Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (12): 3976-3985.doi: 10.13229/j.cnki.jdxbgxb.20240286

Shear resistance of UHPC⁃NC planting bar interface

Hua-nan HE1( ),Qi-ze WU2,Xiao ZHANG3,Song SUN1,Bing LI1,Xuan-yi ZHANG1

),Qi-ze WU2,Xiao ZHANG3,Song SUN1,Bing LI1,Xuan-yi ZHANG1

- 1.State Key Laboratory of Coastal and Offshore Engineering,Dalian University of Technology,Dalian 116024,China

2.Tengzhou Housing and Urban-Rural Development Bureau,Zaozhuang 277500,China

3.Liaoning Provincial Transportation Planning and Design Institute Co. ,Ltd. ,Shenyang 110000,China

CLC Number:

- TU528.572

| [1] | 赵一鹤, 孙振平, 穆帆远, 等.钢纤维对UHPC拉伸性能及其拔出行为的影响[J]. 建筑材料学报, 2021, 24(2): 276-282. |

| Zhao Yi-he, Sun Zhen-ping, Mu Fan-yuan, et al.Effect of steel fiber on tensile properties and pullout behavior of UHPC[J]. Journal of Building Materials, 2021,24(2): 276-282. | |

| [2] | 邵旭东, 邱明红, 晏班夫, 等. 超高性能混凝土在国内外桥梁工程中的研究与应用进展[J]. 材料导报, 2017, 31(23): 33-43. |

| Shao Xu-dong, Qiu Ming-hong, Yan Ban-fu, et al. Research and application progress of ultra high performance concrete in bridge engineering at home and abroad[J]. Material Guide, 2017, 31(23): 33-43. | |

| [3] | 霍文斌, 张阳, 黄龙田, 等. 配筋UHPC湿接缝界面抗弯性能及影响因素[J]. 建筑材料学报, 2021, 24(3): 525-532. |

| Huo Wen-bin, Zhang Yang, Huang Long-tian, et al. Flexural properties and influencing factors of reinforced UHPC wet joint interface [J]. Journal of Building Materials, 2021,24(3): 525-532. | |

| [4] | 陈甫亮, 胥卉, 廖桢颖, 等. 新旧混凝土叠合面抗剪性能研究[J]. 混凝土与水泥制品, 2020(10): 75-79. |

| Chen Fu-liang, Xu Hui, Liao Zhen-ying, et al.Study on shear resistance of new and old concrete composite surface[J]. Concrete and cement products, 2020(10): 75-79. | |

| [5] | 王兴旺. UHPC与普通钢筋混凝土结构界面抗剪性能研究[D]. 长沙: 湖南大学土木工程学院, 2016. |

| Wang Xing-wang. Study on shear resistance of interface between UHPC and ordinary reinforced concrete structure[D]. Changsha: College of Civil Engineering, Hunan University, 2016. | |

| [6] | Jiang H, Dong X, Fang Z, et al. Experimental study on shear behavior of a UHPC connection between adjacent precast prestressed concrete voided beams[J]. Journal of Bridge Engineering, 2020, 25(12): 1-13. |

| [7] | Jiang H, Shao T, Fang Z, et al. Shear-friction behavior of grooved construction joints between a precast UHPC girder and a cast-in-place concrete slab[J]. Engineering Structures, 2021, 228: 1-12. |

| [8] | . 普通混凝土长期性能和耐久性能试验方法标准 [S]. |

| [9] | . 活性粉末混凝土 [S]. |

| [10] | Dulacska H. Dowel action of reinforcement crossing cracks in concrete[J]. ACI Journal, 1972,69(12):754-757. |

| [11] | Randl N.Investigations on transfer of forces between old and new concrete at different jointroughness[D].Innsbruck: Faculty of Civil Engineering Sciences, University of Innsbruck,1997. |

| [12] | 刘向华. 植筋粘结锚固性能的试验研究及可靠度分析[D]. 合肥: 合肥工业大学土木与水利工程学院, 2004. |

| Liu Xiang-hua.The experiment study on bonded anchor behavior of planted bar and reliability analysis[D].Hefei:College of Civil and Hydraulic Engineering, Hefei University of Technology, 2004. | |

| [13] | 李鹏飞. 考虑混凝土耦合损伤效应的钢筋销栓作用承载研究[D].北京:清华大学土木水利学院, 2016. |

| Li Peng-fei.Research on bearing capacity of reinforcement dowel action considering concrete coupling damage effect[D].Beijing:School of Civil and Hydraulic Engineering, Tsinghua University,2016. | |

| [14] | . 工程结构加固材料安全性鉴定技术规范 [S]. |

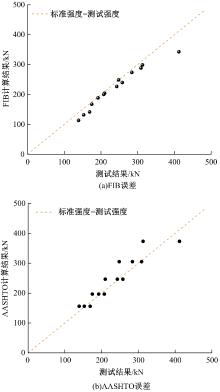

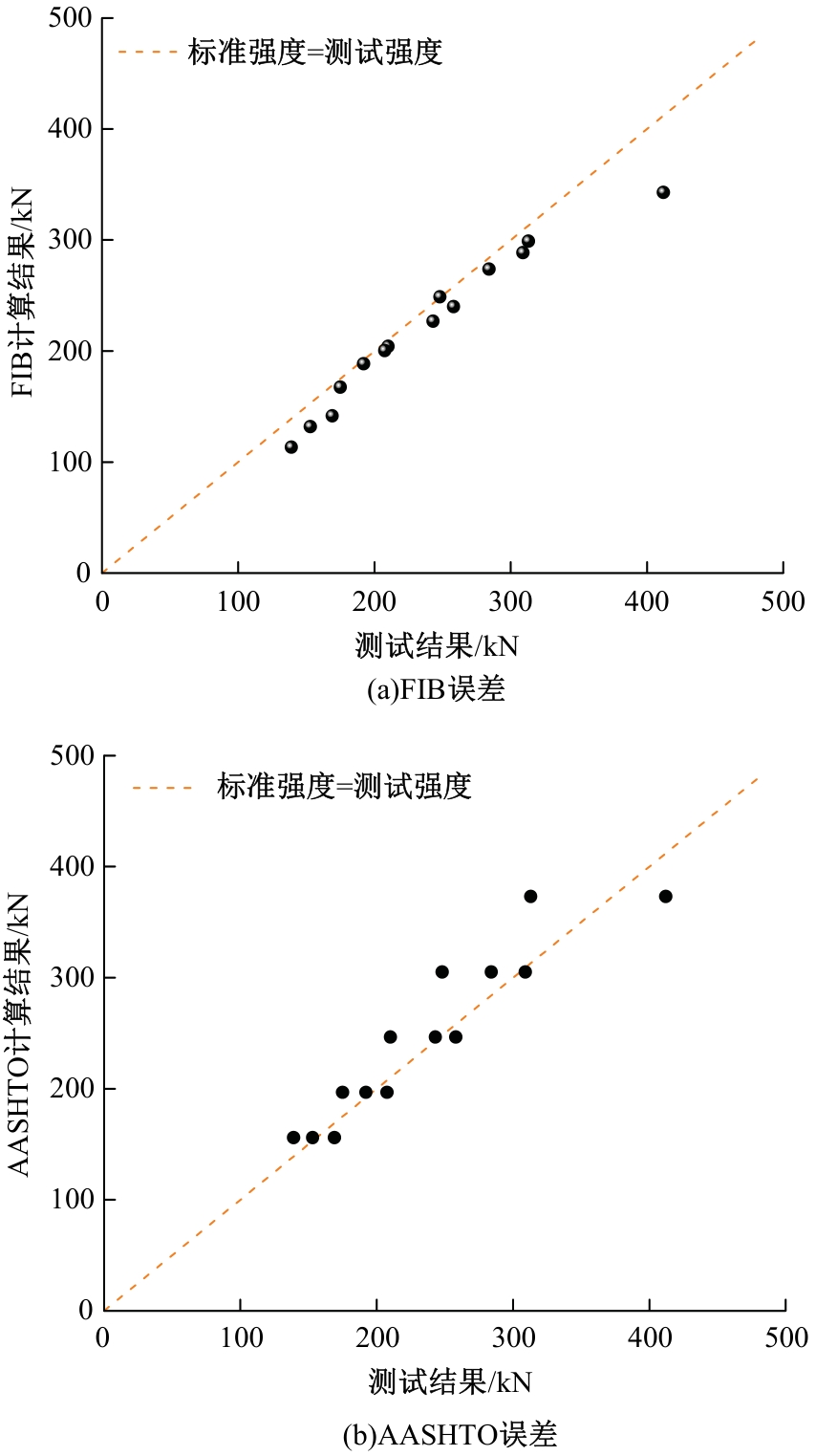

| [15] | The International Federation for Structural Concrete. Fib model code for concrete structures 2010[EB/OL].[2024-02-25]. |

| [16] | AASHO. LRFD bridge design specifications [S]. |

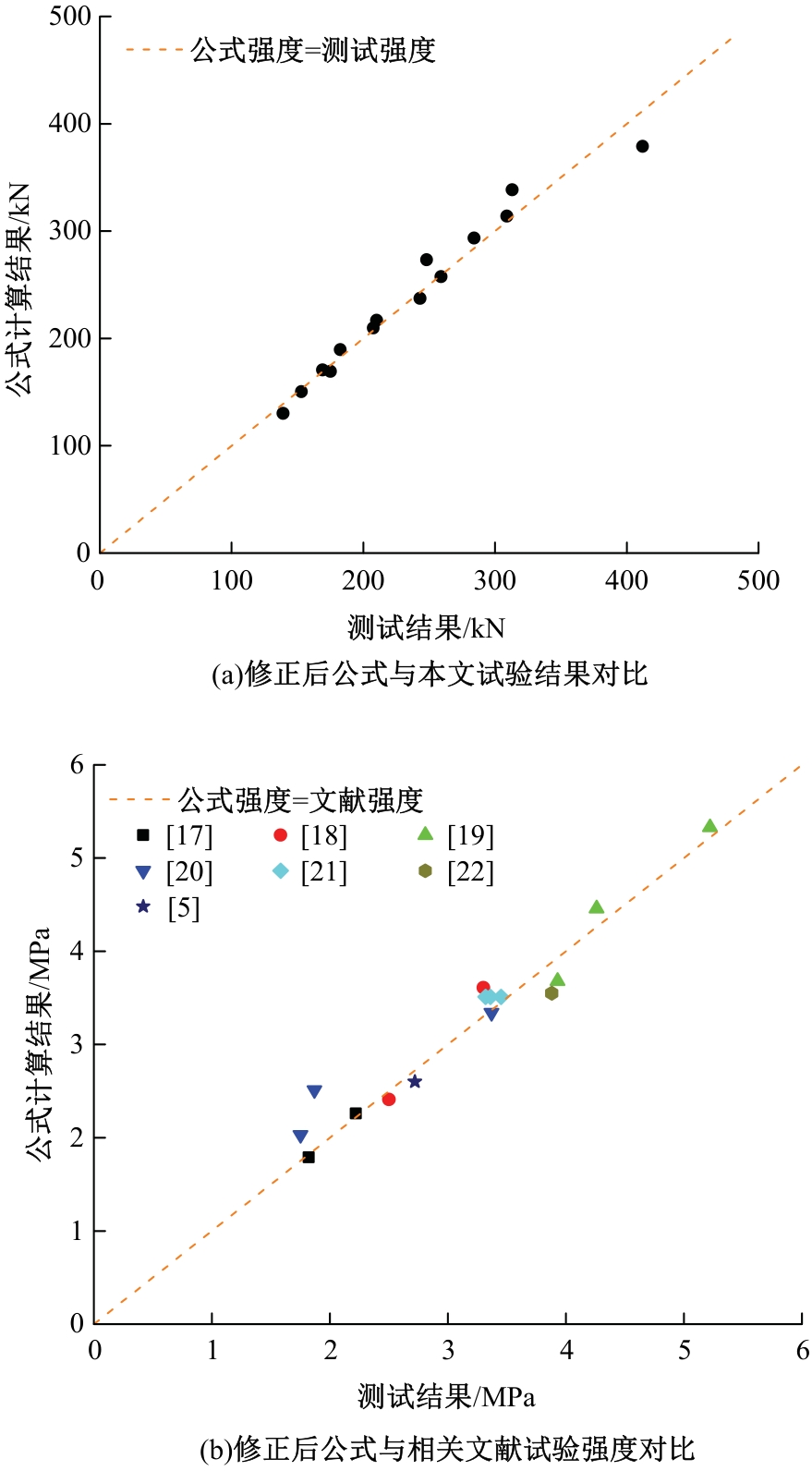

| [17] | 舒睿彬. 植筋系统粘结滑移性能及受力机理研究[D]. 上海: 同济大学土木工程学院, 2008. |

| Shu Rui-bin. Study on the bond-slip performance and load-transfer mechanism of bonded rebars system[D]. Shanghai: College of Civil Engineering, Tongji University, 2008. | |

| [18] | 林新鹏, 黄璐, 林燕英, 等.带植筋新旧混凝土粘结界面剪切强度试验研究[J]. 福建建筑, 2016(4): 48-53. |

| Lin Xin-peng, Huang Lu, Lin Yan-ying, et al.Experimental study on shear strength of bonding interface between new and old concrete with embedded bars[J] .Fujian architecture, 2016 (4): 48-53. | |

| [19] | 王二花. 植筋法新老混凝土粘结面剪切性能试验研究[D]. 郑州: 郑州大学环境与水利学院, 2006. |

| Wang Er-hua. Experimental study on shear performance of bonding interface between new and old concrete by bar planting method[D]. Zhengzhou: College of Environmental and Water Conservancy Engineering, Zhengzhou University, 2006. | |

| [20] | 江志伟. 沟槽和植筋新旧混凝土界面抗剪性能试验研究[D]. 广州: 广东工业大学土木与交通工程学院, 2014. |

| Jiang Zhi-wei. Experimental study on shear performance of interface between new and old concrete with groove and bar planting[D]. Guangzhou: School of Civil and Traffic Engineering, Guangdong University of Technology, 2014. | |

| [21] | 朱瑞经. 新老混凝土粘结面抗剪性能研究[D]. 石家庄: 河北工业大学土木与交通学院,2016. |

| Zhu Rui-jing. Study on shear property of new and old concrete bonding surface[D]. Shijiazhuang: School of Civil and Transportation Engineering, Hebei University of Technology, 2016. | |

| [22] | Zhang Y, Zhang C, Zhu Y, et al. An experimental study: various influence factors affecting interfacial shear performance of UHPC-NSC[J]. Construction and Building Materials, 2019, 236:No.117480. |

| [1] | Wen-yuan XU,Wei LI,Da-yang WANG,Yong-cheng JI. Damage mechanism of FRP reinforced concrete under alkali freezing coupling effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 2050-2062. |

| [2] | Sheng-qi MEI,Xiao-dong LIU,Xing-ju WANG,Xu-feng LI,Teng WU,Xiang-xu CHENG. Prediction of high strength concrete creep based on parametric MIC analysis and machine learning algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1595-1603. |

| [3] | Xue-ping FAN,Du YANG,Jiu-yu LI,Qi-fan ZHAO,Yue-fei LIU. Dynamic prediction of bridge coupled extreme stresses produced by temperature and vehicle loads [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1588-1594. |

| [4] | Jie YUAN,Jun-bo WANG,Xin CHEN,Xin HUANG,Ao-xiang ZHANG,An-qi CUI. Research progress on application of artificial intelligence in ultra⁃high performance concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 771-789. |

| [5] | Yu ZHOU,Meng LI,Sheng-kui DI,Xian-zeng SHI,Dong CHEN. Analytical solution of thrust influence line of variable section two-hinged arch and application of damage identification [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 664-672. |

| [6] | Fang-fang WEI,Li-ping LI,Qing-peng XU,You-zheng ZHAO,Jing-jing YANG. Experiment on seismic behavior of fire-fired composite shear wall with double steel plates and infill concrete after reinforcement [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 230-244. |

| [7] | Hao JIANG,Zheng-wen ZHAO. Experiment on shear performance of RC beams strengthened with basalt fiber grid cement-based composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 211-220. |

| [8] | Yu-dai WANG,Bin WANG,Fu-sheng MIAO,Nan MA. Freezing and expansion response of lined channels under changes in hydrothermal coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 256-268. |

| [9] | Yong-xin SUN,Peng-zhen LIN,Zi-jiang YANG,Wei JI. Calculation method for crack width of UHPC beams considering bond slip effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2600-2608. |

| [10] | Wei-song YANG,An ZHANG,Wei-xiao XU,Hai-sheng LI,Ke DU. Seismic performance of stiffness enhanced metal coupling beam damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2469-2483. |

| [11] | Jin-song ZHU,Xin-yao TONG,Xiao-xu LIU. Flexural behavior of ultra-high performance concrete joint without formwork in prefabricated small box girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2568-2580. |

| [12] | Jin-quan ZHAO,Long ZHOU,Yong-gang DING,Rong-ji ZHU. Experiment on anchoring performance of spiral stirrup-corrugated pipe grout splicing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2484-2494. |

| [13] | Feng-guo JIANG,Yu-ming ZHOU,Li-li BAI,Shuang LIANG. Improved krill algorithm and its application in structural optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2256-2266. |

| [14] | Qi-wu YAN,Zhong-liang ZOU. Hybrid algorithm for seismic energy-dissipated structures based on optimal placement of dampers [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2267-2274. |

| [15] | Guang-tai ZHANG,Cheng-xiao ZHOU,Shi-tuo LIU. Restoring force model of fiber lithium slag concrete column in saline soil environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1944-1957. |

|

||