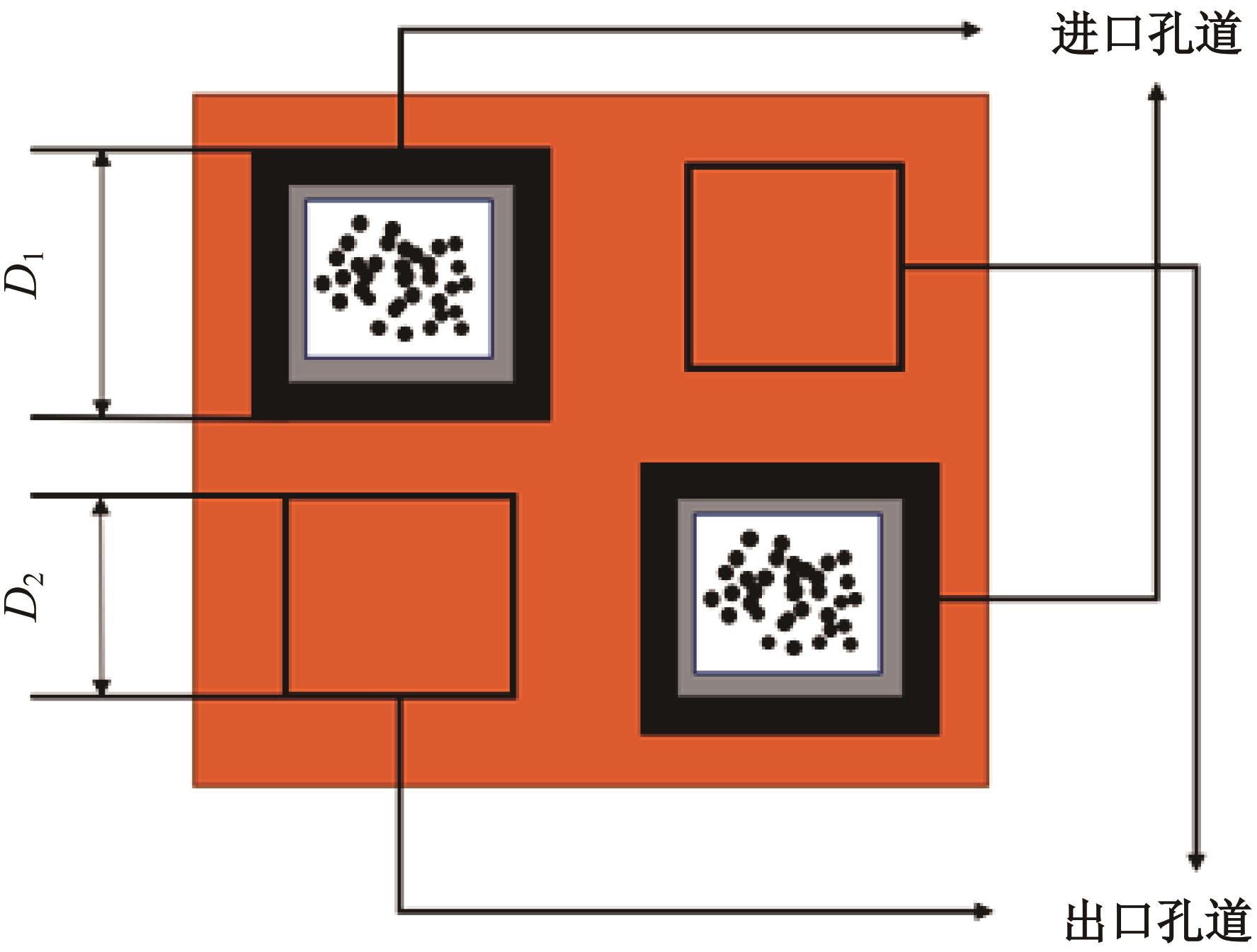

| 11 | 沈颖刚, 吕誉, 陈春林, 等. 非对称孔结构载体对DPF及柴油机性能的影响研究[J]. 内燃机工程, 2018, 39(6): 31-38. |

| Shen Ying-gang, Yu Lyu, Chen Chun-lin, et al. Influence of asymmetric cell carrier on DPF and diesel engine performance[J]. Internal Combustion Engine Engineering, 2018, 39(6): 31-38. | |

| 12 | Zhang X, Tennison P, Ruona W. 3D numerical study of pressure Loss characteristics and filtration efficiency through a frontal unplugged DPF[J]. SAE International Journal of Fuels &Lubricants, 2010, 3(1): 177-193. |

| 13 | 朱亚永, 赵昌普, 王耀辉, 等. 柴油机 DPF 流场压降及微粒沉积特性数值模拟[J]. 内燃机学报, 2017, 35(6): 538-547. |

| Zhu Ya-yong, Zhao Chang-pu, Wang Yao-hui, et al. Numerical simulation of DPF flow field pressure drop and particle deposition characteristics of diesel engine [J]. Transactions of CSICE, 2017, 35(6): 538-547. | |

| 14 | 李志军, 侯普辉, 焦鹏昊, 等. DPF孔道内流场及微粒沉积特性的数值模拟[J]. 天津大学学报: 自然科学与工程技术版, 2015, 48(10): 914-920. |

| Li Zhi-jun, Hou Pu-hui, Jiao Peng-hao, et al. Numerical simulation of flow field and particle deposition characteristics in DPF pores[J]. Journal of Tianjin University (Natural Science and Engineering Technology Edition), 2015, 48(10): 914-920. | |

| 15 | Liu H, Cao C, Huang J, et al. Progress on particulate matter filtration technology: basic concepts, advanced materials, and performances[J]. Nanoscale, 2020, 12(2): 437-453. |

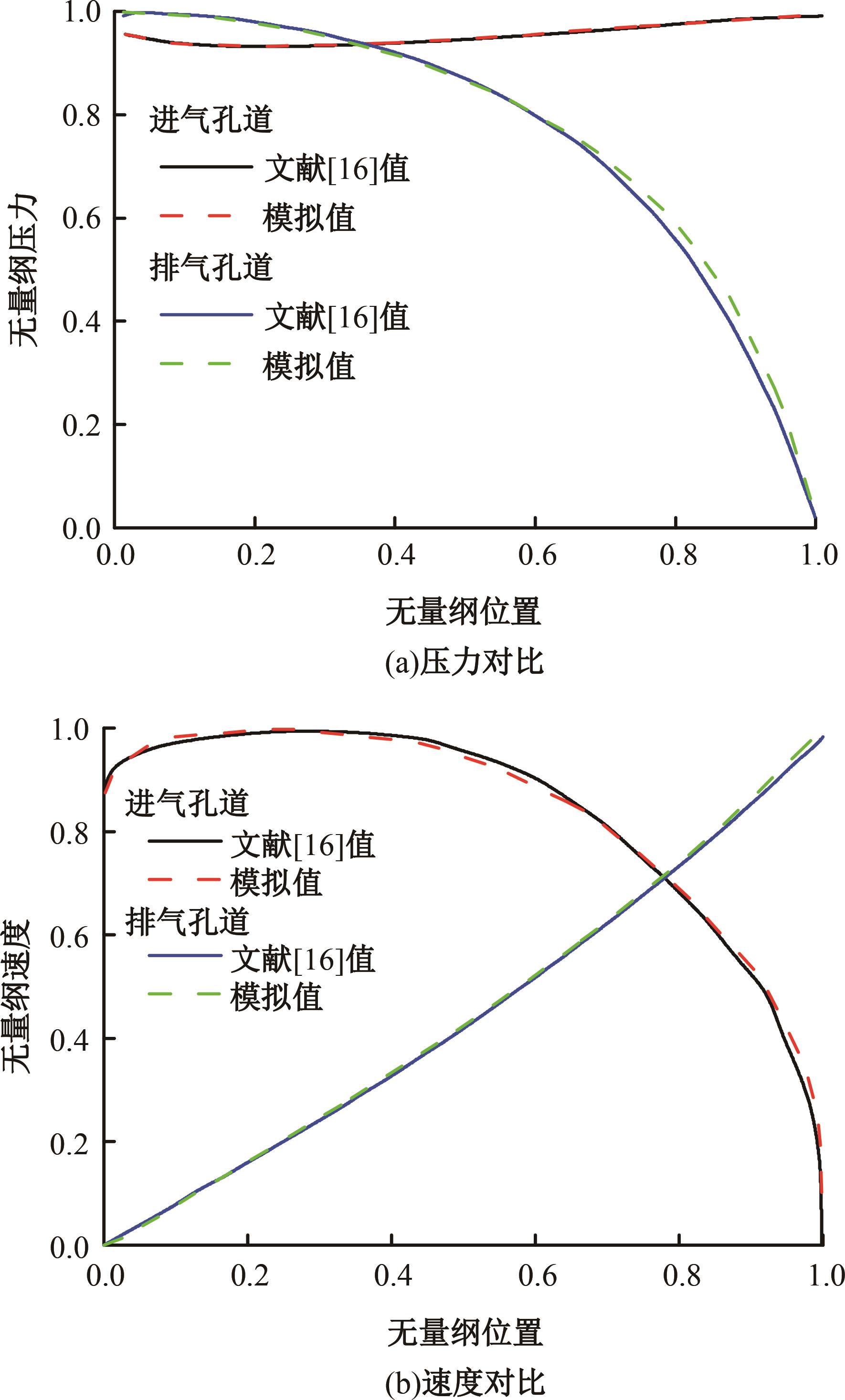

| 16 | Zhang X, Tennison P, Ruona W. 3D numerical study of pressure loss characteristics and filtration efficiency through a frontal unplugged DPF[J]. SAE International Journal of Fuels &Lubricants, 2010, 3(1): 177-193. |

| [1] | Yu FANG,De-qing MEI,Hui-long ZHENG,Xiao-fang YANG,Hai-long WU,Xiao-wu ZHANG. Ground⁃based experiments of measuring flame speed for combustion science rack aboard china space station [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2460-2468. |

| [2] | Fan ZHANG,Ning HAN,Qing DU,Jing-qi BU,Zhi-jun PENG. Numerical simulation of evaporation and combustion of MMH gel droplets [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(11): 3114-3124. |

| [3] | Gui-sheng CHEN,Guo-yan LUO,Liang-xue LI,Zhen HUANG,Yi LI. Analysis of diesel particulate filter channel flow field and its noise characteristics in plateau environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1892-1901. |

| [4] | Yan ZHANG,Wei LIU,Shu-yong ZHANG,Yi-qiang PEI,Meng-meng DONG,Jing QIN. Optimization on thermal load of combustion chamber on two/four⁃stroke switchable diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 504-514. |

| [5] | Zhong-hua GU,Pei-gang YAN,Pan-hong LIU,Xiang-feng WANG. Applying data driven algorithm to promote prediction accuracy of separation boundary simulation with eddy viscosity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2532-2541. |

| [6] | Dong TANG,Yu-bin HAN,Lun HUA,Jin-chong PAN,Sheng LIU. Effect of lubricating oil ash on performance of gasoline particle filter in direct injection gasoline engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2501-2507. |

| [7] | Wen-bo ZHAO,Yu-jie LI,Jun DENG,Li-guang LI,Zhi-jun WU. Needle motion and its influence on in-nozzle flow and spray jet characteristics [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2234-2243. |

| [8] | Zhi-jun LI,Hao LIU,Li-peng ZHANG,Zhen-guo LI,Yuan-kai SHAO,Zhi-yang LI. Simulation on influence of microstructure of the wall on deep bed filtration of particulate filter [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 422-434. |

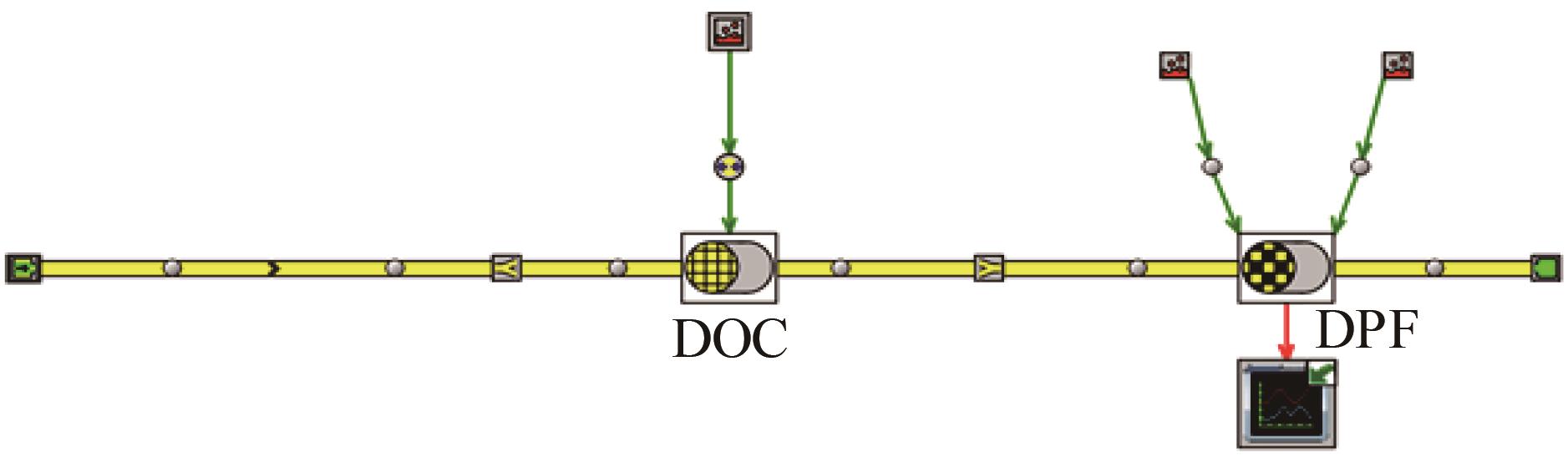

| [9] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [10] | Chang-qing SONG,Wen-miao CHEN,Jun LI,Da-wei QU,Hao CUI. Effects of single and dual ignition on combustion characteristics of natural gas under different equivalence ratios [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1929-1935. |

| [11] | Yi-xiao ZHU,Xiao-min HE,Yi JIN. Effects of radial strut width on flow structure ofsingle⁃cavity trapped vortex combustor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1936-1944. |

| [12] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

| [13] | Chang-cheng LIU,Zhong-chang LIU,Jing TIAN,Yun XU,Ze-yu YANG. In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1911-1919. |

| [14] | Xiao-yu HU,Guo-xiang LI,Shu-zhan BAI,Ke SUN,Si-yuan LI. Modified boiling heat transfer model considering roughness and material of heating surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1945-1950. |

| [15] | De⁃jun WANG,Zhi⁃chao LYU,Qi⁃ming WANG,Jian⁃rui ZHANG,Jian⁃nan DING. Cylinder pressure identification based on EKF and frequency⁃amplitude modulation Fourier series [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1174-1185. |

|

||